Introduction

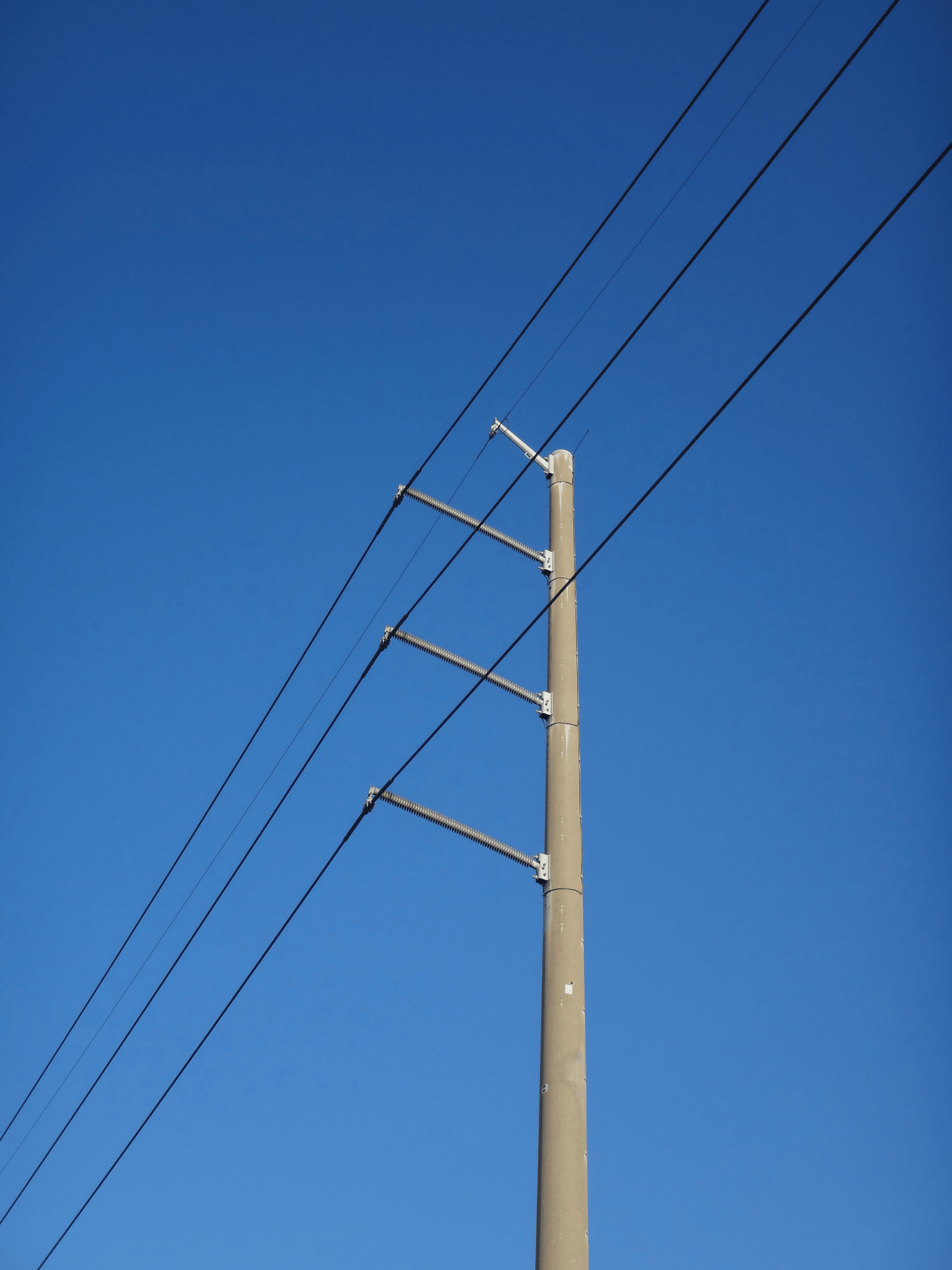

In the world of electrical engineering, the stability of transmission lines is paramount. Without robust mechanisms to support and maintain these lines, we risk outages, inefficiencies, and costly repairs. This is where the top tie comes into play, serving as a critical component that ensures line stability and operational efficiency.

