Introduction

When it comes to ensuring the safety and integrity of overhead lines, the unsung hero is often the guy clamp. These clamping clamps play a crucial role in securing anchor guys, providing stability and support to electrical poles and communication towers. Without high-quality wire clamps, the risks associated with line hardware can increase exponentially, making it essential for professionals to understand their importance.

Discovering Guy Clamps for Safety

Guy clamps are designed specifically to secure anchor guys to utility poles or structures, preventing any undue movement that could compromise safety. The effectiveness of these clamping products hinges on their quality; a poorly made clamp can lead to catastrophic failures in line hardware systems. Therefore, understanding how guy clamps function and their applications is paramount for anyone involved in installation or maintenance.

The Role of Spark Fittings in Line Hardware

Spark Fittings stands at the forefront of innovation in line hardware solutions, specializing in high-quality guy clamps that ensure reliability and safety. Their expertise in creating durable clamping solutions has positioned them as a trusted name among contractors and utility companies alike. By focusing on advanced technologies behind clamp and bolt systems, Spark Fittings elevates industry standards while prioritizing user safety.

Why Quality Matters in Pole Line Hardware

In the world of pole line hardware, quality is not just a buzzword; it's a necessity that can mean the difference between stability and disaster. High-quality wire clamps are engineered to withstand environmental stresses, ensuring long-term performance under various conditions. Investing in reliable clamping products like those from Spark Fittings not only enhances safety but also reduces maintenance costs over time.

Understanding Guy Clamps

What is a Guy Clamp?

A guy clamp is a specialized device used to secure guy wires to poles or other structures, ensuring that everything remains firmly in place. Typically made from durable materials, these clamps can withstand various environmental conditions while providing reliable support. The importance of using a quality guy clamp cannot be overstated; it’s the unsung hero that keeps your installations safe and sound.

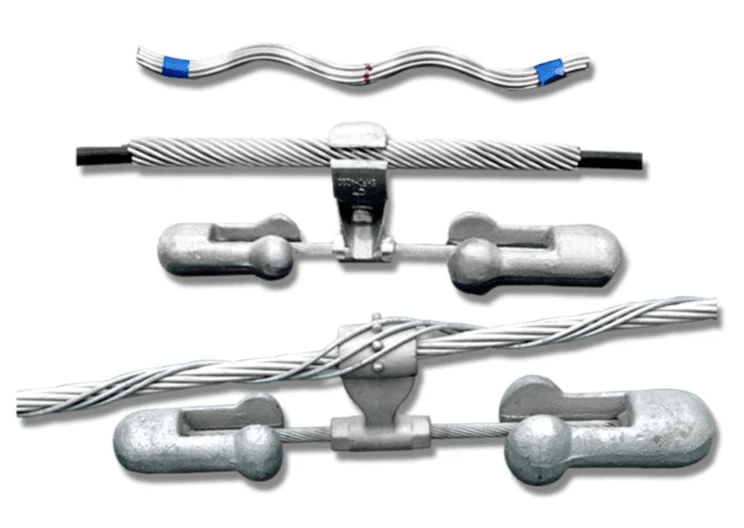

Different Types of Clamping Products

There is an array of clamping products available on the market today, each designed for specific applications and needs. From basic wire clamps to more advanced line clamps with integrated bolt-on fasteners, the options are vast. Knowing which type best suits your requirements will help ensure optimal performance and safety for your installations.

Applications of Wire Clamps in Installation

Wire clamps play a crucial role during installation processes across various industries, especially in telecommunications and power distribution. They secure anchor guys effectively, preventing unwanted movement or sagging that could jeopardize structural integrity. Whether you're working with residential lines or large-scale utility projects, utilizing high-quality wire clamps ensures that your setup remains stable over time.

Spark Fittings: Innovating Clamping Solutions

Overview of Spark Fittings’ Expertise

Spark Fittings has built a solid reputation for providing durable and effective clamping solutions tailored for various applications. Their team consists of skilled engineers and technicians who understand the intricacies of line hardware, ensuring that every wire clamp produced meets stringent quality standards. This expertise allows them to offer not just products but comprehensive solutions that enhance safety during installation and maintenance.

