Introduction

In the world of manufacturing and assembly, chamfering machines play a pivotal role in enhancing the efficiency and quality of production processes. These machines are designed to create beveled edges on materials, which not only improves their aesthetic appeal but also ensures better fitment and safety in various applications. With the increasing demand for precision engineering, the significance of high-quality chamfering machines cannot be overstated.

Importance of Chamfering Machines

Chamfering machines are essential tools in numerous industries, including automotive, aerospace, and construction. They facilitate the smooth finishing of edges on components, preventing potential injuries during handling and installation. Furthermore, a well-executed chamfer can significantly improve the assembly process by ensuring that parts fit together seamlessly.

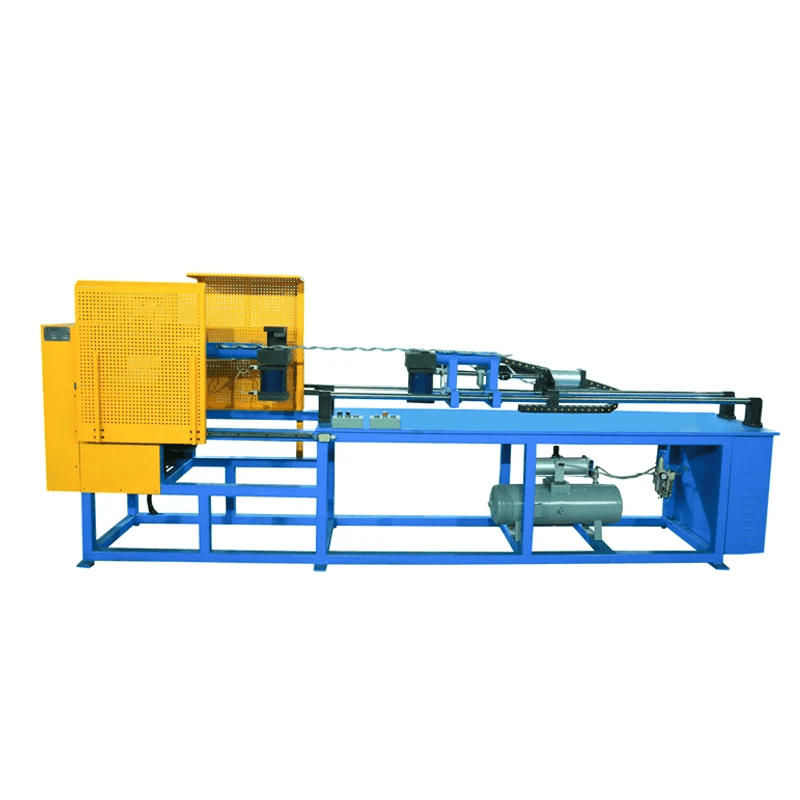

Key Features of Armor Rod Machines

Armor Rod Machines are specialized equipment designed for producing preformed armor rods used in electrical applications. These machines boast advanced technology that allows for precise shaping and consistent quality across large production runs. Key features often include automated controls, adjustable settings for different rod sizes, and robust construction to handle demanding operational environments.

