Introduction

In the world of electrical systems, the significance of choosing the right components cannot be overstated. One such crucial component is the cable clamp connector, which plays a vital role in ensuring secure and reliable connections. Understanding what a cable clamp is and its importance can make all the difference in your electrical projects.

What is a Clamp Type Connector

A clamp type connector, often referred to as a cable clamp connector, is designed to hold cables securely in place while providing an electrical connection. These connectors are essential for maintaining the integrity of electrical circuits, preventing wear and tear over time. They come in various designs tailored for specific applications, making them versatile tools in any electrician's toolkit.

Importance of Choosing Quality Connectors

High-quality cable connectors ensure optimal performance and safety, reducing the risk of failures that could lead to costly repairs or even hazardous situations. By investing in reliable wire connector types, you not only enhance your system's efficiency but also extend its lifespan.

Overview of Spark Fittings

Enter Spark Fittings—a leader in providing innovative solutions for cable accessories including top-notch cable clamp connectors. Their commitment to quality means that each product undergoes rigorous testing before reaching consumers, ensuring reliability and performance are at the forefront. With custom solutions available, Spark Fittings stands out as a go-to choice for those seeking superior electrical wire connectors tailored to their specific needs.

Understanding Cable Clamp Connectors

Cable clamp connectors are essential components in electrical systems, providing stability and security for various wire configurations. These connectors serve to hold cables firmly in place, preventing movement that could lead to wear or damage over time. By ensuring a reliable connection, cable clamp connectors play a pivotal role in maintaining the integrity of electrical systems.

Definition and Function

A cable clamp connector is designed specifically to secure cables and wires, ensuring they remain connected without risk of disconnection or damage. The primary function of these connectors is to provide mechanical support while also safeguarding electrical connections from environmental factors like moisture and vibration. In essence, cable clamps act as the unsung heroes in the world of electrical connectors, holding everything together so you can focus on more important tasks.

