Introduction

Guy wires play a pivotal role in providing stability and support to various structures, from utility poles to telecommunications towers. Understanding the basics of guy wires is essential for anyone involved in construction or infrastructure projects, as they are critical for ensuring safety and functionality. The right choice of guy wire can mean the difference between a secure installation and potential failure, making it crucial to grasp the nuances of these essential components.

Understanding Guy Wire Basics

At its core, a guy wire is a tensioned cable used to stabilize structures by anchoring them to the ground or another fixed point. Typically made from steel or synthetic materials, guy wires work by counteracting lateral forces that can cause instability in tall structures like wind turbines or radio towers. Familiarity with terms such as Guy Wire & Stay Wire helps clarify their specific applications and functionalities within different engineering contexts.

Importance of Choosing the Right Guy Wire

Selecting the appropriate guy wire is paramount for ensuring structural integrity and longevity. Different applications require different specifications; for instance, telecommunications installations may demand more robust materials compared to those used in solar arrays. Moreover, using subpar guy wire clamps or fittings can compromise an entire project’s safety, highlighting why careful consideration should be given during selection.

Key Considerations for Guy Wire Selection

When selecting a guy wire, several factors must be evaluated: material type, load capacity, environmental conditions, and compatibility with fittings used with the guy wire are all critical elements that influence performance and durability. Additionally, understanding industry standards ensures compliance with regulations while providing peace of mind regarding safety measures in place. Ultimately, thorough research into various manufacturers will help identify high-quality options that align with specific project needs.

Types of Guy Wire

When it comes to guy wire, understanding the types available is essential for any project involving structural support. The choice between steel and synthetic options can significantly impact the overall effectiveness and durability of your setup. Each type of guy wire has its own strengths and weaknesses, making it crucial to consider your specific needs before making a selection.

Steel vs. Synthetic Options

Steel guy wires are renowned for their strength and durability, making them a popular choice in many applications of guy wire. They can withstand heavy loads and are often used in telecommunications and utility poles where stability is paramount. On the other hand, synthetic options offer flexibility and resistance to corrosion, which can be advantageous in environments prone to moisture or extreme weather conditions.

Choosing between steel and synthetic options often boils down to the specific functions of guy wire you need to fulfill. For instance, if you're looking at long-term infrastructure projects, steel may be preferred due to its longevity under stress. However, if you're dealing with temporary installations or need lightweight solutions, synthetic materials might just fit the bill perfectly.

Comparison of Guy Wire Materials

When comparing materials for guy wire, it's essential to evaluate factors such as tensile strength, weight, and environmental resistance. Steel wires typically have higher tensile strength compared to their synthetic counterparts but can be heavier and more challenging to handle during installation. Conversely, while synthetic wires may not match steel's load-bearing capabilities directly, advancements in material science have led to highly durable synthetics that perform admirably under various conditions.

In addition to performance characteristics like these, consider how each material interacts with fittings used with the guy wire—like clamps or tensioning devices—which also play a critical role in overall system integrity. A robust connection between your chosen guy wire material and these fittings ensures optimal load distribution across structures like wind turbines or solar arrays. Ultimately, understanding these comparisons will guide you towards selecting the right type that meets both safety standards and application requirements.

Industry Standards for Guy Wire

Industry standards play a vital role when selecting any type of guy wire since they ensure safety and reliability across various applications of guy wire—from construction projects to telecommunications installations. Organizations such as ASTM International provide guidelines that govern specifications for different materials used in manufacturing guys wires—including those made from steel or synthetic fibers—ensuring they meet required performance metrics.

Adhering to these industry standards not only helps maintain structural integrity but also fosters trust among clients regarding quality assurance from manufacturers producing components like guy wire clamps or tensioning devices needed for secure installations. When evaluating potential Guy Wire Manufacturers, always check if their products comply with established industry norms; this could save you from future headaches related to equipment failure or safety hazards.

