Introduction

In the world of electrical utilities, understanding spool and shackle insulators is crucial for ensuring safety and efficiency in power transmission. These components play a vital role in supporting electrical conductors while preventing leakage currents, making them essential to any utility infrastructure. As we look ahead to 2025, it's important to explore how advancements in technology and material science are shaping the future of these insulators.

Understanding Spool and Shackle Insulators

So, what is a spool insulator? A spool insulator is designed to hold wires or cables securely while providing electrical insulation. In contrast, shackle insulators are typically used for overhead lines where they support conductors at angles or changes in elevation. Both types of insulators serve critical functions in maintaining the integrity of power systems, but their applications and designs differ significantly.

The Importance of Material Choices

When it comes to spool and shackle insulators, material choices can make all the difference in performance and durability. The right materials not only enhance insulation properties but also influence factors like weight, resistance to environmental stressors, and overall lifespan. Understanding how various materials impact these components is essential for making informed decisions about installation—especially when considering questions like how to install a spool insulator effectively.

Overview of 2025 Trends

Looking toward 2025, several trends are emerging that will redefine the landscape of electrical insulation technology. Innovations such as advanced composites and sustainable materials are gaining traction as utilities seek more efficient solutions that align with environmental goals. Additionally, understanding what a reel insulator is used for will be crucial as industries adapt to new standards and practices—ensuring that both spool and shackle insulators meet evolving demands within the sector.

What is a Spool Insulator?

