Introduction

Sandblast systems are powerful tools that can transform surfaces with precision and efficiency. From removing rust to preparing surfaces for painting, these systems play a crucial role in various industries. Understanding the different types of sandblasting equipment available is essential for selecting the best fit for your specific needs.

Understanding the Basics of Sandblast Systems

At their core, sandblast systems use high-pressure air to propel abrasive materials against a surface, effectively cleaning or reshaping it. This method is not only effective but also versatile, making it popular in automotive, construction, and manufacturing sectors. By familiarizing yourself with how these systems work, you can better appreciate their importance and applications.

Types of Sandblasting Equipment Explained

Commercial sand blasting machines are designed for heavy-duty use in industrial settings, while portable sandblasting equipment offers flexibility for smaller jobs or on-site applications. Understanding these distinctions will help you make an informed decision when purchasing or renting equipment.

The Importance of Choosing Quality Equipment

Investing in quality sandblasting equipment can significantly impact your project's success and efficiency. High-quality industrial sandblasting equipment ensures durability and performance while reducing downtime caused by maintenance issues. Ultimately, selecting the right tools will save you time and money while delivering superior results that meet your expectations.

What are Sandblast Systems?

Sandblast systems are essential tools used in various industries for surface preparation and finishing. These systems use a high-pressure stream of abrasive material, often sand, to clean, etch, or shape surfaces. Whether you're looking at a commercial sand blasting machine or portable sandblasting equipment, the core functionality remains the same: achieving a smooth and clean finish on various materials.

