Introduction

In the fast-paced world of manufacturing and assembly, automatic wire cutting machines have become indispensable tools that streamline processes and enhance productivity. These machines not only save time but also ensure precision, making them a vital asset in various industries, from automotive to electronics. As companies strive for efficiency, understanding the importance of these machines is crucial for staying competitive.

Importance of Automatic Wire Cutting Machines

Automatic wire cutting machines are essential for any operation that involves handling wires or cables. Their ability to perform repetitive tasks with high accuracy significantly reduces labor costs and minimizes human error. In an industry where time is money, investing in reliable wire cutters and automatic wire stripping machines can lead to substantial gains in productivity.

Key Features to Consider

When selecting an automatic wire cutting machine, several key features should be on your radar. Look for speed and cutting capacity to match your production needs, as well as versatility with different wire types to ensure compatibility with various projects. Additionally, user-friendly interfaces can make a significant difference in operator efficiency and overall satisfaction.

Top Brands and Models

The market is filled with reputable brands offering top-notch automatic wire cutting machines tailored to diverse applications. Notable names like Spark Fittings, Schleuniger, and Komax stand out for their innovative designs and robust performance capabilities. By exploring these brands and their models, you can find the perfect fit for your specific requirements.

What Are Automatic Wire Cutting Machines

Automatic wire cutting machines are essential tools designed to streamline the process of cutting wires with precision and efficiency. These machines automate what was once a labor-intensive task, significantly reducing human error and increasing productivity in various settings. By utilizing advanced technology, they ensure that wires are cut to exact specifications, making them invaluable in manufacturing and assembly processes.

Definition and Functionality

At their core, automatic wire cutting machines are devices engineered to cut wires of varying lengths and materials automatically. They work by feeding wire through a series of rollers and blades that make precise cuts based on pre-set measurements. This functionality not only enhances the accuracy of cuts but also allows for high-speed production, making them ideal for industries requiring large volumes of wire components.

Types of Wire Cutting Machines

There are several types of wire cutting machines available on the market today, each designed for specific tasks or materials. For instance, some models function as simple wire cutters that handle basic tasks efficiently, while others incorporate advanced features like programmable settings for complex operations. Additionally, there are specialized machines such as cable stripping machines or automatic wire stripping machines that remove insulation from wires before they are cut—perfect for preparing electrical components.

Applications in Various Industries

The applications for automatic wire cutting machines span across numerous industries including automotive, aerospace, telecommunications, and electronics manufacturing. In these sectors, precise cuts can mean the difference between a successful assembly line and costly mistakes due to faulty wiring connections. Furthermore, their ability to quickly adapt to different types of wires makes them versatile tools in any production environment where efficiency is key—think about how many times you’ve seen a cable cutter or a wire stripping machine at work behind the scenes!

Benefits of Using Automatic Wire Cutting Machines

Automatic wire cutting machines have revolutionized the way industries handle wire processing, providing numerous benefits that enhance productivity and quality. These machines streamline operations, allowing for faster production times without sacrificing precision. With the ability to automate repetitive tasks, businesses can allocate their workforce to more strategic roles, leading to overall improved efficiency.

Enhanced Precision and Efficiency

These advanced wire cutters utilize sophisticated technology to ensure each cut is accurate, reducing the risk of human error that often plagues manual methods. This enhanced precision not only boosts efficiency but also contributes to higher quality end products—after all, no one wants a cable with uneven lengths or jagged edges!

Moreover, the speed at which these automatic wire stripping machines operate means that production lines can keep up with high demand without breaking a sweat. By minimizing downtime and maximizing output, businesses can enjoy a significant competitive edge in their respective markets. In short, investing in these machines translates into a smoother workflow and happier customers.

Cost-Effectiveness in Production

In an age where every penny counts, automatic wire cutting machines prove their worth through cost-effectiveness in production processes. Initially perceived as an investment with a hefty price tag, these machines quickly pay for themselves by reducing labor costs associated with manual wire cutting and stripping tasks. The efficiency gained from automation means fewer workers are needed on the floor while still maintaining high output.