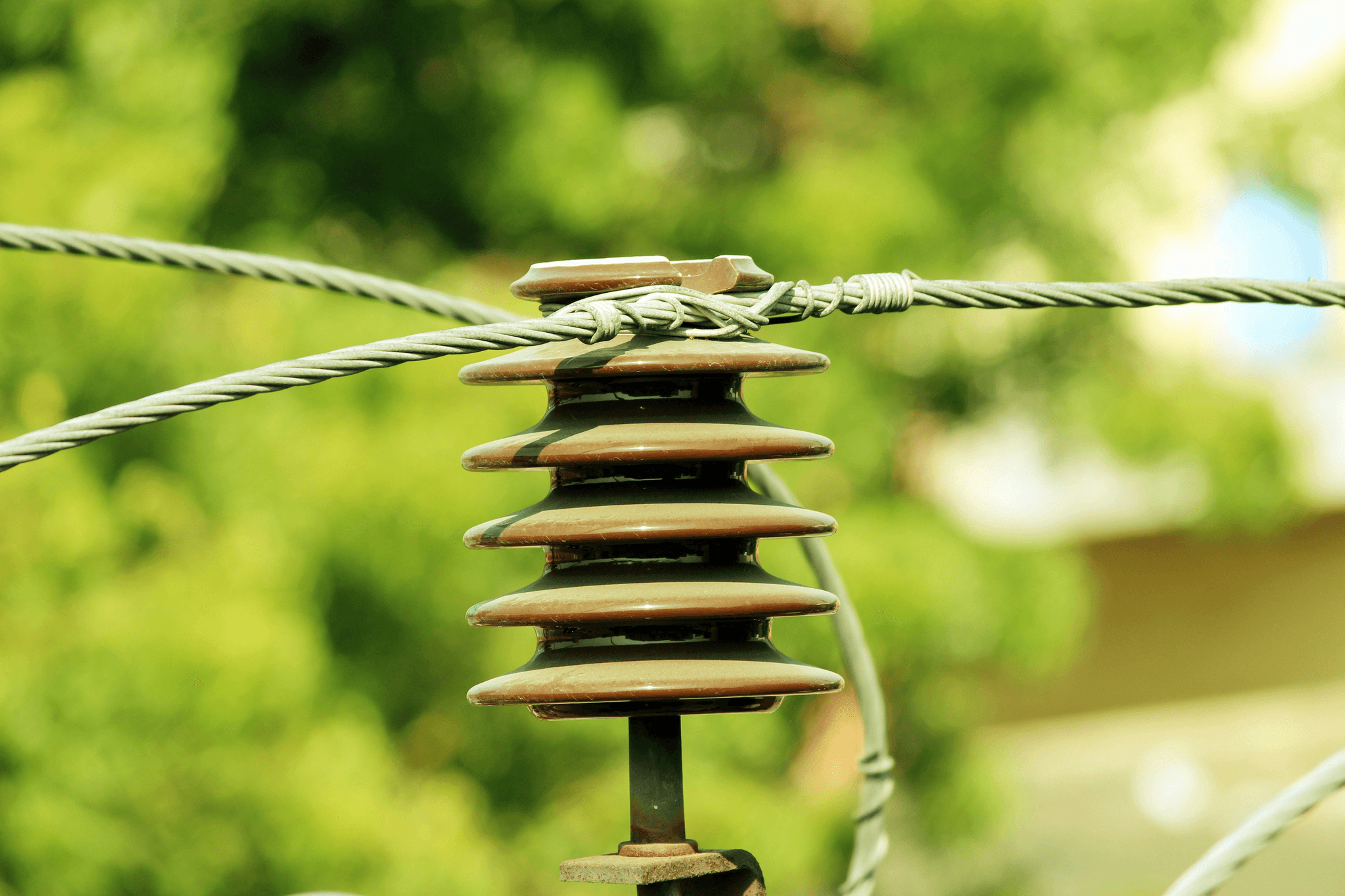

Spool insulators are essential components in the electrical utility industry, designed to support and insulate overhead conductors. These unique devices play a crucial role in ensuring that electrical energy is transmitted safely and efficiently while minimizing the risk of short circuits or power outages. Understanding what a spool insulator is can help utilities make informed decisions about their infrastructure.

Definition and Functionality

So, what is a spool insulator? At its core, a spool insulator is a type of electrical insulator shaped like a spool, which allows it to effectively hold wires while preventing electrical leakage. The design ensures that the conductor remains isolated from supporting structures, such as poles or towers, thereby reducing the chances of electricity escaping into unintended areas. This functionality is vital for maintaining safety standards and operational efficiency in power transmission systems.

Key Applications in Utilities

When it comes to key applications in utilities, spool insulators shine brightly (pun intended!). They are primarily used in overhead power lines where they provide both mechanical support and electrical insulation for conductors. Additionally, these devices are often found in substations and distribution networks where reliable performance is paramount for uninterrupted service delivery.

Common Materials Used

Common materials used for spool insulators include ceramics, polymers, and composite materials, each offering distinct advantages depending on environmental conditions and specific application needs. Ceramic materials are known for their durability and resistance to weathering but can be heavier than alternatives; meanwhile, polymer-based designs offer lighter weight solutions with excellent insulation properties. Innovations continue to emerge within this space as manufacturers explore new composites that combine the best traits of both ceramics and polymers—making them even more effective at serving their purpose as crucial components of spool and shackle insulators.

Types of Materials for Spool Insulators

When it comes to spool insulators, the choice of materials is not just a technicality; it's a crucial factor that influences performance, durability, and cost-effectiveness. Understanding the various materials available for spool insulators can help utilities make informed decisions about which type best suits their needs. From polymers to ceramics and innovative composites, each material offers unique benefits and challenges that must be considered.

Polymer vs. Ceramic: Pros and Cons

Polymers are often favored for their lightweight nature and resistance to environmental factors such as moisture and chemicals. This makes them an excellent choice for applications where flexibility is essential, allowing for easier handling during installation—so if you're wondering how to install a spool insulator efficiently, polymers might just make your life easier! However, ceramics bring their own advantages to the table; they are typically more robust and can withstand higher temperatures and electrical stresses, making them ideal in harsher environments.

On the flip side, while ceramic spool insulators may offer superior strength, they can also be brittle and prone to cracking under sudden impact or stress. The choice between polymer and ceramic ultimately depends on specific application requirements—what is a spool insulator used for? If your project demands resilience against extreme weather conditions or high voltage scenarios, ceramics might be your go-to option; otherwise, polymers could serve you well in less demanding environments.

