Introduction

In the world of power line installation, secondary clevises play a crucial role that often goes unnoticed. These specialized fittings are essential for ensuring the stability and reliability of power lines, making them a key component in any electrical infrastructure project. Understanding their usage not only enhances performance but also contributes to safety and longevity in power line systems.

Understanding Secondary Clevis Usage

A secondary clevis is designed to provide additional support and secure connections between various components of power lines. Unlike standard clevises, which may serve broader applications, secondary clevises are tailored specifically for critical load-bearing tasks in electrical installations. By knowing how to utilize these fittings properly, professionals can significantly improve the overall integrity of their work.

Importance of Proper Power Line Installation

Proper installation of power lines is paramount for ensuring consistent electricity delivery and minimizing outages or failures. Using high-quality components, such as those from a reputable China clevis manufacturer, can make all the difference in achieving optimal performance and safety standards. When every piece fits together seamlessly, it not only enhances efficiency but also protects against potential hazards associated with faulty installations.

Key Features of High-Quality Clevis

When selecting a secondary clevis, certain features should be prioritized to ensure durability and effectiveness. Look for materials that resist corrosion and wear while providing robust strength under load—qualities typically offered by trusted China clevis manufacturers. Additionally, features like precision engineering and ease of installation can further enhance the reliability and functionality of your power line systems.

What is a Secondary Clevis?

When it comes to power line installations, understanding the components involved is crucial, and the secondary clevis plays a significant role. Essentially, a secondary clevis serves as an intermediary connector in power lines, ensuring that wires and cables are secured effectively and safely. This component not only enhances structural integrity but also adds flexibility to installation processes.

