Introduction

Understanding the functionality of a corona ring is essential for anyone involved in electrical transmission systems. This introduction will provide insights into the key components of corona rings and highlight the importance of regular maintenance practices to ensure optimal performance.

Understanding the Corona Ring Functionality

A corona ring is designed to mitigate electrical discharge at high voltage points, reducing the risk of corona effects that can lead to energy loss or equipment damage. By creating a more uniform electric field, these rings help maintain system reliability and enhance power efficiency in various applications. Additionally, understanding how these components function allows engineers and technicians to better integrate them into existing infrastructure.

Key Components of Corona Rings

The effectiveness of a corona ring relies heavily on its various components, which include conductive materials, insulators, and spark fittings that facilitate manufacturing processes. Each element plays a significant role in achieving optimal performance under high-voltage conditions. By familiarizing oneself with these key components, one can appreciate how they contribute to the overall functionality and reliability of electrical systems.

Importance of Corona Ring Maintenance

Regular maintenance is vital for ensuring that corona rings continue to perform effectively over time. Neglecting this aspect can lead to increased wear and tear or even catastrophic failures in electrical transmission systems. Implementing proper maintenance practices not only prolongs the lifespan of these critical components but also enhances safety, reliability, and operational efficiency across various application areas.

Exploring Corona Ring Components

Understanding the components that make up a corona ring is essential for appreciating its functionality and effectiveness in various applications. These components work together to ensure that the corona ring performs optimally, whether in electrical transmission systems or high-voltage applications. In this section, we will delve into what constitutes a corona ring, the role of Spark Fittings in its manufacturing, and the materials used in production.

What Makes Up a Corona Ring

A typical corona ring consists of several key components designed to mitigate electrical discharge and enhance efficiency. The primary structure often includes conductive materials shaped into rings or shields that encircle electrical conductors. Additionally, these rings may incorporate insulators or spacers that help maintain appropriate distances between conductive parts to prevent unwanted arcing.

The design of these corona ring components plays a crucial role in their performance across various application areas of corona rings. By optimizing the geometry and material selection, manufacturers can significantly reduce energy loss due to corona discharge. Furthermore, understanding these components helps users choose the best corona rings tailored to specific needs.

Role of Spark Fittings in Manufacturing

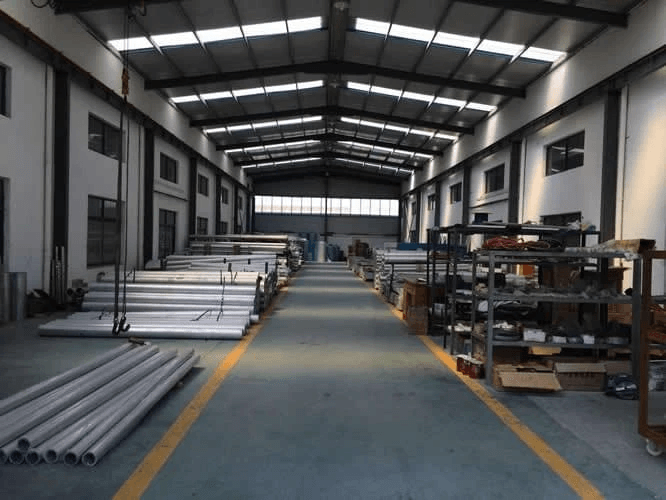

Spark Fittings is a significant player in the manufacturing landscape for corona rings, known for its commitment to quality and innovation. They specialize in producing customized solutions that cater to diverse client specifications while ensuring compliance with industry standards. Their expertise allows them to engineer unique designs that enhance both functionality and longevity.

In addition to custom solutions, Spark Fittings employs advanced manufacturing techniques that improve efficiency during production. This capability not only streamlines processes but also reduces costs associated with installation of corona rings for end-users. By focusing on precision engineering, they ensure each component meets rigorous performance requirements.

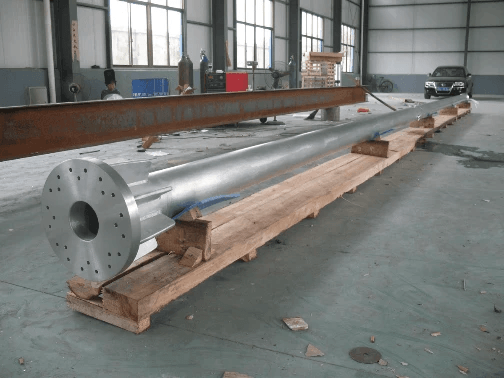

Materials Used in Corona Ring Production

The choice of materials is pivotal when it comes to producing effective and durable corona rings. Commonly used materials include aluminum, copper, and specialized polymers designed for high-voltage applications. Each material offers distinct advantages; for instance, aluminum is lightweight yet strong, while copper provides excellent conductivity.