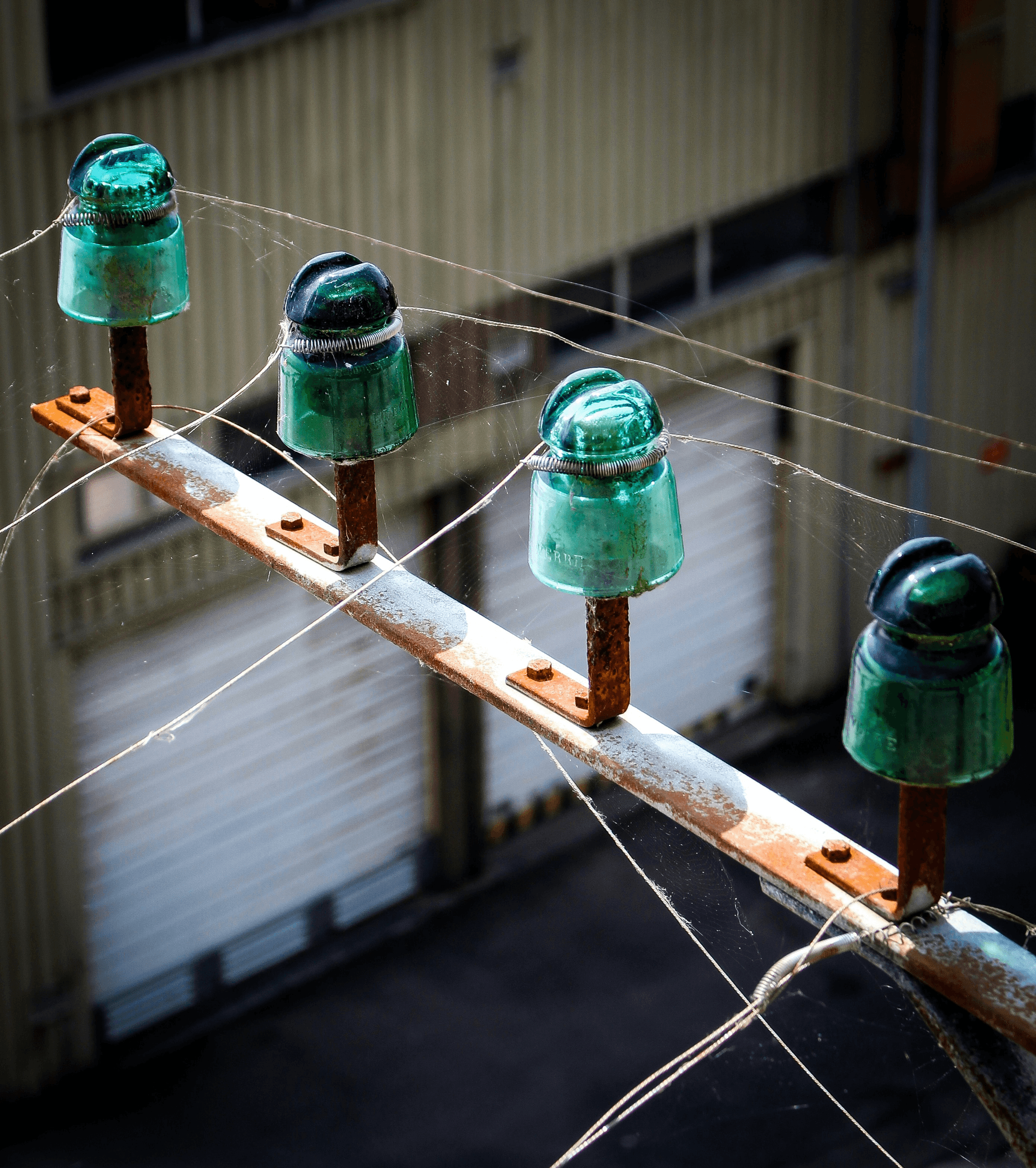

The Role of Glass Reinforcement

Glass reinforcement has emerged as a game-changer in the realm of spool insulators by enhancing strength without significantly increasing weight. By incorporating glass fibers into polymer matrices, manufacturers have created composite materials that exhibit improved mechanical properties compared to traditional options. This innovation not only extends the lifespan of spool insulators but also provides utilities with more versatile solutions tailored to various operational demands.