Why Transmission Line Stability Matters

Transmission line stability is essential for maintaining a reliable power supply and preventing disruptions in service. Any instability can lead to voltage fluctuations, equipment damage, or even blackouts that affect entire regions. By understanding the importance of stability, we can appreciate how top ties contribute significantly to the overall health of electrical infrastructure.

Understanding Top Tie Mechanisms

Top ties are specialized fittings designed to secure transmission lines while allowing for necessary movement due to environmental factors like wind or temperature changes. These mechanisms play a vital role in ensuring that the lines remain taut yet flexible enough to withstand various stresses without compromising performance. By grasping how top ties function within a transmission system, we can better understand their impact on overall line integrity.

Overview of Key Features

The key features of top ties include their durable material composition and advanced technology that enhance their performance in demanding environments. Additionally, they are engineered specifically to maintain line stability while offering advantages such as reduced maintenance needs and increased lifespan compared to traditional tie mechanisms. When considering the selection of top tie options, one must evaluate these features closely alongside routine maintenance and inspection practices that ensure optimal functionality over time.

What is a Top Tie?

Definition and Importance

A top tie can be defined as a fastening mechanism used at the upper section of transmission line structures to secure conductors in place. Its importance cannot be overstated; without proper support from top ties, electrical lines could sag or sway excessively under wind loads or ice accumulation, leading to potential outages or even catastrophic failures. In essence, the top tie acts as a guardian for electrical stability, making it indispensable in any transmission line setup.

Applications in Transmission Lines

Top ties find their applications across various types of transmission lines—be it high-voltage or low-voltage systems—where they are employed to ensure that conductors remain stable during operation. They are particularly useful in areas prone to harsh weather conditions, where maintaining line integrity is critical for reliable service delivery. Additionally, these mechanisms are often utilized in renewable energy projects like wind farms and solar installations, where consistent power transfer plays an essential role.

