Introduction

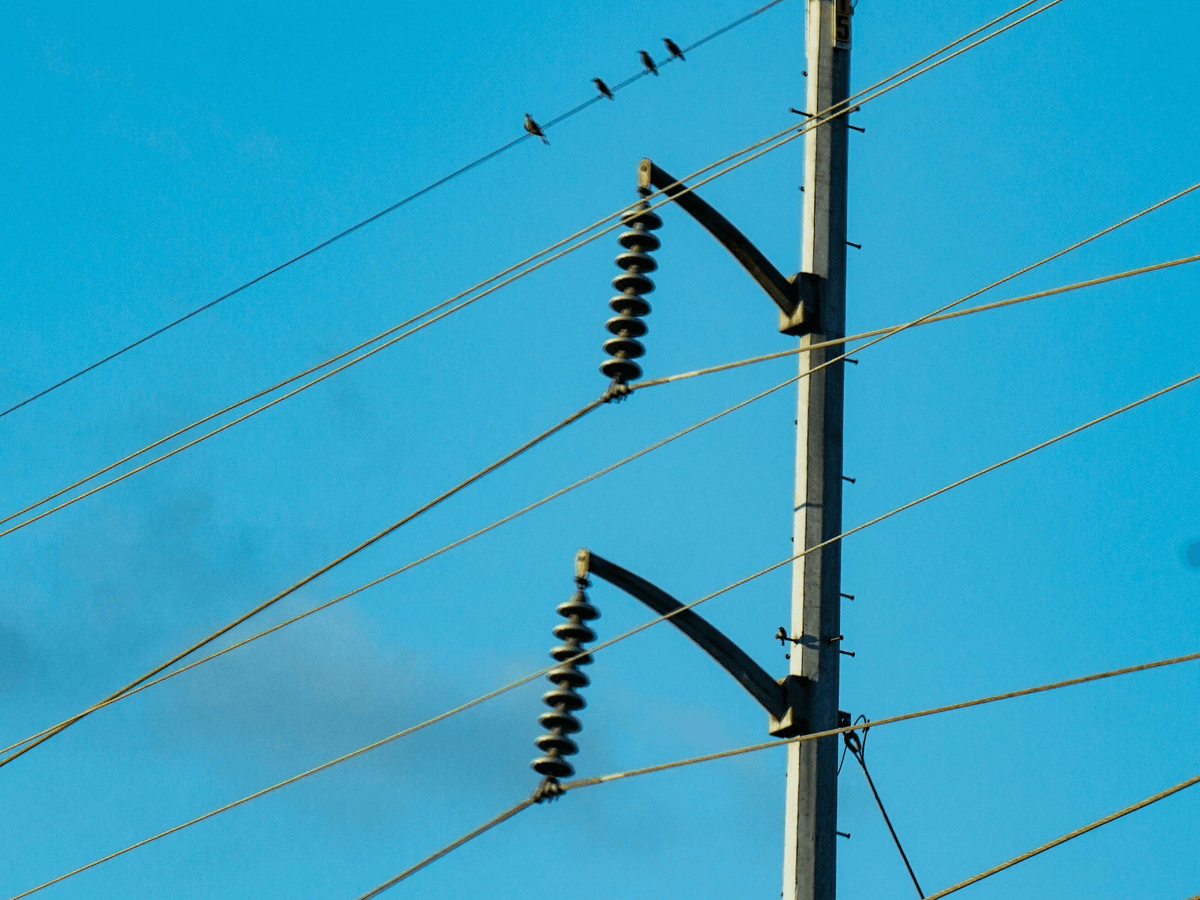

Transmission line hardware is the backbone of our electrical infrastructure, connecting power generation to distribution networks. Understanding the various components, such as the ball link, U Bolt, and Ball Eye, is crucial for anyone involved in this industry. These fittings not only ensure stability but also enhance the overall efficiency of transmission lines.

