Introduction

In the intricate world of power grids, small components play a monumental role in ensuring efficiency and reliability. These seemingly insignificant parts, such as the y clevis eye, are essential for maintaining the structural integrity and functionality of electrical systems. Understanding their importance is crucial for anyone involved in power distribution, as these components often make the difference between a reliable service and unexpected outages.

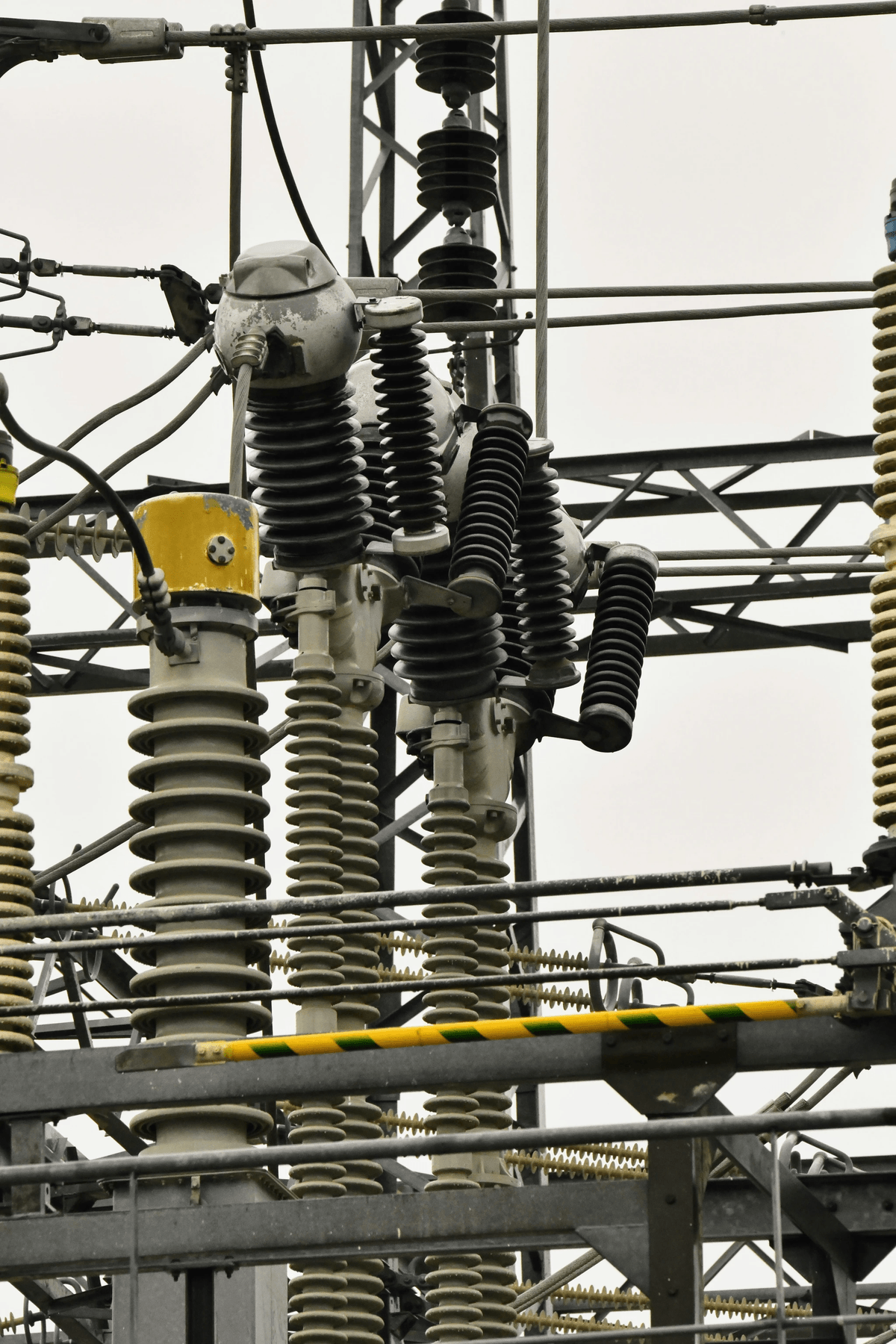

Importance of Small Components in Power Grids

Small components might not grab headlines, but they are the unsung heroes of power grids. They work quietly behind the scenes to support larger structures and facilitate smooth operations. The y clevis eye exemplifies this notion; it may be small in size but is pivotal in connecting conductors and ensuring that everything stays securely in place.

