Introduction

These little wonders are essential for securing cables and wires, ensuring that everything stays in place and functions smoothly. Understanding the various types of clamps available, including preformed suspension clamps, can make all the difference in a successful project.

Understanding Suspension Clamps

Suspension clamps are specialized devices designed to support and stabilize cables and wires in electrical systems. They come in various shapes and sizes to accommodate different types of cables—think of them as the backbone of your wiring setup. Whether you're dealing with a simple cable with clamp or more complex wire with clamp configurations, knowing how they work is key to effective installation.

Importance of Choosing the Right Clamp

Selecting the right clamp for your project is crucial; it can affect everything from safety to performance. An inappropriate choice could lead to cable damage or even system failure, which no one wants on their watch! By understanding the specific requirements—like load capacity and environmental resistance—you can ensure that your grip cable or wire clamp will stand up to the task at hand.

Overview of Available Options

From standard models to high-performance preformed suspension clamps, there's something for everyone. Familiarizing yourself with these choices will empower you to make informed decisions that enhance both safety and functionality in your electrical projects.

What is a Suspension Clamp?

Suspension clamps are essential components in electrical systems, providing the necessary support and stability for various types of cables and wires. They serve as a bridge between the cable and its mounting structure, ensuring that the cable remains securely in place while allowing for some movement to accommodate thermal expansion or contraction. Understanding how suspension clamps work can help you choose the right type for your specific needs.

Definition and Purpose

A suspension clamp is designed to hold cables or wires in place while suspended from overhead structures, such as poles or crossarms. Its primary purpose is to prevent sagging, which could lead to damage or failure of the electrical system. By maintaining proper tension and alignment, these clamps help ensure optimal performance and safety of electrical installations.

Types of Suspension Clamps

There are various types of suspension clamps available on the market, each tailored for specific applications and environments. Preformed suspension clamps are particularly popular due to their ease of installation and ability to provide superior grip on cables without causing damage. Other types include standard wire clamps, which offer versatility but may require additional hardware for secure installation.