Differences from Other Tie Mechanisms

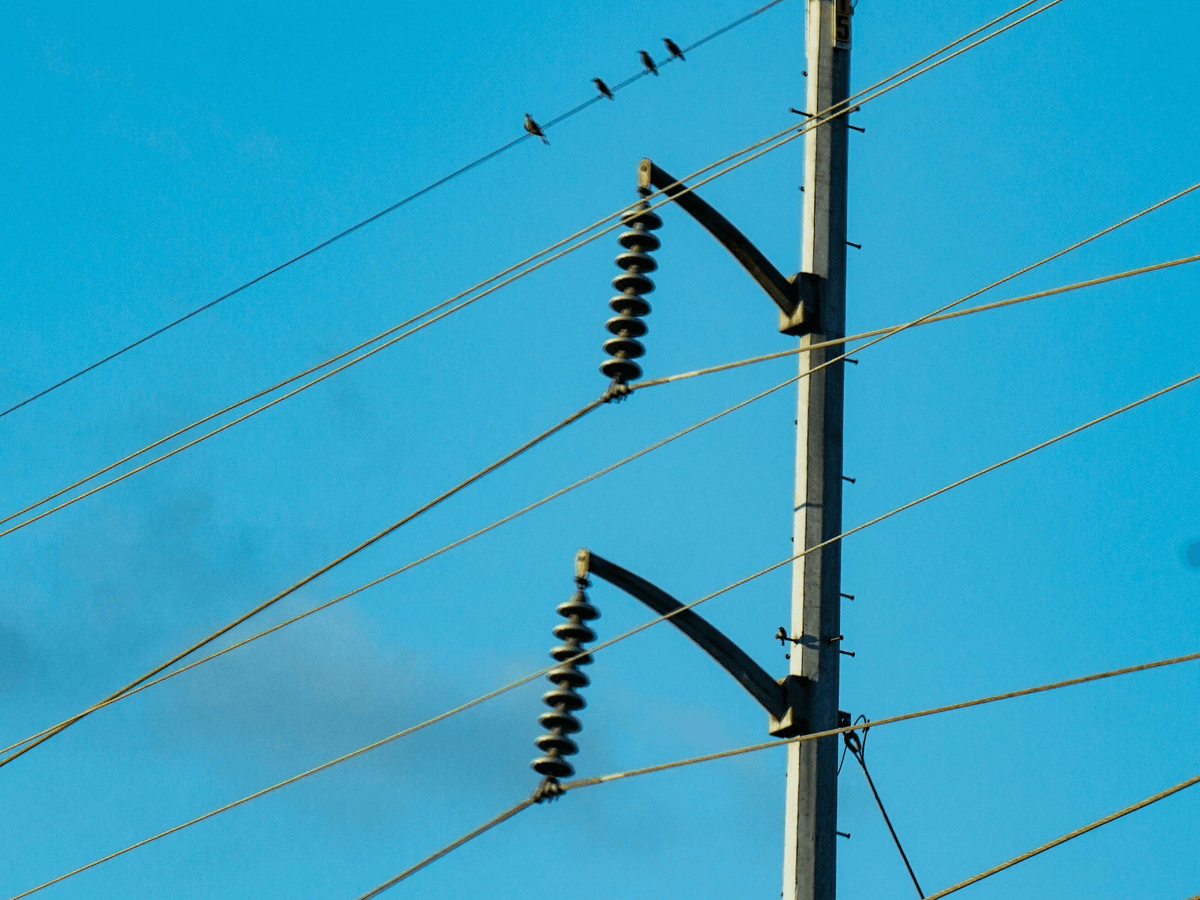

While there are several fastening methods available for securing conductors on transmission lines, top ties distinguish themselves through their unique design and functionality. Unlike other tie mechanisms that may rely on lower placements or different materials, top ties are specifically engineered to address challenges related to height and tension management at elevated positions. This makes them not only effective but also essential when considering factors like load distribution and environmental resilience—qualities that set them apart from alternative solutions within the same domain.

Key Features of Top Tie

When we talk about the key features of top tie mechanisms, it’s crucial to understand how they contribute to the overall stability and efficiency of transmission lines. A well-designed top tie not only supports the physical structure but also enhances electrical performance. Let's delve into its material composition, role in line stability, and advantages for electrical transmission.

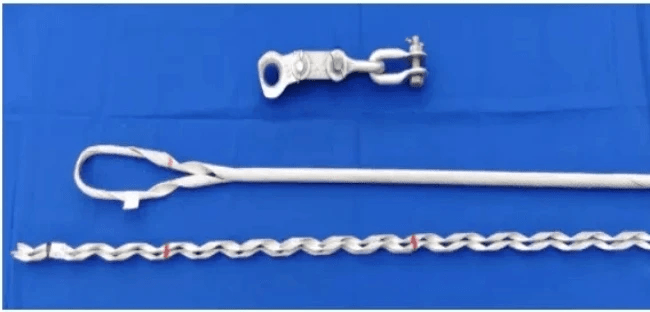

Material Composition and Technology

The material composition of a top tie is paramount for its effectiveness and durability. Typically constructed from high-strength materials such as aluminum or composite polymers, these components are designed to withstand extreme weather conditions while maintaining structural integrity. Advanced technology in manufacturing ensures that top ties are lightweight yet robust, making them ideal for various applications in the transmission line industry.

Moreover, modern innovations have led to the incorporation of smart materials that can adapt to environmental changes. This adaptability not only boosts their lifespan but also contributes significantly to the overall performance of transmission lines. When selecting a top tie, understanding its material properties can help ensure optimal functionality and longevity.

Role in Maintaining Line Stability

Top ties play a critical role in maintaining line stability by providing necessary tension and support across transmission lines. They help prevent sagging or swaying during adverse weather conditions or heavy electrical loads, ensuring a consistent flow of electricity without interruptions. By securing conductors firmly in place, top ties minimize mechanical stress on both the lines and supporting structures.

In addition to physical support, top ties also contribute to thermal management within transmission systems. Properly installed top ties allow for efficient heat dissipation from electrical currents, reducing the risk of overheating which can lead to failures or outages. Thus, their role is indispensable when considering both stability and safety within power distribution networks.

Advantages for Electrical Transmission

One cannot overlook the numerous advantages that come with using high-quality top ties in electrical transmission systems. Firstly, they enhance reliability by reducing downtime caused by equipment failure; this is particularly vital for utilities aiming for uninterrupted service delivery. Secondly, because they are engineered with advanced materials and technologies, these components offer significant weight savings compared to traditional solutions—leading to lower installation costs.

