Introduction

Insulators play a crucial role in electrical engineering, serving as the silent guardians of our power systems. Without insulator fittings, we would face a myriad of challenges in maintaining safety and efficiency across various applications. Understanding the significance of these components is essential for anyone involved in the design or maintenance of electrical infrastructure.

Overview of Insulator Hardware Importance

Insulator hardware is vital for ensuring that high-voltage electricity travels safely without causing disruptions or hazards. They prevent the unwanted flow of current and protect both equipment and personnel from electric shocks, making them indispensable in power transmission systems. Furthermore, insulators are also key components in public transport systems and renewable energy solutions, highlighting their versatility and importance across multiple sectors.

Key Properties of Insulators

These include voltage ratings, mechanical strength, and environmental resistance features that help insulators withstand various conditions. Additionally, understanding what an insulator is used for—whether it’s for overhead lines or substations—can help clarify which type suits your specific needs best.

Insulator Fittings Explained

Insulator fittings are the connectors that secure insulators to structures like poles or towers, ensuring stability under load conditions. They come in various types designed to accommodate different kinds of insulators; knowing what are the 5 types of insulators can guide you in selecting compatible fittings. These fittings not only enhance performance but also contribute significantly to overall safety; after all, no one wants an accidental short circuit when they could have chosen better options!

Types of Insulators

Porcelain Insulators

Porcelain insulators are some of the most traditional and widely used types in electrical systems. Known for their durability and excellent dielectric properties, they can withstand high voltage levels while providing reliable insulation. However, they are also prone to breakage under extreme conditions, which is why proper insulator fittings are crucial for their installation.

These insulators have a smooth surface that helps reduce contamination build-up, making them suitable for various environments. Additionally, porcelain's resistance to thermal shock allows it to perform well even in fluctuating temperatures. So when you ask yourself, What are 5 good insulators? porcelain should definitely make the cut!

Polymer Insulators

Polymer insulators have gained popularity in recent years due to their lightweight nature and superior performance in harsh conditions. Made from advanced composite materials, they offer excellent weather resistance and mechanical strength without the fragility associated with porcelain or glass options. These characteristics make polymer insulators ideal for high-voltage transmission lines where weight savings can significantly impact installation costs.

One standout feature is their ability to self-clean; rainwater helps wash away dirt and pollutants that could otherwise affect performance over time. This self-maintenance aspect is a game-changer when considering What is an insulator used for? since it reduces maintenance efforts significantly! With appropriate insulator fittings, polymer options can be seamlessly integrated into existing systems.

