Introduction

These versatile components are more than just fasteners; they are essential for ensuring structural integrity and reliability in numerous industries. Understanding the nuances of these fittings, including what a clevis is used for and the difference between a clevis and a shackle, can significantly influence your choice of hardware.

Understanding Rectangular Clevis Fittings

Rectangular clevis fittings are specialized connectors designed to provide strong attachment points in various mechanical systems. They come in different shapes and sizes, but their rectangular form offers unique advantages that make them suitable for specific applications. By understanding what makes rectangular clevis fittings distinct, you can better appreciate their importance in both everyday uses and industrial settings.

The Role of Clevis Fasteners

Clevis fasteners serve as vital components that connect two or more parts securely while allowing for some degree of movement or flexibility. They are widely used across industries ranging from construction to aerospace, ensuring that loads are distributed evenly without compromising safety. When you're pondering what are the two types of clevis, remember that choosing the right type can make all the difference in performance and reliability.

Importance of Choosing the Right Fitting

Selecting the appropriate fitting is crucial not only for functionality but also for safety in any application involving mechanical connections. The right rectangular clevis can enhance performance while reducing wear and tear on equipment over time. With questions like What is the difference between a shackle and a clevis? often arising during selection processes, it's clear that informed decisions lead to better outcomes.

What Are Rectangular Clevis Fittings?

Rectangular clevis fittings are specialized components that play a crucial role in connecting and securing various elements, particularly in rigging and structural applications. These fittings are designed to provide strong, reliable connections while allowing for some movement, making them ideal for dynamic environments. Understanding their definition and functionality is key to appreciating their importance in various industries.

Definition and Overview

A rectangular clevis is a type of clevis fastener characterized by its rectangular shape, which allows it to accommodate specific types of pins or bolts. This design enhances the versatility of the fitting, enabling it to be used in a wide range of applications where strength and stability are paramount. Essentially, what is a clevis used for? It's primarily employed to connect two components while allowing for controlled movement or alignment.

Common Materials Used

Common materials include stainless steel for corrosion resistance, carbon steel for high tensile strength, and aluminum for lightweight applications. Each material offers unique benefits; thus, knowing what are the two types of clevis can help you choose the right one based on your specific requirements.

Applications in Various Industries

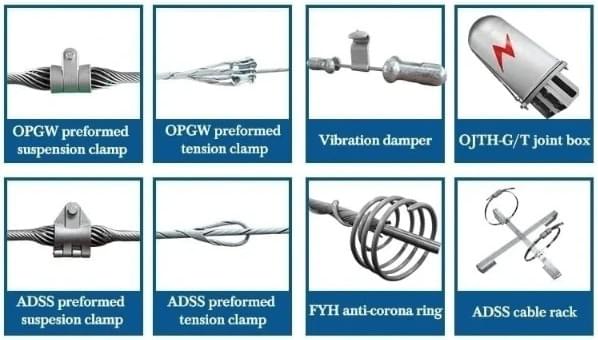

Rectangular clevis fittings find applications across numerous industries ranging from construction to telecommunications. They are essential in rigging systems where secure connections are vital for safety and performance—think cranes or hoists! Additionally, they’re also widely used in electrical infrastructure where they support overhead lines; understanding the difference between a shackle and a clevis can further clarify when each should be utilized effectively.

Different Types of Clevis Fasteners

Overview of Clevis Types

Clevis fasteners come in several varieties, each designed for specific applications and environments. The two primary types of clevis are the standard clevis and the rectangular clevis, which differ mainly in shape and functionality. While standard clevis fittings often accommodate round pins or rods, rectangular clevis fittings offer a more stable connection that can handle greater loads and forces.

Additionally, there are specialized variations like adjustable clevises that allow for length modifications and locking clevises that secure connections more firmly. Knowing these distinctions is crucial when asking yourself, What is a clevis used for? as each type has its own strengths suited for different tasks. Whether you’re working on construction projects or automotive repairs, selecting the right type ensures optimal performance.

