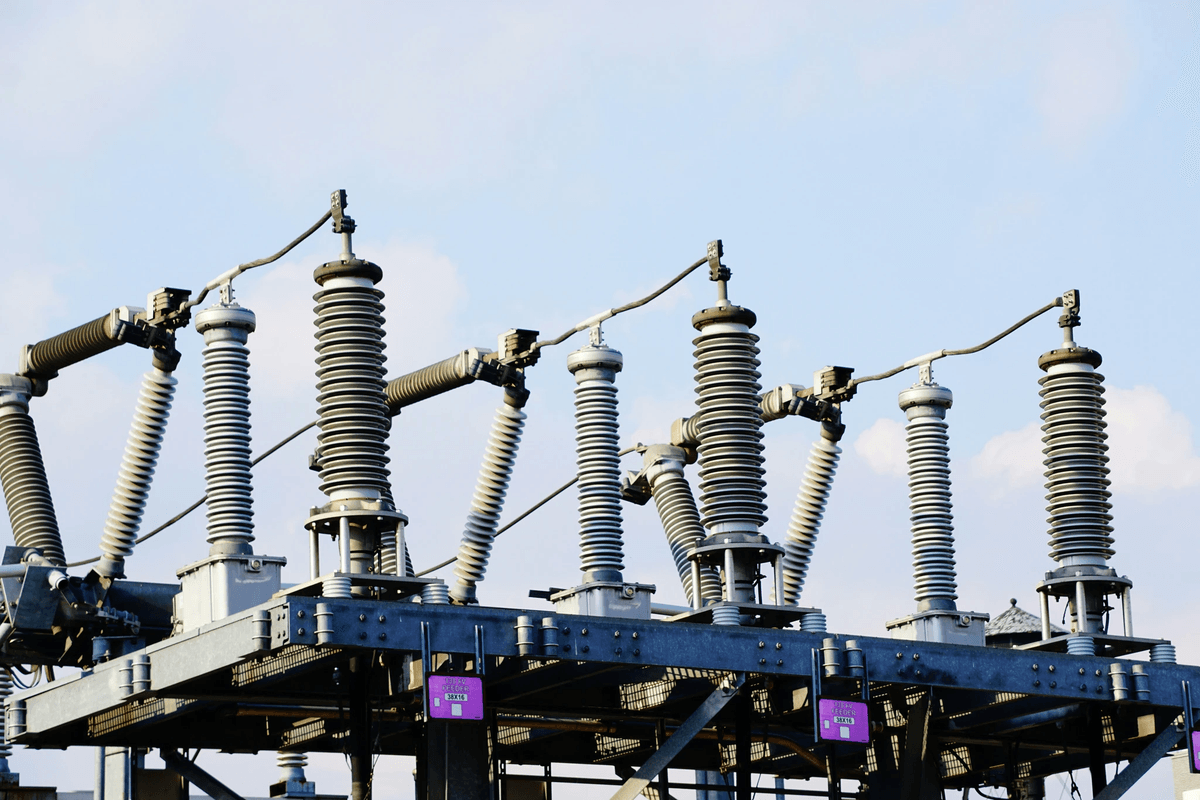

Introduction

A well-selected line guard not only enhances safety but also ensures that your setup remains stable and secure under varying conditions. With so many options available, understanding the importance of choosing the right line guard can make all the difference in achieving a successful installation.

Importance of Choosing the Right Line Guard

Selecting the appropriate line guard is essential for protecting cables and wires from wear and tear, especially in high-traffic areas or harsh environments. The right line guard acts as a shield, preventing damage from environmental factors while also ensuring that your setup remains organized and functional. By investing time in choosing a quality line guard, you’re safeguarding not just your equipment but also enhancing operational efficiency.

Overview of U-Bolts and Anchor Bolts

U-bolts and anchor bolts are integral components in securing various structures, providing stability for everything from fences to heavy machinery. U-bolts are shaped like the letter U, making them perfect for clamping around pipes or rods, while anchor bolts serve as fixed points that secure structures to concrete or other surfaces. Understanding these bolts—along with their sizes and materials—can help you make informed decisions when setting up your line guards.