Understanding Transmission Line Hardware

Transmission line hardware encompasses a wide array of fittings and supports that hold high-voltage lines in place while allowing for necessary movement and flexibility. Components like Socket Eyes and Socket Clevises play vital roles in securing cables and managing tension within the system. Each piece of hardware must be designed with precision to withstand environmental stressors and operational demands.

Key Components of Transmission Lines

Key components include not just the aforementioned fittings but also essential items like arcing horns that protect against electrical discharges. The ball link serves as a critical connector, providing flexibility while maintaining structural integrity under load. U Bolts are indispensable for supporting structures, ensuring that everything remains firmly anchored during adverse conditions.

Importance of Quality Hardware in Transmission Systems

Quality hardware is paramount in transmission systems; it directly impacts reliability and safety across vast networks. Inferior components can lead to failures that disrupt service and pose risks to both equipment and personnel. Investing in high-quality fittings like Ball Eyes or Arcing Horns ensures longevity, efficiency, and peace of mind for all stakeholders involved.

Overview of Transmission Line Hardware

Transmission line hardware plays a pivotal role in ensuring the efficiency and reliability of power transmission systems. Understanding the various hardware fittings, such as ball links, U bolts, ball eyes, socket eyes, and arcing horns, is crucial for anyone involved in the design or maintenance of these systems. In this section, we will explore the types of hardware fittings available, their contributions to transmission efficiency, and the quality standards that govern their use.

Types of Hardware Fittings

You’ll find an array of components like ball links that provide flexibility in connections and U bolts that offer robust support for structures. Other essential fittings include ball eyes and socket clevises which help secure cables effectively while arcing horns play a vital role in preventing electrical arcing at critical points.

Each type of fitting serves a unique purpose; for instance, ball links are designed to allow movement under load while maintaining stability. U bolts are typically used to anchor cables or rods firmly to poles or structures. Meanwhile, socket eyes and socket clevises facilitate easy attachment and detachment during installation or maintenance work.

Understanding these different types is essential for selecting the right components for your specific application needs. Whether you’re outfitting new lines or upgrading existing ones, knowing when to use a ball link versus a U bolt can make all the difference in performance.

Their Role in Transmission Efficiency

The efficiency of transmission lines heavily relies on the quality and design of their hardware fittings. Properly installed components like ball links ensure that energy flows smoothly without unnecessary friction or resistance that can lead to power loss. Similarly, U bolts provide structural integrity by securely fastening elements together—keeping everything aligned even under stress.

In addition to enhancing performance, well-designed fittings contribute significantly to reducing maintenance costs over time. For example, using high-quality arcing horns can prevent electrical faults by diverting excess energy away from vulnerable areas—thus minimizing downtime due to repairs or replacements. The strategic placement of ball eyes also allows for flexibility during adverse weather conditions without compromising safety.

Overall, each fitting plays an integral role in optimizing transmission efficiency while ensuring reliability throughout the system's lifecycle. By prioritizing quality hardware like socket clevises alongside other components mentioned above, operators can maximize both performance and longevity.

Quality Standards and Regulations

Organizations such as IEEE (Institute of Electrical and Electronics Engineers) have established guidelines that manufacturers must follow regarding materials used for items like ball links or U bolts. Compliance with these regulations not only ensures durability but also helps prevent catastrophic failures down the line.

Moreover, regular inspections are necessary to confirm that all components—including socket eyes and arcing horns—meet industry standards throughout their operational life span. This commitment extends beyond initial installation; ongoing adherence guarantees optimal performance under varying loads and environmental conditions.

In conclusion, understanding types such as ball links or benefits provided by using reliable components is crucial for maintaining efficient operations within transmission systems today—and tomorrow! By focusing on quality standards set forth by industry leaders while choosing appropriate hardware options tailored specifically toward your needs will undoubtedly pave the way towards more resilient infrastructure development.