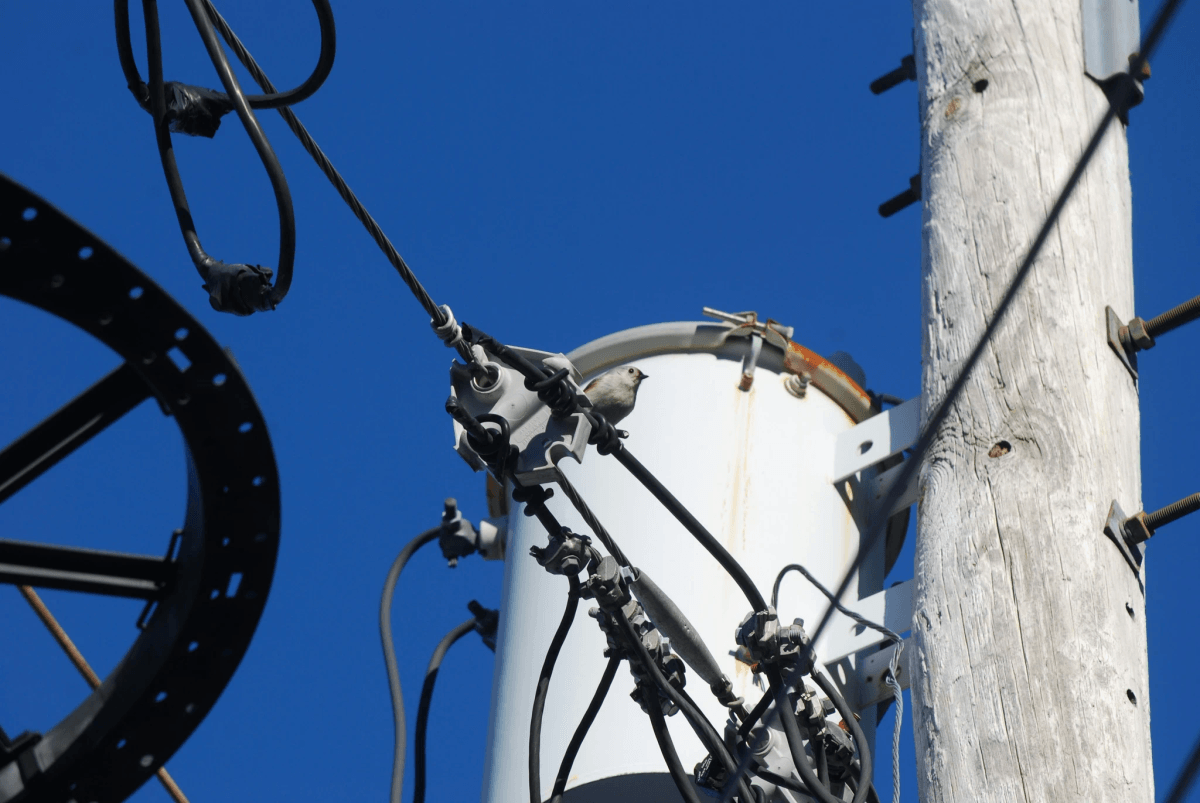

Applications in Electrical Systems

Cable clamp connectors find their place in a variety of applications within electrical systems, ranging from residential wiring to industrial machinery. They are commonly used in power distribution panels, automotive wiring harnesses, and even outdoor lighting setups where stability is crucial. Their versatility makes them indispensable across multiple sectors where reliable electrical connections are needed.

Advantages of Using Cable Clamp Connectors

Using cable clamp connectors offers numerous advantages that can enhance the performance and longevity of your electrical systems. First off, they provide excellent strain relief which minimizes the risk of wire fatigue due to movement or tension over time. Additionally, quality cable clamps can improve safety by reducing the chances of short circuits caused by loose wires—because nobody wants a surprise zap when flipping a switch!

Exploring Wire Connector Types

Understanding the various cable connectors available is essential for ensuring safety and reliability in your projects. This section will delve into common types of cable connectors, highlight their differences, and help you select the best option for your specific needs.

Common Types of Cable Connectors

Cable connectors come in various forms, each designed for specific applications and environments. Among the most widely used are butt connectors, spade connectors, and ring terminals. Each type serves a unique purpose in connecting wires, ensuring that electrical currents flow smoothly while maintaining a secure connection.

Butt connectors are typically used to join two wires end-to-end, making them ideal for extending cable lengths without compromising integrity. Spade connectors allow for quick disconnection and reconnection of wires, which is particularly useful in applications requiring frequent maintenance or adjustments. Ring terminals provide a solid connection to screws or studs, making them perfect for grounding applications or where a secure attachment is critical.

Differences Between Wire Connectors

Understanding the differences between wire connector types is crucial when selecting the appropriate cable clamp connector for your project. One key distinction lies in their design; some are insulated while others are not, impacting their suitability for different environments. Additionally, wire gauge compatibility varies among connector types—using an incompatible connector can lead to overheating or failure.

Another factor to consider is how each type handles mechanical stress and vibration; some connectors may be more robust than others depending on their construction materials and design features. Moreover, ease of installation can differ significantly: some wire clamp options require specialized tools while others can be easily crimped by hand. Making an informed choice based on these differences will ensure optimal performance in your electrical system.

Selecting the Right Connector for Your Needs

Choosing the right cable clamp or electrical wire connector involves evaluating several factors tailored to your specific application requirements. Start by assessing the voltage and current ratings of your system; ensure that any selected cable connectors meet or exceed these specifications to avoid potential failures down the line.

Next, consider environmental factors such as temperature extremes or exposure to moisture—some wire connector types may offer better resistance against corrosion or degradation than others. Lastly, think about future needs: if you anticipate modifications or upgrades to your system later on, opt for versatile connectors that allow easy adjustments without requiring complete overhauls.

The Role of Electrical Connectors

Importance in Power Transmission

In power transmission, electrical connectors are indispensable for maintaining a reliable flow of electricity. They facilitate connections between wires, cables, and devices, ensuring that energy reaches its destination without interruption. A well-chosen wire connector type can significantly enhance system performance while reducing risks associated with electrical failures.