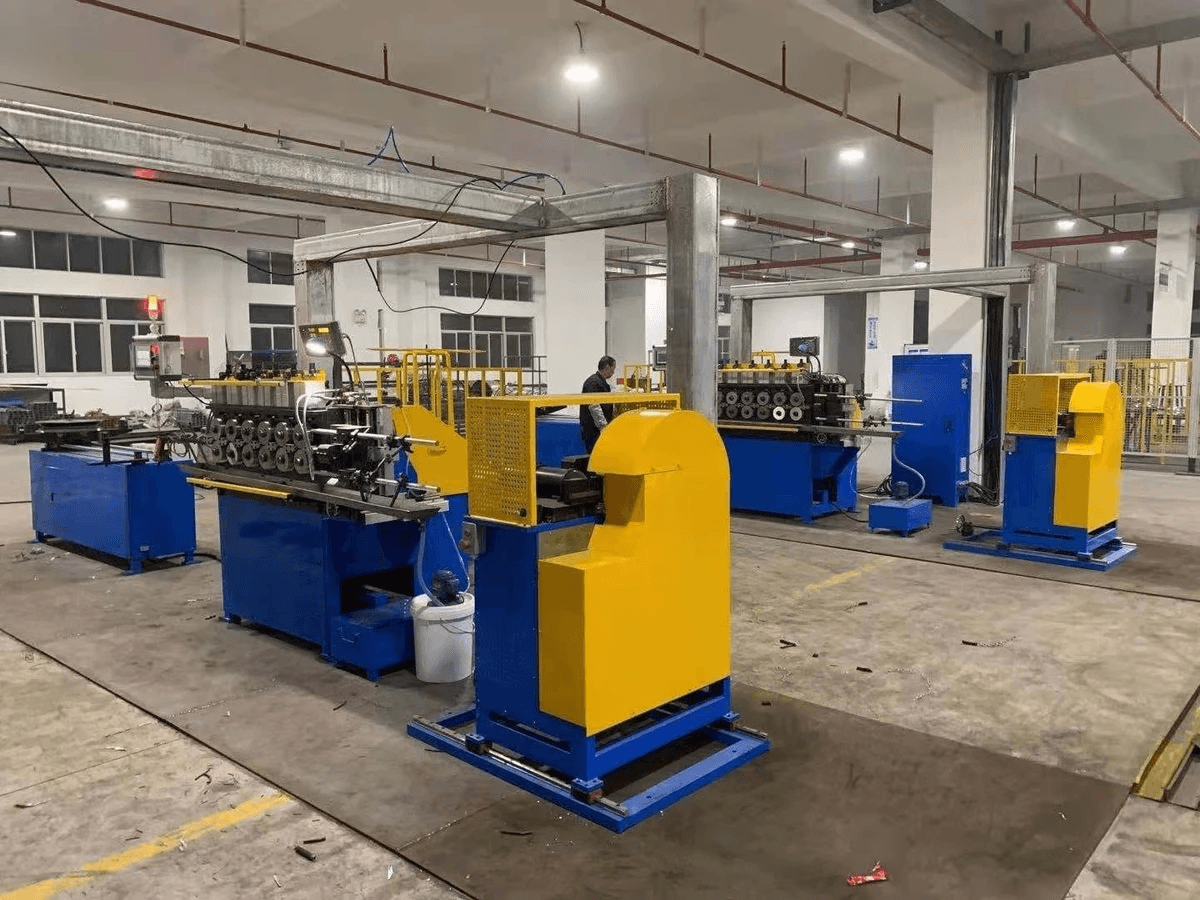

Overview of Chinese Manufacturers

China has emerged as a leading hub for manufacturing chamfering machines and Armor Rod Machines due to its vast industrial capabilities and competitive pricing. Many Chinese manufacturers offer innovative solutions that cater to both local and international markets while maintaining high standards of quality assurance. As businesses seek reliable suppliers for their chamfering needs, exploring options from Chinese manufacturers presents an opportunity to enhance production efficiency without compromising on quality.

The Role of Chamfering Machines

Chamfering machines play a crucial role in the manufacturing landscape, ensuring that components are properly finished for optimal performance. These machines are designed to create beveled edges on materials, which not only enhances aesthetics but also improves the fit and function of parts in various applications. Whether it's metal, plastic, or wood, a chamfering machine is essential for achieving precision and quality.

Definition and Purpose

At its core, a chamfering machine is engineered to remove sharp edges from workpieces by creating a sloped surface or bevel. This process reduces the risk of injury during handling and assembly while also facilitating smoother fits between connected parts. In industries where safety and efficiency are paramount, such as automotive and aerospace manufacturing, the purpose of these machines becomes even more critical.

Applications in Various Industries

Chamfering machines find their way into numerous sectors including construction, electronics, and telecommunications. For instance, in the production of Preformed Armor Rods Forming Machines used in electrical applications, chamfered edges ensure better adhesion and stability when rods are applied to cables. Moreover, industries focused on high-volume production benefit significantly from using these machines to maintain consistent quality across thousands of components.

Why Choose a Quality Supplier

Selecting a quality supplier for your chamfering machine can make all the difference in your production process. A reputable manufacturer will not only provide durable machinery but will also offer ongoing support and maintenance services that keep your operations running smoothly. By investing in high-quality equipment from trusted suppliers like those producing Armor Rod Machines or Preformed Armor Rods Forming Machines, businesses can enhance productivity while minimizing downtime caused by equipment failure.

Highlighting Top Manufacturers in China

When it comes to chamfering machines, China is home to a plethora of manufacturers pushing the envelope in innovation and efficiency. Among these, Spark Fittings stands out as a leader in providing state-of-the-art solutions tailored to meet the diverse needs of various industries. Their commitment to quality and advanced technology makes them a go-to choice for businesses looking for reliable chamfering machines and Armor Rod Machines.

Spark Fittings: Innovative Chamfering Solutions

Spark Fittings has carved a niche for itself by offering innovative chamfering machines that cater to the demanding requirements of modern manufacturing processes. Their Preformed Armor Rods Forming Machine is particularly noteworthy, designed with precision engineering that ensures optimal performance and durability. Not only do they focus on functionality, but their machines are also user-friendly, making them accessible even for those who are new to this technology.