The Role of the Y Clevis Eye

The y clevis eye serves as a critical connection point within power distribution systems, allowing for effective load transfer while minimizing stress on cables and other components. Its design enables it to accommodate various conductor sizes, making it a versatile choice for many applications. Moreover, innovations like the Hot Line Y-Clevis Oval-Eye enhance its functionality by allowing maintenance without de-energizing lines—a game-changer for utility companies.

Overview of Spark Fittings' Expertise

With years of experience under their belt, they specialize in producing fittings that meet rigorous standards for reliability and performance. Their commitment to excellence ensures that every Hot Line Y-Clevis Oval-Eye they manufacture contributes significantly to enhancing overall system integrity.

Understanding the Y Clevis Eye

The Y Clevis Eye is a small yet crucial component in power distribution systems, often overlooked but essential for maintaining the integrity of electrical connections. This cleverly designed fitting serves multiple functions, primarily connecting conductors to poles or other structures securely. Its unique shape allows for flexibility and strength, making it a favorite among utility companies and contractors alike.

Definition and Functionality

At its core, the Y Clevis Eye is a connector that provides a reliable link between various components of power distribution networks. It features a Y shape that allows it to accommodate different angles and positions, ensuring optimal alignment of conductors during installation. This functionality is particularly important in high-voltage applications where stability and safety are paramount; any failure in this connection could lead to catastrophic results.

Materials Used in Manufacturing

Manufacturers typically utilize robust materials such as aluminum or stainless steel for the construction of the Y Clevis Eye to withstand harsh environmental conditions. These materials offer excellent corrosion resistance and durability, essential traits for components subjected to outdoor elements like rain, wind, or extreme temperatures. The use of high-quality materials ensures that the Hot Line Y-Clevis Oval-Eye maintains its structural integrity over time, minimizing maintenance needs and enhancing reliability.

Applications in Power Distribution

The applications of the Y Clevis Eye are vast within power distribution systems; it plays an integral role in overhead line construction, especially where tensioning is required. Utility companies rely on this component for connecting conductors to insulators or cross-arms on poles, facilitating efficient energy transmission across long distances. Additionally, its compatibility with various conductor types makes it versatile enough for use in both urban and rural settings—making sure that electricity reaches every corner efficiently.

The Benefits of Hot Line Y-Clevis Oval-Eye

This small yet mighty fitting plays a significant role in enhancing the reliability of power distribution networks. Its design and functionality are tailored to meet the demanding needs of modern electrical infrastructure, making it an indispensable asset for utility companies.

Enhanced Reliability in Power Systems

The reliability of power systems hinges on the quality and durability of their components, and this is where the y clevis eye shines. Constructed with robust materials, the Hot Line Y-Clevis Oval-Eye can withstand extreme weather conditions and mechanical stress, ensuring uninterrupted service. By minimizing failure rates and extending service life, this fitting contributes significantly to overall system reliability.

Additionally, because it is designed for hot line work—meaning it can be installed on live lines without de-energizing circuits—the y clevis eye enhances operational efficiency. Utility workers can perform maintenance or upgrades without disrupting service to customers, which is a win-win situation for everyone involved. In an industry where downtime can lead to substantial economic losses and customer dissatisfaction, having reliable components like the Hot Line Y-Clevis Oval-Eye is essential.

Compatibility with Various Conductors

One of the standout features of the y clevis eye is its versatility in compatibility with various conductor types. Whether dealing with aluminum or copper conductors, this fitting adapts seamlessly to different applications within power distribution systems. This flexibility not only simplifies inventory management but also reduces costs associated with sourcing multiple specialized fittings.

Moreover, its universal design allows for easy integration into existing systems without requiring extensive modifications or additional equipment. This compatibility ensures that utility companies can streamline their operations while maintaining high safety standards across diverse installations. Ultimately, this makes the Hot Line Y-Clevis Oval-Eye an attractive option for utilities looking to enhance their infrastructure efficiently.

Ease of Installation and Maintenance

Installation should never feel like rocket science—and with the y clevis eye, it’s anything but! The Hot Line Y-Clevis Oval-Eye is designed for straightforward installation processes that save time and labor costs on-site. With user-friendly features that accommodate both experienced technicians and newcomers alike, this fitting allows utility workers to focus on what really matters: keeping power flowing smoothly.

