Introduction

Shackle insulators play a crucial role in the realm of overhead power line construction, ensuring that electrical systems operate safely and efficiently. These unsung heroes of the electrical world are essential for maintaining the integrity of power transmission, preventing dangerous faults and outages. Their importance cannot be overstated, as they provide both support and insulation to high-voltage lines, allowing for the safe delivery of electricity to homes and businesses.

Importance of Shackle Insulators

The significance of shackle insulators lies in their ability to withstand harsh environmental conditions while maintaining electrical insulation. Without these vital components, overhead power lines would be susceptible to short circuits and failures due to weather-related stressors or physical damage. Among the various types of shackle insulators available, each serves a unique purpose in enhancing reliability and safety within electrical systems.

Overview of Key Types

When discussing types of shackle insulators in overhead power line construction, several key varieties come into play: 14-24 kV shackle insulators, porcelain shackle insulators, glass shackle insulators, polymer insulators, solid core shackle insulators, and stack-type shackle insulators. Each type is designed with specific properties that cater to different voltage levels and environmental factors. Understanding these variations is essential for selecting the right solution for any given application.

Functions in Power Line Safety

The primary functions of shackle insulators revolve around supporting conductors while providing necessary insulation from ground faults or short circuits. By effectively isolating live wires from their surroundings, they help maintain safe operational standards for power lines under various conditions. Additionally, proper installation and selection of suitable types—be it porcelain or polymer—can significantly enhance overall safety measures within electrical infrastructure.

Understanding Shackle Insulators

Shackle insulators are essential components in the world of overhead power lines, ensuring that electrical currents are safely contained and directed. These devices serve as a barrier between conductive materials and their supporting structures, preventing unwanted electrical discharges. In this section, we will delve into what shackle insulators are, their significance in power line systems, and their basic functions.

What are Shackle Insulators

Shackle insulators are specially designed insulating devices that support overhead conductors while maintaining electrical isolation from the supporting structures. Typically shaped like a U, they allow for easy attachment to poles or crossarms while holding the conductor securely in place. Among the various types of shackle insulators in overhead power line construction, you will often find options like 14-24 kV shackle insulators, solid core shackle insulators, stack-type shackle insulators, porcelain shackle insulators, glass shackle insulators, and polymer insulators.

Importance in Overhead Power Lines

They play a crucial role in maintaining safety by preventing electrical leakage and ensuring that high-voltage conductors remain isolated from the surrounding environment. By using different types of shackle insulators—such as porcelain or polymer options—engineers can tailor solutions to specific environmental conditions and voltage requirements.

Basic Functions of Insulators

The basic functions of shackle insulators revolve around providing mechanical support and electrical insulation for conductors within overhead power lines. They ensure that electricity flows through the conductor without leaking to nearby structures or grounding points. Additionally, these devices help withstand environmental stresses such as wind or ice loads while minimizing maintenance needs over time.

Types of Shackle Insulators in Overhead Power Line Construction

These insulators play a vital role in ensuring the safety and efficiency of electrical systems. Among the prominent varieties are the 14-24 kV shackle insulator, solid core shackle insulators, and stack-type shackle insulators, each serving unique functions tailored to specific needs.

14-24 KV Shackle Insulator

The 14-24 kV shackle insulator is designed specifically for medium voltage applications, making it a staple in overhead power line construction. Its robust design ensures that it can handle significant electrical loads while providing reliable insulation against environmental factors like moisture and UV radiation. With their ability to maintain performance under varying conditions, these shackle insulators contribute significantly to the overall reliability of power distribution networks.

In addition to their functional attributes, 14-24 kV shackle insulators come in various materials such as porcelain and polymer, allowing for flexibility based on project requirements. The choice between materials often hinges on factors like cost-effectiveness and long-term durability. Overall, these versatile shackle insulators are essential components that help maintain operational integrity in electrical systems.

Solid Core Shackle Insulators

Solid core shackle insulators are another key player in overhead power line construction due to their exceptional strength and durability. Typically made from materials like porcelain or glass, they provide excellent mechanical properties while ensuring high dielectric strength—making them ideal for areas with harsh weather conditions or heavy pollution levels. Their solid structure minimizes risks associated with breakage or failure under load.

These types of shackle insulators also offer significant advantages in terms of maintenance; they are less prone to contamination compared to hollow types which can trap dirt and moisture inside them. This ease of maintenance translates into lower operational costs over time—an attractive feature for utility companies looking to optimize their resources effectively. Thus, solid core shackle insulators stand out as a reliable choice for safe power transmission.