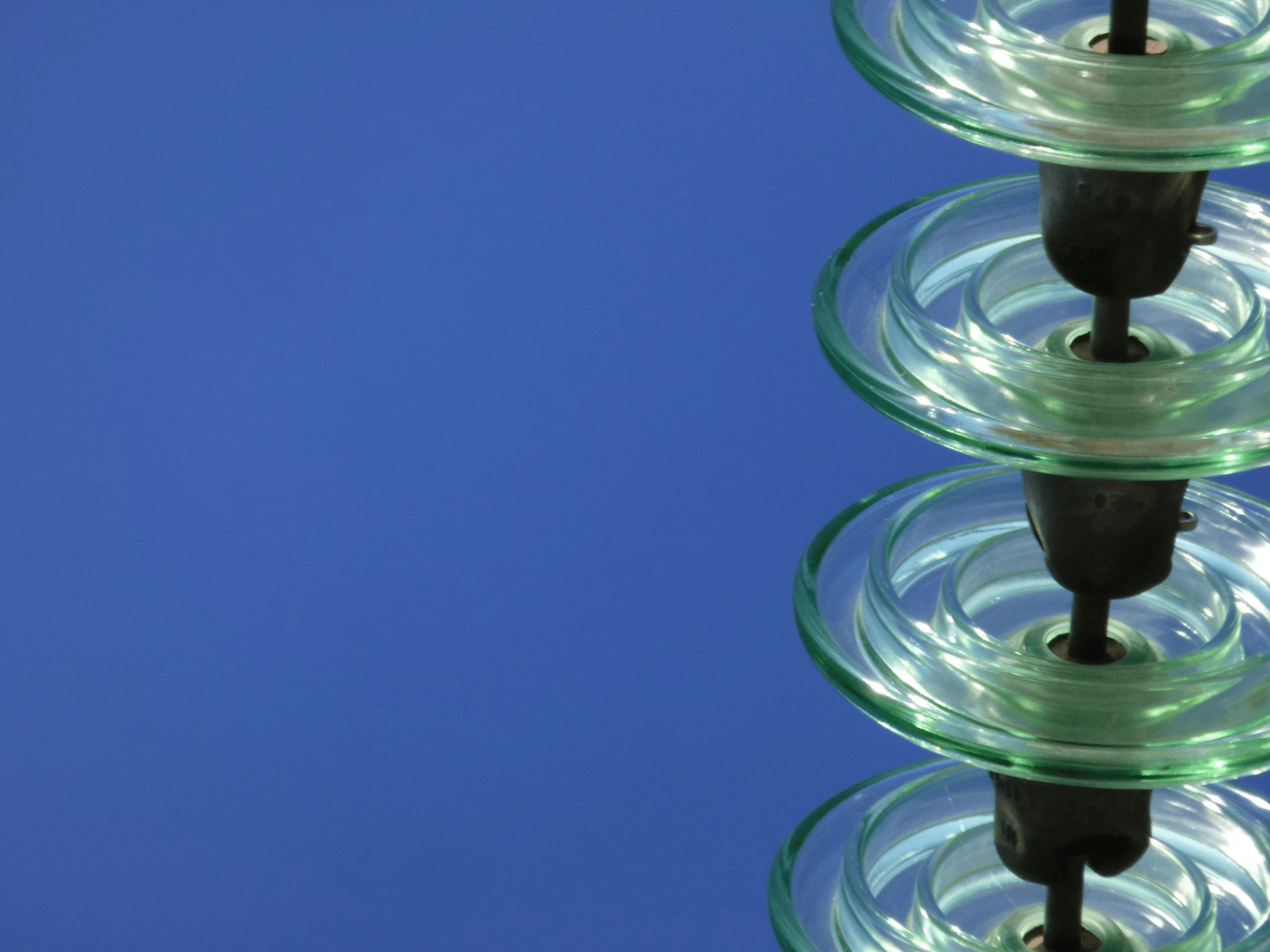

Glass Insulators

Glass insulators may not be as common as porcelain or polymer varieties but certainly hold their own in specific applications! Renowned for their transparency and longevity, glass provides a visual cue that makes it easier to spot defects or contamination on the surface—an advantage over opaque materials like porcelain or polymers. They also exhibit excellent electrical properties and can handle high voltages efficiently.

While glass might seem fragile at first glance, it's surprisingly tough when properly installed with suitable fittings! Their resistance to UV degradation means they maintain performance over long periods without significant wear or tear. If you’re pondering What is an insulator? 5 examples, consider adding glass insulation into your list alongside its more conventional counterparts!

Detailed Specifications

Voltage Ratings of Insulators

Voltage ratings are one of the most critical specifications for insulators, determining their ability to handle electrical stress without failure. Insulators must be selected based on their voltage rating to ensure safety and reliability, especially in high-voltage applications like power transmission systems. To answer the question, What are the 5 types of insulators? it's essential to know that each type—porcelain, polymer, glass, composite, and silicone—has specific voltage ratings tailored for different uses.

Choosing an insulator with an appropriate voltage rating not only prevents breakdowns but also ensures longevity under operational conditions. High-voltage insulator fittings must be compatible with the rated voltage to avoid catastrophic failures that could lead to outages or equipment damage. Therefore, understanding what an insulator is used for helps engineers select suitable types based on voltage requirements.

Mechanical Strength Considerations

Mechanical strength is another vital aspect when considering insulator specifications; it refers to how well an insulator can withstand physical forces without breaking or deforming. Insulator fittings must accommodate these mechanical stresses during installation and operation, particularly in areas prone to extreme weather or seismic activity. The mechanical strength of an insulator can vary widely depending on its material composition—porcelain offers excellent rigidity while polymer provides flexibility.

For instance, when assessing What are 5 good insulators? one might consider materials like porcelain and glass due to their robust mechanical properties under tension and compression forces. By ensuring that both the insulator itself and its fittings have adequate mechanical strength ratings, you can significantly enhance system reliability over time. This consideration becomes increasingly important as infrastructure ages or if subjected to dynamic loads from wind or ice accumulation.

Environmental Resistance Features

Environmental resistance features are essential for ensuring that insulators perform effectively across various conditions—from scorching heat to freezing cold—and everything in between. Different types of environmental stressors can impact insulation materials differently; hence it's crucial to choose wisely based on application needs while considering factors like UV exposure and pollution levels. For example, polymer-based insulators often excel in environments where chemical exposure is a concern.

