Introduction

In the intricate world of electrical infrastructure, pole clamps play a pivotal role in ensuring stability and safety. These essential components secure various elements of transmission lines, which are crucial for delivering electricity efficiently across vast distances. Understanding the significance of pole clamps is vital for anyone involved in the power industry.

Importance of Electrical Pole Clamps

Pole clamps serve as the unsung heroes of transmission lines, providing critical support that helps maintain structural integrity. Without these sturdy attachments, the entire system could face severe risks, including disconnections or even catastrophic failures. Their ability to withstand environmental challenges makes them indispensable in modern electrical engineering.

Overview of Hot-DIP Galvanization

Hot-DIP galvanization is a process that enhances the durability and longevity of pole clamps by coating them with zinc. This protective layer prevents rust and corrosion, ensuring that the clamps remain functional even in harsh weather conditions. The result is a reliable product that can withstand years of exposure while maintaining its strength.

Applications in the Power Industry

The applications of pole clamps extend beyond mere attachment; they are integral to various systems such as Transmission Line End Earthing Clamps and other vital components within transmission networks. In addition to securing wires and cables, they help facilitate grounding processes essential for safety and efficiency. Understanding how far apart transmission lines are pole to pole also highlights their importance in maintaining proper spacing for optimal functionality.

Understanding Pole Clamps

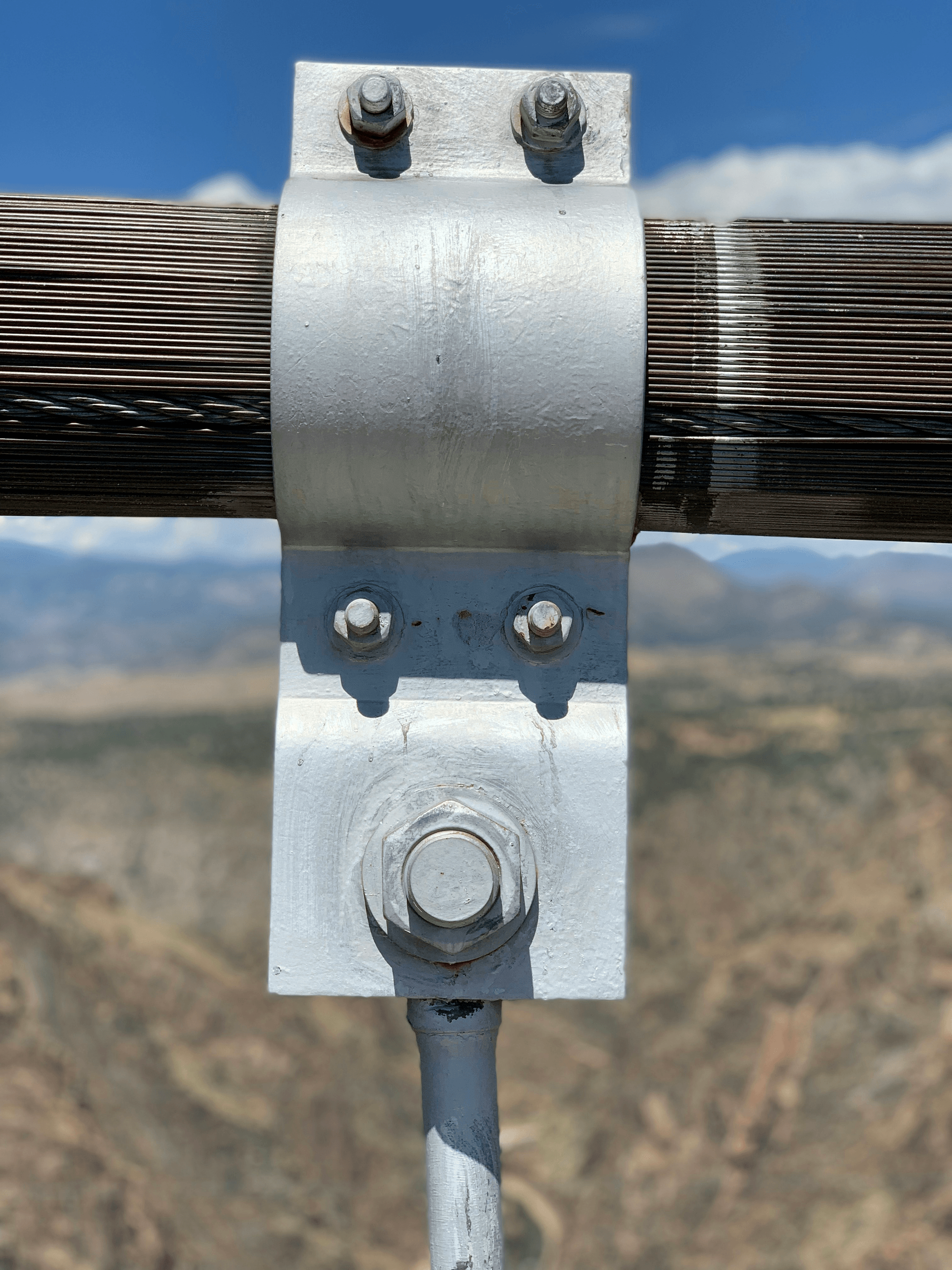

What is a pole clamp?

So, what is a pole clamp? In simple terms, it’s a mechanical device designed to hold and support electrical conductors or other equipment on utility poles. These clamps are crucial for maintaining the integrity of transmission lines and preventing sagging or displacement that could lead to outages or hazards.

