Introduction

In the world of electrical engineering, understanding the various **types of electrical insulators** is fundamental to ensuring safety and efficiency in power systems. Electrical insulators serve a crucial role in preventing unwanted current flow, thereby protecting both equipment and personnel from potential hazards. With a variety of options available, selecting the right insulator is not just a matter of preference; it’s essential for optimal performance.

Understanding Electrical Insulators

Electrical insulators are materials that resist the flow of electric current, effectively separating conductive parts and preventing short circuits. They act as barriers that keep electricity contained within designated pathways, ensuring that power transmission occurs safely and efficiently. By understanding how these materials work, one can appreciate their significance in various applications—from residential wiring to large-scale electrical grids.

Importance of Choosing the Right Insulator

The choice of insulator can significantly impact the reliability and longevity of an electrical system. Different **types of electrical insulators**, such as pin type insulators or suspension insulators, have unique characteristics tailored for specific environments and loads. Making an informed decision when selecting an insulator helps mitigate risks associated with electrical failures and enhances overall system performance.

Overview of Common Insulator Types

Among the most commonly used **types of electrical insulators** are pin type insulators, suspension insulators, strain insulators, shackle insulators, and post insulators. Each type has its own set of benefits suited for particular applications; for instance, pin type insulators are ideal for overhead lines while suspension types excel in supporting longer spans across towers. Understanding these distinctions will guide you in making the best choice for your specific needs.

What Are Electrical Insulators?

Electrical insulators are crucial components in electrical engineering, designed to prevent the unintended flow of current. They serve the primary purpose of separating conductive materials, ensuring that electricity travels only along intended paths. This function is vital for maintaining safety and efficiency in electrical systems, which is why understanding the various types of electrical insulators—like pin type insulators and suspension insulators—is essential.

Definition and Purpose

At their core, electrical insulators are materials that resist the flow of electric current. Their main purpose is to protect both people and equipment from electric shocks and short circuits by providing a barrier between conductive parts. Different types of electrical insulators, such as strain insulators or shackle insulators, serve specific roles based on their design and application requirements.

How Do Insulators Work?

Insulators work by creating a high resistance path for electrical current. When voltage is applied, these materials inhibit electron movement, preventing current from flowing through them freely. This property allows for safe transmission of electricity across various systems while utilizing different types of electrical insulators to suit specific needs—like post insulators for stability or suspension insulators for load-bearing applications.

Key Materials Used in Insulators

The effectiveness of an electrical insulator largely depends on its material composition. Common materials include ceramics, glass, and polymers—all known for their high dielectric strength and durability under various environmental conditions. For instance, pin type insulators often use porcelain or composite materials to withstand mechanical stress while maintaining insulation properties; similarly, suspension and strain insulators utilize robust materials tailored to their unique functionalities.