Definition and Functionality

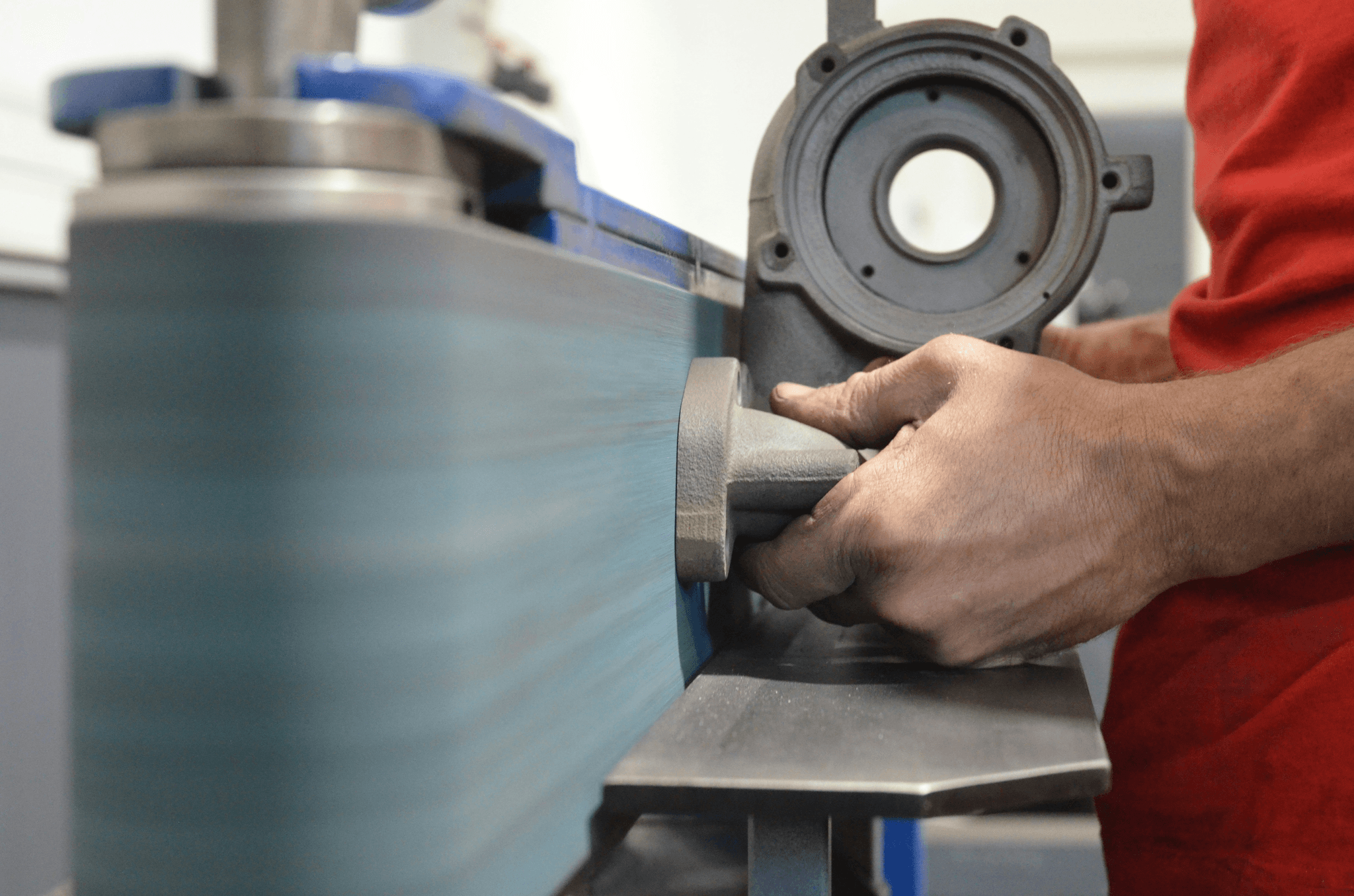

At its core, a sandblast system comprises an air compressor, an abrasive material reservoir, and a nozzle through which the abrasive is propelled at high speed. This process not only removes unwanted contaminants like rust and paint but also prepares surfaces for painting or coating. The versatility of these systems makes them indispensable in tasks ranging from automotive repairs to industrial manufacturing.