One of the standout features of Spark Fittings’ chamfering machine lineup is their ability to adapt to various materials and production scales. Whether you’re producing small batches or large volumes, their equipment can be customized to fit your specific needs without compromising on quality or efficiency. This flexibility sets them apart in an industry where versatility often dictates success.

Additionally, Spark Fittings places a strong emphasis on customer service and support. They understand that investing in an Armor Rod Machine is not just about purchasing equipment; it's about building long-lasting partnerships that foster growth and innovation. With dedicated technical assistance and comprehensive training programs, they ensure that clients can maximize the potential of their chamfering machines right from day one.

Choosing the Right Chamfering Machine

Selecting the right chamfering machine can feel like navigating a maze, especially with so many options available on the market. It’s essential to focus on what will best meet your production needs while ensuring quality and efficiency. By understanding key factors, comparing specifications, and assessing production capacity, you can make an informed decision that enhances your operations.

Factors to Consider

When choosing a chamfering machine, several critical factors come into play. First, consider the type of materials you'll be working with; different machines excel with various materials such as metal or plastic. Additionally, evaluate the size and complexity of your projects; larger or more intricate pieces may require a more robust Armor Rod Machine or Preformed Armor Rods Forming Machine to achieve precise results.

Another factor is automation level; some machines offer advanced features like programmable settings for increased efficiency. Maintenance requirements are also vital; machines that are easier to maintain often lead to less downtime and higher productivity. Lastly, budget constraints should never be overlooked—investing in quality now can save costs in repairs and replacements later.

Comparing Specifications and Features

Once you've considered essential factors, it's time to dive into specifications and features of various chamfering machines. Look for details such as cutting speed, accuracy levels, and the range of angles that can be achieved—these aspects directly influence performance quality. The versatility of a chamfering machine is crucial; models that accommodate multiple functions are particularly advantageous for diverse production lines.

Don’t forget about ease of use! Machines equipped with user-friendly interfaces simplify training processes for operators and reduce errors during operation. Additionally, consider safety features such as emergency stop buttons or protective guards—these not only protect operators but also enhance overall workplace safety.

Efficiency and Production Capacity

Efficiency is where champions are made in any manufacturing process—and choosing the right chamfering machine plays a significant role in this equation. Assess how quickly each model can complete tasks without sacrificing quality; faster machines can lead to increased output volume over time. Moreover, look at their operational flexibility; machines capable of handling various sizes or types of workpieces tend to maximize production capacity effectively.

Production capacity isn’t just about speed—it’s also about consistency in results across batches. A reliable Armor Rod Machine designed for high-volume production ensures uniformity in preformed armor rods every time it operates. Ultimately, investing in an efficient chamfering machine today means paving the way for future growth tomorrow.

The Armor Rod Machine Advantage

In the world of electrical and telecommunications applications, the Armor Rod Machine stands out as a game-changer. These machines specialize in the production of preformed armor rods, which are essential for ensuring the durability and reliability of overhead power lines. By utilizing a chamfering machine in conjunction with the Armor Rod Machine, manufacturers can enhance their efficiency and product quality significantly.

Understanding Preformed Armor Rods

Preformed armor rods are critical components designed to protect and reinforce electrical conductors. They are typically made from high-strength materials that can withstand environmental stressors while providing excellent insulation properties. Utilizing a Preformed Armor Rods Forming Machine allows manufacturers to create these rods with precision, ensuring they meet stringent industry standards.

Benefits of Using Armor Rod Machines

Investing in an Armor Rod Machine yields numerous benefits for manufacturers looking to optimize their production processes. First and foremost, these machines increase efficiency by automating the forming process of preformed armor rods, reducing labor costs and minimizing human error. Additionally, using a chamfering machine alongside enhances the finishing touches on each rod, ensuring smooth edges that facilitate better installation.

Applications in Electrical and Telecommunications

The applications of armor rod machines extend far beyond simple cable protection; they play a vital role in various sectors within electrical and telecommunications industries. For instance, these machines are instrumental in producing components used for overhead transmission lines, where durability is paramount against harsh weather conditions. Furthermore, as telecommunications networks expand globally, reliable preformed armor rods become increasingly essential for safeguarding sensitive cables from wear and tear.

Quality Assurance and Standards

In the world of manufacturing, quality assurance is not just a buzzword; it’s a necessity that ensures the reliability and effectiveness of equipment like chamfering machines and Armor Rod Machines. These machines are critical in producing components that meet stringent industry standards, especially when it comes to applications involving Preformed Armor Rods Forming Machines. By adhering to recognized quality standards, manufacturers can assure their clients that their products will perform consistently and efficiently.