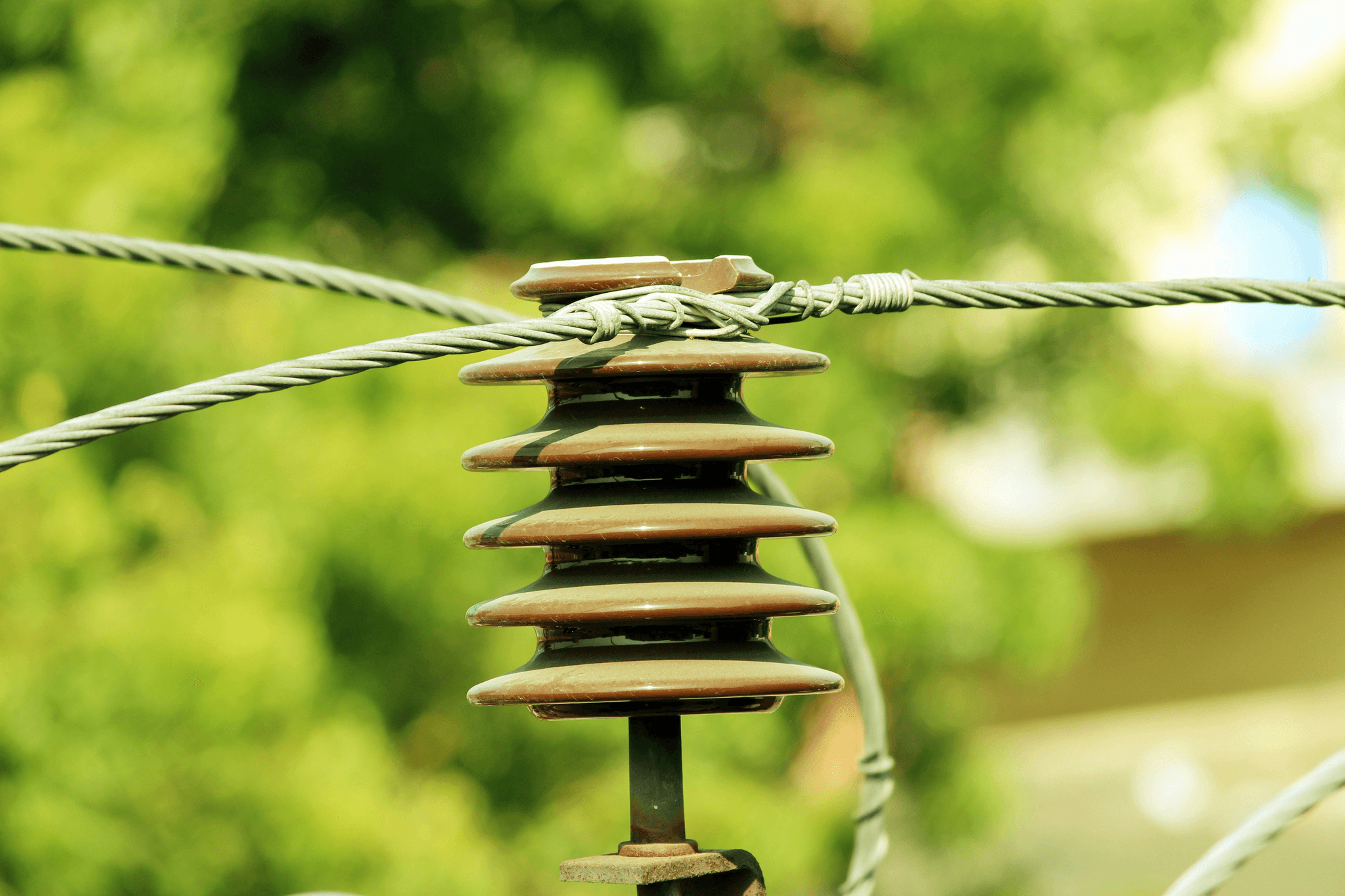

Exploring Pin Type Insulators

They are designed to support overhead power lines and ensure that electricity flows smoothly without any interruptions or leaks. Their unique structure makes them an essential component in the broader category of electrical insulators, including suspension insulators, strain insulators, shackle insulators, and post insulators.

Benefits of Pin Type Insulators

Pin type insulators offer several advantages that make them a preferred option for utility companies and contractors alike. Firstly, their compact design allows for easy installation on wooden or concrete poles, providing versatility in various environments. Additionally, pin type insulators boast excellent mechanical strength and resistance to environmental factors such as moisture and pollution, ensuring long-term performance and reliability.

Another significant benefit is their cost-effectiveness compared to other types of electrical insulators like suspension or strain insulators. With lower maintenance needs and robust durability, pin type insulators provide a great return on investment over time. This combination of affordability and resilience makes them an attractive option for those looking to optimize their electrical infrastructure.

Ideal Applications for Pin Type Insulators

Pin type insulators are ideally suited for a range of applications within the electric utility sector. They are commonly used in distribution lines where space is limited but reliable insulation is still crucial. Their ability to support lower voltage lines while maintaining safety standards makes them perfect for rural electrification projects.

Moreover, these types of electrical insulators excel in urban settings where aesthetics matter; they can blend seamlessly with existing structures while ensuring efficient power transmission. Whether it’s powering homes or commercial buildings, pin type insulators play an essential role in maintaining the integrity of the electrical system without compromising on safety or performance.

Leading Manufacturers of Pin Type Insulators

When seeking high-quality pin type insulators, it's essential to turn to reputable manufacturers known for their reliability and innovation in the field. Companies like General Electric (GE) have established themselves as leaders by providing durable solutions that meet industry standards while also investing in research and development for improved materials and designs.

