Introduction

These versatile components play a crucial role in various applications, making it vital to grasp what are ball clevis and their functionalities. In this guide, we'll explore the different types of ball clevis, their functions, and why selecting the right manufacturer can make all the difference in ensuring safety and efficiency.

Understanding Ball Clevis Basics

At its core, a ball clevis is a mechanical device used for connecting two components in a secure manner. It typically consists of a hook or loop that accommodates a ball-shaped end fitting, allowing for flexible movement while maintaining stability under load. Knowing what are ball clevis helps users appreciate their significance in construction and manufacturing settings where reliability is paramount.

Types of Ball Clevis Explained

There are primarily two types of clevis: U type and Y type, each designed for specific applications and load requirements. The U type offers greater strength for heavier loads, while the Y type provides flexibility and ease of use in less demanding situations. Understanding what are the two types of clevis will help you choose the right one based on your needs.

Importance of Choosing the Right Manufacturer

Selecting a reputable manufacturer when sourcing your ball clevis is crucial for safety and performance. High-quality materials and precise engineering ensure that these devices can withstand significant stress without failure. With so many options available, knowing who makes reliable products can save you from potential mishaps down the line.

What Are Ball Clevis?

When you hear the term ball clevis, you might wonder what exactly it refers to in the world of rigging and hardware. A ball clevis is a specialized component designed to connect different elements securely while allowing for some movement or flexibility. These devices are crucial in various applications, ensuring that loads are distributed evenly and that connections remain stable under pressure.

Definition and Key Features

So, what are ball clevis? At its core, a ball clevis is a type of connector featuring a spherical head that fits into a corresponding socket or yoke. This design allows for rotational movement, making it ideal for applications where alignment may change frequently. Key features include durable materials like steel or aluminum, corrosion resistance for outdoor use, and load ratings that ensure safety during operation.

Common Applications of Ball Clevis

Ball clevises find their way into numerous applications across different sectors. You’ll often see them used in construction, transportation, and even aerospace industries where secure yet flexible connections are paramount. Whether it's connecting cables in rigging setups or linking components in heavy machinery, the versatility of ball clevis makes it an indispensable tool.

The Role of Ball Clevis in Various Industries

The role of ball clevis cannot be understated; it serves as a backbone for many operational systems across industries. In construction, these connectors help maintain stability while allowing equipment to adjust to varying loads and angles—think cranes lifting heavy materials with precision! Similarly, in automotive sectors, ball clevises support suspension systems by providing necessary flexibility without compromising strength or safety standards.

What Are the Two Types of Clevis?

When it comes to understanding what are ball clevis, it’s essential to explore the two primary types: U Type and Y Type ball clevis. Each type serves distinct purposes and is designed for specific applications, making it important to know their characteristics. In this section, we'll delve into the overview of each type, highlighting their unique features and advantages.

Overview of U Type Ball Clevis

U Type ball clevis is a popular choice in various rigging applications due to its simple yet effective design. This type features a U-shaped fork that allows for easy attachment and detachment of components, making it user-friendly in many scenarios. Its robust construction provides excellent load-bearing capabilities, ensuring stability during operations—a crucial factor when considering what is the function of a clevis.

Often utilized in construction and manufacturing settings, U Type ball clevis connects cables or rods securely while allowing for some degree of movement. This flexibility can be advantageous when dealing with dynamic loads or environments where adjustments may be necessary. Ultimately, choosing a U Type ball clevis can enhance safety and efficiency in your projects.

Overview of Y Type Ball Clevis

On the other hand, the Y Type ball clevis presents a different design that caters to specific needs within rigging systems. Characterized by its Y-shaped fork, this type offers enhanced load distribution capabilities compared to its U counterpart. The unique shape allows for more versatile connections—ideal for situations where multiple attachment points are required.

Y Type ball clevis is often found in applications involving heavy machinery or complex rigging setups where stability is paramount. Its configuration not only supports better alignment but also reduces stress on components during operation, which speaks volumes about what are the two types of clevis available today. By utilizing a Y Type option, users can ensure improved performance under challenging conditions.

Differences and Advantages of Each Type

The differences between U Type and Y Type ball clevis boil down to their designs and intended uses—each offering distinct advantages tailored to varying needs. While the U Type excels in simplicity and ease-of-use for straightforward connections, the Y Type shines when load distribution and versatility are critical factors in your project setup.

In terms of advantages, selecting a U Type might be beneficial if you prioritize quick assembly or disassembly without compromising safety; however, if your application demands robust support across multiple points or greater stability under heavy loads, opting for a Y Type would be wise. Understanding these differences not only answers what are the two types of clevis but also aids you in choosing between shackles and clevis based on operational requirements.

What is a Shackle vs Clevis?

When it comes to rigging and lifting applications, understanding the differences between shackles and clevises is crucial. Both are essential components used to connect various elements in a system, but they serve different purposes and come with unique features. In this section, we will delve into the definitions and key differences between these two hardware types, explore their usage scenarios, and help you decide when to choose one over the other.

