Introduction

These unassuming components serve a critical role in protecting electrical conductors from damage caused by environmental factors and mechanical stress. Without preformed armor rods, the risk of line failure would significantly increase, leading to costly outages and repairs.

The Importance of Armour Rods

Armour rods are vital in ensuring the longevity and reliability of transmission lines. They provide essential support and protection for conductors, particularly at points where they are most vulnerable, such as at splices or terminations. By using PLP armor rods or AFL armor rods, utility companies can enhance their infrastructure's resilience against natural elements and operational wear.

A Brief History of Armour Rods

The development of armour rods dates back several decades when engineers recognized the need for improved protection methods for overhead lines. Initially made from simple materials, these components have evolved significantly over time with advancements in technology and materials science. Today’s preformed line products offer enhanced durability and performance features that were unimaginable in earlier designs.

How Armour Rods Protect Your Lines

Armour rods protect your lines by distributing mechanical loads evenly along conductors, reducing stress concentrations that could lead to failure. They act as a shield against abrasion from wind or ice accumulation while also preventing conductor wear due to vibration during operation. By incorporating effective armor rod installation techniques, utilities can ensure their lines remain operational under various conditions, safeguarding both infrastructure and service reliability.

What Are Armour Rods?

Armour rods are crucial components used in electrical transmission lines to provide protection and enhance the durability of conductors. These preformed armor rods serve a dual purpose: they shield the conductor from abrasion and mechanical stress while also maintaining its structural integrity. By distributing tension along the line, they prevent damage that can lead to costly outages and maintenance.

Definition and Purpose

At their core, armour rods are protective devices designed to safeguard conductors in transmission lines from environmental wear and tear. They are typically made from durable materials that can withstand extreme weather conditions, ensuring longevity and reliability in electrical systems. The primary purpose of these rods is to minimize the risk of conductor failure by absorbing mechanical loads and reducing localized stresses.

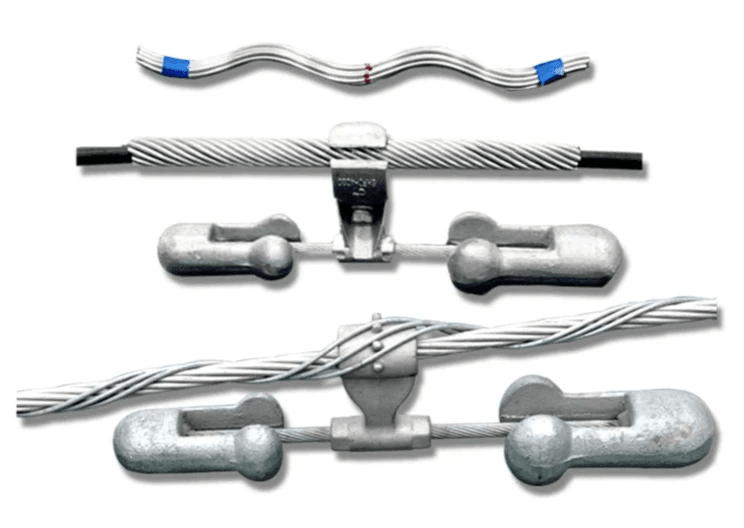

Key Features of Armour Rods

Armour rods boast several key features that make them indispensable for any transmission line setup. First, they are preformed to fit snugly around conductors, providing a tailored protective layer that enhances their effectiveness. Additionally, these rods come with high tensile strength, which ensures they can handle significant loads without compromising performance—ideal for heavy-duty applications like PLP armor rods or Afl armor rods.

Types of Materials Used

The materials used in manufacturing armour rods play a pivotal role in their performance characteristics. Typically crafted from fiberglass or aluminum alloy, each material brings unique benefits; fiberglass is known for its lightweight properties while aluminum offers excellent conductivity and strength. The choice between different types often depends on specific project requirements—whether it's for standard installations or specialized needs such as custom armor rod solutions from Spark Fittings.