Additionally, automated systems reduce the likelihood of costly mistakes during production runs—think about how much money is wasted on scrapped wires due to incorrect cuts or improper stripping! By utilizing reliable cable cutters that consistently perform at peak levels, companies can streamline their operations while keeping expenses in check. Ultimately, this leads to healthier profit margins and long-term sustainability for businesses.

Reduction in Waste and Errors

One of the standout benefits of using automatic wire cutting machines is their ability to significantly reduce waste and errors throughout the manufacturing process. Manual methods often lead to inconsistencies due to human oversight; however, automated systems are designed for accuracy and repeatability—cutting down on material waste like nobody's business! With precise measurements ensured by advanced technology within these machines, manufacturers can make better use of their raw materials.

Moreover, fewer errors mean less rework or scrap material generated during production runs—a win-win situation! The reduction in waste not only has positive implications for a company's bottom line but also aligns with environmentally conscious practices by minimizing unnecessary resource consumption. As industries continue to embrace automation through tools like automatic wire stripping machines and cable cutters, we can expect a greener future alongside improved operational efficiencies.

Spotlight on Notable Brands

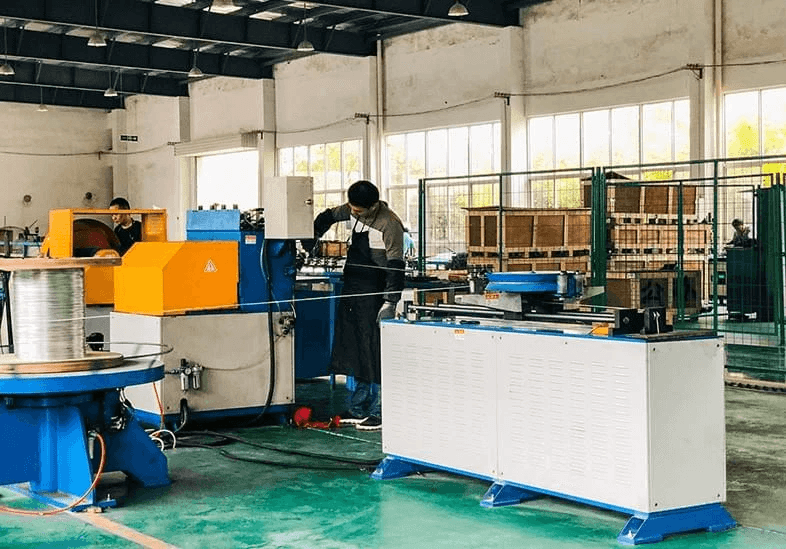

Spark Fittings: 16A Pre-Twisted Wire Production Line

Spark Fittings has carved a niche in the market with its 16A Pre-Twisted Wire Production Line, designed specifically for high-volume production. This automatic wire cutting machine excels in precision, ensuring that every cut is clean and accurate, which minimizes waste and enhances efficiency. With its user-friendly interface, operators can easily adjust settings for various wire types, making it a versatile choice among wire cutters.

The machine's ability to handle different gauges of wire makes it particularly appealing to manufacturers who require flexibility in their operations. Additionally, Spark Fittings prioritizes safety features, ensuring that users can operate the equipment without unnecessary risks. This combination of speed and reliability positions Spark Fittings as a leader in the automatic wire stripping machine market.