In terms of maintenance and inspection of top tie systems, their design allows for easier access during routine checks—making it simpler for technicians to perform necessary evaluations without extensive downtime or disruption to service delivery. Furthermore, effective use of top ties can lead directly to improved energy efficiency across entire grids; less sag means less resistance against wind loads which translates into lower operational costs over time.

Selection of Top Tie

Choosing the right top tie is a critical step in ensuring the stability and efficiency of transmission lines. With various factors influencing the selection process, it’s essential to understand how these elements contribute to overall performance. This section will guide you through the important considerations for selecting a top tie that meets your specific needs.

Factors to Consider When Choosing

When selecting a top tie, several factors come into play, including environmental conditions, load requirements, and material properties. The durability of materials used in top ties can greatly affect their performance in harsh weather conditions or extreme temperatures. Additionally, understanding the electrical load that your transmission line will carry is crucial since it directly influences the type of top tie that will be most effective.

Another key consideration is compatibility with existing infrastructure; ensuring that your chosen top tie aligns with current systems can save time and costs down the line. Furthermore, looking into manufacturer specifications and certifications can provide insights into reliability and longevity. Ultimately, thoughtful consideration of these factors ensures you choose a top tie that enhances both stability and efficiency.

How Spark Fittings Customizes Top Ties

Spark Fittings takes customization seriously when it comes to their top ties, tailoring solutions to meet unique project requirements. By analyzing specific environmental conditions and load capacities, they create bespoke designs that optimize performance in any scenario. This level of customization not only enhances reliability but also extends the lifespan of transmission lines by employing innovative materials and technologies.

Moreover, Spark Fittings collaborates closely with clients during the design phase to ensure all aspects are aligned with operational needs and safety standards. Their expertise allows for adjustments in dimensions or material choices based on real-world applications and challenges faced by users in various sectors. As a result, customers receive personalized solutions that effectively address their unique transmission line demands while maintaining high standards of quality.

Best Practices for Installation

Installing a top tie correctly is just as important as selecting one; improper installation can lead to significant issues down the road. It’s crucial to follow manufacturer guidelines meticulously during installation to ensure optimal performance and safety compliance. Engaging qualified personnel who understand best practices for installing top ties can prevent common pitfalls associated with alignment or tensioning errors.

Furthermore, conducting thorough pre-installation checks ensures all components are compatible and free from defects before assembly begins—this includes examining hardware like bolts or connectors associated with your selected top tie system. Once installed, regular checks should be scheduled as part of maintenance protocols to monitor wear or misalignment over time; this proactive approach safeguards against unexpected failures later on.

In conclusion, selecting an appropriate top tie involves careful consideration of multiple factors while leveraging customized solutions from providers like Spark Fittings ensures optimal results tailored for specific needs—followed by diligent installation practices guarantees long-term success in transmission line stability.

Maintenance and Inspection of Top Tie

Maintaining and inspecting the top tie is crucial for ensuring the stability and longevity of transmission lines. Regular upkeep not only prolongs the life of these components but also enhances their performance in electrical transmission systems. A well-maintained top tie can prevent costly downtimes and ensure a smooth operation.

Routine Maintenance Protocols

Routine maintenance protocols for top ties involve systematic checks and servicing to guarantee optimal functionality. This includes regular inspections to detect any signs of wear or damage, along with tightening loose connections to maintain structural integrity. Additionally, scheduling periodic cleaning can help remove debris or corrosion that may affect the performance of the top tie.

To establish effective maintenance routines, operators should document inspection findings and maintenance activities meticulously. This practice creates a historical record that can be invaluable for future reference, helping with the selection of top ties based on observed performance over time. Furthermore, collaborating with manufacturers like Spark Fittings can provide tailored maintenance schedules specific to your installation needs.

Signs of Wear and Tear to Watch For

Identifying signs of wear and tear on a top tie is essential for preventing unexpected failures in transmission lines. Common indicators include visible rust or corrosion, which can compromise material integrity over time, as well as fraying or deformation caused by environmental stressors. Any unusual noise during operation could also signal an issue that requires immediate attention.

Additionally, operators should keep an eye out for any misalignment in the structure that may indicate shifting or settling due to external factors like wind or temperature changes. Monitoring these signs regularly helps in making informed decisions regarding the selection of top ties when replacements are necessary. Ultimately, early detection leads to timely interventions that enhance overall system reliability.

