Introduction

Understanding the Clevis Bolt Basics

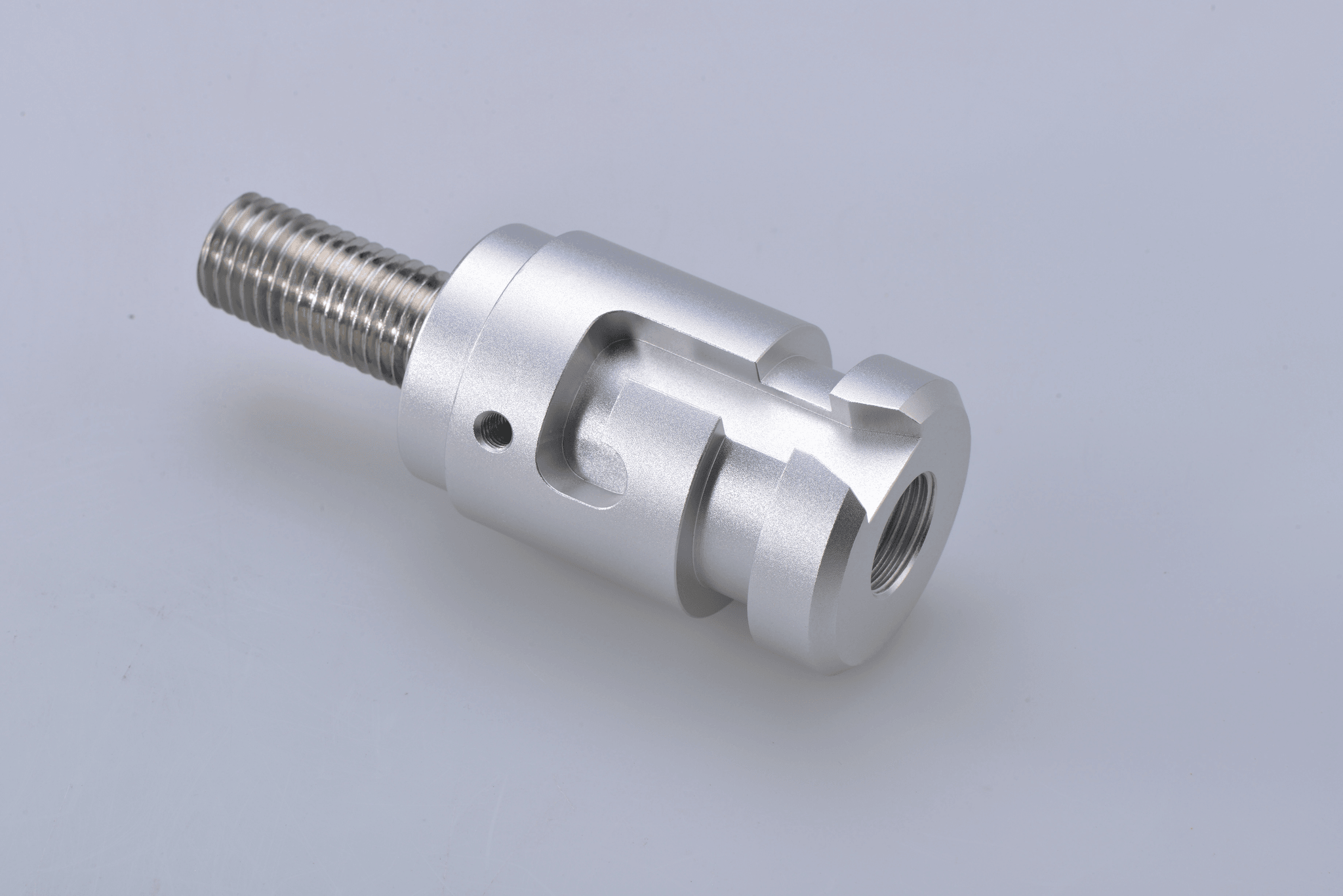

So, what is a clevis bolt? At its core, a clevis bolt is a type of fastener featuring a U-shaped clevis at one end and a threaded shaft at the other. This design allows for easy attachment and detachment while providing robust stability in mechanical assemblies. Identifying a clevis bolt involves looking for its distinctive features: the clevis itself typically has holes for pins or cotter keys that secure it in place.

Importance of Clevis Bolts in Engineering

Clevis bolts are essential components across numerous engineering fields due to their strength and reliability. They are commonly used in applications ranging from automotive suspension systems to structural frameworks, proving their worth time and again. The question often arises: what is a clevis bolt used for? In essence, they facilitate joint connections where flexibility and strength are paramount.