Schleuniger: Innovative Wire Processing Solutions

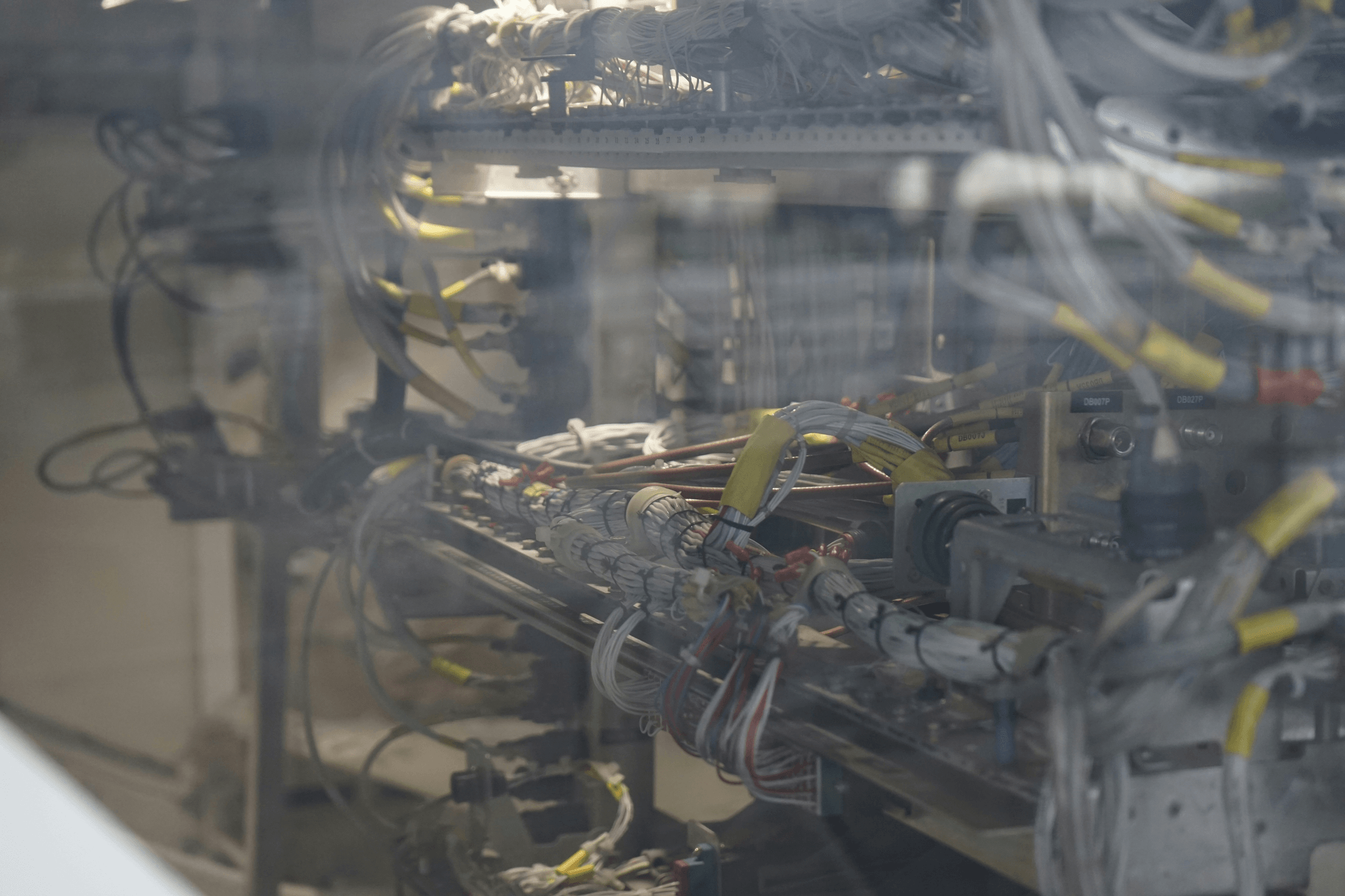

Schleuniger is synonymous with cutting-edge technology in the realm of automatic wire cutting machines and cable processing solutions. Their innovative designs focus on maximizing productivity while minimizing errors in production lines across various industries. With a diverse range of models available, Schleuniger caters to both small workshops and large-scale manufacturing facilities.

One standout feature is their advanced software integration that allows for seamless operation between different machines, including cable cutters and wire strippers. This level of automation not only enhances efficiency but also reduces labor costs significantly—an essential factor for any business looking to optimize its processes. Furthermore, Schleuniger’s commitment to research and development ensures they remain at the forefront of technological advancements in wire processing equipment.