Moreover, glass-reinforced materials often maintain excellent dielectric properties while offering enhanced resistance against thermal degradation—meaning they can perform reliably even under challenging conditions. As we explore what is a reel insulator used for in transmission lines or other high-stress applications, it's clear that glass reinforcement plays an integral role in ensuring safety and efficiency.

Innovations in Composite Materials

The development of composite materials represents one of the most exciting advancements in insulation technology today. These innovative solutions combine multiple substances—such as polymers reinforced with carbon fibers or specialized ceramics—to create products that outperform traditional options on several fronts: weight reduction, increased strength-to-weight ratios, and superior electrical insulation properties are just a few benefits worth noting when discussing what is a shackle insulator used for compared to its spool counterpart.

Furthermore, these composites allow manufacturers to tailor material properties specifically suited for particular applications within utility networks—making it easier than ever before to choose the right insulator based on performance needs rather than settling for one-size-fits-all solutions. As we look toward future trends in insulation technology—including potential advancements related specifically to spool and shackle insulators—it’s clear that innovation will continue driving improvements across this vital industry.

What is a Reel Insulator Used For?

Reel insulators are essential components in the world of electrical transmission, serving to support and insulate conductors while minimizing energy loss. They play a critical role in ensuring that electrical systems operate efficiently and safely, particularly in high-voltage applications. Understanding the specific uses of reel insulators helps clarify their importance alongside spool insulators and shackle insulators.

Specific Applications in Transmission

In transmission lines, reel insulators are primarily used to suspend conductors from supporting structures like towers or poles. Their design allows for effective insulation against electrical leakage, which is crucial for maintaining system integrity and safety. Moreover, reel insulators are often employed in areas where space constraints exist, making them ideal for urban environments or densely populated regions.

Advantages Over Traditional Insulators

One of the standout benefits of using reel insulators over traditional options is their lightweight construction, which reduces the load on supporting structures and eases installation processes. Additionally, they often feature advanced materials that enhance durability and resistance to environmental factors such as UV exposure or extreme temperatures. The combination of these advantages results in lower maintenance costs compared to conventional spool insulator designs.

Case Studies of Effective Use

Several case studies illustrate the effectiveness of reel insulators in real-world applications. For instance, a utility company implemented reel insulators during a major upgrade of its transmission network, resulting in a 20% decrease in energy losses due to improved insulation properties. Another example involved the replacement of outdated spool insulators with modern reel designs; this upgrade led to enhanced reliability and reduced outages during severe weather conditions.

Installation Techniques for Spool Insulators

Installing a spool insulator is crucial for ensuring the reliability and safety of electrical transmission systems. Proper installation not only maximizes the insulator's effectiveness but also minimizes the risk of failure during operation. In this section, we will explore how to install a spool insulator, the tools required, and some best practices to keep in mind.

How to Install a Spool Insulator?

To begin with, understanding what is a spool insulator? It is a component designed to support overhead electrical lines while preventing current leakage through its insulating material. To install a spool insulator effectively, start by securing it onto the crossarm or pole using appropriate hardware such as bolts or clamps. Ensure that the insulator is positioned correctly to maintain tension on the line without compromising its integrity.

Next, carefully attach the conductor wire through the groove of the spool insulator, making sure it fits snugly without any gaps that could lead to wear over time. Once in place, check that all connections are tight and secure before proceeding with any additional lines or components. Finally, conduct a thorough inspection of your work; this step is essential because even minor misalignments can lead to significant issues down the road.

Tools Required for Installation

When considering how to install a spool insulator effectively, having the right tools on hand makes all the difference. Essential tools include insulated wrenches for tightening bolts safely around live wires and pliers for handling smaller components with precision. Additionally, having safety gear such as gloves and goggles will protect you from potential hazards during installation.

Other helpful tools might include a torque wrench for ensuring correct bolt tension and measuring tape for accurate placement measurements on poles or crossarms. A level can also be beneficial to ensure your spool insulators are aligned properly; misalignment could lead to uneven stress distribution along power lines. With these tools at your disposal, you will be well-equipped to tackle any installation challenges that may arise.

Best Practices and Common Pitfalls

When installing spool insulators, adhering to best practices can save you time and trouble later on. Always double-check your measurements—what seems right at first glance can often lead you astray if not verified properly! Also, consider installing one section at a time rather than trying to rush through multiple installations; this allows you more focus on each individual unit's integrity.