Definitions and Key Differences

A shackle is a U-shaped piece of metal with a pin or bolt that secures its ends together, typically designed for heavy lifting or towing applications. On the other hand, a clevis—specifically referring to ball clevis in our context—features a forked end that allows for easy attachment to other hardware like pins or rods. While both serve as connectors in rigging systems, shackles are often more robust for heavy-duty tasks, whereas ball clevises provide versatility in lighter applications.

The design of each component also highlights their primary functions; shackles usually have a more substantial build meant for high-load situations while ball clevises offer flexibility in connection points due to their unique shape. Additionally, shackles can be used with various types of connecting devices such as hooks or chains, while ball clevises are commonly employed where quick detachments are necessary. Understanding these distinctions helps clarify what are ball clevis options available when selecting hardware for specific tasks.

Usage Scenarios for Shackles and Clevis

Shackles find their place predominantly in heavy-lifting scenarios like construction sites or marine environments where strong connections are paramount. They’re often utilized with chains or cables to secure loads during transport or hoisting operations. In contrast, ball clevises shine in applications requiring less weight-bearing capacity but greater adaptability; think of scenarios involving machinery attachments or agricultural uses where quick adjustments may be needed.

For instance, if you’re working on a construction project that requires moving heavy materials frequently, using shackles would be your best bet due to their robust nature. However, if you're setting up an irrigation system that requires frequent adjustments to hoses or pipes, opting for a ball clevis would allow you the flexibility necessary without compromising safety standards. Knowing when to use each type can significantly enhance efficiency and safety on the job.

Choosing Between Shackles and Clevis

When deciding whether to use shackles or ball clevises in your project, consider factors such as load requirements and connection ease. If your application demands high strength under significant loads—like lifting equipment—a shackle would be more suitable due to its durability and reliability under stress conditions. Conversely, if you're looking at lighter connections requiring frequent adjustments—such as those found in agricultural setups—a ball clevis provides the adaptability you need without sacrificing safety.

Moreover, consider compatibility with other hardware; socket clevis options might integrate better with certain systems compared to traditional shackles depending on your project’s design needs. Ultimately, understanding what is the function of a clevis versus that of a shackle will guide you toward making informed choices tailored specifically for your operational requirements while ensuring maximum effectiveness across diverse applications.

What is the Function of a Clevis?

When it comes to understanding what is the function of a clevis, particularly the ball clevis, we delve into its vital role in load management and secure connections. A clevis serves as an essential component in various applications, providing stability and strength where it's needed most. Whether you're rigging equipment or constructing frameworks, knowing how a ball clevis functions can make all the difference.

Load Distribution and Stability

One of the primary functions of a ball clevis is to facilitate effective load distribution and enhance stability during operations. By allowing for a secure attachment point, it ensures that loads are evenly distributed across multiple points, reducing stress on individual components. This stability is crucial in preventing accidents or failures in high-stakes environments like construction sites or heavy machinery applications.

Moreover, when considering what are ball clevis options available, it's evident that their design helps minimize movement under load conditions. The rounded shape of the ball joint allows for some degree of flexibility while maintaining structural integrity. Consequently, this feature not only promotes safety but also improves overall operational efficiency by preventing wear and tear on connected materials.

Connection Options in Rigging

In rigging scenarios, choosing between different connection options can significantly impact performance and safety; this is where understanding what are the two types of clevis becomes important. Ball clevises offer versatile connection options that accommodate various hardware configurations, making them indispensable for many rigging setups. Their ability to connect with different components helps streamline operations across diverse industries.

Additionally, whether you're deciding between a shackle vs clevis setup or exploring other rigging solutions, knowing how each option performs under specific conditions can guide your choice. A ball clevis typically provides a more stable connection than other types due to its unique design features like pivoting capabilities and strong attachment points. This versatility allows users to adapt quickly to changing demands while ensuring that connections remain robust throughout the operation.

Importance in Construction and Manufacturing

The importance of a clevis—especially when discussing socket clevis variants—cannot be overstated within construction and manufacturing sectors. These components play critical roles in securing loads during lifting operations or anchoring structures effectively against environmental forces like wind or seismic activity. Their reliability directly impacts project timelines and safety measures.

Furthermore, understanding what is the function of a clevis extends beyond mere attachment; it encompasses ensuring that all elements work together harmoniously within complex systems. In manufacturing environments where precision matters most, utilizing high-quality ball clevis products ensures consistency in performance across various applications—ultimately leading to better productivity rates and lower operational risks.

In summary, whether you're assessing load distribution capabilities or exploring connection options within rigging practices, recognizing the multifaceted role of ball clevises enhances your operational knowledge significantly.