Pole clamps come in various designs tailored for specific applications, including Transmission Line End Earthing Clamps which are particularly vital for grounding purposes. Their primary function is to ensure that everything stays securely fastened while also allowing for some flexibility under changing weather conditions or loads. This adaptability is key in maintaining reliable power delivery.

Types of pole clamps available

There are several types of pole clamps available on the market today, each serving unique functions within transmission systems. For instance, you’ll find standard conductor clamps designed primarily for holding wires in place and more specialized options like Transmission Line End Earthing Clamps which facilitate grounding connections at line terminations.

Another common type includes suspension clamps that allow conductors to hang freely from the poles while providing necessary support against environmental factors like wind and ice accumulation. Additionally, there are strain clamps used when tension needs to be applied on cables during installation or maintenance work—each type tailored specifically to meet different operational needs.

Key specifications of pole clamps

When selecting pole clamps, several key specifications must be considered to ensure optimal performance and safety standards are met. First among these is load capacity; knowing how much weight a clamp can support is critical for avoiding failures under stress conditions typical of transmission lines.

Material composition also plays an important role; many pole clamps are made from galvanized steel or aluminum alloys that resist corrosion and withstand harsh weather conditions over time. Furthermore, compatibility with existing equipment should not be overlooked—ensuring that your chosen clamp fits well with other components prevents installation headaches down the line.

Lastly, understanding dimensions such as diameter range and fastening mechanisms will help streamline installation processes while ensuring compliance with local regulations regarding spacing between poles—a detail often overlooked but essential for effective operation across vast networks of transmission lines.

