Introduction

In the world of electrical engineering, the evolution of egg insulators has played a pivotal role in ensuring reliable power transmission. These unique components, often overlooked, have undergone significant advancements over the years, transitioning from basic designs to more sophisticated structures that enhance their performance and durability. Understanding how these developments have shaped the design and structure of stay insulators is crucial for appreciating their significance in modern electrical systems.

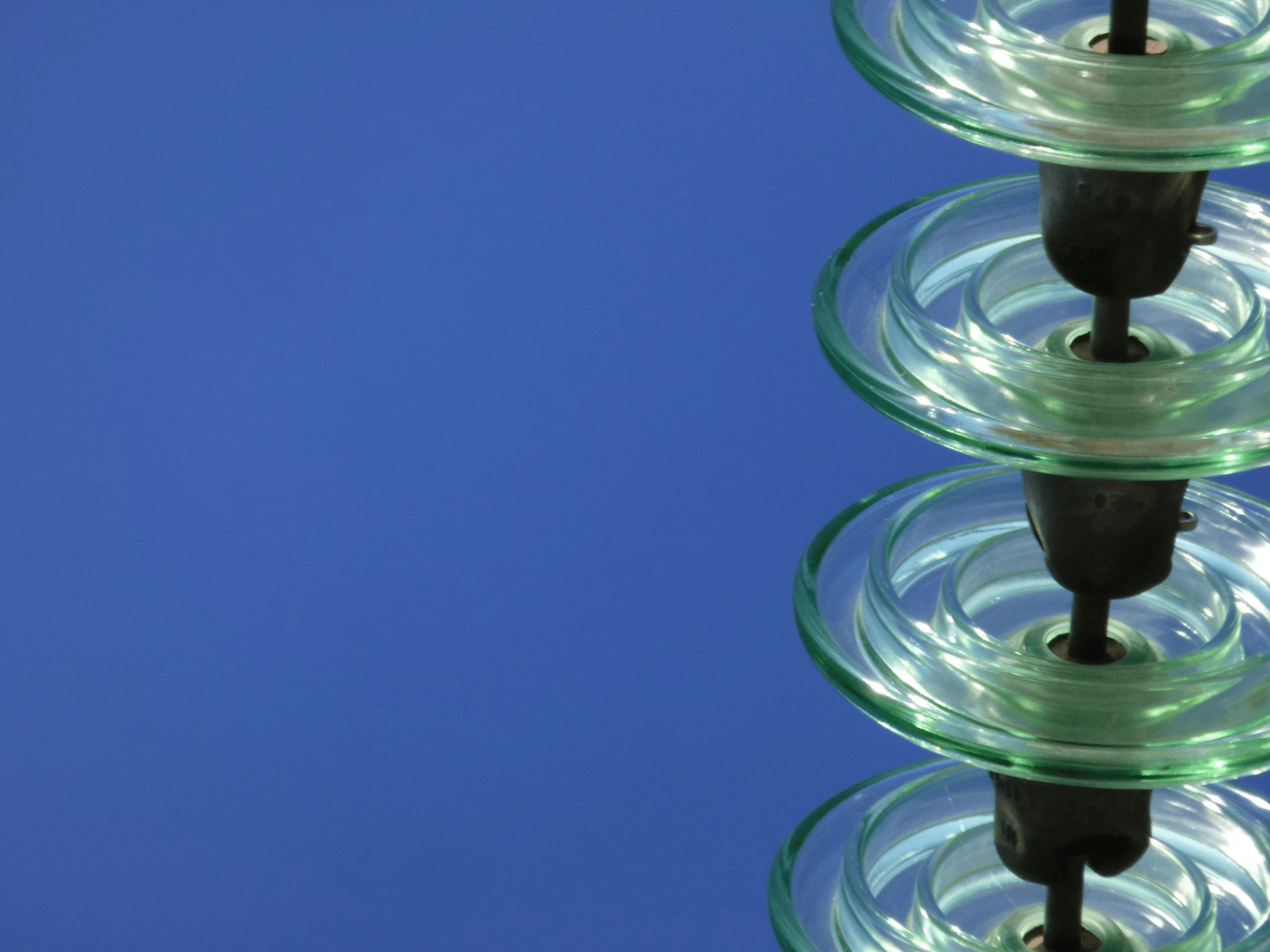

The Evolution of Egg Insulators

Egg insulators have a rich history that traces back to early electrical infrastructure, where they were primarily used to support overhead power lines. Initially crafted from ceramic materials, these insulators were designed with a simple yet effective shape resembling an egg—hence their name. Over time, innovations in material science and engineering practices led to the development of stay insulators that are not only more durable but also capable of withstanding harsher environmental conditions.

