Introduction

Fasteners play a crucial role in the utility industry, serving as the unsung heroes that hold everything together, from towering telephone poles to intricate electrical systems. Understanding the various types of fasteners, including bolts and rivets, is essential for ensuring structural integrity and reliability in utility applications. As the demand for specialized solutions grows, the importance of a custom fasteners manufacturer becomes increasingly evident.

Understanding Fasteners in the Utility Industry

In the utility industry, fasteners are more than just small metal components; they are vital for maintaining safety and functionality in infrastructure projects. Bolts and rivets are commonly used to secure elements such as transmission lines and substations, making them indispensable tools for engineers and contractors alike. A thorough understanding of these fasteners allows professionals to select the right type for each application, ensuring optimal performance.

Importance of Custom Fasteners for Utilities

While standard fasteners serve many purposes, custom fasteners offer tailored solutions that meet specific requirements within the utility sector. A custom fasteners manufacturer can design products that cater to unique challenges posed by different environments or project specifications. This adaptability not only enhances efficiency but also minimizes risks associated with using generic components that may not fully meet operational demands.

Overview of Standard Fasteners and Their Uses

Standard fasteners like bolts and rivets have long been staples in construction projects across various industries, including utilities. These components are readily available and come in a range of sizes and materials suitable for many applications—from securing telephone poles to reinforcing structures against harsh weather conditions. However, while standard options provide convenience, they may lack the precision needed for certain specialized tasks where custom solutions shine.

The Role of Fasteners in Utility Applications

Fasteners play a pivotal role in the utility industry, ensuring that everything from power lines to water pipes remains secure and functional. Without the right fasteners, even the most robust structures could falter, leading to costly repairs and service interruptions. This section delves into how specific fasteners contribute to structural integrity, the essential types like bolts and rivets, and their application in anchoring telephone poles.

Fasteners for Structural Integrity

In the utility industry, maintaining structural integrity is non-negotiable. Fasteners are crucial for securing components that withstand various environmental stresses—think wind, rain, and even seismic activity. A reliable custom fasteners manufacturer understands these demands and provides solutions tailored to ensure that critical infrastructure remains resilient.

Whether it's a bridge supporting electrical lines or a tower holding communication equipment, fasteners must be able to endure harsh conditions while maintaining their grip over time. Thus, investing in durable bolts and rivets is essential for any utility project aiming for longevity.

Moreover, structural failures due to inadequate fastening can lead not only to financial losses but also safety hazards for workers and communities alike. Therefore, utilities must prioritize sourcing from reputable custom fastener manufacturers who specialize in creating products designed specifically for high-stress applications. This approach ultimately enhances reliability across utility infrastructures.

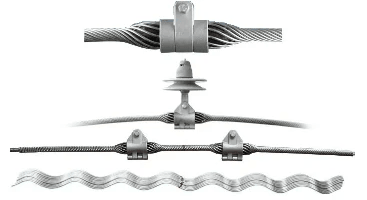

Essential Bolts and Rivets

Bolts and rivets are often considered the unsung heroes of utility applications; they may not steal the spotlight but certainly hold everything together! These essential fasteners come in various types suited for different tasks within the industry—each with its unique strengths. For instance, heavy-duty bolts provide superior load-bearing capacity while rivets offer excellent shear strength when joining metal components.

A custom fasteners manufacturer can help utilities select the right type of bolt or rivet based on specific project requirements such as material compatibility or environmental conditions. The versatility of these fasteners means they can be used across diverse applications—from securing electrical panels to fastening piping systems—making them indispensable tools in any utility toolkit.

Additionally, understanding when to use bolts versus rivets can significantly impact both performance and cost-effectiveness in projects. While bolts may allow for easier disassembly during maintenance work, rivets create a permanent bond that’s ideal when long-term stability is paramount. Ultimately, choosing between these options requires careful consideration of each application’s needs.

Fasteners for Anchoring Telephone Poles

Anchoring telephone poles effectively relies heavily on specialized fasteners designed specifically for this purpose—after all, nobody wants their communication lines swaying precariously! Custom fastener manufacturers often produce unique anchoring solutions tailored to withstand lateral forces caused by wind or ice loads on telephone poles. These specialized designs ensure that poles remain upright even under extreme weather conditions.

