Introduction

Suspension clamps play a crucial role in the world of cable management, specifically designed to support and secure cables in various applications. Understanding their importance is essential for anyone involved in electrical infrastructure, as these clamps ensure stability and reliability for cable systems. Without proper suspension clamps, the risk of cable sagging or damage increases significantly, leading to potential outages or failures.

Understanding Suspension Clamps Importance

These clamps are engineered to withstand environmental stresses while providing robust support for cables, including the popular suspension clamp for ABC cable. By ensuring that cables are properly secured with quality clamps for cables, we can enhance both safety and performance across electrical networks.

Key Functions of Suspension Clamps

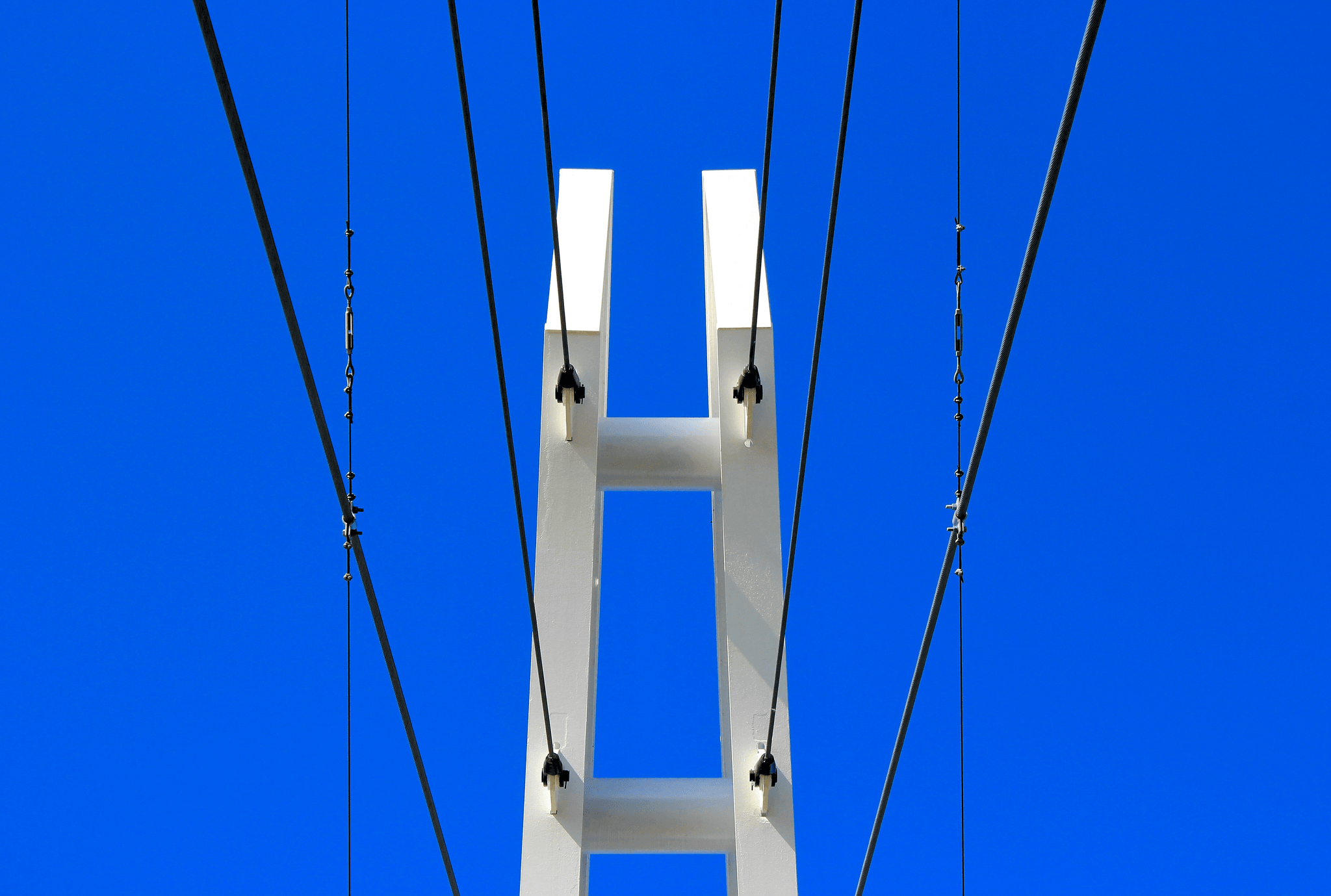

Suspension clamps serve several key functions that contribute to their widespread use in various industries. Primarily, they provide mechanical support by holding cables securely in place while minimizing strain on the conductors themselves. Additionally, these cable clamps help distribute weight evenly across the installation points, reducing stress on any single point and enhancing overall system durability.