Definition and Functionality

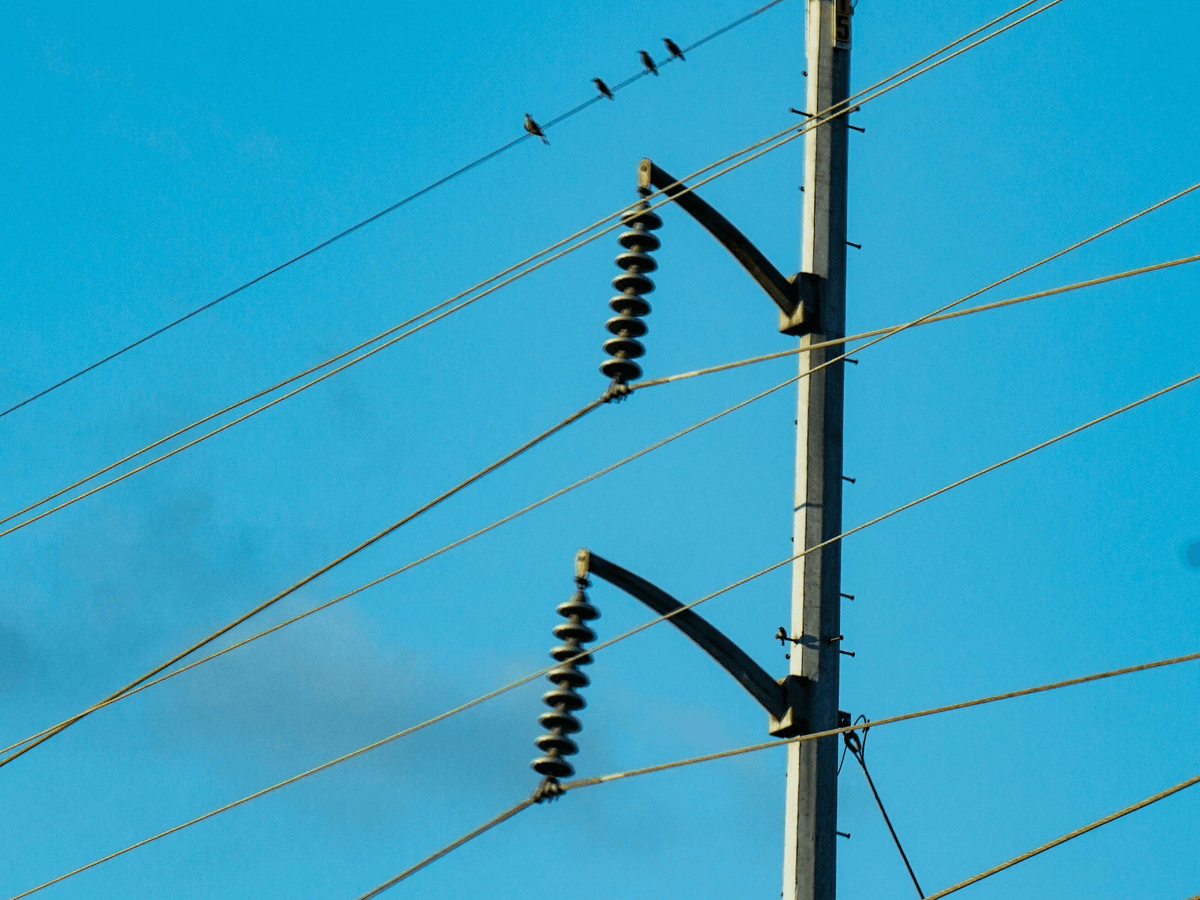

A secondary clevis is a specialized fitting designed to connect various elements of power line systems, such as insulators or conductors. Its primary function is to provide a reliable connection point that can endure environmental stresses like wind or ice loads while allowing for some degree of movement. This unique functionality makes it indispensable for maintaining the stability and efficiency of power transmission.

Common Applications in Power Lines

In the realm of electrical infrastructure, secondary clevises find their applications primarily in overhead power lines and substations. They are often used to secure insulators, which help prevent electrical arcing and ensure safe operation under varying weather conditions. Furthermore, these fittings are favored by many utility companies due to their ability to facilitate quick repairs or adjustments during maintenance activities.

Differences from Standard Clevis

While both standard clevises and secondary clevises serve similar purposes, there are notable differences between them that can impact their performance in specific applications. Standard clevises typically provide fixed connections without any allowance for movement or adjustment, making them less versatile than their secondary counterparts. In contrast, a secondary clevis offers enhanced flexibility due to its design features tailored for dynamic environments—this is particularly important when working with high-voltage power lines where adaptability can be key.

Selecting the Right Clevis

Choosing the right secondary clevis is critical for ensuring the stability and safety of power line installations. With various options available, it’s essential to consider several factors that influence performance and durability. A well-selected clevis can make a significant difference in your project’s success, so let’s dive into what you need to know.

Factors to Consider When Choosing

When selecting a secondary clevis, start by assessing the material it’s made from—this can affect its strength and resistance to environmental factors like corrosion. Look for high-quality materials such as galvanized steel or stainless steel, which offer longevity and reliability in harsh conditions. Additionally, consider load capacity; ensure that the clevis can handle the specific weight requirements of your power lines without compromising safety.

Another crucial factor is compatibility with existing hardware. The clevis should seamlessly integrate with other components in your setup, such as insulators and crossarms, to ensure efficient operation. Finally, always check for compliance with industry standards; this guarantees that your selected clevis meets safety regulations and performance benchmarks.

Trusted China Clevis Manufacturer Insights

China has become a powerhouse in manufacturing high-quality clevises due to its advanced technology and competitive pricing. When looking for a china clevis manufacturer, prioritize those with established reputations for quality control and customer service. Many manufacturers provide certifications that validate their products' compliance with international standards—be sure to request these documents before making a purchase.

Additionally, consider manufacturers who offer customization options; this allows you to tailor specifications according to your unique project needs. Engaging directly with manufacturers can also lead to better pricing arrangements or bulk discounts—an opportunity worth exploring if you're working on larger projects.