What Makes Stay Insulators Unique?

What sets stay insulators apart from other types is their specific functionality and design tailored for tension applications within electrical systems. Unlike traditional insulators that primarily prevent current leakage, stay insulators provide essential support and stability for overhead lines under various loads. This unique role emphasizes their importance in maintaining the integrity of power distribution networks while ensuring safety and efficiency.

Understanding the Importance of Design

The design of stay insulators is critical not just for aesthetic purposes but also for enhancing their performance across various applications. Factors such as structural integrity, resistance to environmental factors, and versatility are all influenced by thoughtful design choices made during manufacturing. As we delve deeper into this topic, we will explore common features of a stay insulator alongside its differences compared to guy and strain insulators.

Design and Structure of Stay Insulators

Stay insulators play a crucial role in maintaining the integrity and functionality of electrical systems. Their design and structure are meticulously crafted to ensure they meet rigorous standards while adapting to various environmental conditions. Understanding the components that contribute to the effectiveness of stay insulators is essential for engineers and designers alike.

Key Materials Used in Construction

The materials used in the construction of stay insulators significantly impact their performance and longevity. Traditional egg insulators, often made from high-strength ceramic, provide excellent electrical insulation properties while being resistant to weathering. In contrast, modern designs incorporate composite materials that offer lightweight durability without compromising on strength, allowing for innovative applications across different industries.

Composite materials have gained popularity due to their resistance to corrosion and reduced weight compared to traditional options. This shift not only enhances the structural integrity of stay insulators but also opens up new possibilities for installation in challenging environments. Ultimately, the choice of materials directly influences both the common features of a stay insulator and its adaptability in various applications.

Innovative Features in Modern Designs

Recent advancements have led to innovative features that enhance the design and structure of stay insulators significantly. Many modern models now include integrated monitoring systems that can detect stress or damage, providing real-time data for maintenance teams. These smart functionalities not only improve safety but also extend the lifespan of stay insulators by enabling proactive management before issues escalate.

Another impressive innovation is the use of modular designs that allow for easy customization based on specific project requirements or environmental conditions. This versatility ensures that each egg insulator can be tailored to fit its unique application seamlessly, whether it's supporting transmission lines or securing renewable energy systems. As a result, these cutting-edge designs are reshaping industry standards and driving future developments.

Case Study: Spark Fittings' Custom Solutions

Spark Fittings has emerged as a notable player in providing custom solutions tailored specifically for stay insulators. Their commitment to innovation has resulted in unique designs that cater to diverse needs within electrical infrastructure projects—ranging from urban settings to remote areas requiring robust support structures. By utilizing advanced materials alongside intelligent design principles, Spark Fittings has set new benchmarks for quality within this niche market.

One standout example includes their bespoke egg insulator solutions designed explicitly for high-stress environments where conventional options may falter under pressure or extreme weather conditions. These custom solutions not only enhance reliability but also exemplify how strategic thinking can lead to groundbreaking advancements in types of stay insulators available today. With such initiatives, Spark Fittings continues to influence industry standards positively while addressing real-world challenges faced by engineers globally.

Common Features of a Stay Insulator

Stay insulators, often referred to as egg insulators due to their distinctive shape, are integral components in electrical systems. These insulators not only ensure the stability and safety of overhead lines but also exhibit several common features that enhance their functionality. Understanding these features is crucial for anyone involved in the design and structure of stay insulators.

Structural Integrity and Durability

One of the primary characteristics of stay insulators is their structural integrity, which ensures they can withstand significant mechanical loads without failure. Made from high-quality materials, such as ceramics or composites, these egg insulators are designed to endure harsh conditions while maintaining their performance over time. This durability is essential for applications where reliability is paramount, particularly in transmission and distribution lines.

Resistance to Environmental Factors

Stay insulators are engineered to resist a variety of environmental factors that could compromise their effectiveness. Whether it’s extreme temperatures, moisture exposure, or UV radiation, these egg insulators boast materials that provide excellent insulation properties and longevity. This resistance not only enhances the overall lifespan of the stay insulator but also reduces maintenance costs associated with frequent replacements.