Overview of Suspension Clamp Types

When it comes to suspension clamp types, there’s a wide variety suited for different applications and environments. From standard wire clamp designs to specialized models tailored for specific installations like ABC cables, each type has its unique features and benefits. Understanding these differences is vital when selecting the right clamp type for your specific project needs—ensuring that you have the best solution for your cable management challenges.

What is a Suspension Clamp?

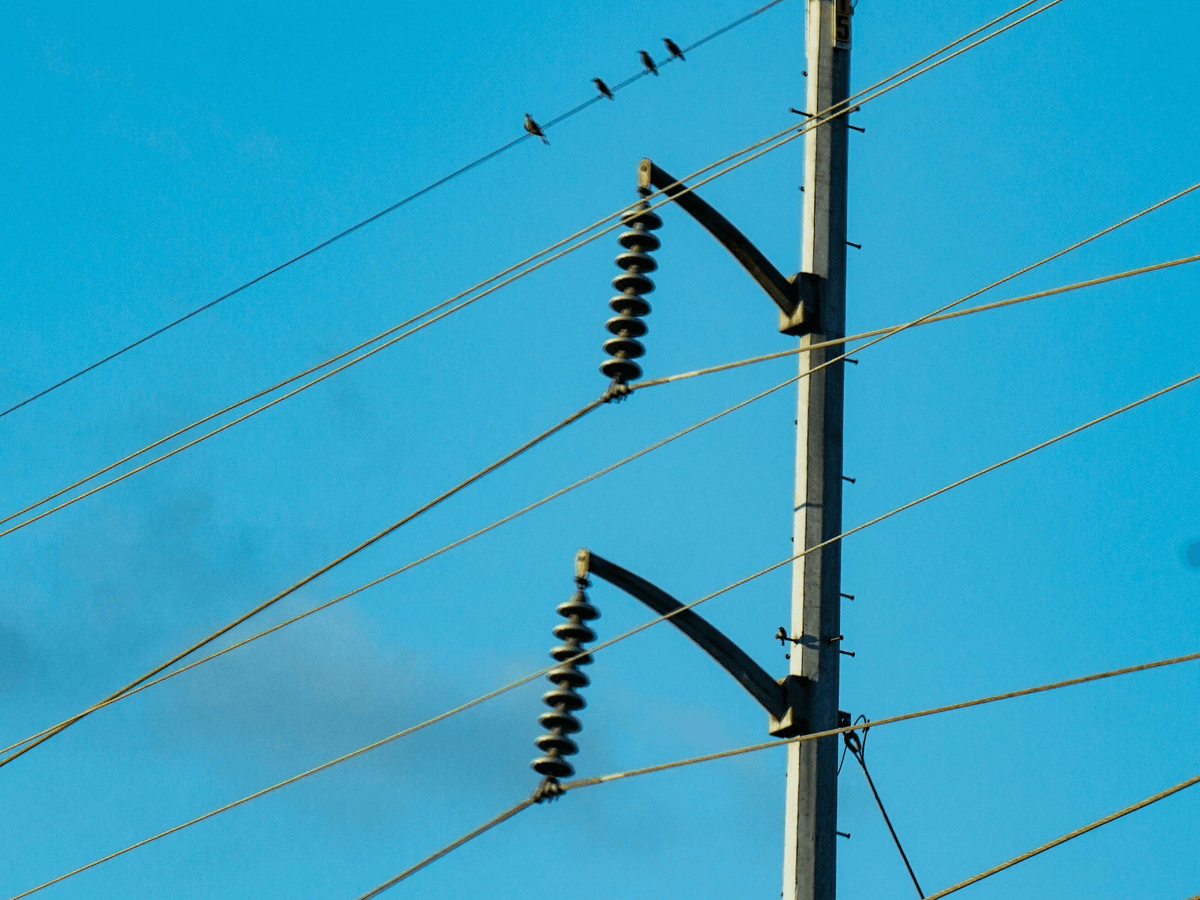

Suspension clamps are essential components used in overhead power line systems, designed to secure and support cables, particularly ABC (Aerial Bundled Cable). These clamps play a crucial role in maintaining the stability and integrity of cable installations, ensuring that cables remain suspended securely above ground. Their design allows for flexibility in installation while providing strong resistance to environmental stresses.

Definition and Purpose

A suspension clamp is a type of hardware specifically engineered to hold cables in place without applying excessive pressure that might cause damage. The primary purpose of these clamps is to suspend cables from poles or other structures, allowing them to hang freely while minimizing the risk of sagging or displacement. By using a suspension clamp for ABC cable, utilities can ensure reliable performance and longevity of their electrical systems.

Common Applications

Suspension clamps find their way into various applications across different sectors, primarily in power distribution networks. They are widely used for securing overhead lines where space constraints require efficient use of vertical airspace, making them indispensable for urban environments. Additionally, these clamps are utilized in telecommunications and street lighting installations, showcasing their versatility as effective clamps for cables.

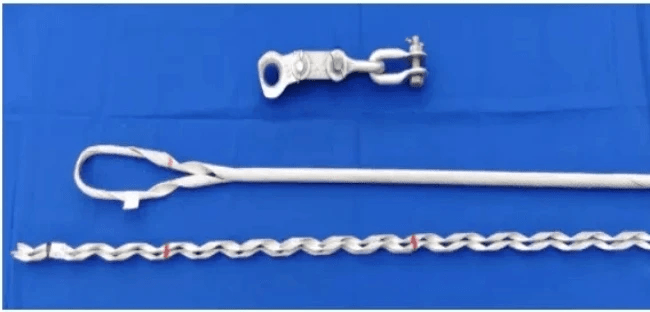

Materials Used in Manufacturing

Manufacturing suspension clamps involves selecting materials that offer durability and resistance to environmental factors such as corrosion and UV radiation. Common materials include aluminum alloys for lightweight strength and galvanized steel for enhanced longevity under harsh conditions. The choice of material not only impacts the performance of the cable clamp but also its ability to withstand mechanical stresses over time, ensuring reliability across various installations.