The Role of Spark Fittings in Clevis Bolt Production

In the realm of manufacturing, Spark Fittings plays an integral role by enhancing the quality and efficiency of clevis bolt production. Their innovative methods ensure that each bolted connection meets stringent industry standards while maintaining cost-effectiveness. Additionally, understanding the difference between a bolt and a clevis pin can help consumers make informed choices; while both serve fastening purposes, they differ significantly in design and application specifics.

What is a Clevis Bolt?

A clevis bolt is a specialized type of fastener that plays a crucial role in various mechanical applications. It consists of a cylindrical shaft with a head at one end and a clevis—a U-shaped component—at the other, designed to accommodate a pin or latch. This unique design allows for easy assembly and disassembly, making it particularly useful in situations where frequent adjustments are necessary.

Definition and Design Features

So, what exactly is a clevis bolt? At its core, it’s an elongated fastener that combines the functionality of both bolts and pins. The head provides stability while the clevis end allows for attachment to other components via a pin or similar device. This design not only enhances load distribution but also facilitates quick connections, which is essential in many engineering applications.

To identify a clevis bolt, look for its distinct features: the rounded head, the long shaft, and the U-shaped clevis at one end—this combination sets it apart from standard bolts or pins. The dimensions can vary based on specific applications; however, they typically adhere to industry standards for compatibility with various fittings and attachments.

Common Applications and Uses

What is a clevis bolt used for? These versatile fasteners find their way into numerous industries including automotive, aerospace, construction, and machinery maintenance. They are commonly used to secure linkages in suspension systems or connect different parts of heavy machinery where flexibility and strength are paramount.

In addition to their use in heavy equipment assembly, clevis bolts are also prevalent in rigging applications within maritime industries due to their ability to withstand significant loads while allowing movement between connected components. Their adaptability makes them ideal for scenarios where traditional fastening methods may struggle under dynamic conditions.

Comparison with Other Fasteners

When it comes down to comparing fasteners like the clevis bolt with others such as standard bolts or shackles, there are some notable differences worth mentioning. A key distinction between a bolt and a clevis pin lies in their design; while both serve fastening purposes, only the clevis bolt offers that unique U-shape which allows for quick release connections without compromising structural integrity.

Moreover, understanding what is the difference between a clevis and a shackle reveals further nuances: while both serve as connectors in rigging operations, shackles typically handle heavier loads but lack the ease of disassembly offered by clevis bolts. Therefore, choosing between these options often depends on specific application needs—strength versus convenience.

In summary, knowing how to identify these features can greatly enhance your understanding of mechanical assemblies where precision matters most!

Types of Clevis Bolts

When it comes to clevis bolts, variety is the spice of life! These fasteners come in several forms, each tailored for specific applications and requirements. Understanding the different types can help engineers and DIY enthusiasts alike select the right clevis bolt for their projects.

Standard Clevis Bolt Variants

Standard clevis bolt variants are the most commonly used types in various industries. They typically feature a cylindrical body with a threaded end and an eyelet at one end, which allows for easy attachment to other components. What is a clevis bolt used for? These versatile fasteners are often employed in construction, automotive applications, and even recreational equipment like trailers.

In addition to standard sizes, you'll find that these bolts are available in various lengths and diameters to accommodate different loads and stresses. The design ensures easy installation and removal while providing reliable strength under tension or shear forces. This makes them an excellent choice when you need a dependable connection without the hassle of complex assembly processes.

Materials Used in Clevis Bolts

The materials utilized in manufacturing clevis bolts can significantly affect their performance characteristics. Most standard variants are made from high-strength steel or stainless steel, offering durability and corrosion resistance for outdoor applications. However, specialized materials like aluminum or titanium may be employed for lightweight or high-performance requirements.

When considering what is the difference between a bolt and a clevis pin?, it's essential to note that while both serve fastening purposes, they differ primarily in design features—clevis bolts have an eyelet that allows them to pivot when attached with a pin or other fastener. The material choice impacts not only strength but also weight; lighter materials can be beneficial where reducing overall mass is crucial.

Specialty Clevis Bolts for Unique Applications

Specialty clevis bolts cater to unique needs across various sectors, including aerospace, marine engineering, and heavy machinery manufacturing. For instance, some may feature additional coatings or treatments to enhance resistance against extreme temperatures or harsh chemicals—perfect for environments where standard materials might fail.

How do you identify a clevis bolt? Typically marked by their distinctive shape with an eyelet on one end and threading on the other, these bolts stand out among other fasteners like shackles or regular bolts. Speaking of which: what is the difference between a clevis and a shackle? While both connect components securely, shackles usually offer more flexibility due to their open design but lack the threaded capability found in clevis bolts.