Common pitfalls include neglecting proper torque specifications when fastening hardware or failing to verify that all components are compatible with one another—different types of materials have unique requirements! Additionally, overlooking environmental factors like wind loads or ice accumulation can impact how well your spool insulators perform over time. By being mindful of these aspects during installation, you'll set yourself up for long-term success in maintaining reliable electrical transmission systems.

Exploring Shackle Insulators

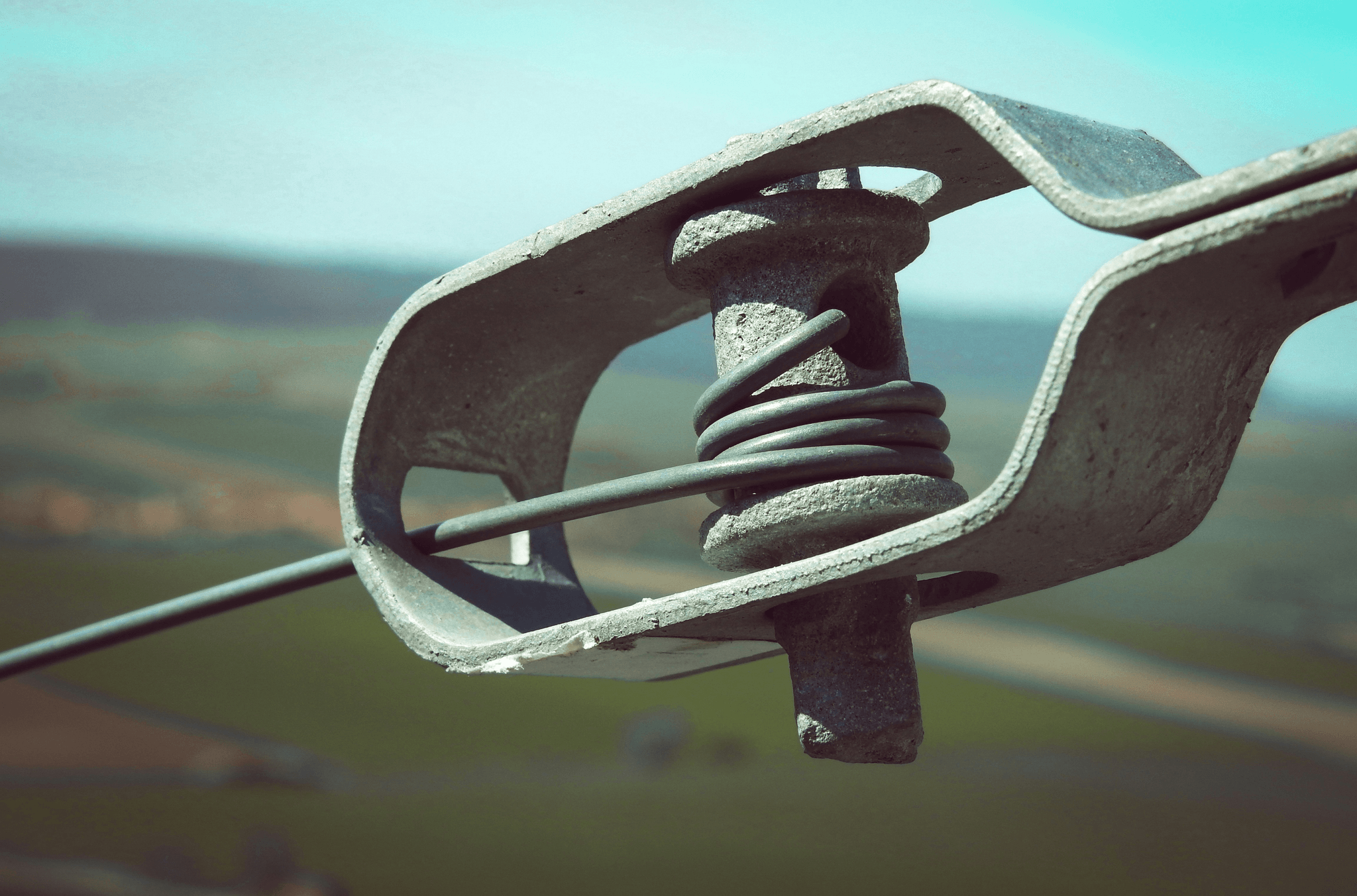

Shackle insulators play a crucial role in electrical systems, particularly in overhead power lines. They are designed to provide insulation and mechanical support, ensuring that conductors remain secure while preventing electrical leakage. Understanding what a shackle insulator is used for can help utilities make informed decisions about their infrastructure.