Detailed Look at Ball Link

This clever little device is designed to connect various fittings and hardware elements, ensuring that everything works in perfect harmony. With its unique shape and functionality, the ball link plays a crucial role in maintaining structural integrity and facilitating smooth movement within transmission systems.

Definition and Functionality

A ball link is essentially a spherical joint that allows for multidirectional movement between connected components, such as U bolts or socket eyes. Its design enables flexibility while providing robust support, which is vital in environments where tension and load can fluctuate dramatically. By linking different elements like ball clevises or arcing horns together, the ball link ensures that each part can pivot smoothly without compromising stability.

Advantages of Using Ball Links

One of the primary advantages of using a ball link is its ability to accommodate misalignments between connected parts without causing undue stress on the system. This flexibility reduces wear and tear on components like socket clevises and U bolts over time, ultimately extending their lifespan. Additionally, by allowing for easy adjustments during installation or maintenance, ball links contribute significantly to overall efficiency in transmission line setups.

Applications in Transmission Lines

Ball links are widely used across various applications within transmission lines, particularly where flexibility and strength are paramount. They can be found connecting conductors to insulators or supporting structures like towers through U bolts or socket eyes. Moreover, their compatibility with other essential components—such as arcing horns—makes them indispensable for ensuring safe and reliable operation throughout electrical networks.

Exploring U Bolt and Its Uses

This simple yet effective component serves as a crucial element in support structures, ensuring that everything stays securely in place. With its unique shape and versatility, the U Bolt is often paired with other fittings like ball links and socket eyes to enhance overall stability.

What is a U Bolt?

A U Bolt is essentially a bent piece of metal shaped like the letter U, featuring two threaded ends that allow for secure fastening. It’s commonly used to attach pipes or poles to various surfaces, providing essential support in transmission systems. Whether it's part of a larger assembly involving ball clevis or socket clevis, the U Bolt plays an integral role in maintaining structural integrity.

Benefits of U Bolts in Support Structures

One of the primary benefits of using U Bolts is their ability to distribute weight evenly across a surface, reducing stress on individual components like ball eyes and arcing horns. This makes them ideal for applications where stability is paramount, such as overhead power lines or telecommunications towers. Additionally, their durability ensures that they can withstand harsh environmental conditions while maintaining performance over time.

Installation Tips for U Bolts

Installing a U Bolt may seem straightforward, but there are some best practices worth noting to ensure optimal performance. First off, make sure you choose the right size and material; stainless steel options are often preferred for their corrosion resistance when paired with components like socket eyes and ball links. When tightening, use a torque wrench for precision—over-tightening can lead to stripped threads or compromised structural integrity.

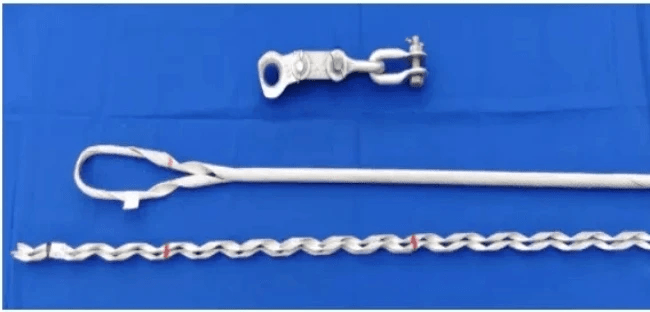

The Versatile Ball Eye

This component is a key player in ensuring smooth operation and flexibility within the system. With its rounded shape, the ball eye allows for a range of motion that is crucial for accommodating various stresses and movements in transmission lines.

Features of Ball Eyes

Ball eyes are typically made from high-strength materials that can withstand significant loads while maintaining their integrity over time. They feature a spherical design that enables easy connection to other components like U bolts, socket eyes, and ball clevises. This design not only enhances their strength but also allows for greater adaptability in different installation scenarios.

