Introduction

In the intricate world of electrical infrastructure, stay fittings play a pivotal role that often goes unnoticed. These components serve as the unsung heroes, providing essential support to overhead transmission lines and ensuring stability in various electrical applications. Understanding stay fittings is crucial for anyone involved in the design, installation, or maintenance of electrical systems.

Understanding Stay Fittings

Stay fittings are specialized hardware used to secure stay wires that support overhead structures like transmission lines and communication towers. They come in various forms, including clamps and brackets, designed to withstand significant tension and environmental stressors. By anchoring stay wires effectively, these fittings maintain the integrity of electric line fitting galvanized steel stay rod assemblies and ensure safe operation.

Importance of Stay Wires

Stay wires are vital components that provide the necessary tension to keep overhead transmission lines upright and stable under various conditions. Without them, power lines would be at risk of sagging or collapsing due to wind loads or other external forces. The proper use of stay wire line fittings helps maintain structural integrity while enhancing safety across electrical infrastructure.

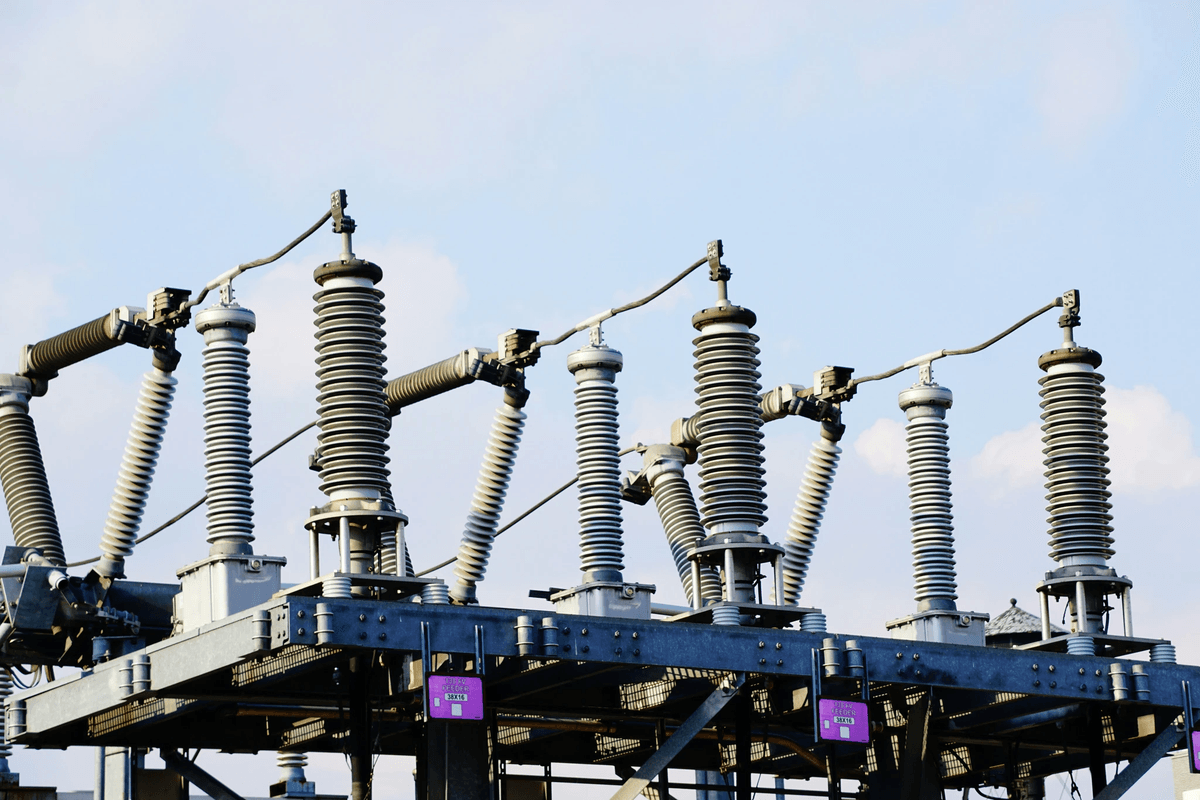

Applications in Electrical Infrastructure

Stay fittings find their applications across a wide range of electrical infrastructure projects, from urban power distribution networks to remote telecommunications setups. They are critical in ensuring that overhead transmission lines can withstand environmental challenges while maintaining optimal performance levels. Whether it's supporting an electric line fitting galvanized steel stay rod assembly or securing communication towers, these fittings are fundamental for reliable operations in today's interconnected world.

What Are Stay Fittings?