Installation and Maintenance Tips

When it comes to installing and maintaining clevis bolts, a little knowledge goes a long way. Proper installation ensures that the clevis bolt functions effectively, while regular maintenance can extend its life and performance. This section will guide you through the essential techniques for installing clevis bolts, keeping them in top shape, and troubleshooting any issues that may arise.

Proper Installation Techniques

To ensure your clevis bolt is installed correctly, start by aligning the components precisely where the clevis bolt will be used. This alignment is crucial because misalignment can lead to undue stress on the bolt, potentially compromising its integrity over time. Once aligned, insert the clevis pin through the hole of the clevis bolt and secure it with a retaining clip or nut to prevent any unwanted movement.

It's also important to consider torque specifications when tightening your clevis bolts. Over-tightening can cause damage not only to the bolt but also to surrounding materials; under-tightening may result in a loose fit that could lead to failure during operation. So remember: achieving that perfect balance is key!

Regular Maintenance Practices

Regular maintenance of your clevis bolts is essential for ensuring their longevity and functionality. Start by inspecting your installations periodically for signs of wear or corrosion; this includes checking for rust on metal parts or deformation of the bolt itself. If you notice any issues during these inspections, addressing them promptly can save you from more extensive repairs down the line.

Lubrication is another critical aspect of maintaining your clevis bolts—especially if they are exposed to harsh environments or heavy loads. A good quality lubricant will reduce friction between moving parts and help prevent wear over time. Additionally, always keep an eye on load conditions; if you frequently exceed recommended limits, it might be time to rethink what a clevis bolt is used for in your application.

Troubleshooting Common Issues

Even with proper installation and maintenance practices in place, issues may still arise with your clevis bolts from time to time. One common problem is loosening due to vibrations—if you find that your fasteners are becoming loose frequently, consider using locking mechanisms like nylon inserts or lock washers designed specifically for this purpose.

Another issue could be misalignment during installation which may lead you to ask: What is the difference between a bolt and a clevis pin? While both serve similar purposes as fasteners, their designs differ significantly in terms of how they connect components together; understanding these differences can help troubleshoot potential problems effectively.

Lastly, if you're ever confused about whether you're dealing with a clevis or a shackle during repairs or installations—don’t fret! A simple visual inspection should clarify things; remember that while both serve as connectors in various applications, their shapes and uses differ significantly.

The Manufacturing Process

The manufacturing process of a clevis bolt is both intricate and fascinating, involving various stages that ensure the final product meets high standards of quality and performance. From the selection of materials to the final assembly, each step is crucial in producing a reliable fastener that can withstand significant loads and stresses. Understanding how these components are made not only highlights their importance in engineering but also sheds light on innovations that improve their functionality.

Overview of Clevis Bolt Production

To grasp what is a clevis bolt used for, one must first understand its production journey. The process begins with raw materials, typically high-strength steel or alloy metals, which are meticulously chosen for their durability and resistance to wear. Once the materials are selected, they undergo processes such as forging, machining, and heat treatment to achieve the desired specifications for strength and performance.

After fabrication, each clevis bolt is shaped with specific design features that differentiate it from other fasteners. For example, a clevis bolt often includes a pin hole for securing attachments while providing a pivot point—this sets it apart when considering what is the difference between a bolt and a clevis pin? The entire production cycle ensures that every component adheres to stringent safety standards before it's ready for distribution.

Innovations in Manufacturing by Spark Fittings

Spark Fittings has been at the forefront of introducing cutting-edge technologies in clevis bolt manufacturing. One notable innovation is the implementation of automated machinery that enhances precision during machining processes—this results in more consistent dimensions across large batches. Additionally, Spark Fittings utilizes advanced materials science techniques to develop specialty clevis bolts tailored for unique applications across various industries.

These innovations not only streamline production but also improve overall efficiency—what does this mean for engineers? It translates into reduced costs without compromising quality or performance; an essential factor when considering cost-effectiveness in engineering solutions. Moreover, by integrating smart manufacturing practices like real-time monitoring systems, Spark Fittings ensures that any discrepancies can be addressed promptly during production.

Quality Control Measures in Production

Quality control measures play an indispensable role in ensuring every clevis bolt produced meets rigorous industry standards. To identify a clevis bolt effectively during inspections, manufacturers employ various testing methods such as tensile strength tests and dimensional checks—these verify that each piece can withstand operational demands without failure. Furthermore, comprehensive visual inspections help catch any surface defects or irregularities before products leave the factory floor.