How to Choose the Right Type

Choosing the right type of clevis fastener involves considering multiple factors such as load requirements, environmental conditions, and application specifics. First off, assess what you need; if you're dealing with heavy loads or high-stress situations, a rectangular clevis might be your best bet due to its robust design. Conversely, if flexibility is key—like in adjustable setups—you may want to explore other options.

Another important consideration is compatibility with existing hardware; ensure that your chosen fastener fits well within your assembly without compromising integrity or functionality. Don’t forget to ask yourself: “What are the two types of clevis?”—this will help guide your selection process effectively by narrowing down choices based on application needs.

Spark Fittings and Their Offerings

Spark Fittings stands out in the market by offering an impressive range of high-quality rectangular clevis products tailored for various industrial applications. Their commitment to durability means you can trust their fittings under demanding conditions without second-guessing whether they’ll hold up when it counts most. From standard configurations to custom solutions designed specifically for unique challenges, Spark Fittings ensures you have options at your fingertips.

Moreover, their expertise extends beyond just manufacturing; they provide valuable insights into how best to utilize their products effectively within different contexts—be it construction sites or specialized machinery setups. With Spark Fittings leading the charge in innovation and quality assurance within this niche market segment, choosing them could very well enhance both efficiency and safety in your projects involving rectangularclevis fasteners.

Rectangular Clevis vs. Shackle

When it comes to securing loads and connecting components, understanding the differences between rectangular clevis fittings and shackles can make all the difference in your project’s success. Both are essential types of fasteners used in various applications, but they serve distinct purposes and come with unique advantages. In this section, we’ll explore what sets these two fasteners apart, their specific use cases, and guidance on when to choose one over the other.

Key Differences Explained

At first glance, a rectangular clevis and a shackle might seem similar—they both connect components securely—but they are designed for different functions. A rectangular clevis is typically a U-shaped fitting with a pin that allows for easy attachment and detachment of items like cables or rods. On the other hand, a shackle resembles a metal loop with a removable pin or bolt that provides robust strength for heavy loads.

One key difference lies in their design: while the rectangular clevis is flat and often used in applications requiring alignment along a plane, shackles are more rounded and suited for multi-directional load applications. Additionally, the materials used can vary; clevis fasteners may be made from lighter materials like aluminum or steel depending on their intended use, while shackles are usually crafted from heavier-duty metals to withstand extreme forces. Understanding these differences is crucial when determining which fastener will best suit your needs.

Use Cases for Each

Rectangular clevis fittings shine in applications where precise alignment is crucial—think cable systems or suspension setups where stability matters most. They’re commonly found in industries like construction and telecommunications where equipment must be securely anchored without excessive movement. Their ability to allow for quick adjustments makes them ideal for temporary setups or projects needing frequent modifications.

Conversely, shackles are often employed in scenarios demanding high strength and durability under tension—like lifting heavy machinery or securing loads during transport. They’re frequently utilized in maritime settings as well as rigging operations due to their capacity to handle significant weight without risk of failure. Knowing when each type excels helps ensure safety and efficiency during operations involving heavy lifting or complex assemblies.

When to Use What

So when should you reach for that rectangular clevis versus opting for a trusty shackle? If your application involves connecting components that require stable alignment along a single axis—such as attaching cables to poles—a rectangular clevis is your go-to choice due to its straightforward design and ease of use. It allows for quick adjustments while maintaining structural integrity.

On the flip side, if you find yourself dealing with heavy loads that need secure attachment points capable of withstanding dynamic forces—like hoisting equipment—then shackles should be at the top of your list due to their robust construction designed specifically for such tasks. Ultimately, consider factors such as load requirements, environmental conditions, ease of installation, and whether you need flexibility or rigidity when making your decision on which fastener fits best.

The Functionality of a Clevis

When it comes to securing components in various applications, the clevis fastener stands out as a reliable choice. A clevis, especially the rectangular clevis type, is designed to connect two parts together while allowing for some degree of movement or adjustment. This makes it an essential component in numerous industries, from construction to aerospace.

What Is a Clevis Used For?

So, what is a clevis used for? Primarily, a clevis serves as a connection point for rods or cables in mechanical assemblies. Its unique design allows it to accommodate various types of fasteners and attachments, making it versatile enough for different applications—think lifting equipment or tensioning systems.