In answering What is an insulator used for? we find that environmental resistance plays a key role in applications such as renewable energy solutions where durability against elements is paramount. Additionally, many manufacturers provide data sheets detailing how well their products resist degradation from specific environmental factors—this information is invaluable when selecting suitable options among “what is insulation 5 examples” available today! Ultimately, understanding these features will help you make informed decisions about which type of fitting works best with your chosen insulation solution.

Insulator Fittings and Their Role

Insulator fittings are the unsung heroes of electrical systems, ensuring that insulators remain securely attached while performing their critical functions. Choosing the right insulator fittings is essential for maintaining safety and efficiency in power transmission, public transport systems, and renewable energy solutions. This section will explore the importance of correct insulator fittings, the various types available, and a closer look at spark fittings.

Importance of Correct Insulator Fittings

When it comes to insulators, proper fittings are paramount. Incorrect or poorly fitted insulator fittings can lead to electrical failures, safety hazards, and costly downtime—nobody wants that! Additionally, the right fit enhances mechanical strength and environmental resistance features in different types of insulators like porcelain or polymer options.

Ensuring that your insulator fittings match your specific needs can significantly improve performance. For instance, if you're working with high-voltage applications or in harsh environments, you need robust fittings that can withstand stress while ensuring reliability.

Types of Insulator Fittings in Use

There’s a variety of insulator fittings designed for specific applications; knowing which type suits your needs is crucial. Common types include pin-type fittings for overhead lines, suspension-type fittings for long spans between towers, and strain-type fittings used where tension is needed. Each fitting type serves a unique purpose based on the application requirements.

For example, pin-type insulators are often used in distribution lines due to their straightforward installation process and compatibility with many types of insulators such as glass or porcelain varieties. Meanwhile, suspension-type fixtures are preferred in high-voltage transmission lines because they allow more flexibility under load conditions—vital when considering environmental resistance features!

As you consider “What are 5 good insulators?” remember that each insulation material may require different fitting styles to ensure optimal performance.

Spark Fittings in Action

Spark fittings play a critical role when it comes to protecting electrical systems from flashovers—a fancy term for unwanted electrical discharges! These specialized components help ensure that any stray voltage doesn't compromise system integrity by directing potential sparks safely away from sensitive areas. In this way, spark fittings act as guardians against unexpected surges.

You might wonder why these are so important when discussing “What is an insulator used for?” Well-placed spark fittings can mean the difference between a safe operation and catastrophic failure during peak load times or adverse weather conditions! Whether you’re utilizing porcelain or polymer-based insulation materials, integrating effective spark fitting solutions into your setup will enhance both safety and reliability.

In conclusion, understanding the role of various types of insulator fittings—including their importance—can help optimize your electrical systems while answering questions like “What is an insulator?” with confidence!

Real-World Applications

Insulators play a crucial role in various sectors, ensuring safety and efficiency in electrical systems. Their applications range from power transmission to renewable energy solutions, highlighting their versatility and importance. Understanding how insulator fittings work within these applications can help us appreciate their significance even more.

Insulators in Power Transmission

Insulators are essential components in power transmission systems, providing the necessary support and insulation for high-voltage lines. They prevent electrical leakage while maintaining the structural integrity of overhead lines, ensuring that electricity travels safely from generation points to consumers. In this context, what is an insulator used for? Primarily, it keeps conductors separated from each other and from the supporting structures, reducing the risk of short circuits.

When discussing what are the 5 types of insulators commonly used in power transmission, we typically refer to porcelain, polymer, glass, composite, and pin-type insulators. Each type has unique properties that make them suitable for specific voltage ratings and environmental conditions. The right selection of insulator fittings is crucial to ensure optimal performance and longevity of these systems.

Insulators in Public Transport Systems

In public transport systems like railways and tramways, insulators serve as vital components for maintaining safe operations. They help manage electric currents while keeping tracks insulated from surrounding structures—this is particularly important when trains operate at high speeds or under varying weather conditions. Here again arises the question: what is an insulator used for? In this case, it’s about ensuring that electrical supply remains consistent without risking safety.

Among the five good insulators utilized in public transport are porcelain insulators due to their mechanical strength and resistance to environmental factors like moisture or temperature fluctuations. Additionally, polymer insulators offer lightweight alternatives that reduce overall system weight without compromising performance—ideal for modern rail networks striving for efficiency! Properly designed insulator fittings are key here; they connect wires securely while allowing some flexibility needed during operation.