Stack-Type Shackle Insulators

Stack-type shackle insulators bring a unique twist to traditional designs by combining multiple insulating units into one cohesive assembly. This configuration allows them to achieve higher voltage ratings without increasing physical size—a crucial advantage when space is at a premium on utility poles or towers. As a result, stack-type shackle insulators are particularly favored where weight limitations exist but high performance is still required.

Another notable benefit lies in their adaptability; these types of shackle insulators can be configured for different voltage levels simply by adjusting the number of stacked units used in each assembly. This flexibility makes them suitable for diverse applications across various regions with differing voltage requirements. In essence, stack-type shackle insulators provide an innovative solution that meets modern demands while enhancing safety standards within overhead power line infrastructure.

Materials Used for Shackle Insulators

The three main types of materials used for shackle insulators in overhead power line construction are porcelain, glass, and polymer. Each material offers unique benefits and limitations that can significantly impact the effectiveness of the 14-24 kV shackle insulator.

Porcelain Shackle Insulators

Porcelain shackle insulators are a classic choice in the world of electrical insulation, known for their durability and high dielectric strength. These insulators can withstand extreme weather conditions, making them ideal for overhead power lines where reliability is paramount. However, while porcelain is robust, it can be susceptible to breakage if subjected to mechanical stress or extreme temperature fluctuations.

One significant advantage of porcelain shackle insulators is their resistance to UV degradation and environmental pollutants, ensuring they maintain performance over time. They also provide excellent electrical insulation properties which are essential for preventing power leakage in high-voltage applications like solid core shackle insulators. Overall, porcelain remains a popular option due to its proven track record in safety and efficiency.

