Introduction

When it comes to the stability of structures like power poles and communication towers, guy wires are the unsung heroes. These essential components provide the necessary support to keep tall structures upright and secure against wind and other forces. Understanding utility pole guy wire requirements is crucial for anyone involved in construction or maintenance in this field.

Understanding Guy Wire Fundamentals

Guy wires are tensioned cables that help stabilize vertical structures by anchoring them to the ground or other points. Their design may seem simple, but they play a pivotal role in ensuring safety and durability. By grasping the components of guy wires, including their materials and configurations, you can appreciate how they contribute to structural integrity.

Importance of Properly Tensioned Guy Wires

Proper tensioning of guy wires is vital; too loose, and they won't provide adequate support; too tight, and they risk damaging both themselves and the structure they're meant to protect. Maintaining correct tension helps distribute loads evenly across all components involved, ensuring long-lasting stability. This balance is essential for meeting utility pole guy wire requirements while also adhering to safety standards.

Common Applications for Guy Wires

Guy wires find their way into various applications beyond just utility poles; they're used in communication towers, radio masts, and even some architectural designs. Each application requires careful consideration of types of guy wires suitable for specific conditions, load capacities, and environmental factors. Knowing when and where to use properly tensioned guy wires can make all the difference in structural resilience.

Overview of Utility Pole Guy Wire Requirements

When it comes to utility pole guy wire requirements, understanding the foundational elements is crucial for ensuring stability and safety. These requirements encompass various specifications that dictate how guy wires should be designed, installed, and maintained. Failing to adhere to these guidelines can lead to structural failures or accidents, making it imperative to grasp the components of guy wires in detail.

Key Specifications to Consider

The first step in navigating utility pole guy wire requirements is identifying key specifications such as tensile strength, diameter, and length. The tensile strength must match or exceed the forces anticipated from wind loads and other environmental factors. Additionally, the diameter of the wire plays a vital role in its ability to withstand tension without yielding or breaking; thus, selecting the right type of guy wires tailored for specific applications is essential.

Another important specification involves the materials used in constructing these guy wires. Common materials include steel and synthetic fibers, each offering distinct advantages depending on their intended use. Understanding these specifications not only helps in selecting appropriate types of guy wires but also ensures they perform effectively under various conditions.

Load Calculations and Safety Factors

Load calculations are fundamental when assessing utility pole guy wire requirements since they determine how much weight each wire must support under different conditions. Engineers typically consider factors like wind speed, pole height, and environmental variables when calculating loads on each guy wire system. Incorporating safety factors into these calculations ensures that even during unexpected events—like severe storms—the integrity of the structure remains intact.

Safety factors are typically expressed as a ratio that compares the maximum load capacity of a component with its expected load during operation. For example, a safety factor of 2 means that if a load is expected to be 1,000 pounds, the component should be able to withstand at least 2,000 pounds without failure. This principle underscores why proper installation techniques—such as those outlined in how to install and anchor guy wires for power poles—are integral for long-term reliability.

Compliance with Industry Standards

Compliance with industry standards is another critical aspect of utility pole guy wire requirements that cannot be overlooked. Organizations such as ANSI (American National Standards Institute) provide guidelines that ensure products meet minimum safety criteria across various applications including power distribution and telecommunications towers. Adhering strictly to these standards not only enhances safety but also promotes consistency across different projects involving types of guy wires.

Moreover, compliance often requires regular inspections and maintenance checks on installed systems to ensure ongoing adherence over time; this includes evaluating existing installations against current standards which may evolve over time due to technological advancements or changes in regulations. Ultimately, staying updated with compliance helps professionals select the best guy wire for their application while minimizing risks associated with structural failures.

Components of Guy Wires

Understanding the components of guy wires is essential for ensuring their proper function and effectiveness in various applications. These components work together to provide stability and support, particularly in meeting utility pole guy wire requirements. Knowing how each part contributes can help with selecting the best guy wire for your application.