Moreover, some manufacturers incorporate coatings or treatments on these materials to enhance their resistance against environmental factors such as moisture and corrosion—key considerations during installation of corona rings in outdoor settings. Understanding these material properties aids users not only in choosing the best corona rings but also ensures optimal performance throughout their lifespan.

Applications Areas of Corona Rings

These specialized components are essential for ensuring the efficiency and safety of high-voltage operations. Let's dive into how corona rings play a pivotal role in electrical transmission systems, high voltage applications, and improving overall power efficiency.

Use in Electrical Transmission Systems

Corona rings are integral to electrical transmission systems, acting as a shield that mitigates the adverse effects of electrical discharges. By reducing the electric field intensity at conductor ends, they help prevent unwanted corona discharge that can lead to energy loss and equipment damage. This functionality not only enhances system reliability but also contributes to the longevity of other crucial corona ring components.

Importance in High Voltage Applications

In high voltage applications, corona rings are indispensable for maintaining operational integrity and safety standards. Their design minimizes the risk of arcing and flashover events that could compromise equipment and pose safety hazards. The importance of choosing the best corona rings for these environments cannot be emphasized enough; they ensure that systems operate smoothly under extreme conditions while adhering to regulatory requirements.

Role in Improving Power Efficiency

One of the lesser-known benefits of using corona rings is their role in improving power efficiency across electrical networks. By effectively managing electric fields, these components reduce energy losses associated with ionization processes during transmission. In turn, this translates into lower operational costs and enhanced performance metrics—factors that make regular installation of corona rings a wise investment for any facility aiming for optimal energy use.

Choosing the Best Corona Rings

Choosing the best corona rings for your specific needs can be a daunting task, especially with the myriad of options available on the market. Factors such as application areas of corona rings, installation requirements, and maintenance practices should all be taken into account. Understanding these elements will help you select a corona ring that maximizes performance while ensuring longevity.

Factors to Consider When Selecting

When selecting a corona ring, consider factors like voltage rating, environmental conditions, and compatibility with existing systems. The application areas of corona rings can greatly influence which components are necessary for your setup; for instance, high-voltage applications may require robust materials that withstand extreme conditions. Additionally, evaluating the installation of corona rings is crucial—some designs may require specialized tools or techniques that could complicate the process.

Another essential factor is the anticipated maintenance practices required to keep your corona ring in optimal condition. Regular checks and upkeep are vital to prolonging lifespan and preventing issues down the road. Therefore, choosing a product that aligns not only with immediate needs but also future maintenance capabilities is imperative.

How Spark Fittings Customizes Solutions

Spark Fittings stands out in providing tailored solutions for various applications involving corona rings. Their expertise allows them to customize components based on specific requirements such as size, material composition, and intended use within electrical transmission systems. This level of customization ensures that customers receive products designed specifically for their unique challenges while enhancing overall efficiency.

By consulting with Spark Fittings' knowledgeable team, you can gain insights into how different corona ring components can be optimized for your particular scenario. Whether it’s improving power efficiency or addressing specific environmental concerns, their bespoke solutions cater to diverse needs across industries focused on high voltage applications.

Moreover, their commitment to innovation means you'll always have access to cutting-edge technology designed with reliability in mind—making it easier than ever to choose the best options available.

Comparing Different Types of Corona Rings

There are several variations suited for various applications areas of corona rings—ranging from standard designs used in typical electrical transmission setups to specialized options engineered for extreme environments or high-voltage scenarios.

Each type has its own set of advantages: some may prioritize durability while others enhance performance through innovative design features aimed at reducing electrical stress and improving power efficiency. It’s essential to weigh these factors against your specific requirements when choosing among them.

Additionally, don’t forget about installation considerations; some models might offer easier installation processes than others due to their design simplicity or included hardware packages—making them more user-friendly during setup and eventual maintenance practices.

Installation of Corona Rings

Installing a corona ring may seem daunting, but with the right guidance and preparation, it can be a smooth process. Understanding the installation steps is crucial for ensuring the effectiveness of the corona ring components in your electrical systems. Proper installation directly impacts performance, longevity, and overall safety during high voltage applications.

Step-by-Step Installation Guide

To begin with, ensure that you have all necessary tools and materials ready before starting the installation of corona rings. Start by turning off all power sources to avoid any accidents; safety first! Next, clean the area where you will install the corona ring to remove any dirt or debris that could interfere with its functionality.