Common Applications in Various Industries

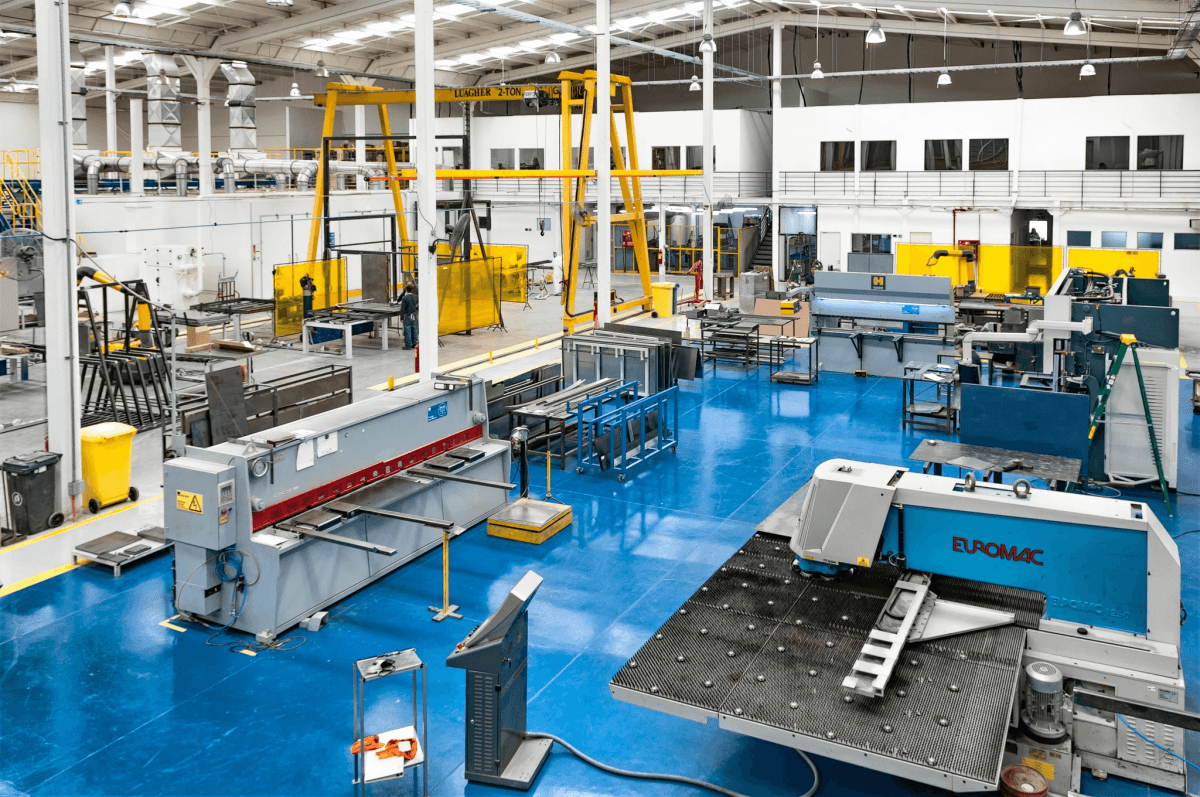

Sandblasting equipment finds its niche across multiple sectors. In construction and renovation, it’s crucial for cleaning brickwork or removing old paint from surfaces. Similarly, the automotive industry utilizes these systems for restoring car bodies by stripping away layers of grime and corrosion before repainting.

In manufacturing settings, industrial sandblasting equipment is often employed to prepare metal parts for assembly or coating processes. Additionally, artistic applications like glass etching showcase the creative potential of sandblast systems in producing intricate designs on various materials.

Differences Between Portable and Industrial Sandblasting

When it comes to choosing between portable and industrial sandblasting options, understanding their differences is key to making an informed decision. Portable sandblasting equipment is designed for mobility; it's lightweight and easy to transport to different job sites while still delivering effective results on smaller projects.

On the other hand, industrial sandblasting equipment typically offers higher power levels suited for larger-scale operations that require continuous use over extended periods. This type of equipment can handle heavier abrasives and larger workpieces but may lack the convenience that portable models provide.

Choosing the Right Sandblasting Equipment

Selecting the right sandblasting equipment can make or break your project’s success. With a plethora of options available, it’s crucial to understand what fits your specific needs. The right choice will not only enhance efficiency but also ensure that you achieve the desired finish on your surfaces.

Factors to Consider When Selecting Equipment

When choosing sandblast systems, several factors come into play. First, consider the type of material you’ll be working with; different materials require different abrasive media and equipment settings. Next, think about the scale of your projects—are you tackling small DIY tasks or large industrial jobs? This will help determine whether you need a portable sandblasting equipment setup or a more robust industrial sandblasting equipment solution.

Another key factor is the ease of use and maintenance of the equipment. You want something that not only gets the job done efficiently but can also be maintained without excessive hassle. Lastly, budget is always a consideration; investing in quality commercial sand blasting machines may cost more upfront but can save money in repairs and replacements down the line.

Overview of Commercial Sand Blasting Machines

Commercial sand blasting machines are designed for heavy-duty applications, making them ideal for businesses that require consistent performance and durability. These machines often feature larger tanks and more powerful compressors compared to their portable counterparts, allowing them to handle bigger workloads and tougher materials with ease. They are commonly used in industries such as automotive restoration, metal fabrication, and construction.

One significant advantage of commercial sand blasting machines is their ability to accommodate various abrasive materials, from fine silica to heavier grit options like aluminum oxide or steel shot. This versatility ensures that you can tackle multiple projects without needing separate equipment for each type of abrasive material. Plus, many models come equipped with advanced features like adjustable pressure settings and automatic feed systems for added convenience.

The Role of Portable Sandblasting Equipment

Portable sandblasting equipment has revolutionized how smaller projects are approached by offering flexibility without sacrificing performance. These compact systems are perfect for on-site jobs where space is limited or when mobility is essential—think home renovations or vehicle detailing at a customer’s location! Despite their size, many portable systems still deliver impressive power comparable to larger commercial units.

The beauty of portable sandblasting equipment lies in its user-friendly design; they typically require less setup time and are easier to operate than larger models. Additionally, advancements in technology mean that even these smaller units can handle diverse applications—from light cleaning tasks to heavy-duty surface preparation—making them an invaluable asset for both hobbyists and professionals alike.

Spark Electronic: A Leader in Sandblasting Technology

When it comes to sandblast systems, Spark Electronic Technology Wuxi Co., Ltd. stands out as a leader in the industry. This innovative company has made a name for itself by providing high-quality sandblasting equipment that caters to both commercial and industrial needs. Their commitment to excellence ensures that users get reliable and efficient solutions for all their sandblasting projects.

