Introduction

In the world of electrical infrastructure, understanding transmission line hardware is crucial for ensuring efficient power distribution. Transmission line hardware encompasses a variety of components that work together to support the entire system, including essential hardware fittings for transmission lines. These fittings play a pivotal role in not only maintaining structural integrity but also enhancing the overall performance of transmission lines.

Understanding Transmission Line Hardware

What is transmission line hardware? It's a broad term that refers to all the equipment and components used in high-voltage power transmission systems, from conductors and insulators to the various fittings that hold everything together. Each piece of hardware is designed with a specific function in mind, contributing to the safety and reliability of power delivery across vast distances.

Importance of Hardware Fittings

When we talk about what are hardware fittings, we refer to those small yet mighty components that connect larger elements within a transmission line system. The importance of these fittings cannot be overstated; they ensure that everything stays securely in place while also allowing for necessary adjustments and maintenance over time. Quality hardware fittings for transmission lines directly influence operational efficiency and can prevent costly downtimes due to failures.

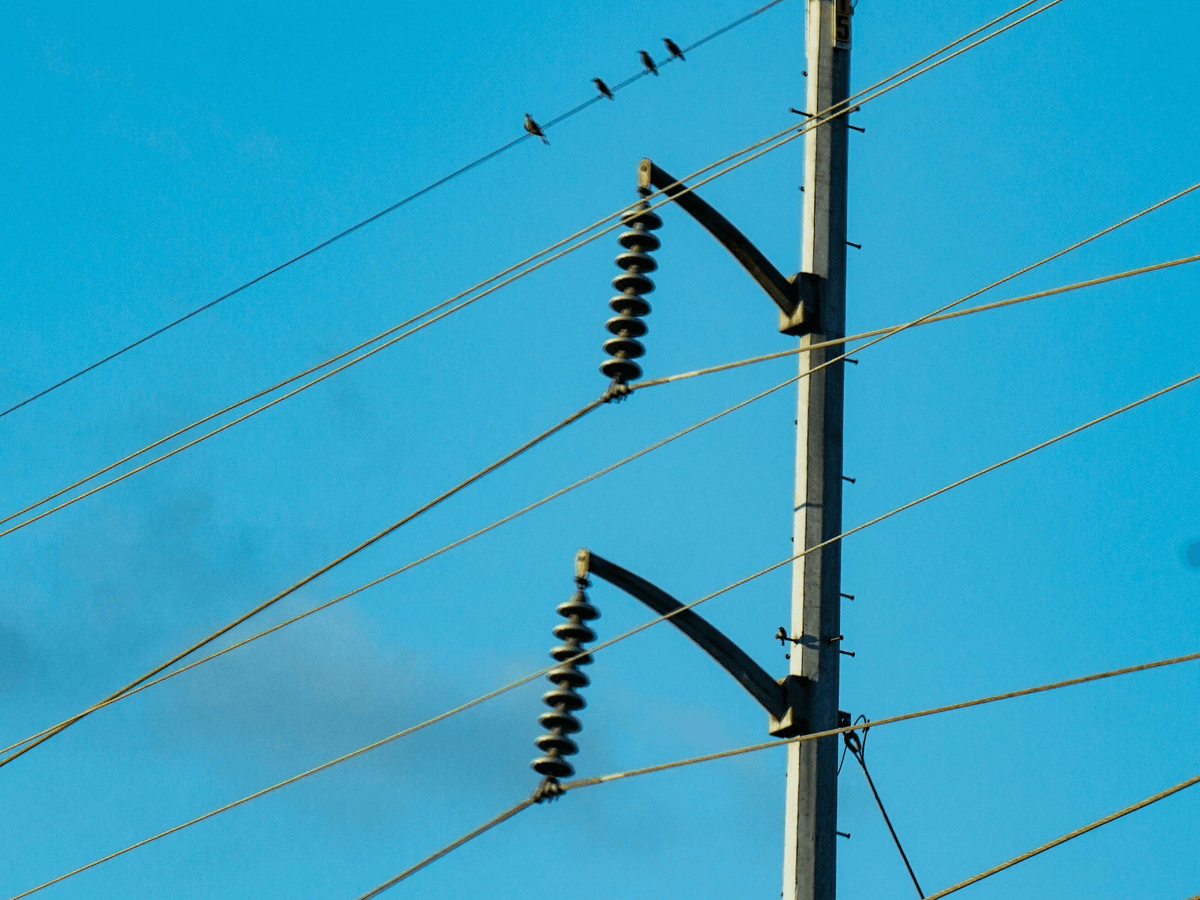

Overview of Transmission Tower Accessories

Transmission tower accessories are integral parts of any robust power distribution network, serving as vital links between different components like conductors and insulators in transmission lines. These accessories include everything from brackets and clamps to specialized connectors designed for specific applications within Tower Line Hardware Fittings. Understanding these accessories helps us appreciate how they contribute not only to stability but also to the overall safety of electrical systems.

What is Transmission Line Hardware?

Transmission line hardware encompasses a broad range of components crucial for the effective transmission of electricity over long distances. This includes everything from the cables themselves to various fittings and accessories that ensure stability, safety, and efficiency in power delivery. Understanding what transmission line hardware is lays the groundwork for appreciating its significance in modern electrical infrastructure.

Components of Transmission Line Systems

At its core, a transmission line system consists of conductors, insulators in transmission lines, support structures like towers, and the essential hardware fittings for transmission lines that tie everything together. Each component plays a vital role; conductors carry electrical current while insulators prevent unwanted leakage and maintain system integrity. Additionally, Tower Line Hardware Fittings are pivotal in maintaining the structural stability of transmission towers under varying environmental conditions.

Role of Hardware in Transmission Efficiency

The role of hardware within transmission systems cannot be overstated; it directly impacts both efficiency and reliability. Quality hardware fittings for transmission lines ensure that connections are secure and can withstand physical stresses such as wind or thermal expansion. When we ask ourselves, What is transmission hardware? it becomes clear that these components facilitate optimal performance by minimizing energy loss during power transfer.

