Introduction

In the world of construction and electrical projects, understanding formed wire is crucial for ensuring safety and efficiency. Formed wire, which includes various types such as the Formed Wire Dead End and aluminum suspension clamp, serves essential functions in supporting electrical systems. Additionally, incorporating wire armor into these setups enhances durability and performance, making it a key consideration for any project.

Understanding the Basics of Formed Wire

Formed wire refers to metal wires that have been shaped or configured to meet specific requirements in construction and electrical applications. This versatile material comes in various types, including cushion grip suspension and tension dead ends, each designed for unique tasks. By grasping the basics of formed wire, you can make informed decisions about which type best suits your project's needs.

The Importance of Wire Armor in Construction

Wire armor plays a pivotal role in protecting cables from environmental hazards and physical damage during installation and use. Incorporating wire armor not only increases the lifespan of your electrical systems but also enhances overall performance by providing additional support against wear and tear. Understanding how to choose the right wire armor can significantly impact your project's success.

How to Choose the Right Manufacturer

Selecting a reliable formed wire manufacturer is crucial for ensuring quality materials that meet industry standards. Look for manufacturers who specialize in different types of formed wire products, such as end sleeves or tension dead ends, to find a partner that aligns with your project goals. A reputable manufacturer will provide not only high-quality products but also valuable insights into selecting appropriate solutions like aluminum suspension clamps or cushion grip suspensions for your specific needs.

What is Formed Wire?

Formed wire is a specialized type of wire that has been shaped and treated for specific applications, particularly in construction and electrical projects. Its unique characteristics, such as strength and flexibility, make it an essential component in various settings. Understanding formed wire can significantly enhance your project’s effectiveness, especially when paired with wire armor for added durability.

Definition and Characteristics

Formed wire refers to wire that has been bent or shaped into a particular form to meet specific functional requirements. This type of wire often exhibits enhanced mechanical properties, allowing it to withstand greater loads than standard wire. Key characteristics include resistance to corrosion and fatigue, making formed wire ideal for long-term use in demanding environments.

Common Applications of Formed Wire

The versatility of formed wire makes it suitable for numerous applications across different industries. In the electrical sector, formed wires are commonly used in suspension systems such as aluminum suspension clamps and cushion grip suspensions for overhead lines. Additionally, they play a crucial role in securing connections through components like end sleeves and tension dead ends.

Key Benefits in Electrical Projects

In electrical projects, the benefits of using formed wire cannot be overstated. First and foremost, its strength contributes to the overall safety and reliability of electrical installations by providing robust support structures. Furthermore, when combined with features like wire armor, formed wires enhance protection against environmental factors while ensuring optimal performance throughout their lifespan.

Exploring Types of Formed Wire

When delving into the world of formed wire, it’s essential to understand the various types available and their specific applications. Each type of formed wire offers unique characteristics that cater to different needs in construction and electrical projects. Knowing these differences can help you make informed decisions when selecting products, ensuring you choose the right solutions for your project.

Overview of Different Formed Wire Types

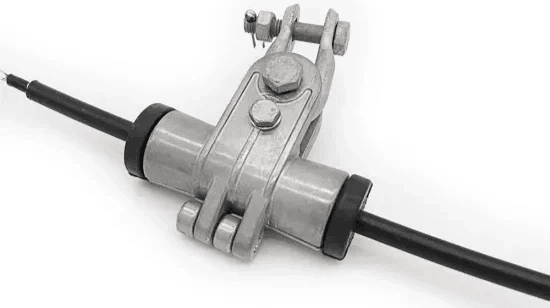

Formed wire comes in several varieties, each designed for distinct purposes. From basic shapes used in structural support to specialized configurations like the Formed Wire Dead End, these products are vital for ensuring stability and safety in electrical systems. Understanding the types of formed wire available—such as Aluminum suspension clamps and cushion grip suspensions—can simplify your selection process and enhance project efficiency.

The versatility of formed wire is evident in its applications across various industries, including telecommunications, power distribution, and construction. For example, aluminum suspension clamps are commonly used for overhead lines due to their lightweight yet sturdy design. In contrast, cushion grip suspensions provide additional flexibility and protection against vibrations, making them ideal for dynamic environments.

Comparison of Aluminum Suspension Clamps and Cushion Grip Suspension

When comparing aluminum suspension clamps with cushion grip suspensions, it's crucial to consider their specific advantages and drawbacks. Aluminum suspension clamps are known for their excellent conductivity and resistance to corrosion; however, they may not absorb shocks as effectively as cushion grip suspensions do. On the other hand, cushion grips offer enhanced protection by minimizing stress on cables during installation or under load conditions.