Another notable player is Siemens, which offers a comprehensive range of electrical insulation products including pin type options tailored for various applications. Additionally, local manufacturers often provide competitive products that cater specifically to regional needs while ensuring compliance with international quality standards.

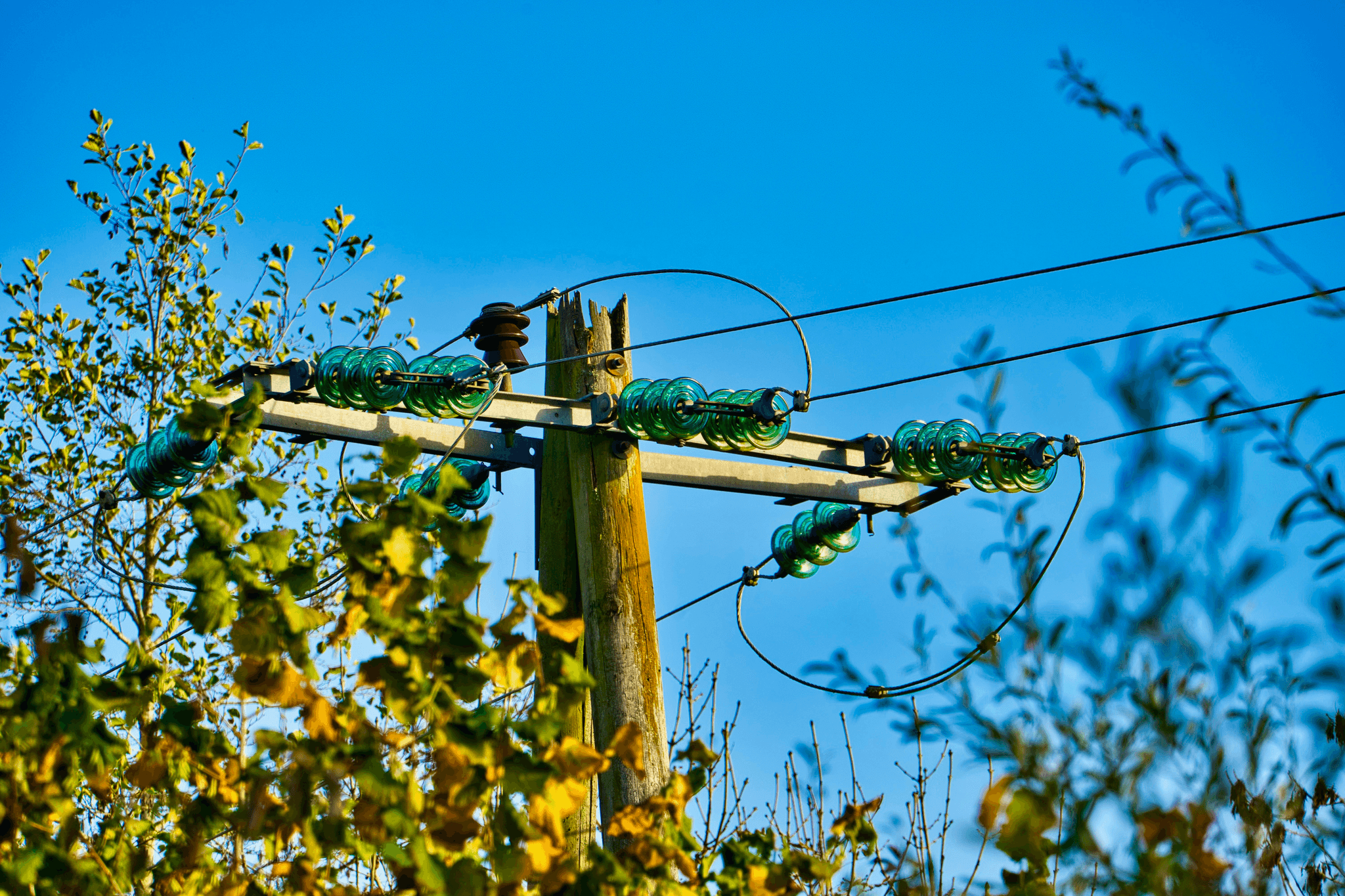

Suspension Insulators: The Heavyweights

Advantages of Suspension Insulators

One of the standout advantages of suspension insulators is their ability to withstand significant mechanical stress without compromising performance. This makes them particularly suitable for high-voltage transmission lines, where tension is a critical factor. Additionally, their design allows for easy maintenance and replacement, which is a boon for utility companies looking to minimize downtime—something that’s less convenient with other types of electrical insulators like pin type insulators or shackle insulators.