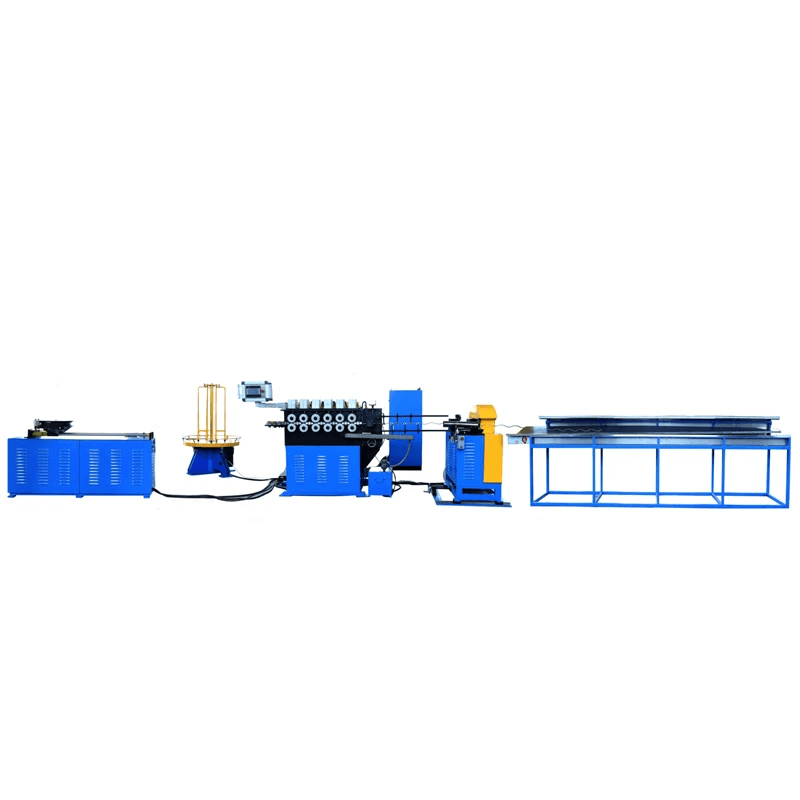

Komax: Versatile Cable Processing Equipment

Komax stands out as a versatile player in the field of cable processing equipment with its comprehensive lineup that includes various models tailored for specific applications. Their automatic wire cutting machines are designed with adaptability in mind; whether you’re working with thin wires or thicker cables, there's likely a Komax model suited for your needs. The precision engineering behind each device ensures consistent performance across all operations.

In addition to their robust line-up of wire cutters and stripping machines, Komax integrates modern technology into their products—think smart interfaces that allow users to program multiple tasks effortlessly. This makes them an excellent choice for businesses aiming to streamline operations without sacrificing quality or accuracy during production runs. As industries evolve towards greater automation, Komax remains committed to leading innovations within the sector.

Features to Look for in Wire Cutters

When selecting automatic wire cutting machines, there are several key features that can significantly influence their performance and usability. Understanding these features can help you make an informed decision when investing in wire cutters or related equipment. Let's dive into the essential aspects you should consider.

Speed and Cutting Capacity

One of the most critical factors in choosing a wire cutter is its speed and cutting capacity. Automatic wire cutting machines are designed to enhance production efficiency, allowing for high-speed operations without sacrificing precision. A machine that boasts a robust cutting capacity will handle various wire sizes and types, making it ideal for diverse applications in industries such as automotive, electronics, and telecommunications.

Moreover, the speed at which a cable cutter operates can dramatically affect your overall productivity levels. High-speed models not only reduce cycle times but also contribute to quicker turnaround rates on projects. When evaluating options, pay attention to specifications like cuts per minute (CPM) to ensure you select a machine that meets your production demands.

Versatility with Different Wire Types

Versatility is another essential feature to consider when looking for automatic wire cutting machines or wire strippers. The ability of a machine to accommodate different types of wires—such as copper, aluminum, or multi-stranded cables—can be crucial depending on your specific needs. This adaptability ensures that you won't be limited by the materials you can work with and allows for greater flexibility in your operations.

Additionally, some advanced cable stripping machines come equipped with adjustable settings that allow users to switch between various wire gauges effortlessly. This feature saves time during setup and reduces the likelihood of errors when transitioning between different projects or materials. Ultimately, a versatile machine ensures that you're prepared for any task thrown your way.

User-Friendly Interfaces

A user-friendly interface is vital for maximizing efficiency when operating automatic wire stripping machines or other types of wire cutters. Machines equipped with intuitive controls make it easier for operators to navigate settings without extensive training or experience. Look for features such as touch screens, programmable functions, and clear displays that simplify operation.