High-Quality Guy Clamps and Their Benefits

The guy clamps produced by Spark Fittings are engineered with precision, combining strength with ease of use. These high-quality clamping clamps provide exceptional support for anchor guys, ensuring stability even in challenging conditions. The benefits extend beyond mere functionality; using reliable wire clamps can significantly reduce the risk of accidents, making installations safer for workers on-site.

The Technology Behind Clamp and Bolt Systems

At the heart of Spark Fittings’ innovation is advanced technology that enhances the performance of clamp and bolt systems. Their designs incorporate features that optimize load distribution, which is crucial when securing lines under tension from wind or other environmental factors. Additionally, their bolt-on fasteners are designed for quick installation while maintaining robust security—making them an indispensable choice for professionals dealing with pole line hardware.

Selecting the Right Clamping Clamp

Choosing the right clamping clamp can feel like navigating a maze, especially when you’re faced with various options for guy clamps and line clamps. The right choice not only enhances safety but also ensures that your installation stands up to the test of time and weather. With a few key factors in mind, you can streamline your selection process and make an informed decision.

Key Factors When Choosing a Clamp

When selecting a clamp, it’s crucial to consider the load capacity; this ensures that your wire clamp can handle the tension applied by anchor guys without failure. Material quality is another key factor; opting for durable materials like galvanized steel or stainless steel can prevent rust and corrosion over time. Additionally, ease of installation should not be overlooked—look for clamping clamps designed for quick assembly with bolt on fasteners to save time in the field.

Comparing Line Clamps for Different Needs

Different applications call for different types of line clamps, so understanding their specific uses can guide your decision-making process. For instance, if you're working with high-tension lines, opting for heavy-duty guy clamps is essential to ensure stability and safety under stress. Conversely, lighter-duty wire clamps may suffice in less demanding scenarios; thus, comparing specifications will help match the clamp type with your project requirements effectively.

Ensuring Compatibility with Anchor Guys

Compatibility between your chosen clamping clamp and anchor guys is vital for maintaining structural integrity in pole line hardware installations. Always check that the dimensions of your guy clamp align well with those of the anchor guys you are using; mismatched sizes can lead to failures that jeopardize safety. Additionally, consider whether additional features like adjustable bolts are necessary to accommodate variations in tension or installation angles—this flexibility could be a game-changer in ensuring secure connections.

Installation Tips for Maximum Safety

Best Practices for Using Line Clamps

First and foremost, always select the right size of line clamps for the job at hand; a poorly fitted wire clamp can lead to disastrous results. When attaching a guy clamp, make sure that it is positioned correctly to distribute tension evenly across the anchor guy, preventing undue stress on any single point. Additionally, always tighten your clamps according to manufacturer specifications; over-tightening can damage components while under-tightening may compromise safety.

Another best practice is to conduct a thorough inspection of all clamping equipment before installation. Check for signs of wear or corrosion on both the clamp and bolt systems; if anything looks suspicious, it's better to replace it than risk failure during operation. Finally, keep a well-organized toolkit handy with all necessary tools so you can work efficiently and safely without unnecessary delays.

Common Mistakes to Avoid

One common mistake when using wire clamps is neglecting compatibility with existing hardware; not all clamping products will fit seamlessly with your anchor guys or other components. Ensure that you choose line clamps specifically designed for your application—using mismatched parts could lead to catastrophic failures down the road. Another pitfall is forgetting about environmental factors: exposure to extreme weather conditions can weaken materials over time, so consider using protective coatings where applicable.

It's also essential not to overlook proper torque settings during installation; failing to adhere strictly to specifications might result in loose connections or even broken bolts later on. Lastly, avoid rushing through installations—taking time ensures that every aspect is checked thoroughly for safety and reliability.

Importance of Proper Bolt on Fasteners

The importance of using proper bolt on fasteners cannot be overstated when securing guy clamps in place; they play a crucial role in maintaining tension and stability within the entire system. Always opt for high-quality bolts designed specifically for use with clamping products; inferior fasteners may not withstand the forces exerted during operation and could lead to catastrophic failure at critical moments.