The Role of Spark Fittings in Setup

In any installation involving u-bolts or anchor bolts, having reliable spark fittings can streamline the process significantly. These fittings ensure that every component aligns perfectly, reducing installation time while enhancing overall durability. When paired with high-quality screws and bolts, spark fittings become an indispensable part of creating a robust setup that stands the test of time.

Understanding Line Guards

They are designed to protect cables, wires, and hoses from damage caused by wear and environmental factors. Understanding what line guards are and the types available can greatly enhance the longevity of your installations.

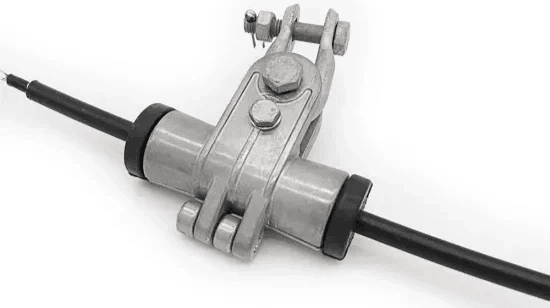

What Are Line Guards?

Line guards are protective devices that shield cables and hoses from abrasion, impact, and other potential hazards. Typically made from durable materials like rubber or plastic, they create a barrier that helps prevent wear over time. By using line guards, you can extend the life of your u-bolts, eye bolts, and other fasteners that hold these components together.

Types of Line Guards Available

There is a variety of line guards available on the market to suit different needs and applications. Some common types include flexible sleeves for added mobility, rigid covers for maximum protection, and specialized designs tailored for specific environments such as marine or industrial settings. Each type serves a unique purpose but ultimately aims to safeguard your bolts and washers from damage.

Benefits of Using Line Guards

Incorporating line guards into your setup offers numerous advantages that go beyond mere protection. They help reduce friction between moving parts, which can lead to less wear on screws and bolts over time. Additionally, using line guards can minimize downtime caused by repairs or replacements of damaged anchor bolts or threaded rods, thereby enhancing overall efficiency in operations.

Choosing the Right U-Bolts

When it comes to securing your line guards effectively, choosing the right u-bolts is crucial. U-bolts are designed to provide strong support and stability, making them an essential component in any setup involving anchor bolts or threaded rods. With various materials and sizes available, it's important to understand how each type can affect your installation.

Materials and Sizes of U-Bolts

U-bolts come in a variety of materials, including stainless steel, galvanized steel, and plastic-coated options. Stainless steel u-bolts are known for their corrosion resistance, making them ideal for outdoor applications or environments exposed to moisture. On the other hand, galvanized steel u-bolts offer a balance between strength and cost-effectiveness; they’re commonly used in general construction where durability is key.

In terms of size, u-bolts are available in different diameters and lengths to accommodate various needs. The size you choose will depend on the thickness of the items you’re securing as well as the load they will bear. Always consult specifications when selecting bolts and washers to ensure a snug fit that won’t compromise safety or performance.

How to Select Proper U-Bolts

Selecting proper u-bolts involves considering several factors including load capacity, environmental conditions, and compatibility with eye bolts or other fastening components like screws and bolts. Start by determining the weight of what you need to secure; this will guide you toward the appropriate size and material that can handle that load without bending or breaking under pressure.

Next, think about where these u-bolts will be used; if they’ll be exposed to harsh weather conditions or chemicals, opting for materials like stainless steel is wise for longevity. Finally, always check whether your chosen u-bolt pairs well with other components like anchor bolts or threaded rods; compatibility ensures a cohesive setup that functions smoothly.

Common Applications for U-Bolts

U-bolts are versatile fasteners used across various applications—from securing pipes in plumbing systems to anchoring structural supports in construction projects. They play an essential role in automotive industries too; often seen holding exhaust systems firmly in place against vibrations from engine operations. Additionally, you'll find them indispensable when setting up line guards where stability is paramount.