Once your workspace is prepared, carefully position the corona ring on the designated component. Make sure it fits snugly without excessive force; it should align perfectly with other parts of your electrical system. After securing it in place using appropriate fasteners, double-check that everything is tightened correctly before restoring power.

Finally, conduct a thorough inspection of your installation to confirm that there are no loose connections or misalignments. This step is essential for ensuring optimal performance in various applications areas of corona rings. Once satisfied with your work, restore power and monitor the system during initial operation to ensure everything runs smoothly.

Common Mistakes During Installation

Even seasoned professionals can make mistakes when installing corona rings—so let’s highlight some common pitfalls to avoid! One frequent error is neglecting proper alignment; if a corona ring isn’t positioned correctly, it may not function as intended and could lead to failures down the line. Always take time to check alignment before securing any components.

Another common mistake involves inadequate cleaning of surfaces prior to installation; residual dirt or grime can create barriers that compromise performance in high voltage applications. Ensure surfaces are clean and dry for optimal contact between components—this simple step can save you headaches later on!

Lastly, many forget about reviewing manufacturer guidelines specific to their chosen type of corona rings; each product might have unique requirements for successful installation and maintenance practices. Familiarizing yourself with these details can greatly enhance reliability and safety during use.

Tools Needed for Effective Installation

Having the right tools at hand is crucial for a successful installation of corona rings—let’s go through what you’ll need! First up are basic hand tools like screwdrivers and wrenches; these will help secure fastenings without damaging sensitive components. A torque wrench may also be beneficial for ensuring connections are tightened appropriately according to specifications.

Next on our list are cleaning supplies such as cloths or brushes designed specifically for electrical installations—keeping surfaces clean ensures better adhesion and performance from your new corona ring setup! Additionally, consider using dielectric grease during assembly; this helps prevent moisture build-up which could compromise functionality over time.

Lastly, don’t underestimate safety equipment like gloves and goggles—it’s always wise to protect yourself while working around electrical systems! With proper tools in hand and awareness of common mistakes during installation, you'll be well-prepared for successfully integrating your chosen corona rings into existing setups.

Corona Ring Maintenance Practices

Maintaining your corona ring is crucial for ensuring optimal performance and longevity. Regular upkeep not only prevents unexpected failures but also enhances the efficiency of the entire electrical system. By adhering to systematic maintenance practices, you can avoid costly downtimes and ensure that your corona ring components remain in top shape.

Regular Checks for Optimal Performance

Conducting regular checks on your corona ring is essential for identifying potential issues before they escalate. These inspections should include visual assessments of the corona ring components, ensuring there are no signs of wear, damage, or buildup of contaminants. Additionally, monitoring performance metrics can help catch anomalies early, allowing for timely interventions and adjustments.

Best Practices for Prolonging Lifespan

To extend the lifespan of your corona rings, it’s important to follow best practices tailored specifically for these components. Keeping the installation area clean and free from debris will minimize contamination risks that could affect performance. Moreover, utilizing protective coatings or treatments can shield your corona rings from environmental factors such as moisture or UV exposure, further enhancing durability.

Troubleshooting Common Issues

Even with diligent maintenance practices in place, issues may occasionally arise with your corona rings. Common problems include excessive noise during operation or visible arcing at high voltages; both can indicate underlying faults within the system. When troubleshooting these common issues, it’s vital to analyze all potential causes systematically—from installation errors to component degradation—ensuring a comprehensive approach to restoring functionality.

Conclusion

In wrapping up our exploration of corona rings, it's clear that these components play a pivotal role in various electrical applications. From enhancing power efficiency to ensuring safety in high voltage environments, the future of corona ring technology looks promising. As we embrace advancements in this field, the emphasis on reliability and safety will only become more pronounced.

The Future of Corona Ring Technology

The future of corona ring technology is poised for exciting developments as industries seek improved performance and sustainability. With increasing demand for renewable energy sources, the applications areas of corona rings are expanding significantly. Innovations such as smart materials and advanced manufacturing techniques promise to enhance the functionality and longevity of corona rings.

Innovations from Spark Fittings

Spark Fittings is at the forefront of innovation when it comes to corona ring components, continuously pushing boundaries to meet evolving industry needs. Their commitment to research and development has led to customized solutions that cater specifically to diverse applications areas of corona rings, ensuring optimal performance under varying conditions. By integrating cutting-edge technologies into their products, Spark Fittings is setting new benchmarks in reliability and efficiency.

Emphasizing Reliability and Safety in Use

When it comes to choosing the best corona rings, prioritizing reliability and safety is non-negotiable. Proper installation of corona rings is crucial; even minor oversights can lead to significant issues down the line. Moreover, regular maintenance practices are essential for prolonging the lifespan of these components while ensuring they operate safely within their intended parameters.