Another perk is their adaptability; suspension insulators can be used in various environmental conditions, from arid deserts to humid coastal areas. They also provide excellent resistance against environmental factors such as pollution and moisture, ensuring longevity that rivals even strain insulators in some cases. With their impressive durability and reliability, suspension insulators truly stand out among different types of electrical insulators.

When to Use Suspension Insulators

Suspension insulators are generally used when there’s a need for long spans between supporting structures—think tall transmission towers that stretch across valleys or rivers. In situations where there’s considerable tension on the line due to wind or ice loading, these heavyweights shine by providing the necessary support without sagging under pressure. If you're working with high-voltage applications that require both strength and flexibility, suspension insulators should be your go-to choice over others like post insulators or shackle insulators.

They’re particularly effective in areas where terrain varies significantly; their ability to accommodate movement helps maintain system integrity despite shifts caused by natural elements or human activity. Moreover, when planning new installations or upgrades in electrical infrastructure, considering suspension insulators can lead to more efficient designs that reduce maintenance costs over time compared to pin type or strain types.

Popular Brands for Suspension Insulators

When it comes to trusted brands in the world of suspension insulators, several names stand out due to their commitment to quality and innovation in manufacturing practices. Companies like Siemens and GE have established themselves as leaders by producing reliable products that meet industry standards while offering advanced technology features tailored for modern needs. Additionally, manufacturers such as Lapp Insulator Company and Hubbell Power Systems also provide a variety of options catering specifically to different applications within this category.

These brands not only focus on creating durable products but also emphasize sustainability in their manufacturing processes—a growing concern within the industry today! By choosing well-known brands for your suspension insulation needs, you’re investing in proven technology designed specifically for safety and reliability across various environments compared with lesser-known alternatives like certain shackle or post type manufacturers who may not have extensive testing data available.

Strain Insulators: Keeping It Tensioned

The Role of Strain Insulators

Strain insulators are primarily used in overhead power lines where tension is a critical factor. They help to support the weight of conductors while preventing excessive movement that could lead to wear and tear over time. By effectively managing the forces acting on electrical lines, strain insulators ensure a stable and reliable transmission of electricity.

In essence, these insulators act as a buffer between the conductive materials and their supporting structures, absorbing shocks and vibrations caused by environmental factors such as wind or ice accumulation. This protective function is especially important in regions prone to severe weather conditions where other types of electrical insulators may not suffice. Therefore, choosing high-quality strain insulators is essential for long-term operational success.

Key Features of Strain Insulators

One standout feature of strain insulators is their robust construction, often made from durable materials like porcelain or composite polymers that resist cracking and degradation over time. These materials not only enhance the lifespan of the strain insulator but also improve its performance under high-stress conditions compared to pin type or suspension insulators. Additionally, many modern designs incorporate features such as tracking resistance and UV stability for added reliability.

Another important aspect is their flexibility in installation; they can be configured for various line tensions and angles depending on specific project requirements. This adaptability makes them suitable for diverse applications—from rural power distribution networks to urban infrastructure projects—where different types of electrical insulators might be employed alongside them. The ability to customize these components ensures optimal performance across various settings.

Trusted Suppliers for Strain Insulators

Companies like Spark Fittings offer a comprehensive range of products tailored specifically for this purpose while ensuring compliance with industry standards—making them a go-to choice for many professionals seeking reliable solutions among different types of electrical insulators available today.

Other notable suppliers include manufacturers known for their expertise in providing complementary products such as pin type and suspension insulators; this synergy allows customers to procure all necessary components from one trusted source without sacrificing quality or performance consistency across their systems. It’s worth investing time into researching these suppliers since selecting the right product can significantly impact both efficiency and safety in your electrical installations.

Shackle Insulators Versus Other Types

Unique Characteristics of Shackle Insulators

Shackle insulators are designed to support overhead conductors and can accommodate a range of voltage levels, making them versatile in application. One of their standout features is their ability to withstand environmental stressors such as wind and ice, which is crucial for ensuring reliability in harsh conditions. Additionally, their compact design allows for easy installation and maintenance compared to larger types of electrical insulators like strain or post insulators.