How Ball Eyes Contribute to Flexibility

One of the primary benefits of using ball eyes is their ability to absorb dynamic forces without compromising structural integrity. Unlike rigid fittings, ball eyes provide the necessary flexibility to accommodate thermal expansion and contraction as well as wind-induced movements. This adaptability ensures that transmission lines remain stable under various environmental conditions, reducing wear on other components such as arcing horns.

Common Applications in the Field

Ball eyes are frequently used in conjunction with other fittings like socket clevises and U bolts to create robust support structures for overhead transmission lines. Their versatility makes them suitable for various applications including tensioning systems, where they help maintain proper alignment under load. Additionally, you’ll find them employed alongside armor rods to protect against wear while enhancing overall system durability.

Socket Eye and Socket Clevis Explained

Among these, the socket eye and socket clevis stand out as essential fittings that ensure stability and flexibility in the system. These components work together effectively, playing a significant role in maintaining the integrity of transmission lines.

Definitions of Socket Eye and Socket Clevis

A socket eye is a type of fitting that provides a secure connection point for other hardware components, such as a U Bolt or a ball link. It typically features a circular opening designed to accommodate various attachments while allowing for movement and alignment adjustments. On the other hand, a socket clevis serves as an anchor point that connects two components securely, often used in conjunction with the ball eye or other fittings to create robust support structures.

Differences and Similarities

While both socket eyes and socket clevises serve similar purposes in providing connection points, their designs cater to different needs within transmission systems. A socket eye is primarily focused on flexibility, allowing for rotational movement when attached to elements like ball links or arcing horns. Conversely, a socket clevis emphasizes strength and stability, making it ideal for applications where rigid support is necessary—think of it as the muscle to the socket eye's agility.

Despite these differences, both components share common features that make them indispensable in transmission line hardware setups. They are usually made from durable materials capable of withstanding harsh environmental conditions while ensuring longevity. Additionally, both can be easily installed using standard tools and techniques; however, care should be taken during installation to ensure optimal performance.

When to Use Each Component

Choosing between a socket eye and a socket clevis often depends on specific application requirements within your transmission system design. If you need flexibility—perhaps when connecting moving parts like ball eyes or arcing horns—a socket eye would be your best bet due to its ability to allow rotation without compromising integrity. On the contrary, if your setup requires robust anchoring capabilities—like securing heavy loads or stabilizing structures—a socket clevis is more appropriate due to its inherent strength.

In summary, understanding when to use each component can significantly impact overall transmission efficiency and safety. By selecting the right fitting—whether it's a versatile ball link or sturdy U Bolt—you can enhance your system's performance while ensuring compliance with quality standards in transmission line hardware.