What is a Shackle Insulator Used For?

A shackle insulator is primarily used to suspend conductors from poles or towers while providing necessary insulation to prevent short circuits. This type of insulator is particularly effective in applications where space is limited, as they can be mounted directly onto the supporting structure. By maintaining the conductor's distance from the grounded surfaces, shackle insulators enhance safety and reliability in power transmission systems.

In addition to their use in overhead lines, shackle insulators are also employed in substations and distribution networks where flexibility and compactness are essential. They can accommodate various conductor sizes and configurations, making them versatile for different applications. Ultimately, understanding what a shackle insulator is used for helps utilities optimize their designs for efficiency and safety.

Material Choices for Shackle Insulators

Common materials include ceramics, polymers, and composite materials—each offering distinct advantages and disadvantages based on factors like durability and resistance to environmental stressors. For instance, ceramic shackle insulators provide excellent mechanical strength but may be more susceptible to breakage under extreme conditions compared to their polymer counterparts.

Polymers have gained popularity due to their lightweight nature and resilience against moisture or chemical exposure; however, they may not always match the electrical performance of ceramics under high-voltage applications. Composite materials combine the best attributes of both worlds by providing enhanced strength while minimizing weight—ideal for modern utility applications looking toward innovation. Thus, selecting the right material choice is key when considering how best to implement spool and shackle insulators effectively.

Comparing Shackle and Spool Insulators

When comparing shackle insulators with spool insulators, it's important first to define each type's unique roles within an electrical system. While both serve as vital components of overhead lines by providing insulation from conductive parts, their designs cater to different needs—shackles excel at supporting conductors directly from structures while spool insulators often manage tension across longer spans between supports.

One major difference lies in installation techniques; understanding how to install a spool insulator differs significantly from installing a shackle due to variations in mounting methods and required tools. Additionally, spool insulators tend towards higher voltage applications because of their larger surface area designed specifically for this purpose—making them ideal candidates when asking what a reel insulator is used for versus traditional options like shackles.

Ultimately, choosing between these two types depends on specific project requirements such as load-bearing needs or environmental factors influencing material selection—ensuring optimal performance through thoughtful design choices across all aspects of electrical infrastructure.

Conclusion

In the world of electrical utilities, understanding the nuances of spool and shackle insulators is essential for effective system design and maintenance. From defining what a spool insulator is to exploring its installation techniques, this guide has highlighted the importance of material choices in optimizing performance. As we move forward, staying abreast of trends and innovations will ensure that we select the best insulators for our specific needs.

Key Takeaways on Insulator Materials

When considering insulator materials, it’s crucial to weigh the pros and cons of polymers versus ceramics. The choice between these materials can significantly impact durability and performance in various applications. Additionally, innovations such as glass reinforcement and composite materials are paving the way for more efficient spool insulators that cater to modern demands.

Future Trends in Insulator Technology

Looking ahead, we can expect to see advancements in both spool and shackle insulators driven by technological innovation and sustainability goals. The integration of smart technologies into insulator systems will likely enhance monitoring capabilities, improving reliability in transmission networks. Furthermore, eco-friendly materials are gaining traction, promising a greener future for what is a spool insulator and other utility components.

Choosing the Right Insulator with Spark Fittings

Selecting the right type of insulation involves understanding what is a reel insulator used for compared to traditional options like shackle insulators. Each type serves specific functions based on application requirements; thus, knowing how to install a spool insulator properly becomes vital for optimal performance. With tools like Spark Fittings at your disposal, you can ensure that your choice meets both safety standards and operational efficiency.