Versatility in Various Applications

The versatility of stay insulators makes them suitable for a wide range of applications across different sectors. From supporting transmission lines in rural areas to enhancing safety in urban infrastructure projects, these egg insulators adapt well to various environments and challenges. Their ability to function effectively in diverse situations highlights why they are considered vital components within electrical systems.

Differences Between a Guy Insulator and a Strain Insulator

When it comes to the world of electrical systems, understanding the differences between guy insulators and strain insulators is crucial. Both types serve essential roles in maintaining stability and safety, but they do so with distinct functionalities and load-bearing capabilities. This section will explore these differences, shedding light on their unique contributions to the design and structure of stay insulators.

Functionality and Load Bearing

Guy insulators are primarily designed to support tension in overhead lines, acting as a bridge between the wire and a supporting pole or tower. They are critical for maintaining proper alignment and reducing stress on the structures they support. On the other hand, strain insulators are built to withstand heavier loads, such as those imposed by wind or ice accumulation on transmission lines, making them essential for high-load applications.

The functionality of these two types of insulators highlights their specific roles within electrical systems. While guy insulators focus on providing lateral support, strain insulators manage vertical forces more effectively. The design and structure of stay insulators incorporate these functionalities to ensure safe operation under various conditions.

Material Composition Variations

Material composition plays a significant role in differentiating guy insulators from strain insulators. Guy insulators are often made from materials like porcelain or composite materials that provide adequate strength without excessive weight. In contrast, strain insulators typically utilize more robust materials such as toughened glass or high-strength polymers that can handle greater stress levels.

These variations in material composition contribute directly to each type's performance characteristics in different environments. For example, while both types may resist environmental factors like moisture or UV exposure, strain insulators often require additional durability features due to their higher load-bearing responsibilities. Understanding these material differences is vital when selecting appropriate stay insulator types for specific applications.

Situational Uses in Electrical Systems

The situational uses of guy and strain insulators further illustrate their distinct functions within electrical systems. Guy insulators are commonly found at angles where wires need lateral support—think about those charming telephone poles you see lining your street! Strain insulators come into play when there’s an increased need for stability under heavy loads—like during stormy weather when ice builds up on power lines.

Incorporating both types into an electrical system ensures optimal performance across various scenarios—from routine operations to extreme weather conditions—making them indispensable components of modern infrastructure. By recognizing how each type fits into overall system design, engineers can enhance safety while minimizing maintenance needs across transmission networks.

Types of Stay Insulators

When it comes to stay insulators, the choices are as varied as the applications they serve. Understanding the types of stay insulators can help in selecting the right one for a specific engineering challenge. From traditional ceramic options to modern composite materials, each type has its unique set of advantages and applications.

Ceramic vs. Composite Insulators

Ceramic insulators have long been a staple in electrical engineering due to their excellent electrical insulating properties and durability. However, composite insulators have emerged as strong contenders, offering lightweight designs and enhanced mechanical strength. While ceramic egg insulators may be more familiar, composite options are gaining traction for their versatility and ability to withstand harsh environmental conditions.

The design and structure of stay insulator technology has evolved significantly over the years, with both ceramic and composite materials playing crucial roles in this evolution. Ceramic egg insulators are often preferred for their robustness in high-voltage scenarios, while composites excel in areas where weight is a critical factor. When considering differences between a guy insulator and a strain insulator, understanding these material variations becomes vital for optimal performance.

Applications of Polymer Insulators

Polymer stay insulators are revolutionizing the industry with their flexible designs and resistance to environmental factors like UV radiation and pollution. These modern marvels provide not only insulation but also structural integrity that meets various application demands—from transmission lines to renewable energy systems. The versatility of polymer materials makes them ideal for urban infrastructure where space is limited but safety cannot be compromised.

Common features of a stay insulator include durability against weather extremes and adaptability across multiple scenarios; polymer options shine particularly bright here. Their lightweight nature allows for easier installation without sacrificing performance or reliability—something that’s increasingly important in today’s fast-paced engineering world. In contrast to traditional materials, polymer egg insulators offer innovative solutions that cater specifically to contemporary needs.