These fittings provide the necessary stability and tension needed to keep wires securely in place, ensuring that they can withstand various environmental factors such as wind, ice, and even seismic activity. Understanding stay fittings is crucial for anyone involved in the installation or maintenance of electric line systems.

Definition of Stay Fittings

At their core, stay fittings are devices used to anchor and support stay wires that help stabilize overhead transmission lines. They work by transferring loads from the wire to the ground or other structures, thus preventing sagging or swaying that could lead to power outages or accidents. In essence, a stay fitting is like a safety belt for your electrical infrastructure—keeping everything secure and functioning smoothly.

Types of Stay Fittings

There are several types of stay fittings designed for various applications within overhead transmission systems. Common examples include adjustable stay rods, clevises, and thimbles—all engineered to work together seamlessly as part of an Electric Line Fitting Galvanized Steel Stay Rod Assembly. Each type serves a specific purpose; for instance, adjustable stay rods allow for fine-tuning tension levels while providing flexibility during installation.

Key Components and Materials

The effectiveness of stay fittings largely depends on their key components and materials used in construction. Typically made from high-strength steel or galvanized steel, these materials offer durability and resistance against corrosion—essential qualities given that many installations occur outdoors where exposure to the elements is inevitable. Additionally, components like turnbuckles and anchors play vital roles in ensuring that Stay Wire Line Fittings maintain optimal tension throughout their lifespan.

Role of Stay Fittings in Overhead Lines

Stay fittings play a pivotal role in ensuring the stability and integrity of overhead transmission lines. They act as crucial support systems that keep the lines taut and properly aligned, preventing sagging or swaying due to environmental factors or electrical loads. By providing this stability, stay wire line fittings contribute significantly to the overall reliability of electrical infrastructure.

Stability for Overhead Transmission Lines

Stay fittings help maintain proper tension on the wires, which is essential for minimizing movement caused by wind or other external forces. This tension not only protects the lines from damage but also ensures efficient power delivery across long distances, making stay wire line fittings indispensable in modern electrical grids.

Impact on Electric Line Fitting Galvanized Steel Stay Rod Assembly

The electric line fitting galvanized steel stay rod assembly is a critical component that works hand-in-hand with stay fittings to bolster overhead transmission systems. These assemblies provide robust support while resisting environmental wear and tear, thanks to their corrosion-resistant properties. The combination of these components enhances the overall strength and longevity of overhead lines, proving that quality stay fittings are foundational to effective electrical infrastructure.

Enhancing Electrical Infrastructure Safety

Safety is always a priority when dealing with electricity, and this is where stay fittings shine brightly. By ensuring that overhead transmission lines remain securely positioned and stable, they help prevent accidents caused by falling wires or equipment failures. In an era where renewable energy sources are becoming more prevalent, investing in reliable stay wire line fittings ensures that our evolving electrical infrastructure remains safe and efficient for all users.

Advantages of Using Stay Wire Line Fittings

These fittings provide a robust framework that supports the entire structure, making them essential for electric line fitting galvanized steel stay rod assemblies. Let's dive into the key advantages that make stay fittings a preferred choice in electrical infrastructure.

Strength and Durability

One of the standout features of stay wire line fittings is their remarkable strength and durability. Constructed from high-quality materials, these fittings can withstand significant tension and environmental stressors, ensuring that overhead transmission lines remain stable even in adverse weather conditions. The use of galvanized steel in electric line fitting galvanized steel stay rod assemblies further enhances their resilience, providing long-lasting support without compromising performance.

Corrosion Resistance

Corrosion can be a silent killer for many structural components, but not for stay fittings! Thanks to advanced galvanization processes, these stay wire line fittings boast exceptional corrosion resistance, making them ideal for outdoor applications where exposure to moisture and pollutants is common. This feature not only prolongs the life span of each fitting but also reduces maintenance costs over time—talk about a win-win!

Cost-Effectiveness in Long-Term Use

While initial investment costs might raise eyebrows, the long-term benefits of using quality stay wire line fittings far outweigh any upfront expenses. Their strength and corrosion resistance translate into fewer replacements and repairs down the line—literally! By choosing durable options like electric line fitting galvanized steel stay rod assemblies, you'll find that your infrastructure investment pays off handsomely over its lifespan.

Spark Fittings and Customized Solutions

These specialized stay fittings are designed to provide tailored solutions for various electrical infrastructure needs. With the right spark fittings, utility companies can ensure that their stay wire line fittings are optimized for both performance and safety.