Introduction to Spark Electronic Technology Wuxi Co., Ltd.

Founded with a vision to revolutionize the sandblasting landscape, Spark Electronic combines cutting-edge technology with practical engineering solutions. Their extensive experience in manufacturing industrial sandblasting equipment allows them to understand the diverse needs of various industries, from automotive to construction. By focusing on quality and performance, they have become a trusted partner for businesses looking for top-notch sandblast systems.

Key Sandblasting Equipment Offered

Spark Electronic offers a range of products tailored for different applications within the realm of sandblasting equipment. Their lineup includes commercial sand blasting machines designed for heavy-duty tasks, as well as portable sandblasting equipment ideal for on-the-go projects. Each piece of equipment is engineered with precision to ensure optimal performance, durability, and ease of use—making them perfect choices whether you're tackling small jobs or large-scale industrial operations.

How Spark Electronic Enhances Sandblast Systems

With an emphasis on innovation, Spark Electronic enhances traditional sandblast systems through advanced technology and design improvements. Their machines feature user-friendly interfaces and efficient dust collection systems that not only improve productivity but also promote safety during operation. By investing in state-of-the-art features, they ensure that both novice and experienced users can achieve exceptional results while minimizing downtime and maintenance costs associated with their industrial sandblasting equipment.

Setting Up Your Sandblast System

Setting up your sandblast system may seem daunting at first, but with the right tools and knowledge, it can be a straightforward process. Whether you're using a commercial sand blasting machine or portable sandblasting equipment, having the essential tools on hand is crucial for achieving optimal results. This section will guide you through the necessary accessories, safety precautions, and tips to ensure efficient operations.

Essential Tools and Accessories

To get started with sandblast systems, you'll need some fundamental tools and accessories that enhance performance and efficiency. First on the list is a reliable air compressor; it provides the necessary pressure for your sandblasting equipment to operate effectively. Additionally, consider investing in quality nozzles that suit different media types, along with hoses that can withstand high pressure without bursting.

Don’t forget about personal protective equipment (PPE) such as gloves, goggles, and respirators—these are vital when working with industrial sandblasting equipment to protect you from harmful dust particles. Also essential are various types of abrasive media like aluminum oxide or glass beads; these will determine the finish of your project based on their grit size. Lastly, a sturdy workbench or platform can help stabilize your workpiece during the blasting process.

Safety Precautions for Beginners

Safety should always be paramount when using any form of sandblasting equipment—especially for beginners who might not be familiar with best practices yet. Start by ensuring that your workspace is well-ventilated; this helps reduce dust accumulation and improves air quality while you work with portable sandblasting equipment or commercial machines. Always wear appropriate PPE to shield yourself from flying debris and inhalation hazards.

Moreover, familiarize yourself with the operational guidelines specific to your chosen industrial sandblasting equipment before starting any project. This includes understanding how to adjust pressure settings correctly according to the type of abrasive material used—too high can damage surfaces while too low may not achieve desired results at all! Finally, keep a fire extinguisher nearby just in case; even though it's rare for issues to arise during operation, it's better to be safe than sorry.

Tips for Efficient Sandblasting Operations

Efficiency in sandblast systems comes down to preparation and technique—both of which can significantly impact productivity levels during projects involving commercial sand blasting machines or portable setups alike. Start by organizing your workspace: having all tools within arm's reach reduces downtime spent searching for items mid-task. Furthermore, pre-mixing abrasives can save time by ensuring you're ready when it’s time for blasting!

Another tip is mastering nozzle distance; maintaining an optimal distance between the nozzle tip and surface allows you to achieve consistent coverage without wasting materials or risking damage—aiming too close could lead to pitting while being too far might result in uneven finishes! Additionally, consider running tests on scrap materials before diving into larger projects; this helps gauge how different pressures affect outcomes without risking valuable pieces.

Lastly, don’t overlook post-blast cleanup—it’s an essential part of maintaining both safety standards and efficiency levels moving forward! Regularly inspect your portable or industrial sandblasting equipment after use; keeping everything in good condition ensures longevity so you can focus more on creating beautiful finishes rather than constant repairs down the line.