Maintenance becomes equally effortless thanks to its durable construction that minimizes wear over time—less frequent replacements mean less hassle in managing inventory or scheduling repairs! Additionally, regular inspections are uncomplicated due to its accessible design; any signs of wear can be quickly identified before they escalate into larger issues. In short, when you choose a y clevis eye like the Hot Line Y-Clevis Oval-Eye, you’re investing in not just reliability but also ease-of-use throughout its lifecycle.

Spark Fittings: A Leader in the Industry

With a strong commitment to quality and innovation, they offer a wide range of products designed to enhance the reliability and efficiency of power grids. Among their notable offerings are the Y Clevis Eye and Hot Line Y-Clevis Oval-Eye, which are essential for ensuring robust connections in electrical systems.

Overview of Spark Fittings' Offerings

Spark Fittings provides an impressive array of components tailored for power distribution needs, including various fittings, connectors, and insulators. Their expertise is particularly evident in the design and manufacturing of Y Clevis Eyes and Hot Line Y-Clevis Oval-Eyes, which facilitate secure connections between conductors and structures. By focusing on advanced engineering practices and high-quality materials, Spark Fittings ensures that their products meet rigorous industry standards.

Importance of Quality in Armor Rod ProductionSpark Fittings utilizes state-of-the-art manufacturing techniques to create armor rods that not only withstand harsh environmental conditions but also enhance the longevity of power systems. The incorporation of premium materials ensures that every Y Clevis Eye or Hot Line Y-Clevis Oval-Eye maintains structural integrity under stress, thereby contributing to overall grid reliability.

Custom Solutions for Unique Needs

Understanding that each project has its unique requirements, Spark Fittings offers custom solutions tailored to specific applications in power distribution networks. Whether it's modifying a standard design or developing entirely new components like specialized Y Clevis Eyes or Hot Line Y-Clevis Oval-Eyes, their team works closely with clients to deliver optimal results. This flexibility allows them to address diverse challenges while ensuring that quality remains uncompromised.

Armor Rod Materials: Why They Matter

Armor rods protect conductors from wear and tear, ensuring that vital connections remain intact under various conditions. Selecting the right material not only enhances performance but also contributes to the overall efficiency of systems that utilize components like the Y clevis eye and Hot Line Y-Clevis Oval-Eye.

Choosing the Right Armor Rod Material

Choosing the right armor rod material can significantly impact a power distribution system's effectiveness. Common materials include fiberglass, aluminum, and composite options, each offering unique benefits tailored to specific environments and applications. For instance, fiberglass provides excellent electrical insulation properties while being lightweight—ideal for installations involving Hot Line Y-Clevis Oval-Eyes where weight can be a concern.

The decision often hinges on factors such as mechanical strength, thermal resistance, and environmental exposure. For example, in coastal areas where saltwater corrosion is prevalent, opting for corrosion-resistant materials can prolong service life significantly. Ultimately, understanding how different materials interact with components like the Y clevis eye helps ensure that power distribution remains uninterrupted.

Avoiding Corrosion: Key Considerations

Corrosion poses one of the most significant threats to armor rods in power grid applications, making it essential to consider protective measures during material selection. Using corrosion-resistant alloys or applying protective coatings can mitigate this risk effectively. When selecting an armor rod suitable for use with a Y clevis eye or Hot Line Y-Clevis Oval-Eye assembly, it's vital to prioritize materials designed specifically to withstand harsh environmental conditions.

Regular maintenance checks are also critical in ensuring that any signs of corrosion are addressed before they lead to failures in power distribution systems. Additionally, utilizing compatible fittings can help minimize contact points where moisture might accumulate—further reducing corrosion risks over time. By taking these steps seriously during installation and maintenance phases, operators can safeguard their assets against premature degradation.

Color Coding for Easy Identification

Color coding armor rods is not just about aesthetics; it plays a vital role in operational efficiency and safety within electrical infrastructure. Different colors signify various specifications or functions of armor rods used with components like the Y clevis eye or Hot Line Y-Clevis Oval-Eye assemblies—making identification quick and intuitive for technicians on-site. This visual cue helps streamline maintenance processes by allowing workers to quickly locate appropriate replacements without confusion.

Moreover, color-coded systems contribute significantly to reducing errors during installation or repairs—ensuring that each component fits its intended purpose seamlessly within a larger network of power distribution elements. This practice fosters an environment where safety becomes paramount; technicians easily recognize potential mismatches before they escalate into more serious issues down the line. Therefore, adopting color coding as part of standard operating procedures is not just smart; it's essential for maintaining reliable operations in modern power grids.