Importance of Certifications

Certifications serve as a badge of honor for manufacturers, showcasing their commitment to quality and safety. For chamfering machines and Armor Rod Machines, certifications from reputable organizations indicate compliance with international standards such as ISO or CE marking. This not only builds trust with customers but also enhances the manufacturer's reputation in a competitive market where precision is paramount.

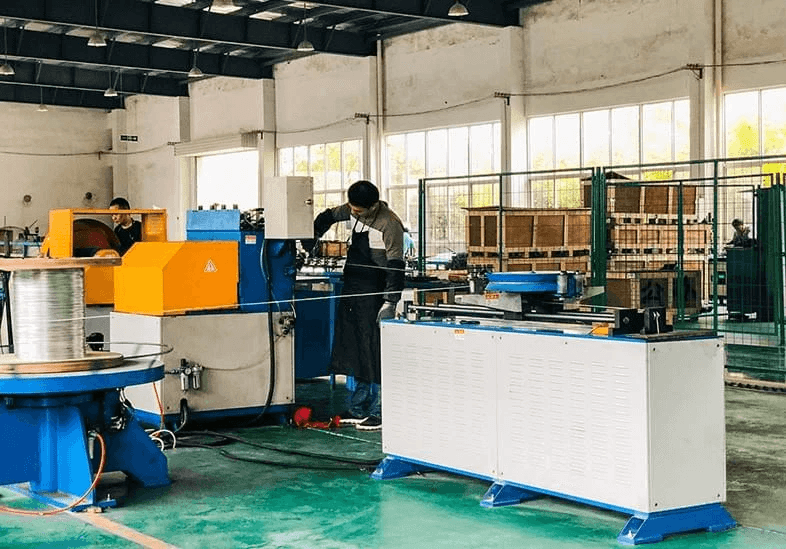

How Manufacturers Ensure Quality

To maintain high-quality production, manufacturers implement rigorous quality control processes throughout the lifecycle of chamfering machines and Armor Rod Machines. This includes sourcing high-grade materials, employing advanced manufacturing techniques, and conducting regular inspections at various stages of production. Additionally, many manufacturers invest in training programs for their workforce to ensure everyone is equipped with the skills necessary to uphold quality standards.

Testing Processes for Chamfering Machines

Before reaching the market, every chamfering machine undergoes thorough testing to ensure optimal performance and durability. These tests often include functionality assessments, stress tests on components like those used in Preformed Armor Rods Forming Machines, and simulation scenarios that mimic real-world usage conditions. By employing comprehensive testing protocols, manufacturers can identify potential issues early on, ensuring that only top-notch equipment makes it into customers’ hands.

Conclusion

In the ever-evolving world of manufacturing, the future of chamfering technology looks promising. As industries continue to demand precision and efficiency, advancements in chamfering machines will play a crucial role in meeting these needs. From enhancing production capabilities to integrating smart technologies, the landscape is set for exciting developments that will redefine how we approach metalworking and assembly processes.

The Future of Chamfering Technology

The future of chamfering machines lies in automation and smart technology integration. With Industry 4.0 on the rise, manufacturers are increasingly adopting advanced robotics and AI to streamline operations and enhance accuracy. This shift not only boosts productivity but also reduces waste, making it an essential consideration for businesses looking to stay competitive.

Moreover, innovations such as adaptive control systems will enable chamfering machines to adjust settings in real-time based on material properties and production requirements. This adaptability ensures optimal performance across various applications while significantly reducing downtime. As we look ahead, it's clear that investment in cutting-edge technology will be pivotal for manufacturers aiming to harness the full potential of their Armor Rod Machines and Preformed Armor Rods Forming Machines.

Selecting the Best Manufacturer

Choosing the right manufacturer for your chamfering machine is paramount to ensuring quality and reliability in your production line. It’s essential to research potential suppliers thoroughly—evaluate their track record, customer reviews, and product offerings before making a decision. A reputable manufacturer should not only provide high-quality machines but also offer excellent after-sales service and support.

Additionally, consider manufacturers who prioritize innovation and adhere to industry standards; this can be a strong indicator of their commitment to quality assurance. By selecting a top-tier supplier specializing in Armor Rod Machines or Preformed Armor Rods Forming Machines, you position your business for success with reliable equipment that meets your operational needs efficiently.

Maximizing Production with Effective Machines

Maximizing production efficiency requires more than just having a chamfering machine; it involves understanding how best to utilize it within your workflow. Regular maintenance is key—keeping machines well-tuned ensures they operate at peak performance while minimizing unexpected downtimes that can disrupt productivity cycles.

Training staff on effective operation techniques can also lead to significant improvements in output quality and speed when using Armor Rod Machines or other specialized equipment like Preformed Armor Rods Forming Machines. By fostering an environment where employees feel empowered to leverage these tools effectively, businesses can achieve impressive gains in both efficiency and overall production capacity.