Key Players in the Industry

The landscape of transmission line hardware features several key players who specialize in manufacturing high-quality components designed to enhance overall system performance. These companies produce everything from standard fittings to innovative solutions tailored to specific challenges faced by utility providers today. By focusing on what are hardware fittings? we can appreciate how these industry leaders contribute to advancements in technology related to Transmission Tower Accessories and other essential elements.

What are Hardware Fittings?

When discussing transmission lines, one cannot overlook the significance of hardware fittings for transmission lines. These fittings play a crucial role in ensuring that the components of a transmission system work harmoniously together, maintaining both stability and efficiency. Essentially, hardware fittings serve as the backbone of transmission line infrastructure, facilitating connections between various elements and ensuring reliable performance.

Definition and Purpose of Hardware Fittings

So, what are hardware fittings? In simple terms, they are specialized components designed to connect and secure different parts of a transmission line system. Their primary purpose is to enhance the structural integrity and reliability of the installation while also optimizing performance by minimizing energy losses during electricity transmission.

Understanding what is transmission line hardware leads us directly to these essential fittings. Without them, even the most advanced technology would falter under stress or environmental challenges. Therefore, selecting high-quality hardware fittings is paramount for any successful installation.

Types of Hardware Fittings for Transmission Lines

There are numerous options available that cater to specific needs within electrical systems. Some common types include clamps, brackets, connectors, and spacers—all designed with unique functionalities tailored for different applications.

For instance, insulator in transmission line systems often requires specific fittings that can withstand significant mechanical loads while maintaining electrical insulation properties. Additionally, Tower Line Hardware Fittings encompass several specialized pieces that ensure towers remain stable under various weather conditions and operational stresses. Each fitting type plays a vital role in ensuring overall system efficiency.

Installation and Maintenance Best Practices

Installing hardware fittings correctly is critical for long-term performance; thus understanding best practices can save time and resources down the road! First off, always follow manufacturer guidelines when installing any fitting—this ensures compatibility with existing components while optimizing functionality.

Regular maintenance checks should also be part of your routine; inspecting for wear or damage can prevent costly failures later on. Additionally, keeping an eye on how these fittings interact with other elements like insulators in transmission lines helps identify potential issues early on—after all, prevention is better than cure!