Moreover, using high-quality electrical wire connectors is essential for minimizing energy loss and preventing overheating. Poor connections can lead to increased resistance and heat generation, which may result in equipment damage or even fire hazards. Therefore, investing in quality cable clamp solutions is not just a matter of convenience; it’s a critical safety measure.

Types of Electrical Wire Connectors

When it comes to selecting the right electrical wire connectors, there are several options available that cater to different needs and applications. Common wire connector types include twist-on wire connectors, crimp connectors, and terminal blocks—each designed for specific functions within an electrical system. Understanding these distinctions helps ensure you choose the most suitable cable clamp or other cable connectors for your project.

Twist-on wire connectors are ideal for quick installations and repairs because they allow multiple wires to be joined easily without special tools. Crimp connectors provide a more permanent solution by creating a secure bond when compressed around wires using crimping tools. Terminal blocks offer flexibility by allowing multiple connections in one compact unit; this versatility is invaluable when managing complex wiring systems.

Enhancing Safety with Quality Connectors

Safety should always be at the forefront when dealing with any form of electrical installation or maintenance work—especially regarding cable clamps and other electrical connectors. High-quality products reduce risks associated with poor connectivity that can lead to shorts or fires due to excessive heat buildup from inadequate contact points. By utilizing reliable cable clamp solutions and robust wire connector types, you create safer environments both at home and in industrial settings.

Additionally, regular inspections of your cable wire setups play an essential role in maintaining safety standards over time. Checking for signs of wear or corrosion on your electrical wire connectors ensures that any potential issues are addressed before they escalate into serious problems. Ultimately, prioritizing quality in your choice of cable clamps not only enhances performance but also protects lives and property.