Tools and Techniques for Effective Inspection

Basic tools such as torque wrenches are essential for checking connection tightness while visual inspection tools like magnifying glasses help identify subtle signs of wear not easily seen by the naked eye. Advanced options include drones equipped with cameras that allow remote inspections without disrupting operations.

Techniques such as thermal imaging can also be employed to detect hotspots indicating potential electrical issues within the system associated with faulty connections at the top tie level. Implementing these tools and techniques ensures a comprehensive approach toward maintaining line stability while reinforcing key features of top ties through proactive measures. By integrating technology into inspection routines, operators can significantly enhance their efficiency in monitoring critical components.

Case Studies on Top Tie Use

When it comes to the real-world application of top ties, the evidence is compelling. Numerous major projects have successfully integrated these mechanisms, demonstrating their vital role in ensuring transmission line stability. From sprawling urban infrastructures to remote rural installations, top ties have proven indispensable across various environments.

Successful Applications in Major Projects

One notable example of successful top tie use is the East-West Transmission Corridor project, which spans over 500 miles and connects multiple states. By incorporating advanced top tie systems, engineers were able to enhance line stability significantly, reducing sag and improving load distribution across the entire span. This project not only met its operational goals but also showcased how effective selection of top tie components can lead to long-term reliability in high-demand scenarios.

Another impressive case is the installation of top ties in a wind farm located in a region known for high winds and severe weather conditions. Here, the key features of top tie technology were critical in maintaining structural integrity under extreme stress conditions. The project not only achieved successful energy output but also served as a benchmark for future renewable energy initiatives that require robust transmission solutions.

Lessons Learned from Field Experiences

Field experiences with top ties have revealed several important lessons about their implementation and maintenance. One significant takeaway is that proper selection of top tie materials can greatly influence durability and performance over time, especially in harsh environments where wear and tear are common concerns. Regular maintenance and inspection of these components have proven essential; neglect can lead to failures that disrupt service and incur costly repairs.

Additionally, teams involved in these projects learned that thorough training on installation best practices enhances overall effectiveness. Skilled technicians who understand both the technical aspects and practical applications of top ties can ensure optimal performance throughout their lifecycle. These insights underscore the importance of investing time into education around maintenance protocols for long-lasting results.

Innovations in Top Tie Technology

The evolution of technology surrounding top ties has opened new doors for improved performance and efficiency in electrical transmission systems. Innovations such as smart monitoring systems allow real-time data collection on tension levels, enabling proactive maintenance before issues escalate into significant problems. This technological advancement aligns perfectly with modern demands for reliability while minimizing downtime during inspections.

Moreover, recent developments include lightweight composite materials that maintain strength without adding excessive weight to transmission lines—enhancing stability without compromising design integrity or increasing costs dramatically. As manufacturers continue to refine their offerings based on field feedback, we anticipate even more exciting innovations that will shape the future landscape of electrical infrastructure.

Conclusion

In wrapping up our exploration of top ties, it's clear that their role in transmission line stability is pivotal for the future of electrical infrastructure. As we look ahead, advancements in technology and materials will likely enhance the effectiveness of top ties, ensuring they continue to meet the demands of modern energy systems. The commitment to innovation and reliability will shape how we maintain and optimize transmission lines moving forward.

The Future of Transmission Line Stability

The future of transmission line stability is undoubtedly tied to the evolution of top ties and their key features. Emerging technologies promise to deliver even more robust solutions that can adapt to environmental changes and operational stresses. As utilities invest in smarter grids, the selection of top ties will play a crucial role in maintaining resilience against disruptions.

Best Practices for Using Top Ties

To ensure optimal performance, adopting best practices for using top ties is essential. This includes understanding the selection process by considering factors like load requirements, environmental conditions, and compatibility with existing infrastructure. Regular maintenance and inspection protocols should also be established to identify potential issues before they escalate into costly failures.

How Spark Fittings Enhances Top Tie Solutions

Spark Fittings stands out by providing tailored solutions that enhance the functionality and reliability of top ties across various applications. Their expertise in material composition ensures that each component meets stringent standards for durability while optimizing performance under diverse conditions. By focusing on innovation in both design and installation practices, Spark Fittings significantly contributes to improved stability in transmission lines.