Overview of Spark Fittings

Spark fittings are innovative components that connect stay wires to structures, ensuring that overhead transmission lines remain secure and stable. Unlike standard stay fittings, these offer customizable features that cater to specific installation requirements, making them indispensable in modern electrical infrastructure projects. The adaptability of spark fittings allows engineers to address unique challenges posed by different geographical locations or load conditions effectively.

Importance of Material Similarity

One of the key factors in selecting stay wire line fittings is material similarity, which ensures compatibility between all components involved in an electric line fitting galvanized steel stay rod assembly. Using materials with similar properties prevents issues such as galvanic corrosion, which can significantly reduce the lifespan of the installation. By prioritizing material similarity in spark fittings, utility companies can enhance durability and reliability while minimizing maintenance costs over time.

Color Coding and Identification in Installation

By employing a systematic color-coding scheme for different types of spark fittings, installers can quickly identify components during installation or maintenance tasks. This not only streamlines the process but also enhances safety by reducing the chances of using incorrect parts in critical electric line fitting galvanized steel stay rod assemblies.

Best Practices in Installing Stay Fittings

Installing stay fittings may seem straightforward, but a meticulous approach is essential for ensuring the longevity and safety of your overhead transmission lines. Proper preparation and planning set the stage for a successful installation, while effective techniques can enhance performance. Regular maintenance and inspection are equally crucial to keep your stay wire line fittings in optimal condition.

Preparation and Planning

Before diving into the installation of stay fittings, it's vital to conduct thorough site assessments. Evaluate the terrain, identify potential hazards, and determine the best locations for your electric line fitting galvanized steel stay rod assembly. This preparatory phase will not only help streamline the installation process but also ensure that your overhead transmission line fitting operates efficiently over time.

Creating a detailed plan that outlines every step of the installation process can save you from unexpected hiccups later on. Factor in weather conditions, availability of materials, and workforce skills when scheduling your project timeline. The more organized you are during this phase, the smoother the execution will be!

Installation Techniques

When it comes to installing stay fittings, precision is key! Begin by securing your electric line fitting galvanized steel stay rod assembly firmly into place using appropriate tools and techniques designed for stability. Proper tensioning of stay wires is crucial; too loose can lead to sagging lines while too tight can cause undue stress on structures.

Utilizing specialized equipment like hydraulic tensioners ensures that each stay wire line fitting achieves optimal tension without risking damage during installation. It's also wise to follow manufacturer guidelines closely—these instructions are crafted with both safety and performance in mind! Remember to periodically check alignment during installation; this attention to detail pays dividends down the road.

Maintenance and Inspection Guidelines

Once installed, staying proactive with maintenance will keep your stay fittings functioning at their best! Regular inspections should include checking for wear and tear on both the fittings themselves as well as surrounding components like poles or towers supporting them. Look out for signs of corrosion or loosening connections that could compromise structural integrity over time.

Developing a routine maintenance schedule helps catch potential issues before they escalate into larger problems requiring costly repairs or replacements down the line. Additionally, maintaining clear records of inspections can assist in tracking any recurring issues with specific installations—knowledge is power after all! By prioritizing regular upkeep, you ensure that your overhead transmission lines remain reliable for years to come.

Conclusion

In wrapping up our exploration of stay fittings, it’s clear that these components are pivotal in ensuring the stability and safety of overhead transmission lines. They play a critical role in maintaining the integrity of electrical infrastructure, allowing for efficient energy distribution while minimizing risks associated with environmental factors. As we’ve seen, the importance of stay wire line fittings cannot be overstated; they are essential for reliable power delivery and operational longevity.

The Critical Role of Stay Fittings

Stay fittings serve as the unsung heroes of overhead transmission systems, providing necessary support and stability to electrical lines. Without these fittings, electric line fitting galvanized steel stay rod assemblies would struggle to withstand environmental pressures such as wind and ice loads. Their robust design ensures that cables remain taut and secure, which is vital for preventing outages and maintaining continuous service.

Why Choose Spark Fittings for Quality

When it comes to quality assurance in stay fittings, Spark fittings stand out as a top choice for many professionals in the industry. Known for their superior strength and corrosion resistance, these stay wire line fittings offer long-term reliability that translates into cost savings over time. Choosing Spark means opting for durability and performance—qualities that are essential when supporting critical infrastructure like overhead transmission lines.

Future Innovations in Stay Wire Technology

The future of stay wire technology looks promising with ongoing innovations aimed at enhancing performance and efficiency. We can expect advancements such as improved materials that offer even greater corrosion resistance or unique designs that facilitate easier installation processes for electric line fitting galvanized steel stay rod assemblies. As technology evolves, so will the capabilities of stay fittings, ensuring they continue to meet the demands of modern electrical infrastructure.