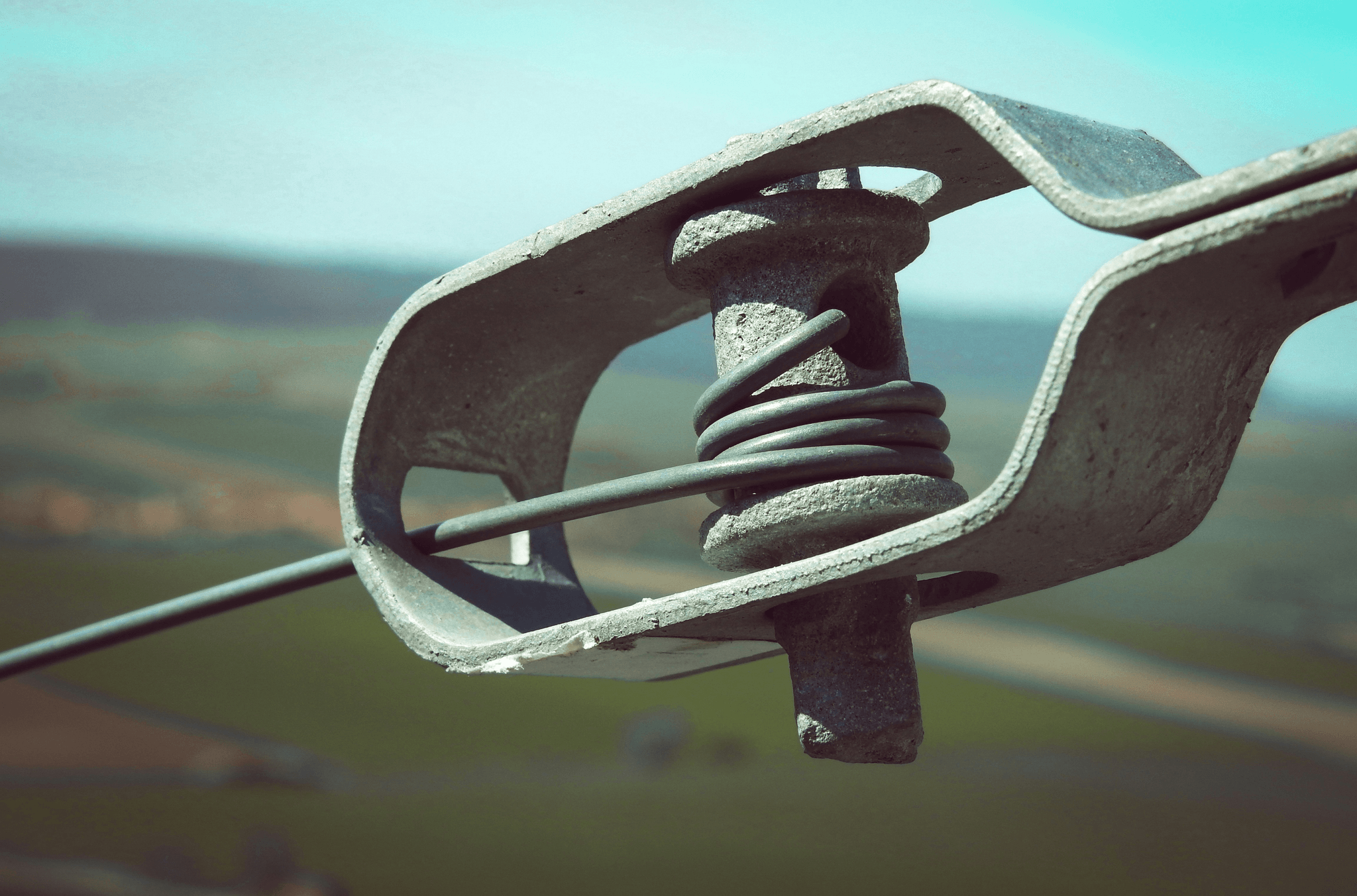

Transmission Line Fittings Explained

When it comes to understanding transmission line systems, distinguishing between hardware and fittings is crucial. While what is transmission line hardware? typically refers to the broader components that make up the system, what are hardware fittings? narrows down the focus to specific items that connect or secure these components. Essentially, all fittings are hardware, but not all hardware can be classified as fittings; it's a nuanced difference that plays a significant role in ensuring efficiency and safety.