The importance of using quality bolts or anchors cannot be overstated; improper fastening can lead not only to service interruptions but also pose serious safety risks if poles were to topple over unexpectedly! In addition to traditional methods like concrete footings secured with robust bolts or anchors made from corrosion-resistant materials are increasingly popular choices among utilities looking for longevity without sacrificing safety standards.

Moreover, innovative designs have emerged within this niche market as technology continues evolving; smart anchors equipped with monitoring systems might soon become commonplace! Such advancements will allow utilities greater insight into their infrastructure's health while ensuring optimal performance throughout its lifespan—a win-win situation facilitated by quality custom fastener solutions!

Custom Fasteners Manufacturer Insights

In the utility industry, the demand for reliable and efficient fastening solutions is paramount. Custom fasteners manufacturers play a crucial role in meeting these needs by providing tailored solutions that standard options simply can't match. When it comes to bolts and rivets used in critical applications—such as securing telephone poles—custom fasteners ensure that every component fits perfectly and performs optimally.

Benefits of Custom Fasteners

Custom fasteners offer several advantages over their standard counterparts, particularly in specialized applications within the utility industry. For instance, they can be designed to withstand unique environmental conditions or specific load requirements, enhancing structural integrity across various projects. Additionally, custom fasteners manufacturers can provide shorter lead times and better availability for unique orders, allowing utilities to keep their operations running smoothly without delays.

Moreover, using custom bolts and rivets can reduce maintenance costs over time due to improved durability and performance tailored specifically for utility needs. When components fit correctly and are made from suitable materials, they are less likely to fail under stress or environmental challenges. This reliability translates into fewer repairs and replacements, ultimately saving money for utility companies while ensuring safe operations.

Tailoring to Specific Utility Needs

Every utility project has its own set of challenges that may require customized solutions for effective implementation. Custom fasteners manufacturers understand this necessity and work closely with clients to develop products that meet their exact specifications—whether it’s a particular size of bolt or a unique rivet design for anchoring telephone poles securely in place. This level of customization ensures that utilities can tackle specific tasks without compromising on quality or safety.

Additionally, custom fasteners allow for innovative designs which can enhance installation efficiency and reduce labor costs during assembly. By tailoring fastening solutions specifically to the project requirements, utilities can streamline their processes while maximizing performance outcomes across various applications—from power lines to telecommunications infrastructure. Ultimately, the ability to customize means utilities can adapt quickly to changing demands without being held back by generic options.

Spark Fittings and Innovative Solutions

One area where custom fastener innovation shines is in spark fittings—a critical component often overlooked but vital in ensuring electrical safety within the utility industry. These fittings require precision engineering because they must handle high-voltage applications while maintaining secure connections between different parts of an electrical system like telephone poles and transformer stations. Custom fastener manufacturers excel at creating such specialized components that not only meet safety standards but also enhance overall system reliability.

Furthermore, advancements in materials science have allowed custom fastener manufacturers to develop new solutions like corrosion-resistant bolts designed specifically for outdoor use in harsh environments typical of many utility installations. These innovations help extend the lifespan of fastening systems while minimizing maintenance needs—a win-win situation for any organization operating within this sector! As we continue down this path of innovation, it’s clear that custom fasteners will play an increasingly significant role in shaping the future landscape of utilities.

Common Standard Fasteners in the Industry

In the utility industry, standard fasteners play a pivotal role in ensuring reliable and efficient operations. These components are not just mere accessories; they are essential for maintaining structural integrity and safety across various applications. Understanding the types of fasteners commonly used can help utilities make informed decisions, whether they opt for standard options or seek out a custom fasteners manufacturer for specialized needs.

Popular Bolt Types Used in Utilities

Bolts are the backbone of many utility applications, providing strength and stability to structures like telephone poles and substations. Among the most popular bolt types found in this sector are hex bolts, which offer excellent tensile strength and ease of installation. Additionally, lag bolts are frequently used to secure heavy fixtures to wooden structures, making them indispensable in anchoring telephone poles securely into place.