The Importance of Arcing Horns

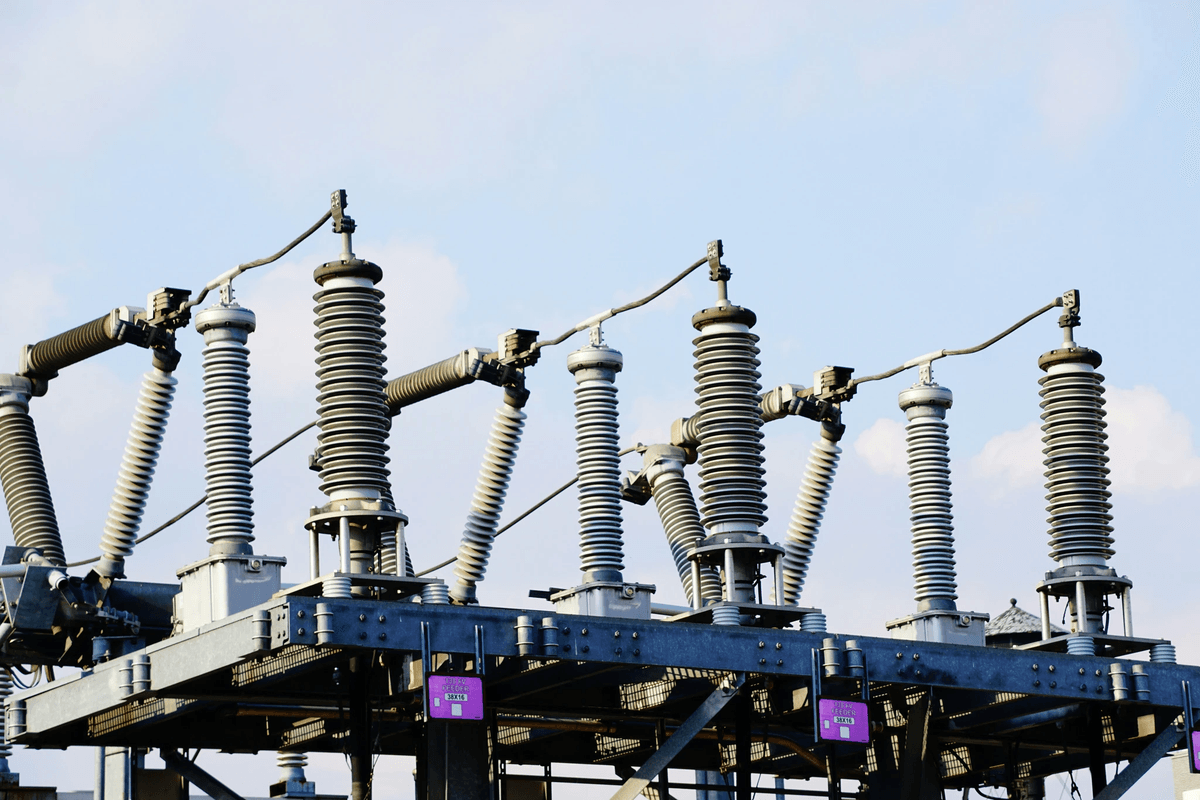

When it comes to the safety and efficiency of transmission lines, arcing horns play a pivotal role. These specialized fittings are designed to redirect electrical discharges, ensuring that energy flows smoothly without causing damage to other components, such as ball links or U bolts. By effectively managing electrical arcs, arcing horns contribute significantly to the longevity and reliability of transmission systems.

What Are Arcing Horns?

Arcing horns are metallic devices installed at specific points along transmission lines to mitigate the risks associated with electrical arcing. Typically made from conductive materials, they protrude outward from insulators and serve as a pathway for stray electrical currents during fault conditions. These components work in conjunction with other hardware fittings like ball eyes and socket clevises to create a comprehensive protective system for high-voltage installations.

How They Prevent Electrical Arcing

The primary function of arcing horns is to prevent electrical arcing by providing an alternative path for electricity during fault conditions. When voltage surges occur, instead of jumping across an insulator or damaging critical hardware like ball links or U bolts, the current is directed through the arcing horn. This action not only protects sensitive equipment but also enhances the overall efficiency of the transmission line by minimizing energy loss due to unwanted discharges.

Best Practices for Installation

To maximize the effectiveness of arcing horns, proper installation is crucial. Ensure that they are positioned at optimal locations on transmission structures where voltage surges are likely to occur; this often includes areas near ball clevises and socket eyes that experience significant stress during operation. Additionally, regular inspections should be conducted to check for wear and tear; maintaining these components ensures they continue functioning effectively in preventing electrical arcs.