Differentiating Between Fittings and Hardware

The distinction between fittings and general transmission hardware lies primarily in their functions and applications within the system. Hardware encompasses a wide range of components used throughout transmission lines, including conductors, insulators in transmission lines, and more. On the other hand, hardware fittings for transmission lines specifically refer to connectors or accessories designed to join various elements of the system securely—think of them as the glue that holds everything together.

This differentiation is not just academic; it has real-world implications for installation and maintenance practices. Understanding what constitutes each category can help engineers choose appropriate materials for their specific needs. This knowledge ultimately leads to enhanced performance and longevity of transmission systems.

Common Fitting Types Used in Transmission

In any discussion about transmission line fittings, several types stand out as essential players in maintaining system integrity. These include clevises, shackles, splices, and tensioning devices—each serving distinct roles within Tower Line Hardware Fittings setups. For example, clevises are often used to attach conductors to insulators or towers while ensuring flexibility under load conditions.

Another common fitting type is the splice fitting which joins two lengths of conductor together without compromising electrical continuity or mechanical strength. Tensioning devices play a crucial role by applying necessary force on cables to prevent sagging—a factor critical for maintaining proper clearance from ground level or other structures. The variety of fitting types available allows engineers to customize solutions based on unique site conditions.

Impact on System Stability and Safety

The impact of well-designed transmission line fittings on overall system stability cannot be overstated; they are often unsung heroes behind reliable power delivery. Properly installed hardware fittings for transmission lines ensure that all components work harmoniously under varying environmental stresses—be it wind loads or thermal expansion from temperature changes. This harmony contributes significantly not only to operational efficiency but also enhances safety by reducing potential hazards like conductor sagging or failure.

Moreover, when considering innovations in fitting design—such as those seen with spark fittings—the opportunity arises for even greater improvements in both stability and safety standards across systems worldwide. As we look toward future advancements in what is transmission hardware? it's clear that investing time into selecting quality tower line accessories will yield dividends long-term through reduced maintenance costs and increased reliability.

Overall, understanding how each component works together helps create robust networks capable of meeting today's energy demands while preparing for tomorrow's challenges—a task made easier with effective use of quality fittings!

The Role of Insulators in Transmission Lines

Insulators play a crucial role in the functionality and safety of transmission lines. They prevent electrical current from leaking to the ground, ensuring that energy is efficiently transmitted over long distances. Without proper insulators, transmission systems would face significant losses and safety hazards, making them essential components in any discussion about what is transmission line hardware.

Function and Importance of Insulators

The primary function of an insulator in transmission lines is to provide electrical isolation between conductive parts and support structures, such as towers or poles. This isolation prevents short circuits and protects both the infrastructure and the surrounding environment from electrical faults. Moreover, high-quality insulators contribute to the overall reliability of power delivery systems by minimizing outages caused by environmental factors like wind or ice accumulation.