Utility companies often rely on high-strength bolts that can withstand harsh environmental conditions, including extreme temperatures and heavy loads. The versatility of these bolts means they can be tailored for specific projects, but when off-the-shelf options suffice, they provide an economical choice that balances quality with cost-efficiency. A custom fasteners manufacturer may also offer specialized bolt designs that cater to unique project requirements without sacrificing performance.

Rivets: The Unsung Heroes

While bolts often steal the spotlight, rivets deserve recognition as unsung heroes in the utility industry. These fasteners create permanent joints by deforming during installation, making them ideal for situations where vibration or movement could loosen traditional screws or bolts over time. In applications such as securing metal structures or reinforcing connections on telephone poles, rivets provide unmatched reliability.

Rivets come in various materials and styles—each designed to meet specific load requirements and environmental conditions faced by utilities daily. Their ability to distribute stress evenly across a joint makes them particularly valuable when constructing durable infrastructure that can withstand nature's whims. As a result, many custom fasteners manufacturers include rivets in their offerings to ensure clients have access to all necessary fastening solutions.

Standard Fasteners vs. Custom Solutions

When weighing standard fasteners against custom solutions within the utility industry, it's essential to consider both immediate needs and long-term implications. Standard fasteners often provide quick availability at lower costs; however, they may not always meet specific project requirements effectively—especially when dealing with unique challenges posed by particular installations like telephone poles or specialized equipment mounts.

On the other hand, opting for a custom fasteners manufacturer allows utilities to tailor designs precisely suited for their operational demands while enhancing overall efficiency and safety standards. Although this approach may involve higher upfront costs due to customization processes, it often leads to better performance outcomes over time—reducing maintenance issues down the line as well as potential failures caused by ill-fitting components.

Ultimately, choosing between standard fasteners and customized options boils down to individual project needs: If you require speed and affordability without compromising quality too much—standard may be your best bet! But if you're tackling unique challenges head-on—or simply want peace of mind knowing every detail has been meticulously crafted—a custom solution could be worth its weight in gold (or at least sturdy steel).

The Manufacturing Process of Fasteners

The manufacturing process of fasteners is a vital aspect of ensuring that the utility industry operates smoothly and efficiently. From bolts to rivets, each component plays a specific role in maintaining structural integrity, especially for critical applications like anchoring telephone poles. Understanding this process can help utilities make informed decisions when sourcing from custom fasteners manufacturers.

Materials and Durability Considerations

When it comes to fasteners, the choice of materials is paramount. Fasteners used in the utility industry must withstand various environmental conditions, including moisture, temperature fluctuations, and mechanical stress. Custom fasteners manufacturers often utilize high-grade stainless steel or specialized alloys that enhance durability while ensuring that bolts and rivets maintain their strength over time.

Moreover, different applications may require unique material properties; for instance, fasteners used in coastal regions must resist corrosion more effectively than those in temperate climates. This tailored approach not only extends the lifespan of the fasteners but also minimizes maintenance costs for utilities relying on these components to secure infrastructure like telephone poles. Ultimately, selecting the right materials is essential for achieving long-lasting performance.

Quality Control in Fastener Production

Quality control is an integral part of the manufacturing process for any custom fasteners manufacturer. Rigorous testing protocols are implemented at various stages to ensure that every bolt or rivet meets stringent industry standards before it reaches the market. This includes dimensional checks, tensile strength tests, and surface finish evaluations—each designed to confirm that these essential components will perform reliably under demanding conditions.

Additionally, many manufacturers adopt advanced technologies such as automated inspection systems and real-time monitoring during production runs to enhance quality assurance further. By prioritizing quality control measures, custom fastener manufacturers can significantly reduce failure rates and improve overall safety within utility applications—especially when considering factors like anchoring telephone poles where reliability is non-negotiable.

Innovations in Fastener Manufacturing

Innovation drives progress in every industry—and fastener manufacturing is no exception. Custom fasteners manufacturers are continually exploring new techniques and technologies to improve production efficiency and product performance while reducing waste and costs associated with traditional methods. For example, advancements in 3D printing technology allow for rapid prototyping of custom bolts or rivets tailored specifically for unique utility needs.