Furthermore, consider regularly inspecting bolt connections as part of routine maintenance checks—this proactive approach helps catch any issues before they escalate into serious problems. Remember that even small details matter: ensure bolts are clean from debris before installation since dirt or rust can interfere with proper tightening and compromise safety.

In summary, adhering to best practices while avoiding common mistakes will significantly enhance the effectiveness of your guy clamp installations while ensuring maximum safety standards are met across all applications.

Maintenance of Guy Clamps and Hardware

Proper maintenance of guy clamps and associated hardware is essential for ensuring safety and longevity in any installation. Regular inspections, timely replacements, and good care practices can make all the difference in the performance of your clamping clamps. Here’s how to keep your wire clamps in top shape.

How to Inspect Your Clamping Equipment

Inspecting your clamping equipment should be a routine part of maintaining your pole line hardware. Start by checking for signs of wear or damage on the guy clamp, such as cracks or corrosion, which could compromise its integrity. Additionally, ensure that the bolt on fasteners are securely tightened; loose bolts can lead to unexpected failures during operation.

Next, examine the alignment of line clamps with anchor guys to ensure they are properly positioned and functioning as intended. Misalignment can cause undue stress on the clamps, leading to premature wear or failure. Finally, keep an eye out for any unusual movement or noise during operation—these could be indicators that something is amiss with your clamping system.

Longevity Tips for Wire Clamps

To extend the life of your wire clamps, consider implementing a few proactive measures into your maintenance routine. First, regularly clean your clamps to remove dirt and debris that can cause corrosion over time; a simple wash with soapy water followed by thorough drying will do wonders. Additionally, applying a protective coating can help shield against moisture and environmental factors that may lead to deterioration.

It's also wise to periodically lubricate moving parts within clamp and bolt systems to reduce friction and wear during operation. Proper lubrication not only enhances functionality but also helps prevent rust formation on metal components—a common enemy for any outdoor hardware like guy clamps.

When to Replace Your Clamp and Bolt

Knowing when it's time to replace your clamp and bolt is crucial for maintaining safety standards in pole line installations. If you notice significant rusting or pitting on either component during inspections, it’s best not to take chances—replace them immediately! Similarly, if you find that bolts have stripped threads or are bent out of shape after regular use, don’t hesitate; these issues can lead to catastrophic failures if left unaddressed.

Another key indicator is age; even high-quality guy clamps have a lifespan influenced by environmental conditions such as temperature fluctuations or exposure to chemicals. If you’ve had them installed for several years without inspection or replacement history documented, it might be wise to conduct a thorough assessment—or simply replace them altogether as a precautionary measure. Remember: investing in new components now will save you from costly repairs down the line!

Conclusion

In the world of pole line hardware, understanding the importance of high-quality equipment cannot be overstated. Whether it's a guy clamp or a clamping clamp, the reliability and durability of these components directly impact safety and performance. Investing in top-notch wire clamps ensures that installations remain secure over time, reducing the likelihood of accidents and costly repairs.

Understanding the Importance of High-Quality Equipment

High-quality equipment is essential for ensuring that installations withstand environmental stresses and operational demands. A sturdy guy clamp or line clamp not only supports structural integrity but also provides peace of mind to those who rely on these systems daily. When it comes to critical applications like anchoring guys, choosing superior clamping solutions can make all the difference in maintaining safety standards.

Spark Fittings: Your Partner in Safety

Spark Fittings stands out as a trusted partner in providing high-quality hardware solutions tailored for safety and efficiency. Their extensive range includes innovative guy clamps designed with precision to meet diverse installation needs, ensuring compatibility with various anchor guys. By focusing on advanced technology in their clamp and bolt systems, Spark Fittings reinforces its commitment to enhancing operational safety across industries.

Future Trends in Pole Line Hardware

Looking ahead, future trends in pole line hardware will likely emphasize sustainability and smart technology integration. Innovative materials may emerge that offer greater strength while being lighter and more environmentally friendly than traditional options used for wire clamps today. Additionally, advancements in monitoring systems could enhance maintenance practices by providing real-time data on the condition of clamping clamps and bolt on fasteners, ultimately improving overall system reliability.