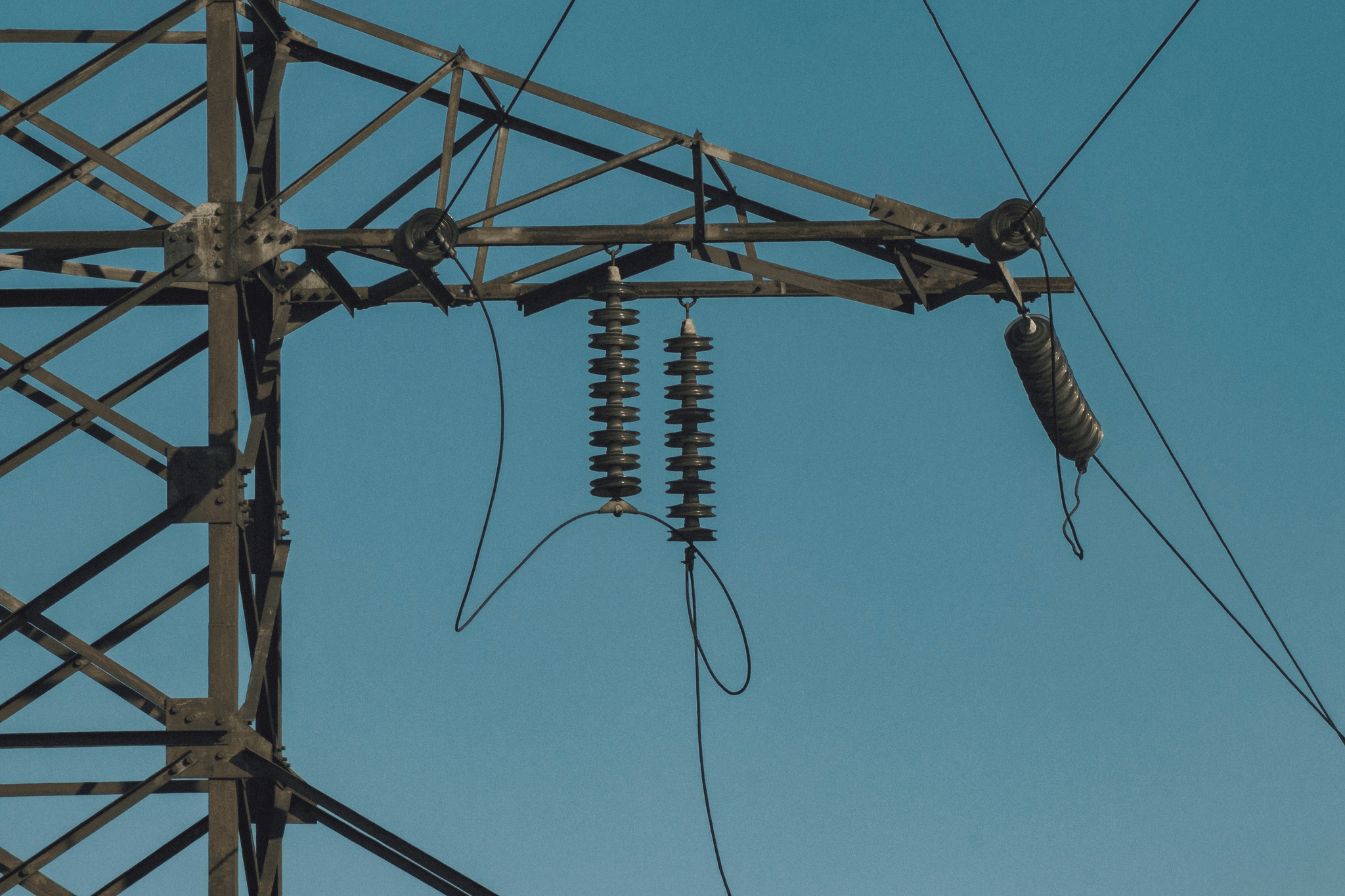

Various Insulator Types and Their Applications

There are several types of insulators used in transmission lines, each tailored for specific applications and environments. Porcelain insulators are commonly used due to their durability and resistance to harsh weather conditions; however, composite insulators have gained popularity for their lighter weight and superior performance under extreme conditions. Additionally, glass insulators offer excellent visibility for maintenance checks while also providing high dielectric strength—each type plays a unique role within the framework of transmission tower accessories.

How Insulators Interact with Hardware Fittings

Insulators do not work alone; they interact closely with hardware fittings for transmission lines to create a cohesive system that ensures stability and safety. These fittings connect the insulator to various structural components like cross-arms or brackets while maintaining proper spacing to avoid electrical discharge. Understanding how these elements work together allows engineers to optimize designs for efficiency—an essential aspect when discussing what are hardware fittings in relation to overall transmission line performance.

Tower Line Hardware Fittings

Tower line hardware fittings are crucial components that ensure the integrity and performance of transmission lines. These fittings serve as the backbone of any transmission system, providing stability and support to the entire structure. Understanding what these hardware fittings for transmission lines entail is essential for anyone involved in the design, maintenance, or operation of electrical networks.