In agricultural settings, u-bolts help secure equipment such as trailers and machinery while ensuring safety during operation on uneven terrain. Their ability to withstand heavy loads makes them perfect for use with eye bolts when rigging heavy objects for lifting purposes too! With so many applications under their belt (pun intended), it's clear why selecting quality u-bolts is vital.

Setting Up Your Line Guard

Setting up your line guard properly is crucial for ensuring safety and efficiency in your project. This section will guide you through the installation process, highlight the essential tools you'll need, and explain why eye bolts are a vital component of the setup. With the right approach, you can ensure that your line guard performs optimally.

Step-by-Step Installation Guide

To begin with, gather all necessary materials including u-bolts, anchor bolts, and screws and bolts to ensure a smooth installation process. Start by marking the desired location for your line guard on the mounting surface; this will help guide where to drill holes for your anchor bolts. Next, use a drill to create holes at the marked spots and insert your anchor bolts securely into place.

Once your anchor bolts are set, it’s time to attach the u-bolts around the line guard itself. Position each u-bolt carefully so that it aligns with both ends of the line guard; then tighten them down using nuts and washers to secure everything firmly in place. Finally, double-check all connections to make sure they’re tight—this step is essential for ensuring safety during operation.

Tools Required for Setup

Before diving into installation, it's important to gather all necessary tools to avoid any interruptions mid-project. You’ll need a power drill for making holes as well as wrenches or socket sets for tightening down those pesky u-bolts and eye bolts securely. Additionally, having a level handy can help ensure that everything is aligned correctly during setup.

Don't forget about measuring tools like tape measures or rulers; these will assist in positioning your line guard accurately before securing it with screws and bolts or anchor bolts. Lastly, consider having safety gear such as gloves and goggles on hand—better safe than sorry when working with heavy-duty hardware!

Importance of Eye Bolts in Installation

Eye bolts play an indispensable role in securing components of your line guard system effectively. These versatile fasteners provide an excellent point of attachment for various cables or ropes that may be necessary during operation or maintenance tasks involving u-bolts and other hardware items like threaded rods or additional screws and bolts.

Using eye bolts can also enhance stability by distributing weight evenly across multiple points—this is especially crucial if you're dealing with heavier loads or dynamic forces acting upon your setup over time. Ultimately, incorporating eye bolts into your installation not only boosts safety but also helps prolong the lifespan of all connected components by reducing stress on individual parts.

Maintenance and Care for Longevity

Maintaining the integrity of your line guard setup is crucial for its longevity and performance. Regular inspections, proper cleaning, and timely replacements of components like u-bolts, anchor bolts, and eye bolts can prevent costly repairs down the line. Let's dive into some essential maintenance tips that will keep your setup in tip-top shape.

Regular Inspection Tips

Regular inspections are vital to ensure that all components—including u-bolts, anchor bolts, and screws—are in good working condition. Look for signs of wear or damage such as rust on the bolts and nuts or deformation in the threaded rod. A quick visual check every few months can save you from unexpected failures; after all, a little vigilance goes a long way!

Make sure to pay special attention to areas where moisture can accumulate, as this can lead to corrosion on your u-bolts and washers. If you notice any loose bolts or nuts during your inspection, tighten them immediately to avoid further complications. Remember: an ounce of prevention is worth a pound of cure!

Cleaning and Storage of Bolts and Washers

When it comes to cleaning your components like u-bolts and washers, it's essential to use the right methods to avoid damaging them. A mild detergent solution should do the trick; just scrub gently with a soft brush to remove dirt or grime without scratching surfaces. After cleaning, rinse thoroughly with fresh water and dry completely before storage.

For long-term storage of screws and bolts, consider using airtight containers that prevent moisture buildup which can lead to rusting over time. Organizing by size will make it easier when you're ready for installation again—no one wants to dig through a jumbled mess! Keeping everything clean not only prolongs their lifespan but also ensures they perform optimally when needed.