Socket Clevis and Its Applications

Socket clevises are an essential component in various rigging and safety applications, serving as a reliable connection point for different hardware. Understanding what socket clevis is can help you appreciate its role in enhancing the stability and security of load-bearing systems. These fittings are specifically designed to accommodate a range of attachments, making them versatile tools in the world of rigging.

Defining Socket Clevis

A socket clevis is a type of fitting characterized by its open-ended design, which allows for easy attachment to other components like hooks or pins. Typically made from durable materials such as steel or aluminum, socket clevises provide robust support while maintaining flexibility in their applications. When considering what are ball clevis options, socket clevis stands out due to its unique ability to connect with various hardware configurations seamlessly.

Common Uses in Rigging and Safety

Socket clevises find their way into numerous applications across industries that require reliable connections for lifting and securing loads. In rigging scenarios, they often serve as connectors between slings, chains, and other load-bearing equipment, ensuring safe transport of materials. Additionally, these fittings play an important role in safety mechanisms where secure connections are paramount—think construction sites or heavy machinery operations where load stability is critical.

Compatibility with Other Hardware

One of the standout features of socket clevises is their compatibility with a wide range of hardware types, making them incredibly useful in diverse settings. Whether you're working with shackles or other types of clevis fittings—like those that answer the question What are the two types of clevis?—socket clevises can integrate smoothly into your existing setup. This versatility not only simplifies assembly but also enhances overall system performance by allowing for easier adjustments and replacements when necessary.

Conclusion

In summary, understanding the intricacies of ball clevis is essential for anyone involved in rigging, construction, or manufacturing. Choosing the right ball clevis can significantly impact the safety and efficiency of your operations. By recognizing what are ball clevis and their applications, you can make informed decisions that enhance your projects.

Choosing Spark Fittings for Quality

Spark fittings are renowned for their durability and reliability in various applications involving ball clevis systems. Opting for high-quality spark fittings ensures that you’re using products designed to withstand the rigors of heavy-duty tasks while maintaining optimal performance.

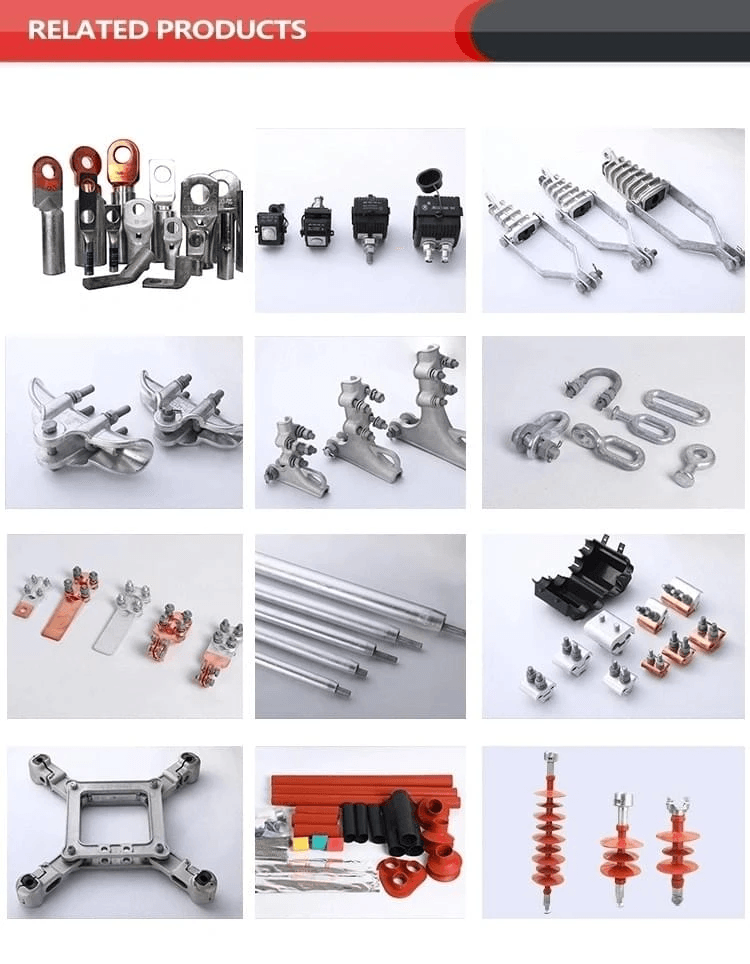

Customization Options for Armor Rods

Many manufacturers offer tailored solutions that cater to specific project requirements, ensuring that each component fits seamlessly into your setup. This level of customization not only enhances functionality but also allows for improved safety measures across different industries.

Final Thoughts on Ball Clevis Manufacturers

Choosing a reputable manufacturer is crucial in ensuring you receive high-quality ball clevis products that meet industry standards. Paying attention to what are the two types of clevis available—U type and Y type—can help streamline your selection process based on specific needs. Ultimately, understanding concepts like what is a shackle vs clevis and what is the function of a clevis will empower you to make choices that bolster both safety and efficiency in your operations.