Essential Parts and Their Functions

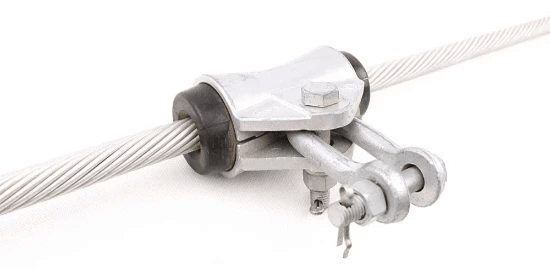

Guy wires consist of several essential parts, each playing a critical role in the overall system's performance. The main components include the wire itself, anchors, tensioning devices, and attachment hardware. Each part must be carefully chosen to ensure they meet the utility pole guy wire requirements and provide reliable support under various loads.

The primary function of the wire is to resist tensile forces that pull it away from its anchor point. Anchors secure the guy wires to the ground or other structures, while tensioning devices allow for adjustments to maintain optimal tension levels. Properly functioning attachment hardware ensures that all components stay connected during adverse weather conditions or heavy loads.

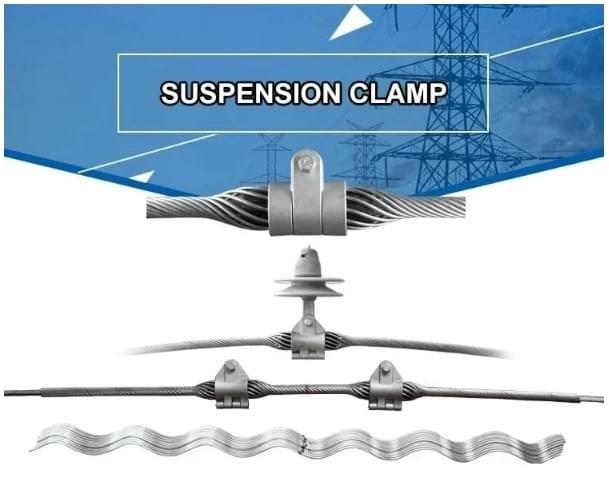

The Role of Armor Rods in Guy Wire Systems

Armor rods are an often-overlooked component that plays a vital role in enhancing the durability of guy wires. These protective coverings are typically made from high-strength materials designed to shield vulnerable areas of the wire from abrasion and wear caused by environmental factors or mechanical stress. By incorporating armor rods into your design, you can significantly extend the lifespan of your guy wires and ensure they continue meeting utility pole guy wire requirements.

In addition to protection, armor rods also help distribute stress more evenly along the wire's length, reducing localized strain points that could lead to failure over time. This feature is particularly beneficial when dealing with types of guy wires used in high-stress environments such as communication towers or power poles. So if you're considering how to install and anchor guy wires for power poles effectively, don't underestimate the importance of these little champions.

Materials Used in Guy Wire Construction

Choosing appropriate materials is crucial when constructing effective guy wires that meet specific applications' needs. Common materials include steel (often galvanized for corrosion resistance), aluminum, and synthetic fibers like Kevlar or nylon—each offering distinct advantages depending on their intended use within various types of guy wires. For instance, steel provides exceptional strength but may require additional maintenance compared to synthetic options which offer lightweight flexibility.

When selecting materials for your project, consider factors such as environmental exposure (like moisture or UV rays), load-bearing capacity, and potential interactions with other structural elements—especially if you're looking at applications involving properly tensioned guy wires on utility poles or communication towers. Ultimately, understanding these material properties will guide you toward making informed choices about which type best suits your needs while adhering closely to utility pole guy wire requirements.

Types of Guy Wires

When it comes to guy wires, variety is the spice of life—or at least, the backbone of stability. Each type has its unique characteristics and applications, making it crucial to understand which one suits your needs best. From utility poles to communication towers, knowing the types of guy wires available can significantly enhance your project's success.

Different Varieties and Their Uses

Guy wires can be classified into several types based on their materials and intended applications. Steel guy wires are commonly used in utility pole installations due to their strength and durability; they meet stringent utility pole guy wire requirements, ensuring safety and reliability. Meanwhile, synthetic options like nylon or polyester are favored for temporary structures or where corrosion is a concern—think communication towers that need flexibility without sacrificing support.

In addition to these materials, there are also specialized guy wires designed for specific applications, such as high-tension cables for wind turbines or lightweight options for portable antennas. Each type serves a distinct purpose in the realm of structural support systems, emphasizing the necessity of selecting the right one based on your project’s demands. Understanding these different varieties will help streamline your decision-making process when installing or maintaining components of guy wires.