The Future of Power Grid Components

The future of power grid components is bright, with advancements poised to reshape how we think about reliability and efficiency. As technology evolves, the integration of innovative materials and designs, particularly in small components like the Y Clevis Eye and Hot Line Y-Clevis Oval-Eye, will play a crucial role. These innovations not only enhance performance but also ensure that power distribution systems can meet the demands of a growing population.

Innovation in Power Distribution Technology

Innovation is at the forefront of transforming power distribution technology. New materials and designs are being developed to improve the functionality and longevity of essential components such as the Y Clevis Eye. This evolution helps utilities respond more adeptly to challenges like increased energy demand and extreme weather conditions, ensuring that systems remain operational when they are needed most.

The introduction of smart technologies into power grids also enhances monitoring capabilities for components like Hot Line Y-Clevis Oval-Eye fittings. These advancements allow for real-time data collection on component performance, leading to proactive maintenance strategies that reduce downtime. Ultimately, innovation in this sector focuses on creating a more resilient electrical infrastructure that can adapt to changing energy landscapes.

The Evolving Role of Small Components

Small components might not always steal the spotlight, but their role in power distribution is becoming increasingly significant as systems grow more complex. The Y Clevis Eye and similar fittings are vital for maintaining structural integrity while allowing flexibility in installation techniques across various applications. As we embrace modular designs in power grids, these small yet mighty elements will be critical for ensuring seamless connectivity.

Moreover, with advancements in manufacturing processes, small components like the Hot Line Y-Clevis Oval-Eye are now produced with enhanced precision and durability. This evolution means that utilities can rely on these fittings to perform under greater stress while minimizing wear over time. Consequently, their importance will only increase as we strive for efficiency and reliability in our electrical infrastructure.

Sustainability in Electrical Infrastructure

Sustainability is no longer just a buzzword; it’s an imperative driving change within electrical infrastructure development today. The focus on eco-friendly materials extends even to small components such as the Y Clevis Eye and Hot Line Y-Clevis Oval-Eye fittings—ensuring they contribute positively to environmental goals rather than detracting from them. By choosing sustainable materials and production methods, manufacturers can reduce waste while delivering high-performance products.

As regulations become stricter concerning environmental impact, there’s a push towards integrating renewable energy sources into existing grids—making reliable connections through quality small components paramount for success. The future holds promise for innovations aimed at reducing carbon footprints across all aspects of electrical infrastructure development by prioritizing sustainability without compromising performance or safety standards.

In conclusion, focusing on innovation within small component design not only enhances their functionality but also aligns with broader sustainability goals essential for modern society's needs.

Conclusion

In the realm of power distribution, the Y Clevis Eye emerges as a small but mighty component, pivotal in ensuring the seamless operation of power grids. Its design and functionality directly contribute to the reliability and efficiency of electrical systems, reinforcing its vital role in modern infrastructure. As we look toward a future that demands more from our energy networks, components like the Hot Line Y-Clevis Oval-Eye will continue to play an indispensable part.

The Vital Role of Y Clevis Eye

The Y Clevis Eye is not just another piece of hardware; it’s a linchpin in maintaining structural integrity within power distribution networks. By providing secure connections for conductors, this component minimizes risks associated with electrical failures and enhances overall system performance. Without the reliable functionality of products like the Hot Line Y-Clevis Oval-Eye, our ability to deliver consistent energy would be significantly compromised.

Spark Fittings’ Commitment to Quality

At Spark Fittings, quality isn’t merely a goal; it’s a guiding principle that permeates every aspect of production. The company prides itself on crafting durable products that withstand harsh conditions while ensuring optimal performance—qualities exemplified by their line of Y Clevis Eyes and Hot Line Y-Clevis Oval-Eyes. With rigorous testing and adherence to industry standards, Spark Fittings guarantees that each component meets or exceeds expectations, solidifying their reputation as leaders in the field.

Enhancing Power Grid Reliability Today

Today’s energy landscape is evolving rapidly, demanding components that not only meet current needs but also anticipate future challenges. The integration of innovative designs like the Hot Line Y-Clevis Oval-Eye into power systems enhances reliability while simplifying installation processes for technicians on-site. As we strive for greater efficiency and sustainability within our electrical infrastructure, embracing quality components such as the Y Clevis Eye becomes essential for building resilient power grids.