Choosing between these two types often depends on your project's specific requirements. If you're looking for a lightweight option that facilitates easy installation without compromising performance, aluminum suspension clamps are an excellent choice. Conversely, if your project involves high vibration areas or requires additional cable protection through wire armor features, opting for cushion grip suspensions would be wise.

When to Use End Sleeves versus Tension Dead Ends

End sleeves and tension dead ends serve different purposes when working with formed wire products; understanding when to use each is crucial for optimal performance. End sleeves provide a protective finish at the ends of wires or cables while helping maintain integrity during installation by preventing fraying or damage from external elements such as moisture or abrasion. They are particularly useful in applications where wires need to be terminated neatly.

Tension dead ends play a different role by anchoring wires securely at critical points within an electrical system while absorbing tension forces effectively throughout operation cycles. These components are essential when dealing with high-stress situations where maintaining line integrity is paramount—especially in overhead power lines subjected to wind or ice loads! By knowing when to deploy end sleeves versus tension dead ends based on specific environmental factors will ensure long-lasting functionality.

Selecting a Reliable Formed Wire Manufacturer

Choosing the right formed wire manufacturer is crucial for ensuring that your electrical projects are safe, efficient, and reliable. With various types of formed wire available—including aluminum suspension clamps and cushion grip suspension products—it's essential to partner with a manufacturer that meets your specific needs. A quality manufacturer will not only provide superior products but also offer valuable insights into the proper use of items like end sleeves and tension dead ends.

What to Look for in a Manufacturer

When selecting a formed wire manufacturer, consider their experience in the industry and the range of products they offer. Look for companies that specialize in various types of formed wire, as this indicates a depth of knowledge and capability to meet diverse project demands. Additionally, ensure they have robust customer service; after all, you want a partner who can assist you with technical queries regarding wire armor or specific applications like formed wire dead ends.

Another critical factor is the manufacturer's reputation. Check customer reviews and testimonials to gauge their reliability and quality standards. A trustworthy manufacturer should be transparent about their production processes and willing to share information about materials used, such as those found in aluminum suspension clamps or other formed wire products.

Spotlight on Spark Fittings: A Key Player

Spark Fittings stands out as a leading formed wire manufacturer known for its commitment to quality and innovation. They offer an extensive range of products including aluminum suspension clamps, cushion grip suspensions, end sleeves, and tension dead ends tailored for various applications. Their focus on developing durable solutions ensures that their offerings meet industry standards while providing excellent performance under challenging conditions.

What sets Spark Fittings apart is their dedication to customer satisfaction—providing not just high-quality products but also expert advice on choosing the right type of formed wire for your project needs. Whether you're working on large-scale electrical installations or smaller projects requiring precision components like wire armor, Spark Fittings has the expertise you can rely on.

Evaluating Quality Standards and Certifications

To ensure you're choosing a reputable formed wire manufacturer like Spark Fittings, it's essential to evaluate their quality standards and certifications rigorously. Look for manufacturers that comply with industry regulations such as ISO certifications which indicate adherence to stringent quality management systems. This compliance assures you that their products—including various types of formed wires—meet safety requirements necessary for installation in electrical projects.

Additionally, inquire about any third-party testing or validation processes they employ; this further enhances confidence in product durability and reliability—particularly important when considering components such as tension dead ends or end sleeves used in high-stress environments. By taking these steps when selecting a manufacturer, you can assure yourself that your investment will yield long-lasting benefits.

Understanding the Role of Wire Armor

Wire armor plays a crucial role in enhancing the strength and longevity of formed wire products used in various applications, particularly in electrical projects. By providing an additional layer of protection, wire armor helps to prevent damage caused by environmental factors, physical wear, and other stresses that can compromise the integrity of formed wire components like Formed Wire Dead Ends. In this section, we will explore how wire armor enhances durability, its impact on performance, and tips for selecting the right type for your specific needs.

How Wire Armor Enhances Durability

Durability is paramount when it comes to formed wire applications; after all, you want your investment to stand the test of time. Wire armor acts as a robust shield against abrasion and corrosion, significantly extending the lifespan of components such as Aluminum Suspension Clamps and Cushion Grip Suspension products. By integrating wire armor into your setup, you not only minimize maintenance costs but also reduce the likelihood of unexpected failures that could lead to costly downtime.

The Impact of Wire Armor on Performance

The performance of formed wire products is often directly linked to their protective features; enter wire armor. With its enhanced resistance to environmental stressors like moisture and temperature fluctuations, wire armor ensures that components maintain their functionality over time. This added layer is especially important for critical elements such as End Sleeves and Tension Dead Ends, where consistent performance is non-negotiable.