Furthermore, smart manufacturing processes incorporating IoT (Internet of Things) devices enable real-time data collection throughout production cycles—allowing manufacturers to identify bottlenecks swiftly or predict maintenance needs proactively. As these innovations continue to evolve within the utility sector's supply chain landscape, we can expect even greater customization options from fastener producers catering specifically to utilities' diverse requirements.

Choosing Between Custom and Standard Fasteners

In the utility industry, the decision to choose between custom and standard fasteners can significantly impact project outcomes. Various factors come into play, including specific application requirements, material compatibility, and performance expectations. Understanding these elements helps in making informed choices that align with both operational needs and budget constraints.

Factors Influencing Your Decision

When selecting fasteners for utility applications, several factors must be considered. The nature of the project—whether it involves securing telephone poles or constructing substations—will dictate the types of bolts or rivets needed. Additionally, environmental conditions such as temperature fluctuations and exposure to moisture can influence whether standard fasteners suffice or if a custom fasteners manufacturer should be consulted for tailored solutions.

Another consideration is the load-bearing capacity required for structural integrity. For instance, heavy-duty applications may necessitate stronger materials that are often only available through custom fabrication. Ultimately, aligning your choice with the specific demands of your utility projects will ensure safety and longevity.

Cost Considerations and Budgeting

Cost is always a significant factor when deciding between custom and standard fasteners in the utility industry. Standard fasteners typically offer a more budget-friendly option due to their mass production; however, they may not always meet unique project specifications effectively. On the other hand, engaging a custom fasteners manufacturer might require a larger initial investment but can lead to long-term savings through enhanced durability and reduced maintenance needs.

Budgeting also extends beyond just purchasing costs; consider potential downtime during installation if standard options fail to perform adequately under stress or environmental conditions. Investing in quality fasteners upfront can mitigate risks associated with replacements or repairs later on down the line. Therefore, weighing immediate costs against future implications is crucial for making financially sound decisions.

Future Trends in Fastener Use in Utilities

As we look ahead in the utility industry, several trends are emerging that could influence how fasteners are used moving forward. An increasing focus on sustainability is prompting many companies to seek eco-friendly materials from their custom fasteners manufacturers, which could reshape traditional approaches to sourcing bolts and rivets alike. Moreover, advancements in technology—including 3D printing—are paving new pathways for producing bespoke fastening solutions tailored precisely to project requirements.

Another trend involves smart technologies integrated into fastening systems that monitor structural health over time; this innovation could revolutionize maintenance strategies for utilities managing critical infrastructure like telephone poles. As these trends continue to evolve, staying informed will empower decision-makers within utilities to adapt their fastening strategies accordingly while maximizing efficiency and safety across projects.

Conclusion

In the ever-evolving landscape of the utility industry, the importance of selecting the right fasteners cannot be overstated. Custom fasteners tailored to specific applications can dramatically enhance efficiency, safety, and longevity in projects involving critical infrastructure like telephone poles. By understanding the unique demands of each utility application, professionals can make informed choices that elevate their operations.

Maximizing Efficiency with the Right Fasteners

Choosing appropriate fasteners is essential for maximizing operational efficiency in utility projects. Custom fasteners can be designed to meet specific load requirements and environmental conditions, ensuring that bolts and rivets perform optimally under stress. By investing in quality custom solutions from a reliable custom fasteners manufacturer, utilities can reduce maintenance costs and extend service life.

The Future of Fasteners in Utility Projects

The future of fasteners in the utility industry is bright and filled with opportunities for innovation. As technology advances, we anticipate a rise in smart fastening solutions that monitor structural integrity and provide real-time data on performance. This evolution will not only enhance safety but also streamline maintenance processes for critical structures like telephone poles.

Finding the Best Custom Fasteners Manufacturer

Look for companies that specialize in producing high-quality bolts and rivets tailored to your specific needs while adhering to industry standards. By partnering with an experienced custom fasteners manufacturer, you ensure that your projects are equipped with reliable components designed to withstand the rigors of the utility environment.