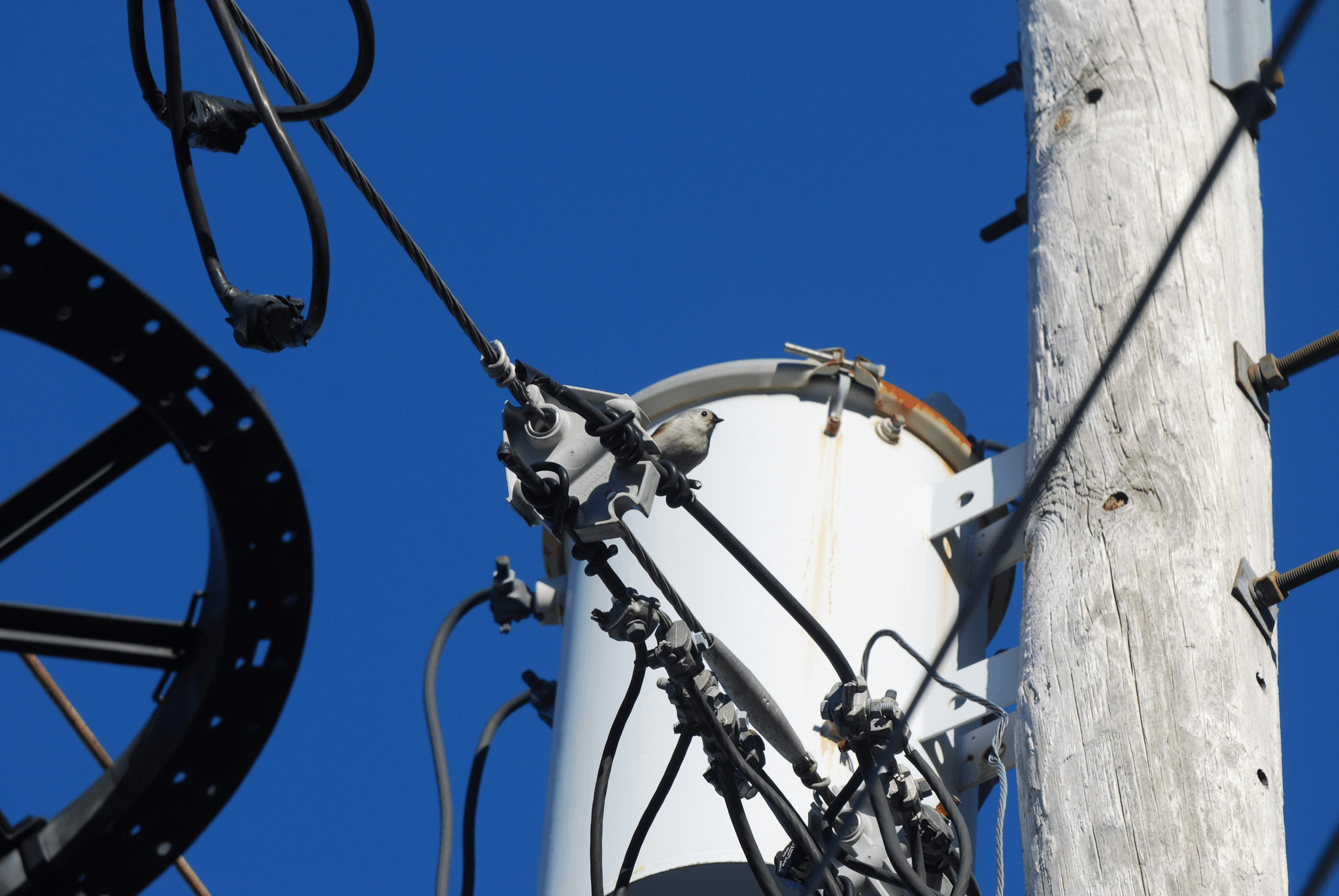

The Role of Transmission Line End Earthing Clamps

Transmission Line End Earthing Clamps play a crucial role in ensuring the safety and efficiency of power systems. These clamps not only secure the electrical connections but also provide a vital link to the ground, preventing potential hazards from electrical faults. Understanding their function is essential for anyone involved in the power industry.

What is a clamp in a transmission line?

A clamp in a transmission line, specifically a pole clamp, serves as an anchoring device that holds conductors securely to poles or other structures. These clamps are designed to withstand environmental stresses while ensuring reliable electrical connections. In essence, they work as connectors that facilitate safe energy transfer through overhead lines.