Overview of Tower Hardware Components

Tower hardware consists of various elements that work together to maintain the stability and functionality of transmission towers. Key components include crossarms, braces, insulator mounts, and tensioning devices—all of which play a vital role in supporting conductors and insulators in transmission lines. By comprehensively understanding what is transmission line hardware?, one can appreciate how these components interact to create a robust infrastructure capable of withstanding environmental stresses.

Essential Fittings for Tower Stability

For instance, tension fittings are designed to keep cables taut while allowing for thermal expansion and contraction. Additionally, properly installed insulators in transmission lines prevent electrical leakage while supporting overhead conductors—making them critical for maintaining both safety and efficiency within the system.

Innovations in Tower Line Hardware

The field of tower line hardware is not static; it’s continuously evolving with advancements aimed at improving durability and performance. New materials such as composite polymers are being utilized to reduce weight without sacrificing strength, leading to lighter structures that are easier to install and maintain. Furthermore, smart technology integration allows for real-time monitoring of structural integrity—an innovative leap forward that enhances overall reliability in transmission systems.

Spotlight on Spark Fittings

When it comes to hardware fittings for transmission lines, Spark Fittings has carved out a niche that’s hard to overlook. Known for their innovative approach and commitment to quality, they have become a prominent player in the realm of transmission line hardware. Their products are designed not just to meet industry standards but also to enhance overall system performance.

Introduction to Spark Fittings

Spark Fittings specializes in manufacturing premium hardware fittings for transmission lines, ensuring that each component plays a vital role in the stability and efficiency of power delivery systems. With years of experience under their belt, they understand the intricacies of what is transmission line hardware and how essential it is for maintaining operational integrity. Their focus on quality means that every fitting is rigorously tested, providing peace of mind for utility companies and engineers alike.

Overview of Their Product Line

The product line at Spark Fittings encompasses a wide array of items tailored specifically for Tower Line Hardware Fittings and more. From insulators in transmission lines to various types of connectors and clamps, their offerings ensure compatibility with diverse applications across the industry. Each product is designed with both functionality and durability in mind, making them an excellent choice when considering what are hardware fittings?

How Spark Fittings Enhance Transmission Systems

Spark Fittings enhances transmission systems by integrating cutting-edge technology with traditional engineering practices, resulting in reliable solutions that improve overall system stability. By focusing on high-quality materials and innovative designs, they ensure that every piece contributes positively to the entire network’s efficiency—making them indispensable when discussing what is transmission hardware? Furthermore, their commitment to customer service means that clients receive support throughout installation and maintenance processes, ensuring longevity and performance from their chosen transmission line fittings.

Conclusion

In wrapping up our exploration of transmission line hardware, it’s crucial to recognize the integral role that hardware fittings play in ensuring the efficiency and reliability of electrical systems. From understanding what transmission line hardware encompasses to delving into the specifics of Tower Line Hardware Fittings, we’ve covered a lot of ground. The combination of various components, including insulators in transmission lines and other accessories, forms a robust framework that supports modern electrical infrastructure.

Recap of Transmission Line Hardware

To recap, transmission line hardware refers to all the components that facilitate the safe and efficient transfer of electricity over long distances. This includes not only the wires themselves but also essential items like insulators in transmission lines, connectors, clamps, and various types of fittings. Understanding what is transmission line hardware allows us to appreciate how each piece contributes to overall system stability and performance.

Significance of Quality Fittings

Quality fittings are paramount when it comes to maintaining operational integrity within any transmission system. Hardware fittings for transmission lines must be durable and reliable; otherwise, they can lead to failures that disrupt service and compromise safety. By investing in top-notch fittings and accessories for towers—like those found in Tower Line Hardware Fittings—we ensure longevity and resilience against environmental factors.

Future Trends in Transmission Line Technology

Looking ahead, future trends in transmission line technology will likely focus on innovation aimed at enhancing efficiency while reducing costs. We can expect advancements in materials used for both hardware fittings and insulators in transmission lines that improve performance under extreme conditions. As we embrace smart grid technologies, integrating advanced monitoring systems with traditional hardware will be essential for optimizing maintenance practices and ensuring seamless energy distribution.