Pros and Cons of Each Type

Every type of guy wire comes with its own set of advantages and disadvantages that must be weighed carefully before making a choice. Steel guy wires are incredibly strong and resistant to environmental factors; however, they can be heavy and prone to rust if not properly treated—this is especially important when considering how to install and anchor guy wires for power poles effectively. On the other hand, synthetic options may lack some strength but offer excellent resistance against corrosion and UV damage while being lightweight.

Another consideration is cost; steel tends to be more expensive upfront but offers long-term durability compared to cheaper synthetic alternatives that may require more frequent replacements over time. Ultimately, understanding these pros and cons will guide you toward selecting the best guy wire for your application while ensuring compliance with industry standards related to utility pole installations.

When to Choose Spark Fittings for Custom Solutions

Spark fittings are an innovative solution when standard components don't quite cut it—especially in unique installations requiring customized configurations. These fittings allow you greater flexibility in design while still adhering closely to utility pole guy wire requirements by providing robust connections between various elements within a system. If you're faced with an unusual setup or specific load conditions that standard fittings can't accommodate effectively, spark fittings become invaluable.

Choosing spark fittings also means you can tailor your approach according to project-specific challenges—like tight spaces or unusual angles—which often arise during installation processes involving how to install and anchor guy wires for power poles securely. These custom solutions not only improve overall performance but also enhance safety by ensuring all components work harmoniously together under varying loads.

Applications of Properly Tensioned Guy Wires

Properly tensioned guy wires are crucial in various structural applications, ensuring stability and safety across different environments. From utility poles to communication towers, the significance of these wires cannot be overstated. Understanding how to install and anchor guy wires for power poles is essential for maintaining the integrity of these structures.

Significance in Power Poles

In the realm of utility pole guy wire requirements, tensioned guy wires play a vital role in stabilizing power poles against wind loads and other environmental forces. Without proper tensioning, utility poles could lean or even topple, leading to power outages and safety hazards. The components of guy wires work together to distribute loads evenly, ensuring that power lines remain secure and operational.

Role in Communication Towers

Communication towers rely heavily on properly tensioned guy wires for structural support and stability. These towers must withstand high winds and other stresses, making it critical to select the best guy wire for your application based on specific project needs. Different types of guy wires offer unique benefits; thus, understanding their pros and cons can help ensure that communication systems function reliably without interruption.

Use in Other Structural Supports

Beyond power poles and communication towers, properly tensioned guy wires find applications in various structural supports such as bridges and cranes. The principles behind the installation process are similar regardless of the structure—proper anchoring techniques are essential for maintaining stability under load conditions. Whether you're evaluating materials or comparing types of guy wires, knowing how to install them correctly can make all the difference in achieving a safe outcome.

How to Install and Anchor Guy Wires for Power Poles

Installing and anchoring guy wires for power poles is a critical task that ensures the stability and safety of utility structures. Proper installation not only adheres to utility pole guy wire requirements but also enhances the overall functionality of these vital components. In this section, we’ll guide you through the installation process, share best practices for anchoring techniques, and outline the tools and equipment needed.

Step-by-Step Installation Process

The first step in installing guy wires is to identify the appropriate location on the utility pole where they will be attached. Begin by measuring and marking the points at which your guy wires will be anchored; this should align with your load calculations based on utility pole guy wire requirements. Next, attach the guy wire to the designated point on the pole using a suitable clamp or fitting, ensuring it’s secure before proceeding.

Once attached to the pole, extend each guy wire toward its anchor point on the ground or another structure. At this stage, it's crucial to maintain proper tension; too loose can lead to instability while too tight can cause damage. Finally, secure each wire at its anchor point using appropriate hardware that matches your selected types of guy wires—this could include turnbuckles or anchors designed for specific applications.

Best Practices for Anchoring Techniques

When it comes to anchoring techniques, following best practices can significantly enhance performance and longevity. First, ensure that your anchors are buried deep enough into stable soil; this depth will vary based on local conditions but generally should be at least two feet deep for optimal support against lateral forces acting on power poles.

Additionally, consider using multiple anchors when dealing with heavier loads or taller poles—this distributes stress more evenly across your system of properly tensioned guy wires. Regularly inspect both your installations and anchor points; over time, environmental factors can affect their integrity.

Tools and Equipment Needed

To successfully install and anchor guy wires for power poles, you’ll need a selection of specialized tools and equipment tailored to meet utility pole guy wire requirements effectively. Essential tools include a wrench set for tightening fittings, a level to ensure proper alignment during installation, and a tape measure for accurate distances between attachments.