Spark Fittings: Innovators in Cable Accessories

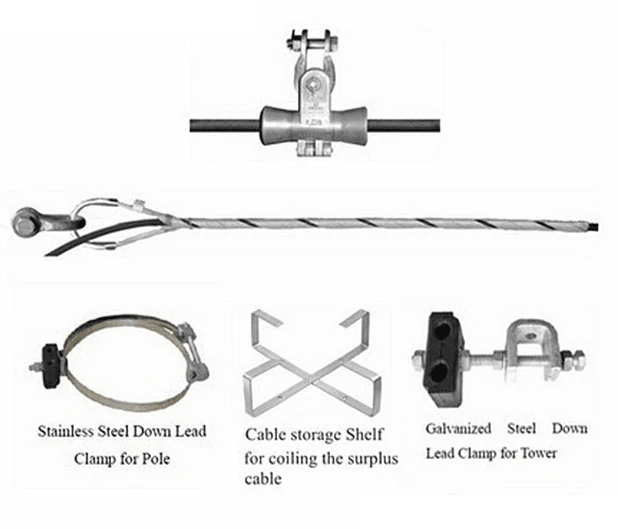

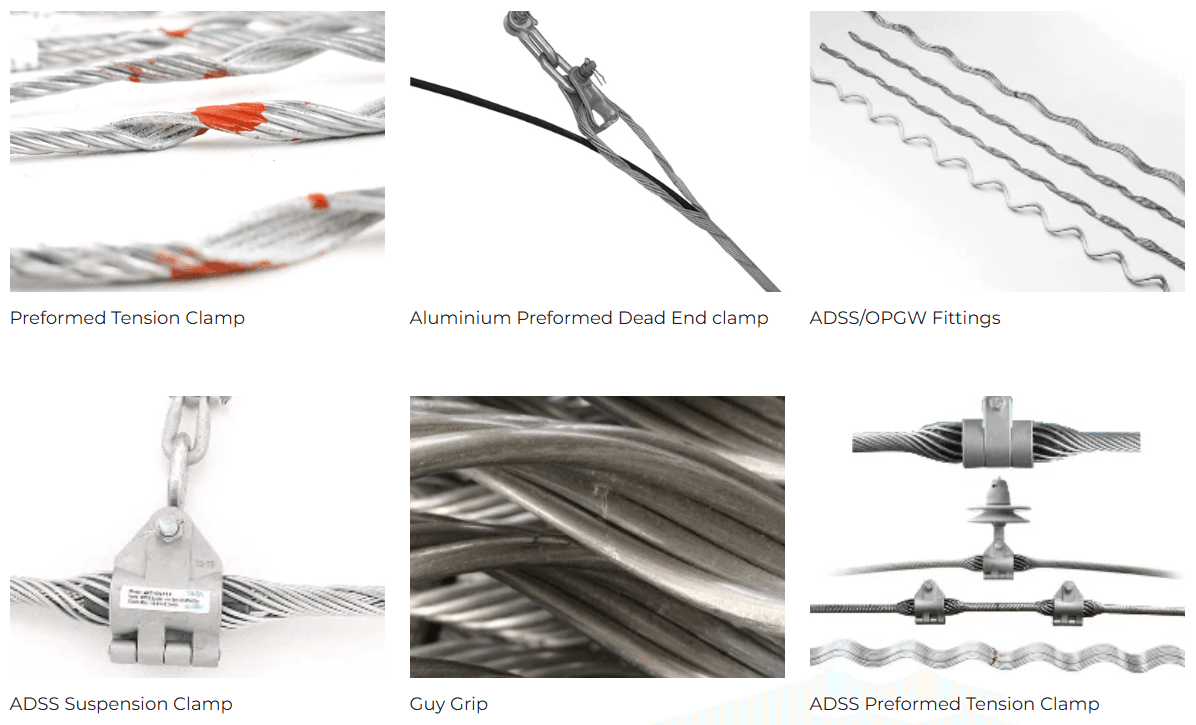

Overview of Spark Fittings' Products

Spark Fittings offers an impressive lineup of products tailored for both commercial and residential applications. Their selection features high-quality cable clamp connectors that ensure secure connections while minimizing the risk of damage to your cables. Additionally, their extensive range includes different wire connector types that cater to various installation requirements, making them a one-stop shop for all your cable connector needs.

The product offerings from Spark Fittings also encompass specialized electrical connectors designed for optimal power transmission and safety. Whether you're looking for robust cable clamps or versatile electrical wire connectors, you can trust that Spark Fittings has something in their catalog to suit your specific requirements. This commitment to providing comprehensive solutions underscores their status as innovators in the field.

How Spark Fittings Ensures Quality

Quality is at the forefront of everything Spark Fittings does; they understand that using subpar components can lead to costly failures down the line. Each cable clamp connector undergoes rigorous testing and quality control measures to ensure compliance with industry standards before it reaches consumers. By utilizing premium materials and advanced manufacturing processes, they guarantee that their cable connectors offer not only durability but also superior performance.

Furthermore, Spark Fittings invests in continuous improvement practices to keep pace with technological advancements in the industry. They actively seek feedback from customers and incorporate it into their product development cycle, ensuring that each new iteration meets or exceeds user expectations for reliability and functionality. This dedication makes them a trusted name when selecting electrical wire connectors for any project.

Custom Solutions in Cable Clamp Technology

Recognizing that one size doesn't fit all, Spark Fittings excels at providing custom solutions tailored to unique customer needs within the realm of cable clamps and connectors. Their team works closely with clients to develop specialized products that address specific challenges faced during installation or operation of electrical systems. This collaborative approach ensures that every solution is practical while maintaining high standards for safety and efficiency.

Whether you require bespoke designs or adaptations of existing products like wire clamps or other types of electrical connections, Spark Fittings is prepared to deliver innovative solutions without compromising on quality. Their commitment extends beyond just selling standard items; they aim to create lasting partnerships by addressing individual requirements effectively through customization options available in their extensive product lineup.

Installation Best Practices for Wire Clamps

Installing a cable clamp connector correctly is essential for ensuring the longevity and reliability of your electrical connections. A proper installation not only enhances performance but also minimizes risks associated with loose or faulty connections. In this section, we will guide you through the best practices for installing wire clamps effectively.

Step-by-Step Installation Guide

1. **Preparation**: Before diving into the installation, gather all necessary tools and materials, including your cable connectors, wire clamps, and any other required hardware. Make sure to turn off power to the circuit you’ll be working on to ensure safety.