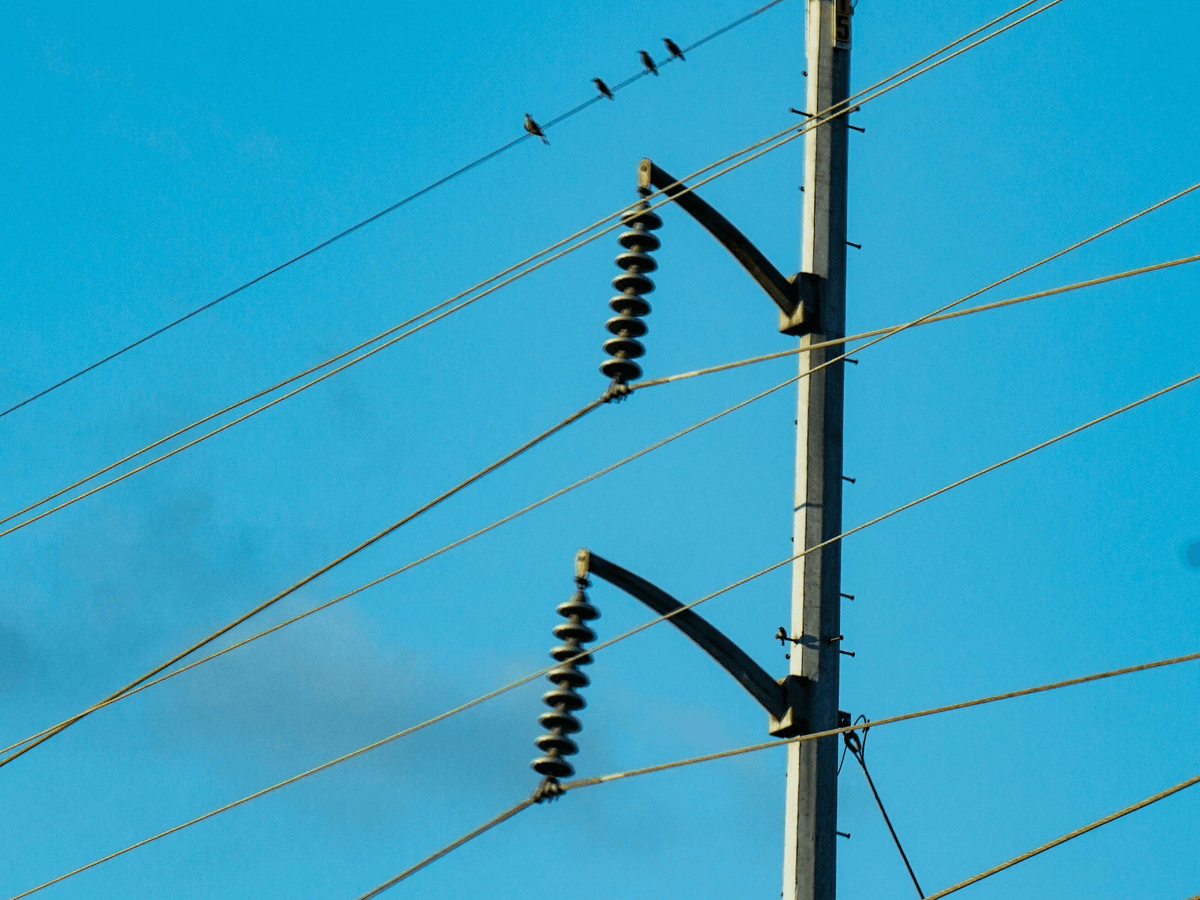

Applications in Electrical Systems

Suspension clamps find their place in numerous applications within electrical systems, from overhead power lines to telecommunications networks. They are commonly used with cables that require reliable support under different environmental conditions—think wind, rain, or even snow! Whether you're dealing with grip cable installations or securing wire with clamp setups, understanding where these components fit into your project can make all the difference.

Key Factors in Selecting a Suspension Clamp

Material Considerations

Material choice is paramount in determining the durability and effectiveness of a suspension clamp. Common materials include aluminum, stainless steel, and polymer composites, each offering unique benefits for different applications. For instance, preformed suspension clamps made from aluminum are lightweight yet robust, making them ideal for overhead cable installations where weight savings are crucial.

Choosing the right material also affects how well the clamp will perform under stress and environmental conditions. If you're working with heavy cables or wires with clamps that need to withstand significant tension, opting for high-strength materials is essential. Remember that using inferior materials can lead to premature failure of your cable clamp or wire clamp, potentially causing costly downtime.

Load Capacity and Strength

The load capacity of a suspension clamp is another vital factor to consider during selection. Each clamp type has a specified load rating that indicates how much weight it can support without compromising integrity. When selecting a grip cable or wire with clamp solution, ensure you choose one that exceeds your expected load requirements to provide an added safety margin.

In addition to load capacity, it's essential to assess the overall strength of the electrical clamps being considered. This includes evaluating their resistance to bending or breaking under pressure when installed on cables or wires in challenging environments. A robust clamp not only secures your cables but also ensures long-term reliability in demanding applications.

Environmental Resistance

Environmental factors play a significant role in determining which suspension clamps will perform best in specific settings. Clamps cable systems exposed to harsh weather conditions must be resistant to corrosion, UV rays, and extreme temperatures; otherwise, they risk deterioration over time. Preformed suspension clamps designed for outdoor use often incorporate protective coatings or specialized materials that enhance their resistance against these elements.

Moreover, considering where you’ll be installing your wire clamp is crucial; different environments—such as coastal areas with salty air or industrial zones with corrosive substances—demand specific features from your clamps cable solutions. Always check manufacturer specifications regarding environmental ratings before making a purchase decision; this ensures you select products designed for optimal performance within their intended application scope.

In conclusion, understanding material considerations, load capacity and strength requirements along with environmental resistance will guide you toward choosing the right suspension clamps for your needs—whether they’re preformed suspension clamps or more traditional options like grip cables and wire clamps.