Types of Suspension Clamps

These clamps are designed to hold cables securely while allowing for some movement due to environmental factors, ensuring longevity and reliability. Understanding the various types of suspension clamps is crucial for selecting the right clamp type for specific applications.

Overview of Clamp Types

Suspension clamps come in various designs tailored to different needs, including those specifically made for ABC (Aerial Bundled Conductors) cables. The most common types include single bolt suspension clamps, double bolt suspension clamps, and adjustable suspension clamps. Each clamp type offers unique features suited to different cable sizes and environmental conditions, making it essential to choose wisely based on your installation requirements.

Specific Uses of Suspension Clamps

Suspension clamps are primarily used in overhead power lines where they support the weight of cables while allowing for thermal expansion and contraction. For instance, a suspension clamp for ABC cable is ideal for urban areas with limited space as it helps bundle multiple conductors together neatly. Additionally, these cable clamps can be used in telecommunications infrastructure, ensuring that both power and data lines remain securely fastened during adverse weather conditions.

Comparison with Other Cable Clamps

While suspension clamps are designed specifically for hanging cables from poles or towers, other types like tension or dead-end clamps serve different purposes within cable systems. Tension clamps are used to anchor cables at specific points along their length while dead-end clamps secure the ends of wires where they terminate at poles or structures. In contrast, a wire clamp may not provide the same level of support as a dedicated suspension clamp but can still be useful in less demanding applications.

The Role of Spark Fittings

Their innovative approach to designing suspension clamps for ABC (Aerial Bundled Cable) ensures that these essential components not only meet industry standards but also exceed them. With a focus on quality and performance, Spark Fittings has become synonymous with excellence in the world of clamps for cables.