In summary, understanding the types of materials available for guy wire—alongside their respective features—can significantly influence your project's success rate while ensuring compliance with industry standards designed for safety and efficiency.

Functions of Guy Wire

Guy wires play a crucial role in ensuring the stability and integrity of various structures. Their primary function is to provide support and prevent swaying or falling, making them essential in numerous applications. Understanding how guy wire functions can help users select the right fittings used with the guy wire for optimal performance.

Supporting Structures Effectively

One of the key functions of guy wire is to support structures effectively, such as utility poles, telecommunications towers, and wind turbines. By anchoring these tall structures securely to the ground, guy wires help maintain their vertical alignment and prevent collapse under various loads. The use of high-quality guy wire clamps ensures that these connections remain secure, enhancing overall safety and reliability.

In applications where stability is paramount, such as in construction projects or large infrastructure installations, selecting the appropriate type of guy wire is vital. The strength and flexibility of materials like steel or synthetic options can significantly impact performance under load. Therefore, understanding how different types of guy wire work together with their fittings can lead to better structural outcomes.

Load Distribution and Stability

Another critical function of guy wire lies in its ability to distribute loads evenly across a structure. This load distribution helps maintain stability by preventing localized stress points that could lead to failure over time. Properly installed guy wires ensure that forces from wind or other environmental factors are shared across multiple points rather than concentrated on a single area.

The effective use of fittings used with the guy wire plays an important role in achieving optimal load distribution. High-quality tensioning devices can adjust slackness and ensure that each segment of the system bears its fair share of weight. This balanced approach not only enhances stability but also prolongs the lifespan of both the structure and its components.

Resistance to Environmental Factors

Guy wires are also designed to resist various environmental factors that could compromise structural integrity over time. Whether it's strong winds, heavy rain, or extreme temperatures, these wires must withstand significant stress without losing their effectiveness. Selecting a durable material for your guy wire will ensure it remains resilient against harsh conditions while maintaining its supporting functions.

Incorporating quality fittings like guy wire clamps further enhances this resistance by providing secure connections that won't easily corrode or fail under pressure from environmental elements. Additionally, understanding how different materials react to weather conditions allows users to make informed choices about their applications of guy wire in specific environments. Ultimately, this knowledge contributes significantly to safety standards within construction projects and other infrastructures.

Applications of Guy Wire

Guy wires are essential components in various industries, providing stability and support for structures that need to withstand environmental challenges. Their versatility is evident in multiple applications, ranging from telecommunications to renewable energy and construction projects. Understanding the specific uses of guy wire helps ensure that each application is executed with the right fittings and materials for maximum safety and efficiency.

Telecommunications and Utility Poles

In the realm of telecommunications, guy wires play a pivotal role in stabilizing utility poles that carry power lines and communication cables. These poles are often subject to high winds and other environmental stresses, making the use of guy wire clamps essential for maintaining their integrity. By distributing loads effectively, guy wire ensures that utility poles remain upright, thereby facilitating uninterrupted service delivery.

Moreover, the selection of suitable Guy Wire & Stay Wire is crucial in this field; different environments may require varying strengths and materials. For instance, synthetic options might be preferred in coastal areas due to their resistance to corrosion from salty air. Ultimately, choosing a reliable Guy Wire Manufacturer can significantly impact the longevity and performance of these installations.

Wind Turbines and Solar Arrays

Wind turbines are another domain where guy wires demonstrate their importance by providing structural support against strong winds. The tall towers must remain stable during turbulent weather conditions; thus, effective load distribution through well-placed guy wires is vital for operational efficiency. Here again, quality fittings used with the guy wire—such as durable clamps—are necessary to ensure secure connections.

Similarly, solar arrays benefit from guy wires by stabilizing mounting structures that hold solar panels at optimal angles for sunlight exposure. In both cases, selecting appropriate materials based on environmental conditions can enhance performance while minimizing maintenance needs over time. As renewable energy continues to grow in importance globally, understanding various applications of guy wire remains key for engineers and installers alike.