Significance of earthing in transmission lines

Earthing is paramount in transmission lines because it provides a pathway for fault currents to safely dissipate into the ground, minimizing risks like electric shocks or equipment damage. Without proper earthing using Transmission Line End Earthing Clamps, any fault could lead to catastrophic failures and safety hazards for both personnel and infrastructure. This grounding mechanism not only protects the system but also enhances overall reliability and performance.

Innovative designs by Spark Fittings

Spark Fittings has been at the forefront of creating innovative designs for Transmission Line End Earthing Clamps that improve functionality and safety standards. Their products incorporate advanced materials and engineering techniques to ensure durability against harsh weather conditions while maintaining excellent conductivity. By focusing on innovation, Spark Fittings continues to lead the industry with solutions that meet modern demands for efficiency and reliability.

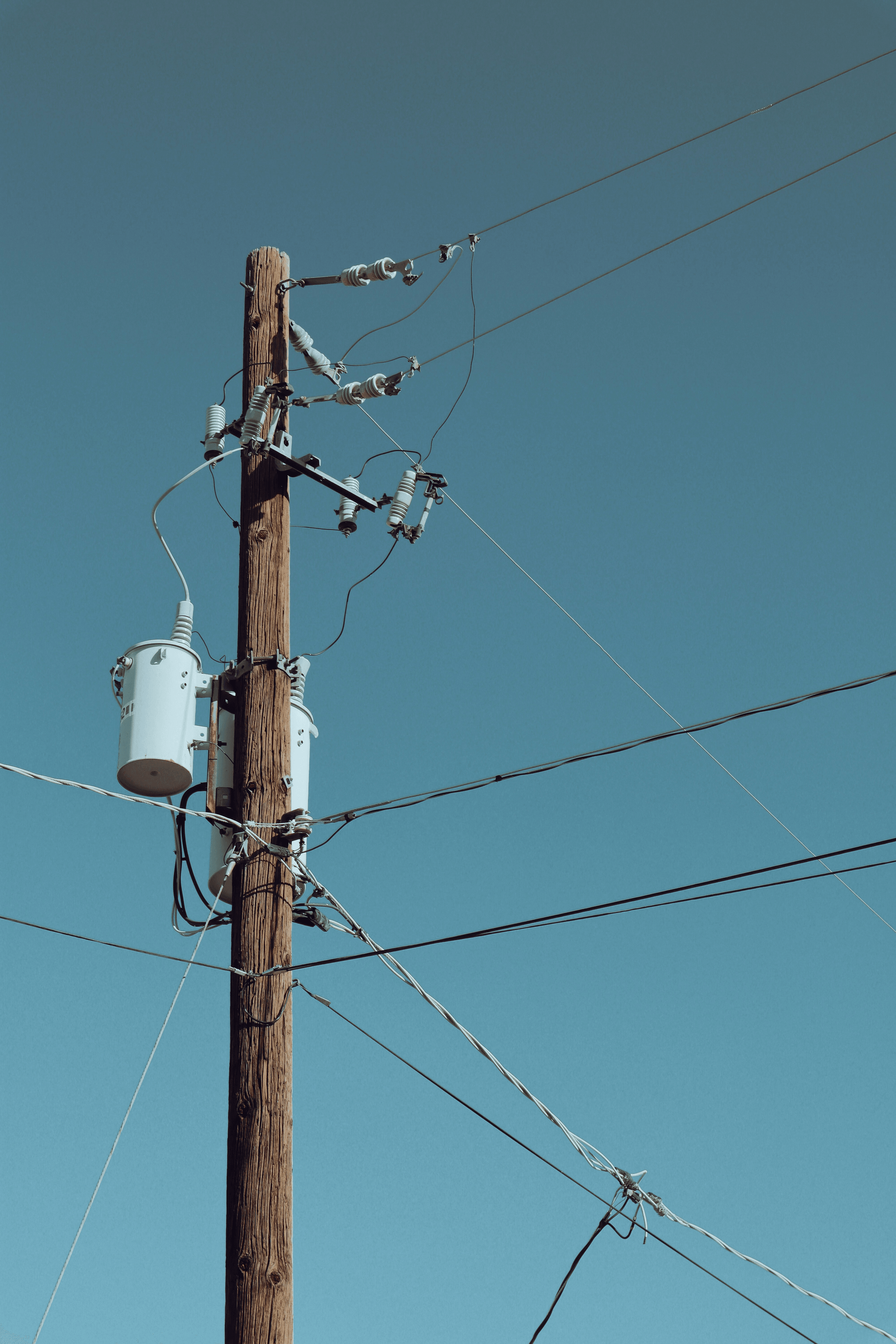

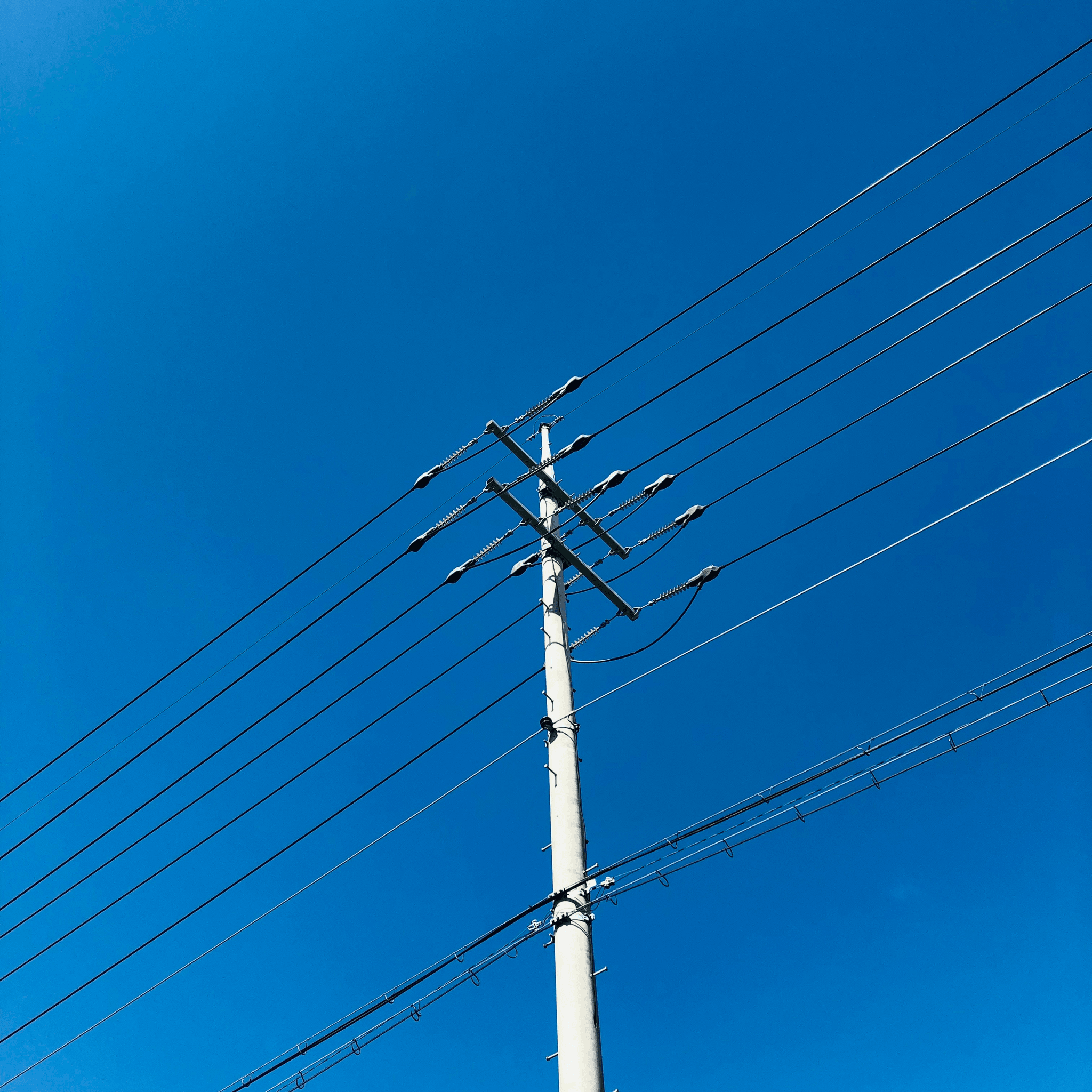

The Purpose of Pole Structures in Transmission Lines

Pole structures play a vital role in the functionality and safety of transmission lines. They provide the necessary support for electrical wires, ensuring that they remain elevated and insulated from the ground. This elevation is crucial for preventing electrical hazards and maintaining a reliable power supply.

What is the purpose of pole structures in a transmission line?

The primary purpose of pole structures in a transmission line is to support conductors while keeping them safely distanced from each other and the ground. By doing so, these structures help maintain proper clearance, which is essential for safe operation and minimizing electrical interference. Pole clamps are often utilized to secure the conductors to these structures, ensuring stability even during adverse weather conditions.