You might wonder: what are the two types of clevis? Generally speaking, there are two main types: the standard clevis and the rectangular clevis. Each type has its own set of advantages depending on the specific application and load requirements.

Importance in Structural Integrity

The importance of using the right fitting cannot be overstated when considering structural integrity. A well-designed rectangular clevis ensures that loads are evenly distributed across connected components, reducing stress points that could lead to failure. In scenarios where safety and reliability are paramount—like in overhead lifting operations—a sturdy clevis fastener is indispensable.

Moreover, using inappropriate fittings can compromise not only performance but also safety standards in critical installations. This highlights why understanding what is a clevis used for is crucial—it’s about more than just connecting parts; it's about ensuring they work harmoniously under pressure.

Examples in Real World Applications

Real-world applications of rectangular clevis fittings can be found everywhere—from telecommunications towers to industrial machinery setups. For instance, they play an integral role in supporting guy wires that stabilize tall structures like radio towers or wind turbines. Additionally, you’ll find them employed in automotive suspension systems where precise adjustments are necessary.

Another great example is their use in agricultural equipment where flexibility and strength are required when connecting implements like plows or seeders to tractors. With so many diverse uses across industries, it's clear that understanding what is the difference between a shackle and a clevis can help one make informed decisions on which fastener better suits their needs.

Armor Rods and Clevis Fittings

When discussing the world of fasteners, particularly rectangular clevis fittings, it’s impossible to overlook the importance of armor rods. These components serve a critical role in supporting overhead power lines and ensuring they maintain structural integrity against various forces. By understanding how armor rods interact with clevis fasteners, we can appreciate their combined significance in electrical infrastructure.

Introduction to Armor Rods

Armor rods are protective devices designed to shield conductors from wear and tear due to environmental factors such as wind, ice, and mechanical stress. Typically made from durable materials like fiberglass or composite materials, these rods wrap around the conductor at points where clevis fittings are utilized. This combination not only enhances the longevity of the conductor but also ensures that the rectangular clevis remains securely fastened, providing reliable connections in demanding conditions.

Role of Spark Fittings

Spark fittings are specialized hardware that complements armor rods by facilitating secure connections between conductors and other line hardware. They work seamlessly with rectangular clevis fittings to ensure that everything stays put under pressure while maintaining flexibility for necessary adjustments or repairs. By utilizing spark fittings alongside armor rods and clevis fasteners, utilities can significantly reduce maintenance costs while enhancing safety across their networks.

Customization Options Available

Manufacturers often provide a range of sizes, materials, and configurations tailored to unique project needs or environmental conditions. Whether you’re dealing with extreme weather or specific load requirements, knowing what are the two types of clevis available—such as standard and adjustable—can guide you in making informed choices that optimize performance.

Conclusion

In summary, rectangular clevis fittings play a pivotal role in various applications across multiple industries. These versatile clevis fasteners are essential for ensuring secure connections and maintaining structural integrity in mechanical systems. Understanding what a clevis is used for, including its importance and functionality, helps users make informed decisions about their hardware needs.

Summarizing the Importance of Clevis Fittings

Clevis fittings are not just simple hardware components; they are critical to the safe operation of machines and structures. The ability to choose the right type of clevis fastener can significantly impact performance and safety outcomes. As we’ve explored, knowing what are the two types of clevis available can help users select the most appropriate fitting for their specific requirements.

The Future of Line Hardware Fittings

Looking ahead, the future of line hardware fittings like rectangular clevises appears bright with advancements in materials and technology. Innovations will likely lead to even more robust designs that enhance durability while reducing weight—an important consideration in many applications today. As industries evolve, so too will the demand for specialized solutions like customized clevis fasteners that meet unique operational challenges.

Final Thoughts on Rectangular Clevis Use

In conclusion, understanding the difference between a shackle and a clevis is crucial for selecting the right fastening solution for your project needs. Whether you’re securing cables or connecting structural elements, knowing what a clevis is used for ensures that you make choices that prioritize safety and efficiency. Embracing these components not only leads to better engineering practices but also enhances overall project success.