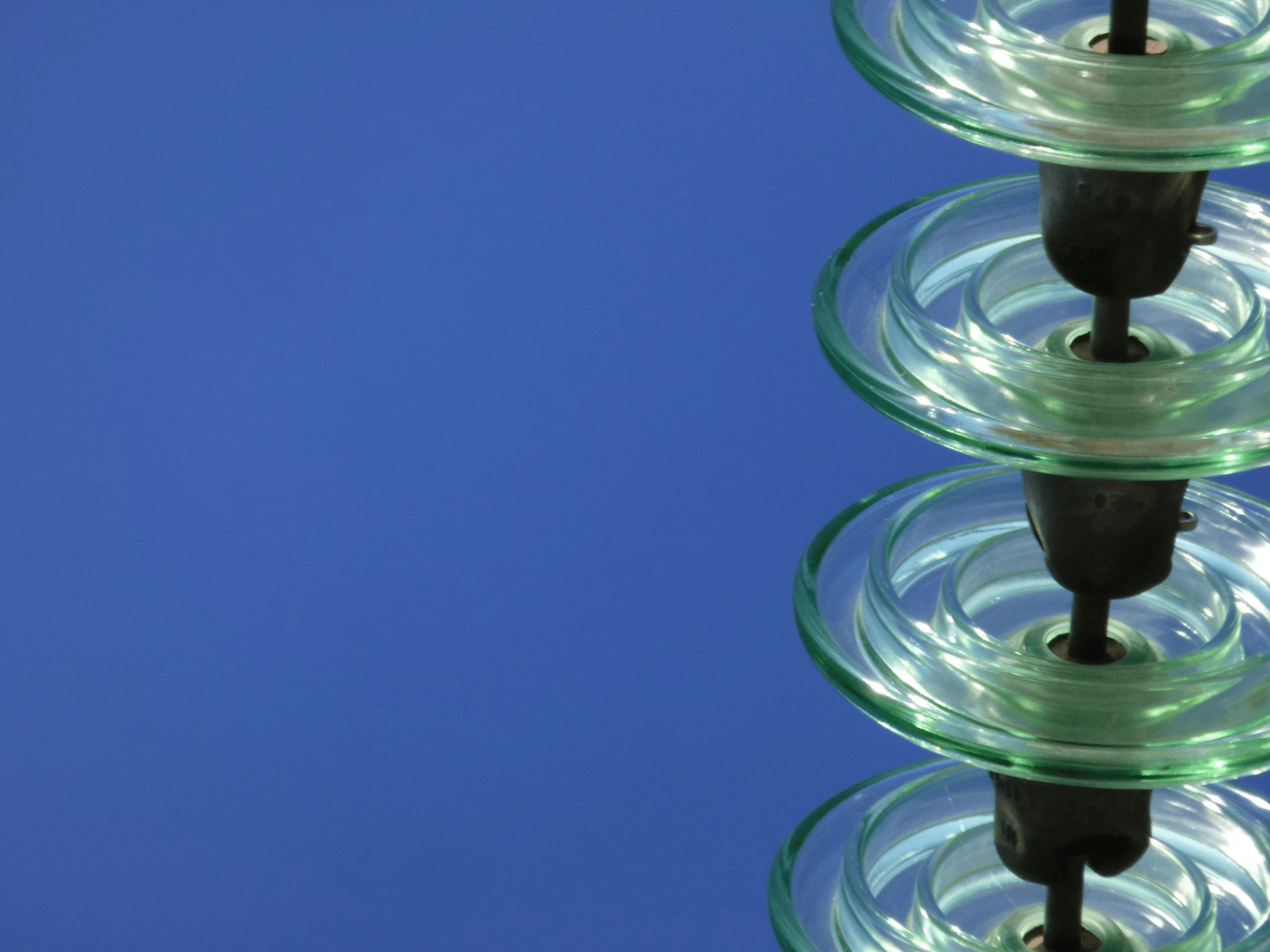

Glass Shackle Insulators

Glass shackle insulators offer another alternative with distinct advantages that make them suitable for various applications within overhead power line construction. These insulators are notable for their transparency which allows users to visually inspect them for any signs of damage or wear—something that’s not possible with opaque materials like porcelain or polymer. This transparency can be a game-changer when it comes to maintenance efficiency.

Moreover, glass has excellent electrical insulating properties similar to those found in porcelain shackle insulators but tends to be lighter and less brittle under certain conditions. This makes glass an attractive option when weight reduction is necessary without compromising on performance or safety standards. However, while glass does resist UV degradation well, it may still require careful handling during installation due to its fragility compared to more robust alternatives.

Polymer Insulators

Polymer insulators have emerged as a modern solution in the realm of electrical insulation technology, particularly appealing for their lightweight nature and flexibility compared to traditional materials like porcelain and glass. Made from composite materials that include silicone rubber or other polymers, these shackle insulators are less prone to breakage under stress—a critical factor during installation or adverse weather conditions associated with overhead power lines.

One standout feature of polymer insulators is their hydrophobic surface properties which help prevent water accumulation—a common issue that can lead to tracking and flashover events on standard solid core shackle insulators made from other materials. Additionally, polymer options often come with improved resistance against environmental factors such as pollution and extreme temperatures; thus enhancing overall longevity and reducing maintenance costs over time.

Overall, each type of material used in manufacturing shackle insulators brings its own set of strengths tailored towards specific operational needs within overhead power line construction—whether you choose porcelain's robustness or polymer’s innovative flexibility depends on your project requirements!

The Role of Spark Fittings in Insulator Systems

When it comes to the world of shackle insulators, spark fittings play a crucial role that often goes unnoticed. These small yet significant components are designed to enhance the overall performance and safety of insulator systems used in overhead power lines. By understanding their function and importance, we can appreciate how they contribute to the reliability of various types of shackle insulators, including 14-24 kV shackle insulators, solid core shackle insulators, and stack-type shackle insulators.

Overview of Spark Fittings

Spark fittings are specialized devices that connect electrical conductors to shackle insulators, ensuring a secure and stable interface between these components. Typically made from robust materials, they are designed to withstand harsh environmental conditions while providing effective electrical insulation. In the context of overhead power line construction, spark fittings serve as critical links that help maintain the integrity of porcelain shackle insulators, glass shackle insulators, and polymer insulators alike.

Contribution to Insulator Performance

The performance of any type of shackle insulator is directly influenced by the quality and design of its spark fittings. Properly installed spark fittings minimize electrical discharge risks by creating a more efficient path for current flow while reducing heat buildup during operation. This efficiency is essential for maintaining optimal performance in various applications involving 14-24 kV shackle insulators or solid core shackle insulators under varying load conditions.

Enhancing Safety with Spark Fittings

Safety is paramount in overhead power line systems; hence spark fittings play an indispensable role in enhancing this aspect significantly. By preventing unwanted electrical arcing or discharges between conductors and their associated insulation systems, these fittings reduce the risk of equipment failure or catastrophic events like fires or outages. Additionally, when paired with stack-type shackle insulators or polymer insulators, well-designed spark fittings can further bolster system resilience against environmental stressors such as moisture or extreme temperatures.

Benefits and Limitations of Each Type

When it comes to shackle insulators, understanding the benefits and limitations of each type is crucial for ensuring reliable performance in overhead power line construction. The three primary types—porcelain, glass, and polymer insulators—each bring unique characteristics to the table. By exploring these differences, we can better appreciate how they function in various applications while keeping safety and efficiency in mind.