Maintenance and Troubleshooting of Sandblast Systems

Maintaining your sandblast systems is crucial for ensuring their longevity and optimal performance. Regular maintenance can prevent costly repairs and extend the lifespan of both commercial sand blasting machines and portable sandblasting equipment. By taking a proactive approach to upkeep, you can keep your industrial sandblasting equipment running smoothly and efficiently.

Regular Maintenance to Ensure Longevity

To ensure the longevity of your sandblast systems, establish a regular maintenance schedule that includes cleaning, inspection, and replacement of worn parts. Check hoses for cracks or leaks, as these can significantly affect performance; replacing them promptly will save you time in the long run. Additionally, keep an eye on the blast nozzle—this small component can wear out quickly but is vital for effective operation.

Another critical aspect of maintenance is monitoring the air supply system. Ensure that filters are clean and free from debris to maintain proper airflow to your commercial sand blasting machine or portable sandblasting equipment. A well-maintained air supply will not only enhance performance but also minimize downtime during projects.

Lastly, don’t overlook the importance of keeping your workspace organized and clean. A clutter-free environment reduces risks associated with accidents while using industrial sandblasting equipment, making it easier to identify any potential issues before they escalate into major problems.

Common Issues and How to Fix Them

Even with diligent care, issues may arise with your sandblast systems from time to time. One common problem is inconsistent blasting pressure; this could stem from clogged hoses or improper air settings in your commercial sand blasting machine or portable sandblasting equipment. To fix this issue, inspect all connections for blockages and adjust air pressure settings according to manufacturer recommendations.

Another frequent concern is excessive dust generation during operation, which can hinder visibility and safety measures in industrial environments. To address this issue, consider upgrading to a more efficient dust collection system that works seamlessly with your existing equipment or adjusting the media type being used in your sandblast systems.

Lastly, if you notice unusual noises or vibrations coming from your industrial sandblasting equipment while in use, it’s essential not to ignore these signs. They may indicate loose components or misalignment; tightening bolts or consulting the user manual could resolve these problems effectively before they lead to more severe damage.

When to Seek Professional Help

While many maintenance tasks can be tackled independently by users familiar with their sandblast systems, there are times when professional help becomes necessary—especially when dealing with complex issues involving commercial or industrial sandblasting equipment. If you're facing persistent problems despite following troubleshooting steps outlined in manuals or guides, don't hesitate to seek assistance from experienced technicians who specialize in repairing such machinery.

Additionally, if you find yourself unsure about how certain components should be maintained or replaced within your portable sandblasting equipment setup, consulting professionals ensures you're taking appropriate actions without risking further damage down the line. Investing in expert guidance at crucial moments not only saves time but also enhances overall safety during operations.

In conclusion, regular maintenance combined with timely troubleshooting makes all the difference for any user invested in maintaining efficient operations within their chosen field—whether utilizing commercial machines at a job site or relying on versatile portable options at home!

Conclusion

In wrapping up our exploration of sandblast systems, it's clear that these powerful tools play a vital role across various industries. Whether you're looking at commercial sand blasting machines for large-scale projects or portable sandblasting equipment for smaller tasks, understanding your options is essential. Quality sandblasting equipment not only enhances efficiency but also ensures safety and effectiveness in your operations.

Key Takeaways About Sandblast Systems

First and foremost, sandblast systems are indispensable for surface preparation and finishing in countless applications, from automotive to construction. The choice between industrial sandblasting equipment and portable alternatives hinges on the specific requirements of your project, including space constraints and the scale of work needed. Ultimately, investing in high-quality sandblasting equipment can lead to better results and longer-lasting performance.

Tips for Beginner Sandblasters

For those just starting their journey into the world of sandblasting, a few tips can make all the difference. Begin by familiarizing yourself with the different types of equipment available—knowing when to use a commercial sand blasting machine versus portable options is key to success. Additionally, always prioritize safety; wearing appropriate protective gear will safeguard you against dust and debris while you learn the ropes.

Next Steps for Your Sandblasting Journey

Now that you have a foundational understanding of sandblast systems, it’s time to take action! Start by researching reputable suppliers of both commercial and portable sandblasting equipment; this will help ensure you choose quality products tailored to your needs. Finally, consider joining forums or local workshops where you can exchange knowledge with experienced professionals—after all, every expert was once a beginner!