Best Use Cases for Shackle Insulators

Shackle insulators are particularly effective in low-voltage distribution lines where space is limited but safety cannot be compromised. They excel in situations where the conductor needs to be anchored securely without excessive weight or bulk—think urban settings with tight clearances or rural areas with challenging terrain. Furthermore, they can also serve as a reliable option when connecting conductors across short spans, making them ideal for use alongside pin type insulators in certain configurations.

Noteworthy Companies Providing Shackle Insulators

Several companies have established themselves as leaders in the production of shackle insulators, ensuring quality and reliability for utility providers worldwide. Brands like Siemens and GE offer a range of options tailored to meet specific needs while adhering to industry standards. Additionally, smaller manufacturers also contribute innovative designs that enhance the overall performance of these important types of electrical insulators.

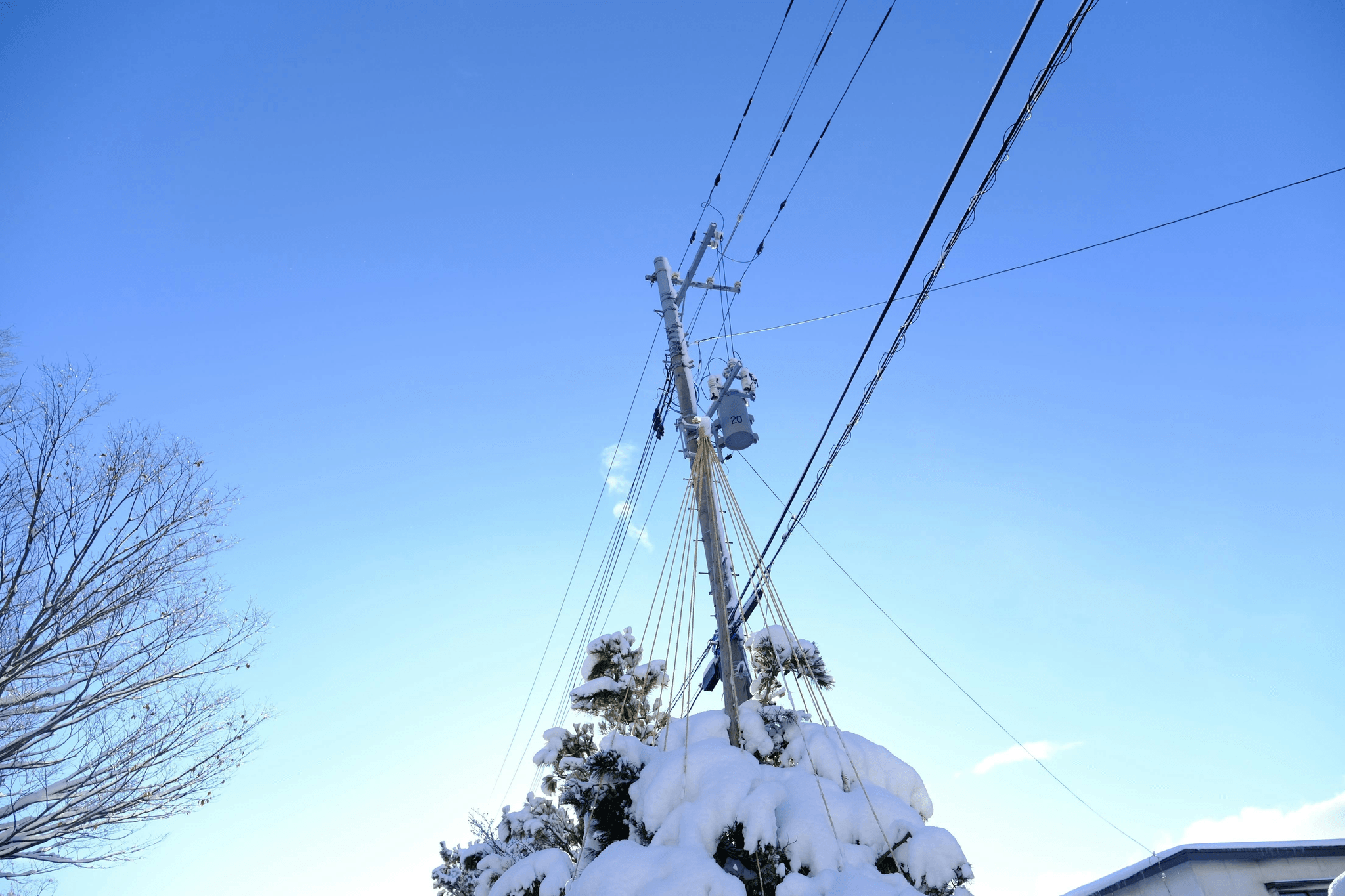

Post Insulators: The Foundation of Stability

Understanding Post Insulators

Post insulators are typically cylindrical in shape and are mounted vertically on structures such as poles or towers. They act as a barrier between conductive materials and the grounded surfaces, ensuring that electricity flows safely through power lines without risk of short-circuiting. Made from materials like porcelain or composite polymers, post insulators are engineered to withstand harsh environmental conditions, making them reliable components in any electrical system.

Applications and Benefits of Post Insulators

These versatile insulators find their place in numerous applications including substations, transmission lines, and distribution networks. One significant advantage is their ability to handle high voltage levels while providing excellent mechanical strength and resistance to environmental stressors like UV rays and moisture. Compared to other types of electrical insulators—such as pin type insulators or suspension insulators—post insulators offer enhanced stability and support for heavy loads.

Top Manufacturers of Post Insulators

Several manufacturers have established themselves as leaders in producing quality post insulators that meet industry standards. Companies like Siemens, GE Grid Solutions, and ABB have developed innovative designs that enhance performance while reducing maintenance needs over time. By choosing reputable suppliers for your post insulator needs, you can ensure longevity and reliability that rivals even pin type or strain insulators.

Conclusion

In the world of electrical systems, selecting the right type of electrical insulators is crucial for ensuring safety and efficiency. With various options available, such as pin type insulators, suspension insulators, strain insulators, shackle insulators, and post insulators, understanding their unique features can significantly impact your project's success. The right choice not only enhances performance but also extends the lifespan of your electrical infrastructure.