Structural integrity and safety considerations

When discussing pole structures, structural integrity cannot be overlooked. These poles must withstand various environmental factors such as wind, ice load, and seismic activity while maintaining their strength over time. Safety considerations also extend to how well pole clamps are installed; improper installation can lead to failures that compromise both structural integrity and safety.

Materials used in pole structures

The materials used in constructing pole structures are critical to their performance and longevity. Commonly employed materials include steel, concrete, and wood—each offering different benefits depending on the application requirements. For instance, steel poles may be favored for their durability and strength while wood offers cost-effectiveness but may require more maintenance over time.

Installation and Maintenance of Pole Clamps

When it comes to ensuring the reliability of power transmission systems, proper installation and maintenance of pole clamps are crucial. These components play an essential role in securing transmission lines and ensuring their safety during operation. A well-executed installation not only enhances the structural integrity but also extends the lifespan of these fittings.

Step-by-step installation process

To install pole clamps effectively, start by gathering all necessary tools and materials, including the clamps themselves, bolts, nuts, a wrench set, and safety gear. First, identify the location on the pole where you will apply the clamp; this is critical for achieving optimal support for your transmission line. Next, position the clamp around the pole securely and align it with your transmission line; ensure that everything is level before tightening.

Once aligned, insert bolts through designated holes in the clamp and secure them with nuts using a wrench—tightening should be done evenly to prevent any misalignment or undue stress on either component. It’s important to double-check that each bolt is sufficiently tightened; loose fittings can lead to significant issues down the line. Finally, inspect your work to confirm that everything is installed correctly before moving onto any further connections or adjustments.

Essential maintenance tips

Maintaining pole clamps is vital for ensuring long-term performance in power transmission applications. Regular inspections should be scheduled every six months; look for signs of wear like rust or corrosion on both clamps and poles as these can compromise structural integrity over time. Additionally, ensure that all bolts remain tight—if you notice any loosening due to environmental factors or vibrations from nearby equipment, re-tighten them promptly.

Cleaning is another critical aspect of maintenance; dirt or debris can accumulate around pole clamps over time which may hinder their effectiveness. Using a soft brush along with mild detergent can help keep them clean without causing damage to protective coatings like hot-dip galvanization. Lastly, if you observe any cracks or deformation in your Transmission Line End Earthing Clamps or other components during inspections, consider replacing them immediately to avoid potential failures.

Common issues and troubleshooting

Despite careful installation and diligent maintenance efforts, issues with pole clamps may still arise from time to time. One common problem includes misalignment due to improper installation—this can lead to uneven weight distribution along transmission lines which could affect their stability over time. If you suspect misalignment has occurred after installation, re-evaluate your setup by checking measurements against manufacturer specifications.