Innovations by Spark Fittings

They have introduced unique designs that improve the ease of installation, ensuring that each clamp type is user-friendly while maintaining high strength and durability. Additionally, their use of cutting-edge materials means that these cable clamps are resistant to environmental factors, thereby extending their lifespan and efficacy.

The commitment to innovation doesn't stop there; Spark Fittings continuously invests in research and development to create products that adapt to evolving industry needs. For instance, they have integrated features such as corrosion resistance and enhanced grip mechanisms in their wire clamps, making them suitable for various applications. This forward-thinking approach not only benefits installers but also contributes significantly to the overall performance of cable systems.

Quality Assurance in Production

Quality assurance is paramount at Spark Fittings, where every clamp undergoes rigorous testing before reaching the market. Each suspension clamp is manufactured using high-grade materials that adhere to strict quality standards, ensuring reliability under demanding conditions. By implementing comprehensive quality control measures throughout the production process, they guarantee that each cable clamp performs optimally when installed.

Their dedication to quality extends beyond just materials; it encompasses every aspect of production—from design validation through manufacturing processes to final inspections. This meticulous attention ensures that their clamps for cables can withstand stressors like temperature fluctuations and mechanical loads without compromising integrity or safety. Consequently, users can trust these products will maintain secure connections in any environment.

Impact on Cable Infrastructure

The impact of Spark Fittings on cable infrastructure cannot be overstated; their reliable suspension clamps are integral components in maintaining the stability and safety of electrical networks. By utilizing effective designs tailored for specific applications, such as those involving ABC cables or other types of overhead lines, they help prevent issues like sagging or excessive strain on conductors over time.

Moreover, these innovative wire clamps contribute positively toward reducing maintenance costs associated with cable systems by minimizing wear and tear on critical components. As infrastructure evolves with new technologies and demands arise from urbanization or renewable energy projects, Spark Fittings remains committed to providing solutions that enhance both efficiency and longevity within this sector.

In conclusion, the role played by Spark Fittings through its innovative approaches and unwavering dedication to quality significantly impacts how we utilize suspension clamps across various applications—ultimately leading towards a more resilient future for our cable infrastructures.

Installation and Maintenance Tips

When it comes to ensuring the longevity and effectiveness of your suspension clamps, proper installation and maintenance are key. These clamps play a crucial role in securing cables, especially when it comes to the suspension clamp for ABC cable. Whether you're dealing with overhead power lines or other cable systems, following best practices can prevent future headaches.

Proper Installation Techniques

Installing a clamp is not just about tightening screws; it’s about understanding the specific requirements of your cable system. For instance, when using a suspension clamp for ABC cable, ensure that the clamp type matches the diameter and weight of the cable to avoid unnecessary strain or damage. Additionally, always refer to manufacturer guidelines for torque specifications—over-tightening can lead to stress fractures in both the clamp and the cable.

Another essential technique involves positioning your clamps correctly along the span of cables. The distance between each clamp should be determined by factors such as environmental conditions and load requirements—this prevents sagging or excessive tension that could compromise performance. Lastly, don’t forget to inspect your work; a quick visual check can save you from potential issues down the line.

Common Maintenance Practices

Regular maintenance is vital for any installation involving clamps for cables. Start by conducting routine inspections every few months to check for signs of wear or corrosion on both clamps and cables; this helps catch minor issues before they escalate into major problems. Cleaning any dirt or debris that accumulates around your wire clamps will also help maintain optimal performance.

In addition to visual checks, consider applying protective coatings or lubricants specifically designed for outdoor use on your cable clamps; this can extend their lifespan significantly against harsh weather elements. If you notice any damaged components during inspections, replace them immediately rather than waiting until they fail completely—this proactive approach keeps everything running smoothly.

Troubleshooting Issues with Clamps

Sometimes even the best-installed suspension clamps can run into trouble; knowing how to troubleshoot these issues is essential for maintaining system integrity. If you observe unusual sagging in your cables, it’s often a sign that one or more clamps have loosened over time—tightening them may solve this problem quickly! However, if you’re dealing with frequent loosening despite proper installation techniques, consider using different clamp types better suited for your specific application.