Recommendations from Spark Fittings

When sourcing secondary clevises, Spark Fittings stands out as a reliable option among china clevis manufacturers. They not only provide an extensive range of products but also emphasize quality assurance through rigorous testing procedures before shipment. Their commitment to customer satisfaction means you can expect prompt support should any issues arise post-purchase.

Moreover, Spark Fittings offers valuable insights into installation best practices and maintenance tips—resources that are indispensable when working on power line projects. By choosing them as your supplier, you’re not just buying hardware; you’re investing in peace of mind knowing you have expert support at every step of your project.

Installing Secondary Clevis Correctly

Installing a secondary clevis may sound daunting, but with the right approach, it can be a straightforward process. Proper installation is crucial for ensuring the reliability and safety of power line systems. Let’s break it down step-by-step to make sure everything goes smoothly.

Step-by-Step Installation Guide

1. **Preparation:** Begin by reviewing the manufacturer's guidelines and ensuring you have all necessary components from your trusted china clevis manufacturer. This includes the secondary clevis itself, any required bolts or pins, and appropriate safety gear.

2. **Positioning:** Next, position the secondary clevis in relation to the power line structure where it will be installed. Ensure that it aligns correctly with both the supporting hardware and any cables that will connect to it.

3. **Securing:** Once positioned, use bolts or pins as specified by your installation guide to secure the clevis in place. Tighten them according to torque specifications provided by your china clevis manufacturer to prevent loosening over time.

4. **Final Check:** After installation, conduct a thorough inspection of your work area and connections to ensure everything is properly secured and aligned before moving on to operational tests.

Tools Required for Efficient Setup

Having the right tools at hand can significantly streamline your installation process of a secondary clevis. Essential tools include a torque wrench for accurate tightening of bolts, pliers for securing pins, and a level for ensuring proper alignment during setup.

Additionally, having safety equipment like gloves and helmets is non-negotiable when working near power lines—safety first! A checklist can also help keep track of all necessary tools and materials from your chosen china clevis manufacturer before you start working.

Common Mistakes to Avoid

Even seasoned professionals can make mistakes during installation that could lead to issues later on—so let's avoid them! One common error is failing to follow torque specifications provided by your china clevis manufacturer; over-tightening or under-tightening can compromise integrity.

Another pitfall is neglecting routine checks after installation; always inspect connections periodically to ensure they remain secure over time. Lastly, don’t forget about proper alignment; an improperly positioned secondary clevis can lead not only to performance issues but also pose significant safety risks.

Maintenance Tips for Longevity

When it comes to ensuring the longevity of your secondary clevis, regular maintenance is key. Proper care not only extends the life of the equipment but also enhances safety and reliability in power line operations. By following some simple yet effective maintenance tips, you can keep your clevis in top-notch condition for years to come.

Routine Inspection and Care

Routine inspections are vital to identify any wear and tear on your secondary clevis. Make it a habit to check for signs of corrosion, cracks, or deformation that could compromise its integrity. Additionally, keeping an eye on the connection points will help you catch potential issues early, ensuring that your power line remains safe and operational.

It’s wise to establish a regular schedule for these inspections—monthly or quarterly depending on usage—and document your findings. This proactive approach allows you to track any changes over time and address them before they escalate into major problems. As always, sourcing from a reputable china clevis manufacturer ensures that you're starting with quality parts that can withstand the test of time.

Cleaning and Lubrication Guidelines

Cleaning your secondary clevis is just as important as inspecting it; dirt and debris can lead to premature wear if left unchecked. Use a non-abrasive cleaner suitable for metal surfaces and a soft cloth or brush to gently remove grime without causing damage. After cleaning, applying a light layer of lubricant will help reduce friction at moving parts while preventing rust formation.

Make sure you choose lubricants recommended by manufacturers or those specifically designed for outdoor equipment exposure—after all, not all greases are created equal! Regular cleaning combined with proper lubrication will keep everything functioning smoothly while prolonging the life of components sourced from trusted china clevis manufacturers.