Choosing the Right Insulator for Your Needs

When it comes to choosing the right type of electrical insulator, it's essential to consider factors like voltage levels, environmental conditions, and mechanical stress. For instance, pin type insulators are ideal for lower voltage applications while suspension insulators are better suited for high-voltage lines due to their ability to handle greater tension. Strain insulators come into play when additional support is needed in tensioned lines, while shackle and post insulators provide stability in various configurations.

Understanding these distinctions allows you to make informed decisions based on your specific requirements. Whether you're working on a residential project or a large-scale industrial installation, knowing which type of electrical insulator aligns with your needs can save you time and money in the long run. Ultimately, choosing wisely ensures that your electrical systems will operate safely and efficiently.

Comparing Different Types of Electrical Insulators

Each type of electrical insulation has its strengths and weaknesses that cater to different applications. Pin type insulators offer simplicity and ease of installation but may not be suitable for high-stress environments like those handled by suspension or strain insulators. On the other hand, shackle insulators excel in providing flexibility where space is limited while post insulators deliver robust support for various installations.

When comparing these options side by side, it becomes evident that no single solution fits all scenarios; each has its niche where it performs best. For example, if you're dealing with transmission lines that require significant tension management, opting for strain or suspension types would be wise over pin types which are more limited in scope. By evaluating each option's characteristics against your project's demands, you can ensure optimal performance from your chosen insulation solution.

Why Spark Fittings Is Your Best Partner

Choosing a reliable partner like Spark Fittings can make all the difference when navigating through the myriad options available in types of electrical insulators. With a solid reputation built on quality products—ranging from pin type to post insulators—and exceptional customer service tailored to meet specific needs; they stand out as industry leaders. Their expertise helps guide customers through product selection and ensures compliance with safety standards.

Moreover, Spark Fittings offers an extensive inventory that includes not just standard items but also specialized solutions like customized shackle or strain insulators designed for unique applications. This commitment to meeting diverse customer requirements positions them as an invaluable resource in any project involving electrical insulation needs. When you choose Spark Fittings as your partner in selecting types of electrical insulation solutions—rest assured you’re making a smart investment towards reliability and efficiency.