You’ll also require specific materials such as high-strength steel cables (the components of guy wires), clamps or fittings compatible with your types of guy wires chosen earlier in planning stages, as well as anchors suited for soil conditions in your area. Lastly, having safety gear like gloves and helmets is paramount—safety should always come first when working with potentially hazardous installations.

Selecting the Best Guy Wire for Your Application

Choosing the right guy wire is crucial for ensuring stability and safety in various applications, from utility poles to communication towers. Each project has unique requirements that dictate the type of guy wire needed, making it essential to understand your specific project needs before making a selection. By evaluating factors such as load requirements, environmental conditions, and installation techniques, you can ensure compliance with utility pole guy wire requirements while maximizing performance.

Evaluating Specific Project Needs

When selecting a guy wire, start by assessing the specific demands of your project. Consider aspects like the height and weight of the structures being supported, as well as environmental factors such as wind loads or potential ice accumulation. Understanding these variables will help you determine not only the necessary strength of the guy wire but also its configuration and anchoring method—key components of guy wires that contribute to overall stability.

Additionally, think about how you plan to install and anchor guy wires for power poles or other structures. Do you need a temporary solution for a construction site or a permanent fixture? Each scenario may require different materials or types of guy wires tailored to withstand varying stresses over time.

Comparing Materials and Strengths

Guy wires come in various materials, each with its own strengths and weaknesses that can influence your decision-making process. Common options include steel cables known for their durability and high tensile strength, while synthetic alternatives like Kevlar offer lightweight flexibility without sacrificing resilience. By comparing these materials against your project's specific needs—such as corrosion resistance in coastal areas—you can identify which type aligns best with both performance expectations and budget constraints.

Moreover, understanding how different types of guy wires perform under load can guide you in selecting one that meets safety standards without compromising on functionality. For instance, if you're working on applications of properly tensioned guy wires in high-wind regions, opting for a thicker steel cable may be more advantageous than lighter alternatives that could buckle under pressure.

Making Informed Choices with Spark Fittings

Spark fittings are an excellent option when seeking custom solutions tailored to unique project specifications involving utility pole guy wire requirements. These fittings allow for easy adjustments during installation while providing secure connections between components of guy wires—ensuring optimal tensioning is achieved without hassle. When making informed choices about spark fittings versus traditional options, consider factors such as ease of use during installation and long-term maintenance needs.

Additionally, don’t overlook compatibility; ensure that any selected spark fittings work harmoniously with both your chosen materials and existing hardware systems within your project scope. This attention to detail will enhance overall reliability while streamlining installation processes across diverse applications—from communication towers to industrial supports.

In summary, selecting the best guy wire involves careful evaluation of specific project needs alongside material comparisons and thoughtful integration of spark fittings into your plans—ensuring every aspect aligns perfectly with utility pole guy wire requirements.

Conclusion

In summary, guy wires play a crucial role in ensuring the stability and safety of various structures, particularly utility poles. Understanding the utility pole guy wire requirements is essential for effective installation and maintenance. With proper tensioning and selection, these components of guy wires can significantly enhance structural integrity across multiple applications.

Recap of Guy Wire Importance

Guy wires are indispensable for maintaining the balance and support of tall structures like communication towers and power poles. Their significance lies not only in providing stability but also in ensuring safety through adherence to utility pole guy wire requirements. When properly tensioned, applications of properly tensioned guy wires can prevent catastrophic failures, making them a vital component in modern infrastructure.

Final Tips on Guy Wire Selection

When selecting the best guy wire for your application, consider factors such as environmental conditions, load requirements, and specific project needs. Familiarize yourself with the various types of guy wires available to make an informed choice that meets your project's demands efficiently. Additionally, understanding how to install and anchor guy wires for power poles correctly will ensure optimal performance and longevity.

Resources for Further Learning on Guy Wires

For those looking to delve deeper into the world of guy wires, several resources are available online that cover everything from basic concepts to advanced engineering practices related to components of guy wires. Websites dedicated to electrical engineering standards often provide comprehensive guides on utility pole guy wire requirements as well as installation techniques. Books on structural engineering can also offer valuable insights into selecting the best materials and types of guy wires suited for your specific needs.