Preformed Suspension Clamps Explained

Preformed suspension clamps are an essential component in the world of electrical systems, providing reliable support and stability for cables and wires. These clamps are designed to securely hold cables in place while allowing for some movement, which is crucial in dynamic environments where thermal expansion or contraction can occur. By utilizing a preformed suspension clamp, you can ensure that your cable with clamp setup remains intact and functions optimally.

Benefits of Using Preformed Clamps

One of the standout benefits of using preformed suspension clamps is their ability to reduce stress on cables and wires, ultimately prolonging their lifespan. Unlike standard clamps, these specialized tools distribute loads evenly across the cable, minimizing wear and tear over time. Additionally, preformed clamps often come with enhanced environmental resistance, making them ideal for outdoor applications where exposure to harsh weather conditions is a concern.

Another advantage lies in their ease of installation; preformed suspension clamps typically require less time and fewer tools compared to traditional options. This efficiency translates into lower labor costs and quicker project completion times—definitely a win-win situation! Moreover, these clamps often feature designs that accommodate various cable sizes, ensuring versatility across different electrical setups.

Differences from Standard Clamps

While both preformed suspension clamps and standard clamps serve similar purposes in securing cables, there are notable differences between the two. Standard clamps may not provide the same level of load distribution or stress relief as their preformed counterparts do; this can lead to potential damage over time if not carefully monitored. In contrast, preformed suspension clamps are specifically engineered to handle high-stress environments without compromising the integrity of the cable or wire with clamp system.

Additionally, preformed suspension clamps typically have a more streamlined design that enhances aesthetic appeal while maintaining functionality. This means they not only work well but also look good doing it! When comparing grip cable options between standard and preformed types, it's clear that choosing a preformed option can lead to better overall performance in your electrical installations.

Installation Tips for Preformed Clamps

When it comes to installing preformed suspension clamps, following best practices can make all the difference in achieving optimal performance from your setup. First off, always ensure that you select the appropriate size clamp for your specific cable or wire with clamp application; using an ill-fitting clamp can lead to complications down the line! Proper alignment during installation is crucial—make sure that each clamp sits evenly along its respective length of cable to avoid unnecessary strain on any one section.

Next up: pay attention to torque specifications when tightening your electrical clamp connections; over-tightening can cause damage while under-tightening may result in slippage or movement over time. It's also wise to periodically inspect your installed grips and adjust as needed since environmental factors may influence how well they hold up over extended periods. With these tips in mind, you'll be well-equipped to successfully install your chosen preformed suspension clamp!

The Role of Spark Fittings in Suspension Clamps

When it comes to suspension clamps, Spark Fittings plays a crucial role in enhancing performance and reliability. Their products are designed to integrate seamlessly with various types of clamps, including preformed suspension clamps, ensuring that your cable with clamp setup functions optimally. This section will delve into the offerings from Spark Fittings, focusing on their innovative solutions for electrical systems.

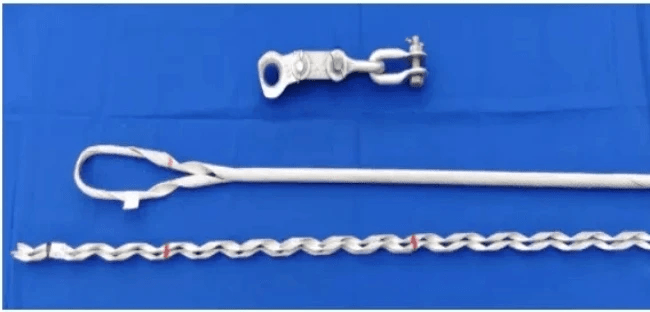

Overview of Spark Fittings Products

Spark Fittings offers a diverse range of products tailored for use with suspension clamps and electrical applications. Their lineup includes high-quality preformed suspension clamps, grip cables, and specialized wire clamps designed to meet rigorous industry standards. By providing various options like custom armor rods and innovative designs, Spark Fittings ensures that every installation is both secure and efficient.