Furthermore, an effective user interface not only enhances productivity but also minimizes the risk of mistakes during operation—an essential factor when dealing with intricate tasks like cable processing. Some models even offer remote monitoring capabilities so operators can oversee multiple machines from one central location! Choosing equipment with user-friendly interfaces will ultimately lead to smoother operations and happier team members.

The Role of Cable Stripping Machines

When it comes to wire processing, understanding the role of cable stripping machines is crucial. While automatic wire cutting machines are designed primarily for cutting wires to specific lengths, cable strippers focus on removing insulation from those wires. This distinction is vital for manufacturers who need both functionalities in their production line.

Difference Between Wire Cutters and Strippers

Wire cutters and wire strippers serve different purposes in the world of wire processing. Wire cutters, also known as automatic wire cutting machines, are built to slice through various types of wires cleanly and efficiently. In contrast, wire strippers or cable stripping machines are specialized tools that remove the insulation from wires without damaging the metal conductor inside.

Understanding these differences can help businesses choose the right equipment for their needs. For instance, if a company requires both cutting and stripping capabilities, investing in a combination machine could be beneficial. Ultimately, knowing whether to use a cable cutter or a wire stripping machine can save time and reduce errors in production.

Best Cable Stripping Machines on the Market

The market is flooded with options when it comes to selecting a top-notch cable stripping machine. Some of the best models include brands like Schleuniger’s UniStrip series, which offer precision and versatility for various wire sizes and types. Another notable mention is Komax's Kappa series; these machines are renowned for their user-friendly interfaces and ability to handle complex tasks efficiently.

For those looking for budget-friendly options without sacrificing quality, there are several reliable choices available that cater specifically to smaller operations or DIY enthusiasts. Whether you need an automatic wire stripping machine or a manual one, researching your options will ensure you find the best fit for your specific requirements. Remember that investing in a quality cable stripper can significantly enhance productivity and reduce waste during manufacturing processes.

Tips for Optimal Performance

To get the most out of your cable stripping machine, consider implementing some best practices that enhance performance. First off, always ensure that your equipment is properly maintained; regular cleaning and lubrication can prevent breakdowns and prolong its lifespan. Additionally, using the correct settings based on wire type will yield better results – too much pressure can damage conductors while too little may leave insulation behind.

Another tip is to train operators thoroughly on how to use both automatic wire cutting machines and cable strippers effectively; this knowledge will minimize errors during operation. Lastly, keep spare parts handy so you’re prepared for any unexpected issues that may arise while working with these essential tools in production lines or workshops.

Conclusion

In the ever-evolving landscape of manufacturing and assembly, automatic wire cutting machines stand out as essential tools that enhance productivity and precision. These machines not only streamline operations but also reduce labor costs and minimize errors, making them a wise investment for various industries. Understanding the key features and benefits of wire cutters, cable stripping machines, and other related equipment is crucial for any business looking to optimize its wire processing capabilities.

Key Takeaways on Wire Processing Equipment

Automatic wire cutting machines are designed to deliver high efficiency and accuracy in cutting wires of different sizes and types. When selecting a wire cutter or a cable stripping machine, consider factors such as speed, capacity, versatility, and user-friendliness to ensure optimal performance in your operations. Additionally, brands like Spark Fittings, Schleuniger, and Komax offer innovative solutions that cater to diverse industrial needs.

Future Trends in Automatic Wire Cutting Technology

The future of automatic wire cutting technology looks promising with advancements in automation and smart manufacturing systems. We can expect more sophisticated features such as enhanced connectivity through IoT integration for real-time monitoring and analytics. Furthermore, developments in artificial intelligence may lead to even more precise adjustments during the cutting process while reducing waste further—making automatic wire stripping machines an even more attractive option for businesses.

Final Recommendations for Your Needs

When choosing among various options for automatic wire cutting machines or cable strippers, prioritize your specific requirements based on production volume and material types handled. Don't overlook the importance of customer support from manufacturers; reliable service can save you time and money down the line when issues arise with your equipment. Ultimately, investing in high-quality wire processing equipment will pay dividends through improved efficiency and reduced operational costs.