The difference between a clevis and a shackle becomes clearer when understanding how quality assurance impacts functionality; both serve different purposes yet require similar scrutiny during production phases to ensure safety under load-bearing conditions. Regular audits throughout the manufacturing process help maintain high-quality benchmarks while fostering continuous improvement initiatives at Spark Fittings—aiming always to enhance their offerings further. Ultimately, these quality control measures instill confidence among engineers who rely on these components daily.

Advantages of Using Clevis Bolts

Clevis bolts are often the unsung heroes of engineering, providing a wealth of benefits that enhance their utility across various applications. From their impressive strength and durability to their cost-effectiveness and versatility, clevis bolts have carved out a significant niche in many industries. Understanding these advantages can help engineers and designers make informed choices when selecting fasteners for their projects.

Strength and Durability Benefits

When considering the question, What is a clevis bolt used for?, one must acknowledge its robust design that allows it to withstand significant loads and stresses. Clevis bolts are typically made from high-strength materials, ensuring they maintain structural integrity even under demanding conditions. This durability not only extends the lifespan of the fastener but also enhances the safety of the overall assembly, making clevis bolts an essential component in critical applications.

Moreover, the unique design features of a clevis bolt—such as its pin and fork structure—allow for easy connection and disconnection without compromising strength. Engineers often choose clevis bolts over other fasteners because they provide reliable performance in environments where vibration or movement could lead to failure. Knowing how to identify a clevis bolt by its distinct shape can save time when selecting the right fastener for your needs.

Cost-Effectiveness in Engineering Solutions

Cost considerations are paramount in any engineering project, and clevis bolts deliver exceptional value without sacrificing quality or performance. Their straightforward design allows for rapid installation, which can significantly reduce labor costs during assembly or maintenance tasks. Additionally, since clevis bolts are reusable—unlike some other fastening solutions—they offer long-term savings by minimizing replacement expenses.

The question What is the difference between a bolt and a clevis pin? highlights another aspect of cost-effectiveness: while traditional bolts may require additional components like washers or nuts to secure them properly, clevis bolts typically come with everything needed for installation right out of the box. This simplicity means fewer parts to purchase and manage throughout your project lifecycle. By choosing clevis bolts, engineers can optimize both budgetary constraints and project timelines.

Versatility in Various Industries

One of the standout features of clevis bolts is their remarkable versatility across different sectors—from construction to automotive engineering and beyond. They serve multiple purposes; whether connecting structural components or acting as pivot points in machinery, you’ll find them hard at work everywhere you look! The adaptability of these fasteners allows them to be tailored for specific applications while maintaining reliability.

Furthermore, understanding What is the difference between a clevis and a shackle? reveals another layer of versatility: while both serve similar functions in securing loads or connections, each has unique properties suited for different scenarios. Clevis bolts excel where precise alignment is crucial due to their fixed nature compared to shackles that allow more movement but may not provide as secure a fit under certain conditions. This flexibility makes clevis bolts invaluable tools across various industries looking for dependable fastening solutions.

Conclusion

In summary, clevis bolts are indispensable components in various engineering applications, providing reliability and strength where it matters most. Understanding what a clevis bolt is used for, its unique design features, and how it differs from other fasteners like clevis pins and shackles can help engineers make informed choices. As we look to the future, advancements in clevis bolt technology promise even greater efficiency and versatility across industries.

Key Takeaways About Clevis Bolts

Clevis bolts serve a specific purpose in fastening systems, offering a combination of strength and ease of use that sets them apart from traditional bolts. When asking what is the difference between a bolt and a clevis pin, it's essential to note that while both serve fastening functions, the clevis bolt is designed for quick assembly and disassembly with its U-shaped end. Additionally, identifying a clevis bolt is straightforward; simply look for its distinctive shape featuring a threaded shaft with a head on one end.

The Future of Clevis Bolt Technology

As industries evolve, so do the materials and technologies used in manufacturing clevis bolts. The future may see innovations such as lightweight composites or advanced coatings that enhance durability while reducing weight—perfect for aerospace applications where every gram counts! Furthermore, smart technology integration could lead to real-time monitoring of structural integrity in critical applications using these fasteners.

How Spark Fittings Enhances Clevis Bolt Quality

Spark Fittings stands at the forefront of enhancing clevis bolt quality through cutting-edge manufacturing processes and rigorous quality control measures. By focusing on precision engineering techniques, they ensure that each clevis bolt meets stringent industry standards while maintaining cost-effectiveness—a crucial factor when considering what is a clevis bolt used for across various sectors. Their commitment to innovation not only improves the longevity of their products but also reinforces their reputation as leaders in fastener solutions.