Construction and Infrastructure Projects

In construction projects ranging from bridges to high-rise buildings, guy wires provide critical support during various phases of development. Temporary structures like scaffolding often rely on these wires to maintain stability while workers perform tasks at height or when erecting large frameworks. The functions of guy wire extend beyond mere support; they also help distribute weight evenly across structures under stress.

Using quality hardware such as guy wire clamps ensures that these connections remain secure throughout construction activities—preventing accidents or structural failures that could have dire consequences. Additionally, integrating stay wires into designs can further enhance stability when dealing with particularly challenging engineering feats like skyscrapers or large-span bridges. As such, a thorough understanding of applications related to guy wire can lead to safer construction practices across industries.

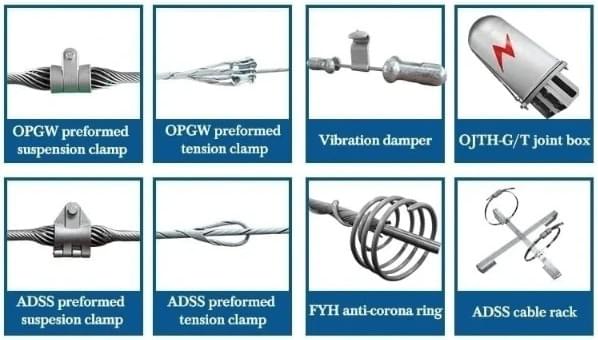

Fittings Used with Guy Wire

When it comes to ensuring the stability and effectiveness of guy wire systems, the fittings used with the guy wire play a crucial role. These components not only enhance the overall performance of the guy wire but also contribute significantly to its longevity and reliability. Understanding the types of fittings available, such as guy wire clamps and tensioning devices, is essential for anyone involved in applications of guy wire.

Overview of Guy Wire Clamps

Guy wire clamps are essential fittings that secure the guy wires to their anchor points or structures. They provide a reliable connection that helps maintain tension in the system, preventing any unwanted movement or slack that could compromise stability. The choice of quality guy wire clamps can greatly influence both the performance and safety of your setup, making them a critical consideration for any project involving Guy Wire & Stay Wire.

In addition to securing connections, these clamps come in various designs tailored for different applications of guy wire. Some are specifically engineered for steel wires, while others accommodate synthetic options, allowing flexibility based on your project needs. Ultimately, investing in high-quality guy wire clamps can save time and resources by reducing maintenance needs and enhancing overall system integrity.

Exploring Tensioning Devices

Tensioning devices are another vital fitting used with guy wire systems that ensure optimal load distribution and stability. These devices allow users to adjust the tension in the wires easily, accommodating changes due to weather conditions or structural shifts over time. Properly tensioned guys not only support structures effectively but also increase resistance against environmental factors like wind or snow loads.

There are various types of tensioning devices available on the market today—each designed with specific functions in mind for different applications of guy wire. From simple turnbuckles to more complex hydraulic systems, selecting an appropriate device is key to achieving desired performance levels. As with all fittings used with guy wire, choosing quality options from reputable manufacturers ensures safety and reliability throughout your project's lifespan.

Importance of Quality Hardware

Quality hardware is paramount when working with any type of fitting used with guys wires; after all, they bear significant loads under varying conditions! Investing in well-manufactured components ensures that you’re not just meeting industry standards but exceeding them—providing peace of mind as you navigate through your projects involving Guy Wire & Stay Wire systems. High-quality hardware contributes directly to both safety and efficiency by minimizing potential failure points within your rigging setup.

Moreover, reputable Guy Wire Manufacturers offer products tested for durability and performance under real-world conditions—a critical factor when selecting fittings like clamps or tensioners for your projects involving applications of guy wire across diverse industries such as telecommunications or construction infrastructure projects. Remember: cutting corners on hardware can lead to costly repairs down the line; prioritize quality now for long-term benefits!