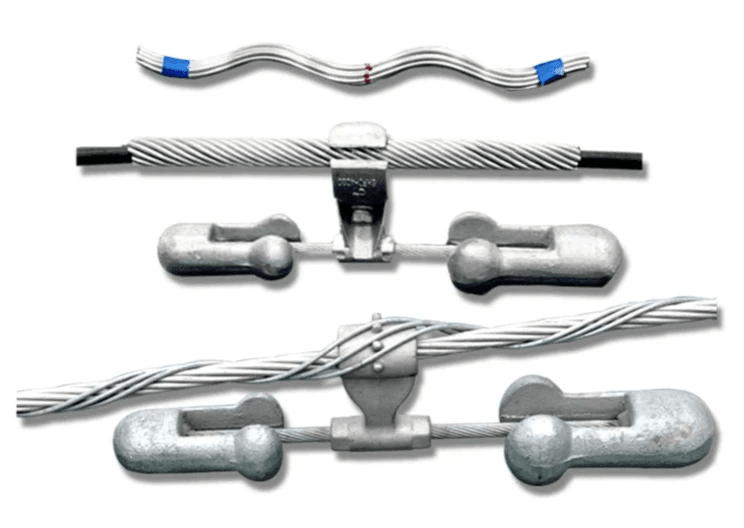

Custom Armor Rod Solutions by Spark Fittings

When it comes to enhancing the durability and performance of transmission lines, Spark Fittings offers a range of custom armor rod solutions designed to meet diverse needs. These armor rods are essential for protecting conductors from wear and tear, ensuring that components like the ball link, U bolt, and socket clevis function optimally over time. With a focus on quality and innovation, Spark Fittings stands out in providing tailored solutions that cater to specific installation requirements.

Overview of Spark Fittings Offerings

Spark Fittings specializes in a variety of hardware fittings crucial for transmission line systems, including armor rods that offer robust protection against environmental factors. Their offerings include not only standard designs but also custom options that can accommodate specific project needs involving components such as ball eyes and arcing horns. By prioritizing compatibility with existing hardware like U bolts and socket eyes, Spark ensures seamless integration into any transmission setup.

Armor Rod Materials and Their Significance

The materials used in armor rods are vital for their performance; they must withstand harsh conditions while providing reliable support to conductors. Common materials include fiberglass and aluminum, which are lightweight yet durable enough to resist corrosion—ideal for components like the ball clevis or socket clevis that might be exposed to moisture or other elements. The choice of material significantly influences the longevity and efficiency of the entire transmission line system.

Understanding Color Codes for Installation

Color coding is an essential aspect of installing armor rods correctly; it provides clear guidelines on which rod fits which application. Different colors indicate various sizes or specifications, helping installers easily identify compatible components such as ball links or U bolts during assembly. Familiarity with these color codes not only streamlines the installation process but also ensures optimal performance across all fittings involved in the transmission line setup.

Conclusion

In wrapping up our exploration of transmission line hardware, it's clear that each component plays a vital role in ensuring efficiency and reliability. From the sturdy U Bolt to the flexible Ball Eye and the protective Arcing Horn, these fittings are not just accessories; they are essential elements of a well-functioning transmission system. Understanding how these components work together can lead to better maintenance practices and improved performance in power delivery.

Key Takeaways on Hardware Fittings

The importance of hardware fittings like the ball link, U Bolt, and Socket Clevis cannot be overstated. These components are designed to withstand various environmental challenges while providing necessary support and flexibility in transmission lines. Additionally, knowing when to use specific parts—such as choosing between a Socket Eye or a Ball Clevis—can significantly enhance installation efficiency and safety.

Why Choose Quality Transmission Line Parts

Investing in quality transmission line parts is paramount for long-term success in any electrical infrastructure project. High-quality components such as Arcing Horns and robust ball links contribute not only to operational efficiency but also ensure safety standards are met, reducing potential risks down the line. When you choose quality over quantity, you're opting for durability that pays off through fewer replacements and repairs.

The Future of Transmission Line Technology

As technology advances, so does the design and functionality of transmission line hardware like Ball Eyes and U Bolts. Innovations aimed at improving material strength while reducing weight will likely dominate future designs, enhancing overall system performance. Moreover, with increasing demands for renewable energy sources, we can expect more sophisticated solutions that integrate seamlessly with emerging technologies for even greater efficiency.