Replacing Screws and Bolts as Needed

Inevitably, there will come a time when screws or bolts need replacing due to wear from constant use or environmental factors like rusting from moisture exposure. Pay close attention during inspections; if you see any signs that indicate fatigue—such as bending or cracking—it’s time for an upgrade! Don’t hesitate; replacing these small parts promptly can save you from larger headaches later on.

When selecting new screws and bolts, ensure they match the specifications required for your application; using mismatched sizes could compromise stability at critical points like where eye bolts attach. Additionally, always replace worn-out anchor bolts with high-quality alternatives designed for durability under stress conditions they may face in operation. A proactive approach here will keep everything secure!

Troubleshooting Common Issues

When it comes to setting up your line guard, issues can arise that may compromise its effectiveness. Understanding how to troubleshoot these problems is essential for maintaining safety and functionality. Let’s dive into some common issues you might encounter and how to address them effectively.

Identifying Worn or Damaged Line Guards

Worn or damaged line guards can lead to serious safety hazards, so it's crucial to inspect them regularly. Look for signs of wear such as fraying, cracking, or any visible deformation around the u‑bolt or anchor bolts securing the guard in place. If you notice any of these issues, it’s time to consider replacing either the line guard itself or the bolts and washers used in its installation.

Another indicator of damage is if the line guard has become loose during operation; this could point to failing screws and bolts that need immediate attention. Regular checks will help you catch these problems early on, ensuring that your setup remains secure and effective. Remember, a small issue today could turn into a major problem tomorrow if left unchecked!

Fixing Problems with Anchor Bolts

Anchor bolts are essential for securing your line guard system; however, they can sometimes loosen over time due to vibrations or environmental factors. If you find that your anchor bolts are not holding firm, start by tightening them with the appropriate tools—this may involve utilizing eye bolts for added leverage during installation. If they continue to loosen despite tightening efforts, it might be time to replace them with new anchor bolts designed for heavy-duty applications.

Additionally, check the compatibility of your anchor bolts with other hardware like u‑bolts and threaded rods; mismatched components can lead to instability in your setup. Always ensure that you're using high-quality materials when replacing any screws and bolts—cheap alternatives may save money initially but can cost more in repairs down the road!

When to Seek Professional Help

While many troubleshooting tasks can be handled independently, certain situations call for professional assistance—especially when safety is at stake! If you're unsure about how to identify worn components like u‑bolts or if fixing anchor bolt issues is beyond your expertise, don’t hesitate to consult a professional technician who specializes in this field. They have the knowledge and experience necessary to ensure everything is installed correctly and safely.

Moreover, if you've attempted repairs but still encounter problems with stability or functionality after replacing parts like screws and bolts or eye bolts, it's best not to risk further complications by going it alone. Professionals will not only address current issues but also provide insights on maintenance practices that can prolong the life of all components involved—keeping your system running smoothly for years ahead!

Conclusion

In the world of line guards, making informed decisions is crucial for ensuring safety and efficiency. The right choice of line guards can significantly impact the performance of your setup, as well as its longevity. By understanding the various options available and their specific applications, you can select line guards that perfectly suit your needs.

Making Informed Decisions on Line Guards

Familiarizing yourself with the different types of line guards and their respective benefits will help you make choices that enhance your project’s durability and effectiveness. Remember to consider factors such as environmental conditions and load requirements to ensure optimal performance.

Importance of Quality U-Bolts and Accessories

Investing in high-quality materials ensures that your setup remains secure over time, reducing the risk of costly repairs or replacements down the road. Additionally, using reliable bolts and washers helps maintain structural integrity while providing peace of mind during operation.

Partnering with Spark Fittings for Success

Collaborating with a trusted supplier like Spark Fittings can elevate your project to new heights. Their expertise in providing top-notch u-bolts, threaded rods, and other essential components means you’ll have access to products that meet industry standards for safety and quality. By choosing Spark Fittings as your partner, you're not just purchasing items; you're investing in a successful outcome for all your line guard needs.