Choosing the Right Wire Armor for Your Needs

Selecting the appropriate type of wire armor can feel overwhelming given the variety available on the market today; however, it doesn't have to be! Start by assessing your specific application requirements—consider factors such as environmental conditions and load capacities when choosing between different types of formed wire options. Remember that not all forms are created equal; thus opting for a reputable Formed Wire Manufacturer will ensure you get quality products tailored to withstand your unique challenges while maximizing efficiency.

Installation Tips for Formed Wire Products

When it comes to installing formed wire products, the right approach can make all the difference. Proper installation not only ensures the longevity of your materials but also enhances performance in electrical projects. With a little know-how and attention to detail, you can avoid headaches down the road.

Best Practices for Using Formed Wire

First things first, always read the manufacturer’s guidelines before diving into installation. Whether you’re working with aluminum suspension clamps or cushion grip suspensions, understanding how each type of formed wire functions is crucial for achieving optimal results. Additionally, ensure that your formed wire dead ends and end sleeves are compatible with the specific project requirements to avoid any mishaps.

Another best practice involves using appropriate tools designed for handling formed wire products. This includes proper crimping tools and safety gear to protect yourself during installation. Remember that a well-prepared workspace contributes significantly to efficiency and safety, so clear any clutter before you get started.

Finally, consider environmental factors when installing wire armor or other formed wire components. Extreme temperatures or moisture can affect performance; therefore, it's wise to select materials that are suited for your specific conditions. The right choices will ensure that your installations stand the test of time while maintaining their integrity.

Common Mistakes to Avoid During Installation

One common mistake is overlooking compatibility between different types of formed wire components like tension dead ends and end sleeves. Mixing incompatible parts may lead to failures during operation or even safety hazards down the line—definitely not what you want! Always double-check specifications and compatibility before proceeding with installation.

Another pitfall is failing to secure connections adequately. Loose fittings can lead to electrical failures or even accidents in extreme cases; nobody wants that! Make sure each connection is tightly secured according to manufacturer recommendations, especially when working with aluminum suspension clamps where strength is crucial.

Lastly, don’t forget about proper training and knowledge sharing among team members involved in installations. Ignoring this aspect may lead to inconsistent practices across your workforce—resulting in errors that could have been easily avoided with a bit of communication and training on types of formed wire being used.

Ensuring Safety and Compliance Regulations

Safety should always be at the forefront when dealing with electrical installations involving formed wires and their accessories like cushion grip suspensions or wire armor. Familiarize yourself with local regulations regarding electrical work; compliance isn’t just a suggestion—it’s a requirement! Regularly reviewing these standards will keep your projects above board while ensuring everyone involved remains safe.

Additionally, ensure all personnel are equipped with personal protective equipment (PPE) suitable for electrical work during installation processes involving tension dead ends or other high-stress components. This includes gloves, goggles, and insulated tools designed specifically for such tasks—safety first!

Finally, conduct regular inspections post-installation as part of your maintenance routine; this will help identify any potential issues early on before they escalate into more significant problems later down the line—saving both time and resources in the long run!

Conclusion

In wrapping up our exploration of formed wire, it’s clear that this essential component plays a pivotal role in various electrical and construction applications. From the sturdy Formed Wire Dead End to the versatile Aluminum Suspension Clamp, understanding the types of formed wire available helps in making informed decisions for your projects. Additionally, we’ve seen how options like Cushion Grip Suspension and End Sleeves can enhance performance while ensuring safety and compliance.

Recap of Key Types of Formed Wire

Throughout this guide, we’ve delved into several key types of formed wire, each serving a unique purpose. The Formed Wire Dead End is crucial for securing cables at their endpoints, while Aluminum Suspension Clamps offer lightweight yet robust support. Meanwhile, Cushion Grip Suspension provides flexibility and protection against wear and tear, making it an ideal choice for dynamic environments.

Importance of Choosing the Right Manufacturer

Selecting a reliable formed wire manufacturer is not just important; it's vital for ensuring quality and durability in your projects. A reputable manufacturer will provide products that meet industry standards while offering valuable insights into the best uses for different types of formed wire. By choosing wisely, you can ensure that components like Tension Dead Ends and End Sleeves perform optimally under various conditions.

Final Thoughts on Wire Armor and Its Advantages

Wire armor stands out as an indispensable feature that enhances the durability and performance of electrical installations. It acts as a protective layer against environmental factors, ensuring longevity even in challenging conditions. Ultimately, investing in quality wire armor not only safeguards your investments but also contributes to safer operational environments across all applications involving formed wire.