Another issue might involve rust formation on galvanized surfaces; while hot-dip galvanization provides excellent protection against corrosion initially, extreme weather conditions may still cause deterioration eventually. If rust appears on your pole clamps despite regular maintenance efforts, consider applying a fresh coat of anti-corrosive paint once they are cleaned thoroughly for added protection against future damage.

Lastly, if there’s noticeable movement in your Transmission Line End Earthing Clamps while under load conditions—this could indicate either loose fittings or inadequate support structures nearby—addressing these concerns promptly will help maintain safety standards across all operations involving power lines.

Spacing Considerations for Transmission Lines

When it comes to transmission lines, the spacing between poles is a critical aspect that ensures safety, efficiency, and reliability. Properly spaced pole clamps and structures help maintain the integrity of the entire system while minimizing risks associated with electrical faults. Understanding how far apart are transmission lines pole to pole can aid in effective planning and installation.

How far apart are transmission lines pole to pole?

The distance between transmission line poles can vary significantly based on several factors, including terrain, voltage level, and environmental conditions. Typically, these distances range from 100 to 150 feet in urban areas but can extend up to 1,000 feet in rural settings where fewer obstacles exist. This variability highlights the importance of understanding what is a clamp in a transmission line context—it's not just about holding wires; it's about maintaining optimal spacing for safety and performance.

Factors influencing pole spacing

Several factors influence how far apart are transmission lines pole to pole. First off, geographical features such as hills or valleys can necessitate closer or farther placement of poles depending on how they affect line sagging and tension. Additionally, local regulations and standards often dictate specific requirements for pole spacing based on safety concerns related to wind loads or seismic activity—factors that must be taken into account when determining the purpose of pole structures in a transmission line.

Another crucial element is the voltage level being transmitted; higher voltages generally require greater distances between poles due to increased electrical field strength around conductors. Weather patterns also play a role; regions prone to heavy winds might necessitate more closely spaced poles equipped with robust Transmission Line End Earthing Clamps for added stability.

Best practices for optimal spacing

To achieve optimal spacing between poles while ensuring safety and functionality, several best practices should be followed. First, conducting thorough site surveys helps identify terrain features that may impact placement decisions—this includes understanding what is a pole clamp's role in maintaining structural integrity under various conditions.

Moreover, utilizing advanced engineering techniques such as computer modeling can predict how changes in spacing might affect overall system performance—the goal being both reliability and cost-effectiveness over time. Lastly, regular inspections of existing installations ensure that any issues related to wear or environmental changes are promptly addressed—after all, even the best-laid plans need adjustments!

Conclusion

In summary, pole clamps play a crucial role in the stability and safety of power transmission lines. Understanding what a pole clamp is and its various types can significantly enhance the reliability of electrical infrastructure. Furthermore, Transmission Line End Earthing Clamps are essential for grounding, ensuring that energy flows safely and efficiently.

Key Takeaways on Pole Clamps

Pole clamps are indispensable components in the construction and maintenance of transmission lines. They provide secure connections between poles and wires, ensuring structural integrity while accommodating various environmental conditions. By grasping what a clamp in a transmission line entails, professionals can make informed choices that enhance safety and performance.

Future Trends in Power Fittings

As technology evolves, so do the designs of pole clamps and related fittings. We can expect innovative materials that offer greater durability while reducing overall weight, which could lead to more efficient installations. Moreover, advancements in smart technology may soon allow for real-time monitoring of pole structures to ensure they remain safe and effective over time.

Spark Fittings: Leading the Industry

When it comes to quality and innovation in power fittings, Spark Fittings stands at the forefront of the industry. Their commitment to creating top-tier Transmission Line End Earthing Clamps ensures that electrical systems remain reliable under various conditions. With an eye toward future trends and customer needs, Spark Fittings continues to set benchmarks for excellence in pole clamp manufacturing.