Specialized Designs for Harsh Environments

In specialized environments—think extreme temperatures or corrosive atmospheres—stay insulation designs must go above and beyond standard offerings. Custom solutions often incorporate advanced materials engineered specifically for resilience against these challenges; thus ensuring that even under duress, they maintain functionality without degradation over time. Whether it's an arctic wind chill or desert heatwave, specialized designs ensure that your egg insulation remains effective when you need it most.

Applications of stay insulators designed for harsh environments vary widely but typically include remote transmission lines or offshore installations where reliability is paramount. The differences between a guy insulator and a strain insulator become especially pronounced when discussing these specialized cases; knowing which type suits your needs can make all the difference in maintaining system integrity under stress conditions. Ultimately, embracing innovative designs not only enhances safety but also sets new standards within the industry.

Applications of Stay Insulators

Stay insulators are integral components in various electrical systems, ensuring stability and safety across multiple applications. Their unique design and structure make them essential for maintaining the integrity of transmission and distribution lines, while also playing a pivotal role in renewable energy systems. Additionally, these insulators enhance safety measures in urban infrastructure, showcasing their versatility and importance.

Use in Transmission and Distribution Lines

In the realm of transmission and distribution lines, stay insulators serve a critical function by providing necessary support to overhead conductors. The design and structure of stay insulators allow them to withstand significant mechanical loads while maintaining electrical insulation properties. This ensures that energy can be transmitted efficiently without compromising safety or performance.

Moreover, the common features of a stay insulator—such as structural integrity and durability—make them ideal for long-term use in challenging environments. By utilizing advanced materials like ceramics or composites, these insulators resist environmental factors such as moisture, temperature fluctuations, and UV exposure. Consequently, they play an indispensable role in the reliability of power supply networks.

Role in Renewable Energy Systems

The rise of renewable energy systems has further highlighted the importance of stay insulators in modern engineering applications. As wind turbines and solar panels become more prevalent, the need for robust electrical connections becomes paramount; this is where egg insulators shine. Their innovative designs cater specifically to the demands of renewable technologies by providing secure anchoring points that can handle dynamic loads.

Additionally, different types of stay insulators are employed based on specific project requirements; polymer options may be favored for their lightweight properties while ceramic variants offer exceptional durability under extreme conditions. The ability to adapt to various applications ensures that these stay insulators contribute significantly to sustainable energy solutions worldwide. Thus, they not only facilitate energy generation but also support efficient distribution.

Enhancing Safety in Urban Infrastructure

In urban settings where space is often at a premium, enhancing safety through effective use of stay insulators is crucial for reliable infrastructure development. These components help manage tension forces within overhead power lines while ensuring minimal risk to pedestrians and vehicles below—a vital consideration when integrating electrical systems into congested areas. The differences between a guy insulator and a strain insulator become evident here; each serves distinct purposes depending on load-bearing requirements.

Furthermore, incorporating egg insulator technology into urban planning helps mitigate hazards associated with electrical installations by maintaining clearances from buildings and other structures effectively. By prioritizing durability against environmental factors like pollution or corrosion, these stay insulators ensure longevity even amidst city challenges. Ultimately, their role enhances not just operational efficiency but also public safety within urban landscapes.

Conclusion

In the grand tapestry of engineering, egg insulators hold a pivotal role, particularly in the realm of electrical systems. Their unique design and structure as stay insulators not only enhance performance but also ensure safety and reliability in various applications. The evolution of these insulators reflects the ingenuity of engineers who continually strive to improve functionality while meeting the demands of modern infrastructure.

Why Egg Insulators Matter in Engineering

Egg insulators are crucial for maintaining the integrity and efficiency of electrical transmission lines. Their distinctive shape and construction contribute to their durability, making them essential components that withstand environmental challenges. Understanding both their common features and specific applications allows engineers to make informed decisions about their deployment in diverse scenarios.

Innovations Shaping Future Insulator Design

The future of stay insulators is bright, thanks to ongoing innovations that push the boundaries of materials science and engineering design. Advances such as composite materials are transforming traditional egg insulator designs into lighter yet equally durable options that can handle extreme conditions. These innovations not only enhance performance but also pave the way for more sustainable practices in electrical infrastructure.

The Impact of Spark Fittings on Industry Standards

Spark Fittings has emerged as a leader in setting industry standards for stay insulators, particularly with their focus on quality and customization. By integrating innovative designs with robust materials, they have created solutions that address specific challenges faced by engineers today. The impact is significant; as more companies adopt these standards, we can expect improved safety and efficiency across various applications involving egg insulators.