Porcelain vs. Glass Insulators

Porcelain shackle insulators have long been a staple in overhead power line systems, known for their robustness and durability. They excel in high-voltage environments like the 14-24 kV shackle insulator range, providing excellent insulation properties even under harsh weather conditions. However, while porcelain is tough as nails, it can be prone to cracking under extreme stress or impact.

On the other hand, glass shackle insulators are renowned for their transparency and ability to withstand electrical stress without degradation over time. Their smooth surface helps prevent dirt accumulation, making maintenance a breeze compared to porcelain options. Yet, they can be heavier than porcelain counterparts and may require additional support during installation.

In summary, both porcelain and glass insulators have their merits; porcelain offers strength while glass provides longevity. Choosing between them often depends on specific project requirements such as environmental conditions or load-bearing needs.

The Versatility of Polymer Insulators

Polymer insulators are increasingly gaining traction in the world of overhead power line construction due to their remarkable versatility. These modern marvels are lightweight yet strong enough to handle significant electrical loads while being resistant to UV radiation and environmental pollutants. This makes polymer shackle insulators particularly suitable for areas with challenging weather patterns or where traditional materials might falter.

One of the standout features of polymer insulators is their lower weight compared to both porcelain and glass options; this can significantly reduce installation costs by minimizing structural reinforcement requirements on poles or towers. Additionally, polymer materials allow for greater design flexibility—engineers can craft shapes that optimize performance without compromising safety standards.

However, it's essential to note that while polymer shackle insulators offer numerous advantages—like reduced maintenance needs—they may not always be suitable for every application due to factors like thermal expansion characteristics or long-term durability concerns compared with traditional materials.

Best Applications for Solid Core Shackle Insulators

Solid core shackle insulators stand out as a preferred choice when reliability is paramount in overhead power line systems. These types of shackle insulators are designed specifically for high-stress environments where mechanical strength is critical; they excel under heavy loads typically found in urban settings or industrial applications requiring robust infrastructure support.

Their solid core design minimizes risk factors associated with breakage or failure during operation—a crucial advantage when dealing with 14-24 kV systems that demand consistent performance under pressure. Furthermore, solid core options often come with enhanced resistance against environmental challenges such as wind loading or ice accumulation—making them ideal candidates for regions prone to severe weather events.

While solid core shackle insulators shine brightly in specific scenarios, it's important not to overlook other types like stack-type options that might better suit different operational contexts based on varying voltage levels or installation environments.

Conclusion

In conclusion, shackle insulators play a pivotal role in ensuring the safety and reliability of overhead power lines. With various types of shackle insulators available, such as the 14-24 kV shackle insulator, selecting the right one is crucial for optimal performance. Understanding their characteristics and applications is essential to making informed decisions that enhance electrical infrastructure.

Choosing the Right Shackle Insulator

For instance, the 14-24 kV shackle insulator is ideal for medium-voltage applications due to its robust design and reliability. Additionally, porcelain shackle insulators offer excellent mechanical strength and thermal stability, while polymer insulators provide lightweight options with superior resistance to environmental stressors.

Selecting between different types of shackle insulators in overhead power line construction can be daunting. Glass shackle insulators are known for their durability but may not be suitable for every climate due to potential fragility concerns. Therefore, assessing specific project needs will guide you toward the most effective choice—whether it's solid core shackle insulators for high-load scenarios or stack-type shackle insulators for unique configurations.

Future Trends in Insulator Technology

The future of shackle insulators is bright with ongoing advancements in materials and design technologies. Innovations such as smart monitoring systems integrated into polymer insulators are paving the way for enhanced performance metrics and predictive maintenance capabilities. These trends aim not only at improving longevity but also at reducing overall costs associated with power line maintenance.

Moreover, research into eco-friendly materials is gaining momentum as industries strive to minimize their carbon footprints. The development of sustainable glass or recycled polymer options could revolutionize how we approach insulation in overhead power lines while maintaining safety standards. As these trends evolve, they promise a more efficient energy distribution system that meets modern demands.

Final Thoughts on Insulator Functions

In summary, understanding the functions of various types of shackle insulators is vital for anyone involved in electrical infrastructure projects. From enhancing safety features through spark fittings to improving load-bearing capabilities with solid core designs, each type serves a distinct purpose that contributes significantly to overall system reliability. Ultimately, staying informed about advancements in technology will empower stakeholders to make better choices regarding their use of shackle insulators.