2. **Select the Right Cable Clamp**: Choose a cable clamp that fits the diameter of your cables snugly without being too tight. The right size will ensure that your electrical connectors maintain a secure grip on the wires.

3. **Secure the Cable**: Position your cable in the clamp and tighten it according to manufacturer instructions. Be cautious not to overtighten, as this can damage both the wire and connector.

4. **Check Connections**: After securing everything, inspect all connections to ensure they are tight and properly seated in their respective electrical wire connectors.

5. **Test Your Setup**: Once installed, restore power and test your setup with a multimeter or similar tool to verify that everything is functioning correctly.

By following these steps carefully, you can ensure that your cable clamp installations are safe and effective.

Common Mistakes to Avoid

Even seasoned professionals can make mistakes when installing wire connector types such as cable clamps; however, avoiding common pitfalls can save time and resources later on. One frequent error is using incompatible sizes of cable clamps; always match clamp sizes with cables for optimal performance.

Another common mistake is neglecting proper torque specifications when tightening clamps; over-tightening can lead to damaged wires or connectors while under-tightening may result in loose connections that compromise safety and efficiency.

Additionally, failing to properly route cables during installation often leads to tangling or stress on connections over time—this can cause premature failure of both electrical connectors and cables themselves.

Maintaining Your Cable Wire Setup

Regular maintenance of your cable wire setup ensures long-lasting performance from both wire clamps and electrical connectors alike. Start by routinely inspecting all visible wiring for signs of wear or damage; frayed wires should be replaced immediately as they pose serious safety hazards.

Keep an eye out for any signs of corrosion around metal parts of your cable clamp connector; if found, clean them promptly with appropriate cleaning solutions designed for electrical contacts—this will help maintain conductivity over time.

Lastly, remember that environmental factors like humidity or extreme temperatures can affect connection integrity; therefore, consider shielding exposed wires with protective conduits where necessary to prolong their lifespan against wear from external elements.

Conclusion

In conclusion, the significance of using a proper cable clamp connector cannot be overstated. These connectors play a vital role in ensuring the safety, reliability, and efficiency of electrical systems. By selecting high-quality cable connectors, users can prevent potential hazards and enhance the overall performance of their setups.

Benefits of Proper Cable Clamp Use

Proper use of cable clamps offers numerous benefits that extend beyond mere aesthetics. First and foremost, they provide secure connections that minimize the risk of electrical failures or short circuits in your system. Additionally, utilizing quality wire connector types can improve longevity and reduce maintenance costs over time, making them an essential component for any electrical project.

Moreover, effective cable clamp solutions contribute to better organization within your wiring setup. By keeping cables neatly secured and organized, you can avoid confusion during maintenance or upgrades while also reducing wear on the wires themselves. In essence, investing in reliable cable clamps is an investment in safety and efficiency.

Why Choose Spark Fittings for Your Needs

When it comes to selecting a provider for your electrical connectors, Spark Fittings stands out as a top choice for several reasons. Their commitment to quality ensures that every cable clamp connector meets rigorous industry standards while also offering innovative designs tailored to diverse applications. With a wide range of options available among their wire connector types, customers can find exactly what they need for any project.

Furthermore, Spark Fittings emphasizes customer satisfaction by providing exceptional support throughout the purchasing process and beyond. Their knowledgeable team is always available to assist with questions or custom solutions tailored specifically to your needs. Choosing Spark Fittings means choosing reliability and expertise in every aspect of your electrical projects.

Future Trends in Electrical Connectors

As technology continues to evolve at an astonishing pace, so too do trends within the realm of electrical connectors. One notable trend is the increasing integration of smart technology into traditional wire clamps and other connectors—allowing for real-time monitoring and improved performance analytics across various applications. This innovation will not only enhance safety but also streamline maintenance efforts significantly.

Moreover, sustainability is becoming paramount as manufacturers explore eco-friendly materials for their cable wire products without compromising on quality or durability. As we look ahead, expect advancements that focus on both functionality and environmental responsibility from leading brands like Spark Fittings. The future promises exciting developments that will undoubtedly shape how we think about electrical wire connectors today.