Importance of Using High-Quality Parts

Using high-quality parts is crucial when it comes to maintaining the integrity of your secondary clevis setup. Cheap alternatives may save you money upfront but often lead to costly repairs down the line due to failure under stress or harsh conditions. By investing in quality components from reliable sources—like established china clevis manufacturers—you'll ensure optimal performance and reduced maintenance needs over time.

Moreover, high-quality materials often come with better warranties and support options, providing peace of mind should anything go wrong unexpectedly. Remember that cutting corners now could result in significant setbacks later; prioritize durability over cost when selecting parts for your power line installation.

Safety Protocols When Working with Power Lines

Working with power lines is no small feat, and ensuring safety is paramount. Adhering to proper protocols not only protects workers but also enhances the reliability of the installation. Understanding the essential safety equipment, best practices for crew safety, and necessary notification guidelines can make all the difference.

Essential Safety Equipment Required

Before starting any work near power lines, it's crucial to equip yourself with the right safety gear. This includes insulated gloves, hard hats, safety goggles, and flame-resistant clothing to protect against electrical hazards and potential falls. Additionally, having a first aid kit on hand is essential for addressing any minor injuries that may occur on-site.

Moreover, investing in high-quality tools from a reputable china clevis manufacturer can ensure that your equipment meets industry standards for safety and performance. These tools should be regularly inspected and maintained to prevent malfunctions during critical tasks.

Best Practices for Crew Safety

Crew safety goes beyond just wearing protective gear; it involves fostering a culture of caution among team members. Regular safety briefings can help remind everyone of potential hazards associated with power line work while encouraging open communication about concerns or unsafe conditions observed on-site. Make sure everyone knows their roles and responsibilities clearly—this reduces confusion during critical moments.

Additionally, establishing a buddy system can enhance overall site safety by ensuring that no one works alone in hazardous areas. Training sessions focusing on emergency response procedures are also invaluable; they prepare crews for unexpected situations like electrical faults or equipment failures that could pose serious risks if not handled promptly. After all, an informed crew is a safe crew!

Notification and Permit Guidelines

Before initiating any work on power lines, it's vital to follow local regulations regarding notifications and permits diligently. This often involves informing utility companies about planned activities so they can take necessary precautions or provide assistance as needed. In some regions, obtaining specific permits may also be required before proceeding with installations or repairs.

Ensuring compliance with these guidelines not only promotes workplace safety but also helps avoid costly delays due to regulatory issues down the line—pun intended! It’s wise to maintain documentation of all notifications made and permits acquired; this serves as proof of diligence should questions arise later on regarding your operations near power lines.

Conclusion

By investing in superior components, operators can enhance the overall performance of their systems while minimizing downtime and maintenance costs. As we've explored, selecting the right clevis is not just about functionality; it's about creating a robust infrastructure that stands the test of time.

Enhancing Reliability with Quality Clevis

Quality clevises are essential for maintaining structural integrity in power line applications. When you choose a reliable secondary clevis from a trusted source, you significantly reduce the risk of failures that could lead to costly outages or dangerous situations. Remember, investing in quality means investing in peace of mind—something every operator should prioritize.

Choosing the Right Manufacturer Matters

The choice of manufacturer plays a critical role in ensuring that you receive top-notch products like secondary clevises. A reputable china clevis manufacturer will not only offer high-quality materials but also provide expert guidance and support throughout your purchasing process. By aligning with trusted manufacturers, you're setting your project up for success with components that meet stringent industry standards.

Future Trends in Power Line Equipment

As technology continues to evolve, so do innovations in power line equipment, including secondary clevises designed for enhanced performance and durability. The future holds exciting developments such as smart materials and improved manufacturing processes that promise greater efficiency and reliability. Staying informed about these trends will empower operators to make better choices when sourcing from china clevis manufacturers and ensure their systems are equipped for tomorrow's challenges.