Insulators in Renewable Energy Solutions

As renewable energy sources gain traction globally, so does the need for reliable insulating materials capable of withstanding diverse conditions—think solar farms or wind turbines! Here’s where we dive into practical applications: what is an insulator used for? In renewable energy solutions like solar panels or wind turbines' wiring systems, they prevent electrical losses while protecting sensitive components from environmental damage.

Five examples of effective insulating materials include polymeric compounds often employed in solar installations due to their lightweight nature and durability against UV exposure. Glass-insulated cables also find use here because they offer excellent thermal stability—a must-have when dealing with fluctuating temperatures common in outdoor settings! Choosing appropriate insulator fittings ensures seamless integration within these innovative technologies while maximizing efficiency across all operations.

Common Questions About Insulators

Insulators play a crucial role in various electrical and mechanical applications, leading to a slew of common questions about their types, properties, and uses. Here, we tackle some frequently asked queries to shed light on these essential components. Understanding the answers can help you appreciate the significance of insulator fittings and their application in different contexts.

What are the 5 types of insulators?

When discussing insulators, we typically refer to five main types: porcelain, polymer, glass, rubber, and ceramic insulators. Porcelain insulators are renowned for their durability and resistance to weather conditions. Polymer insulators offer lightweight options with excellent electrical properties, while glass insulators provide transparency for monitoring wear over time.

Each type has its unique strengths tailored for specific applications; for instance, rubber is often used in overhead power lines due to its flexibility. Understanding these five types is vital when selecting the right insulator fittings for your project needs. Choosing the appropriate type ensures efficiency and safety in your electrical systems.

What are 5 good insulators?

When searching for good insulating materials, consider options like air, rubber, glass wool, foam board insulation, and silicone. Air is one of nature's best insulators due to its low thermal conductivity; it's commonly used in double-glazed windows to improve energy efficiency. Rubber serves as an effective barrier against both heat and electricity while being flexible enough for various applications.

Glass wool provides excellent thermal insulation properties and is often used in building insulation systems; it's lightweight yet effective at reducing heat transfer. Lastly, silicone is favored in high-temperature environments because it retains its insulating properties even under extreme conditions. These five materials exemplify what makes a good insulator—low conductivity combined with durability.

What is an insulator used for?

Insulators are primarily utilized to prevent unwanted flow of electricity or heat between conductive materials or surfaces. In electrical systems like power transmission lines or substations, they ensure that current flows along designated paths without leaking into surrounding structures—this is where proper selection of insulator fittings becomes crucial!

In addition to electrical applications, they also serve as thermal barriers in buildings or appliances by minimizing energy loss—think home insulation during winter months! Their versatility extends beyond just electricity or heat; they can also be employed in chemical processes where non-conductive barriers are necessary.

What is an insulator? 5 examples?

An insulator refers to any material that resists the flow of electric current or heat transfer effectively—essentially acting as a barrier between conductive elements! Five notable examples include porcelain (often seen on utility poles), polymer (used widely due to lightweight characteristics), glass (known for transparency), rubber (common in wiring), and foam board (popular in construction).

These examples highlight how diverse insulating materials can be depending on their intended use; each brings distinct advantages suited for particular environments or requirements! Understanding these examples not only clarifies what constitutes an effective insulating material but also emphasizes the importance of choosing appropriate designs like specialized fittings that enhance performance.

Conclusion

In wrapping up our exploration of insulators, it's clear that these components play a pivotal role in various electrical applications. The future of insulator technology looks promising, with innovations aimed at improving efficiency and sustainability. As we move forward, understanding the nuances of insulator fittings and their types will be essential for anyone involved in electrical engineering or related fields.

The Future of Insulator Technology

The future of insulator technology is poised for exciting advancements, particularly in materials science and design. With growing concerns about environmental impact, manufacturers are focusing on developing more sustainable options that still meet high performance standards. Innovations such as smart insulators that can monitor conditions in real-time could revolutionize how we manage power systems.

Choosing the Right Insulator for Your Needs

So, what are the 5 types of insulators? They include porcelain, polymer, glass, composite, and rubber insulators. Each type has unique properties that make it suitable for specific applications; thus knowing what is an insulator used for will help you make an informed choice.

Final Thoughts on Insulator Fittings and Properties

In conclusion, proper selection and application of insulator fittings can significantly affect overall system performance and reliability. It's not just about picking any fitting; understanding the importance of correct fitment can prevent costly failures down the line. Whether you're curious about what are 5 good insulators or need examples like those mentioned earlier—insulating materials are foundational to modern electrical infrastructure.