Advantages of Custom Armor Rods

One standout feature of Spark Fittings is their custom armor rods that enhance the integrity of cable systems. These rods provide additional support and protection for cables under tension, reducing the risk of damage or failure during operation. With a well-designed armor rod in place alongside your cable clamp or wire with clamp setup, you can rest assured that your electrical components are safeguarded against environmental stresses.

Color Coding for Easy Identification

Navigating the world of electrical components can sometimes feel like deciphering a secret code; however, Spark Fittings simplifies this process with effective color coding strategies. Each type of clamp or fitting is often color-coded to ensure quick identification during installation or maintenance tasks—making it easier to select the right cable clamp or grip cable for your needs at a glance. This thoughtful design feature not only saves time but also minimizes errors when working on complex electrical systems.

Evaluating Options for Cable and Wire Clamps

When it comes to selecting the right cable and wire clamps, the choices can feel overwhelming. With various options like preformed suspension clamps, grip cables, and standard clamps available, it's essential to evaluate their unique features and benefits. Understanding your specific needs will help you make an informed decision that enhances both safety and performance.

How to Choose Between Cable Clamps

Choosing between cable clamps involves assessing several factors that align with your project requirements. First, consider the type of cable with clamp you are using; different cables may require specific clamp styles for optimal support. Additionally, think about the environment where the electrical clamp will be installed—will it face moisture, extreme temperatures, or corrosive elements?

Load capacity is another critical factor; ensure that the selected clamp can handle the weight of your wire with clamp without compromising safety. Lastly, don’t forget to look at installation ease; some clamps are designed for quick setup while others may require more complex mounting procedures.

Grip Cable and Wire Clamp Comparisons

When comparing grip cable options against traditional wire clamps, it's crucial to focus on their gripping mechanisms and overall reliability. Grip cables often provide superior holding power due to their design which minimizes slippage under load conditions. In contrast, standard wire clamps might offer a more straightforward installation but could lack the same level of security in demanding environments.

Another aspect worth considering is versatility; some preformed suspension clamps are designed to accommodate multiple sizes of cables or wires while maintaining a secure fit. This adaptability can be a game-changer in projects where cable types may vary over time or across different installations.

Best Practices for Installation

To ensure optimal performance from your chosen cable clamp—be it a preformed suspension clamp or a standard grip cable—following best practices during installation is vital. Always refer to manufacturer guidelines for specific instructions related to load limits and environmental conditions when installing your electrical clamp.

It's also wise to inspect all components before installation; damaged or worn parts can lead to failure down the line. Finally, after securing your cables with the appropriate clamps, perform regular maintenance checks as part of your routine inspections—this proactive approach helps catch any potential issues before they escalate into costly problems.

Conclusion

In wrapping up our exploration of suspension clamps, it’s clear that making an informed choice is crucial for ensuring the integrity and performance of your electrical systems. Whether you're considering a preformed suspension clamp or a standard cable clamp, understanding their unique features and applications can save you time and money in the long run. Remember to weigh factors like material, load capacity, and environmental resistance to find the best fit for your needs.

Recap of Suspension Clamp Selection Tips

When selecting a suspension clamp, start by identifying the specific requirements of your project. Consider whether a preformed suspension clamp or another type will best accommodate your cable with clamp needs. Don't forget to evaluate the grip cable options available to ensure optimal performance and safety for your electrical installations.

The Impact of Quality on Performance

Investing in high-quality wire clamps ensures that they can withstand environmental stresses while maintaining strong grip capabilities under various loads. Ultimately, choosing top-notch electrical clamps translates into enhanced reliability and longevity for your wiring systems.

Next Steps for Choosing Your Clamp

Now that you’re equipped with essential knowledge about different types of clamps—be it a cable clamp or wire with clamp—it's time to take action! Start by assessing your specific application needs and reviewing various options available in the market, including preformed suspension clamps tailored for unique setups. Don’t hesitate to consult product specifications or seek expert advice if you’re uncertain; after all, the right choice today will pay dividends down the road.