Choosing a Guy Wire Manufacturer

Selecting the right guy wire manufacturer is crucial for ensuring that your projects are safe, effective, and reliable. With numerous options available, it’s essential to consider not just the quality of the guy wire itself but also the fittings used with the guy wire. A reputable manufacturer will provide you with durable materials and excellent customer support, making your choice easier.

Evaluating Spark Fittings and Their Offerings

When evaluating manufacturers like Spark Fittings, it's important to examine their product range closely—especially their offerings related to guy wires and stay wires. Spark Fittings is known for its extensive selection of high-quality hardware designed specifically for enhancing the performance of your installations through reliable connections between components. This includes an array of fittings used with the guy wire that ensure stability and safety.

Look into factors such as material quality, design innovation, and ease of installation when assessing these products. The right fittings can significantly impact how effectively your structures perform under load distribution requirements or resist environmental factors like wind or rain—key applications of guy wire in various industries. Always check if they provide detailed specifications about their products so you can make informed decisions.

Customer Reviews and Feedback

Customer reviews are invaluable when choosing a reputable guy wire manufacturer; they offer insights into real-world experiences from other users who have utilized these products for different applications of guy wire. Look for testimonials highlighting durability, ease of installation, customer service responsiveness, and overall satisfaction with both products like guys wires themselves as well as associated fittings such as clamps or tensioning devices.

Pay attention to recurring themes in feedback—if multiple customers mention issues related to compatibility or performance under stress conditions, it may be wise to reconsider that particular brand or model. Engaging with community forums or industry-specific groups can also provide additional perspectives on which manufacturers consistently deliver high-quality solutions for various functions of guy wire installations.

Conclusion

In wrapping up our exploration of guy wire, it's essential to remember the critical factors that influence your selection process. Whether you're considering the various applications of guy wire or the specific functions it serves, choosing the right materials and fittings is paramount. By focusing on quality manufacturers and understanding the importance of guy wire clamps, you can ensure that your projects are safe and effective.

Summary of Guy Wire Selection Tips

When selecting a guy wire, consider both its material and intended application to ensure maximum effectiveness. Steel offers strength while synthetic options provide flexibility; each has its place depending on environmental factors and load requirements. Don't forget about the fittings used with guy wire—like guy wire clamps—which play a vital role in securing your setup.

Moreover, always check for compliance with industry standards when evaluating potential options from various guy wire manufacturers. Understanding the functions of guy wire will help you make informed decisions based on stability and load distribution needs. Lastly, customer reviews can provide insight into quality and reliability, so be sure to consult them before making a purchase.

Final Thoughts on Quality and Safety

Quality should never be compromised when it comes to selecting a guy wire or its accessories; after all, safety is paramount in all applications of guy wire. Investing in high-quality materials ensures not only durability but also peace of mind as you tackle infrastructure projects or telecommunications setups. Remember that even the best materials require proper installation using reliable fittings like guy wire clamps to maximize their effectiveness.

As we’ve discussed throughout this guide, understanding both the functions of guy wire and its applications can lead to better project outcomes. Safety protocols should always be followed during installation to mitigate risks associated with improper use or failure of components. In short, prioritize quality over cost when seeking out your next supplier; it will pay off in spades down the line.

Resources for Further Reading on Guy Wire

For those looking to delve deeper into the world of guy wires, several resources are available that cover everything from technical specifications to installation guidelines. Industry publications often feature articles discussing advancements in materials used for both Guy Wire & Stay Wire configurations as well as updates on safety standards relevant to their use.

Additionally, websites dedicated to construction equipment often have sections highlighting trusted guys' manufacturers along with user experiences regarding their products—especially useful when assessing potential suppliers for fittings used with the guy wire such as clamps and tensioning devices.

Lastly, online forums can serve as platforms where professionals share insights about best practices related to different applications of guy wires across industries—from telecommunications towers to wind turbine installations.