Another common issue might be corrosion affecting electrical conductivity in wire clamps; if you discover rust or other degradation during inspections, replacing affected parts should be prioritized immediately to prevent further complications down the line. Lastly, remember that environmental factors such as extreme temperatures or high winds can impact performance too—adjusting installation practices based on local conditions ensures better resilience against nature's whims.

Future Trends in Suspension Clamps

The future of suspension clamps is evolving rapidly, driven by technological advancements, sustainability considerations, and emerging market trends. These factors are reshaping how we think about clamps for cables, enhancing their functionality and efficiency in various applications. As industries adapt to changing demands, understanding these trends will be crucial for optimizing performance and reliability.

Technological Advancements

Technological innovations are at the forefront of the evolution of suspension clamps. Manufacturers are increasingly incorporating smart technologies into cable clamps to monitor load and environmental conditions, ensuring optimal performance over time. The integration of advanced materials is also enhancing the durability and strength of suspension clamps for ABC cable, making them more resilient against harsh weather conditions.

Moreover, automation in manufacturing processes is improving precision in producing wire clamps and other clamp types, resulting in better quality control and consistency. With these advancements, users can expect more reliable cable clamp solutions that not only meet but exceed current industry standards. The trend towards smart infrastructure will likely see more sophisticated designs that can adapt to various cable configurations seamlessly.

Sustainability Considerations

Sustainability is becoming a key focus area within the industry as companies strive to reduce their carbon footprint through eco-friendly practices. The production of cable clamps is shifting towards using recycled materials or sustainably sourced components without compromising quality or performance. This trend not only benefits the environment but also appeals to consumers who prioritize green products when selecting suspension clamp options.

Additionally, manufacturers are adopting energy-efficient processes in producing suspension clamps for ABC cables and other types to minimize waste during production. As businesses embrace circular economy principles, we can expect innovative designs that allow for easier recycling or repurposing of old cable with clamp systems once they reach the end of their life cycle. This shift toward sustainability ensures that future generations will have access to effective solutions while protecting our planet.

Emerging Market Trends

The demand for efficient transmission line accessories is on the rise globally due to increasing energy needs and infrastructure development projects. Emerging markets are particularly driving growth as they invest heavily in expanding their electrical grids with reliable suspensions like those found with modern cable clamps. This surge creates opportunities for new players entering the market who specialize in manufacturing high-quality clamps for cables tailored specifically for regional requirements.

Furthermore, there’s a growing trend towards customization within the industry; clients now seek tailored solutions that fit specific applications or environments perfectly—whether it’s a heavy-duty wire clamp designed for extreme weather conditions or specialized clamp types suited for unique installation scenarios. As competition intensifies among manufacturers catering to diverse needs across different sectors—from renewable energy installations to urban development—innovation will remain key in capturing market share.

Conclusion

In summary, suspension clamps play a pivotal role in the stability and efficiency of cable systems, particularly for ABC (Aerial Bundled Cable) applications. They ensure that cables are securely held in place while accommodating various environmental factors, reinforcing their importance in modern infrastructure. Understanding the different types of clamps for cables and their specific uses can significantly enhance the performance and longevity of cable installations.

Essential Insights on Suspension Clamps

Suspension clamps are not just mere accessories; they are essential components that contribute to the overall integrity of cable installations. These clamps help maintain proper tension and alignment, preventing sagging or undue stress on the cables. By utilizing high-quality materials and innovative designs, suspension clamps ensure that cables remain secure under various conditions, making them indispensable for utilities and contractors alike.

Maximizing Cable Performance with Clamps

To maximize cable performance with clamps, it’s crucial to select the right clamp type for your specific application. For instance, using a suspension clamp for ABC cable ensures that your installation can withstand wind loads and thermal expansion without compromising safety or functionality. Regular maintenance practices like inspections can help identify wear or damage to your wire clamp systems early on, thereby prolonging their lifespan and enhancing overall performance.

The Future of Transmission Line Accessories

The future of transmission line accessories looks promising as advancements in technology pave the way for more efficient designs in cable clamps. Innovations focusing on sustainability will likely lead to eco-friendly materials being used in manufacturing these vital components. As market trends shift towards smarter infrastructure solutions, we can expect an increased demand for high-performance suspension clamps that not only meet safety standards but also contribute positively to environmental goals.