Types of Armour Rods

The market offers a variety of products designed to enhance the durability and efficiency of electrical lines, including PLP armor rods, Afl armor rods, and custom solutions from Spark Fittings. Each type has unique features that cater to different installation requirements and environmental conditions.

PLP Armor Rods Explained

PLP Armor Rods are a popular choice among utility companies for their reliability and performance in transmission line applications. These preformed armor rods are engineered with high-strength materials that provide excellent support and protection against wear and tear caused by wind, ice, or other environmental factors. Their design ensures optimal load distribution along the conductor, making them an essential component in effective armor rod installation.

In addition to their strength, PLP armor rods come in various sizes and configurations to suit different conductor types and installation scenarios. The versatility of these preformed line products allows for easy customization based on specific project needs. This adaptability makes PLP armor rods a go-to solution for engineers looking to safeguard their transmission lines effectively.

Afl Armor Rods Overview

Afl armor rods represent another leading option in the realm of armour rod technology, known for their innovative design and robust construction. These preformed armor rods are specifically crafted to withstand harsh conditions while minimizing stress on conductors during operation. With an emphasis on durability, Afl armor rods help extend the lifespan of transmission lines by preventing damage from environmental elements.

One notable feature of Afl armor rods is their lightweight construction without compromising strength or effectiveness. This makes them easier to handle during installation compared to heavier alternatives while still delivering reliable performance in protecting your lines. Utility companies often prefer Afl products due to their proven track record in enhancing system reliability through effective use of preformed armor rod technology.

Custom Armor Rods from Spark Fittings

For projects requiring tailored solutions, custom armor rods from Spark Fittings offer flexibility that standard options may not provide. These specialized preformed line products can be designed according to specific engineering requirements or unique environmental challenges faced by a particular transmission line setup. Whether you need a specific length or unique material properties, Spark Fittings can deliver custom solutions that meet your exact specifications.

The advantage of opting for custom armour rods lies not only in personalization but also in optimizing performance across diverse applications within transmission systems. By working closely with manufacturers like Spark Fittings, utilities can ensure they receive a product that aligns perfectly with their operational goals while enhancing overall system integrity through effective armour rod installation practices.

How Armour Rods Are Used in Transmission Lines

Armour rods play a crucial role in the integrity and longevity of transmission lines. They serve as protective devices that reduce the risk of damage to conductors, especially during adverse weather conditions or when subjected to mechanical stress. By incorporating preformed armor rods into transmission systems, utilities can enhance both reliability and performance.

The Role of Armour Rods in Transmission Systems

In transmission systems, armour rods act as a shield for conductors, preventing wear and tear caused by wind, ice, and other environmental factors. They distribute mechanical loads more evenly across the conductor's surface, thereby minimizing stress points that could lead to failure. Furthermore, PLP Armor Rods are specifically designed to fit various conductor sizes and types, ensuring optimal protection and support.

Benefits of Using Preformed Armor Rod

The use of preformed armor rod offers several advantages over traditional methods of conductor protection. For one, these rods are easy to install and can significantly reduce labor costs during armor rod installation. Additionally, Afl armor rods provide enhanced durability compared to conventional solutions due to their superior material properties—making them a smart choice for long-term investments in transmission infrastructure.

Case Studies in Effective Installation

Several case studies highlight the effectiveness of using preformed armor rods in real-world applications. In one notable project involving a major utility company, the installation of PLP Armor Rods resulted in a 30% reduction in conductor failures over five years—demonstrating their value in maintaining system reliability. Another case featured Afl armor rods being implemented on high-voltage lines; this led to decreased maintenance costs while improving overall line performance during extreme weather events.

Installation Best Practices

Proper installation not only ensures the longevity and effectiveness of the preformed armor rod but also plays a crucial role in maintaining the integrity of transmission lines. Whether you're using PLP Armor Rods or Afl armor rods, following best practices can make all the difference.

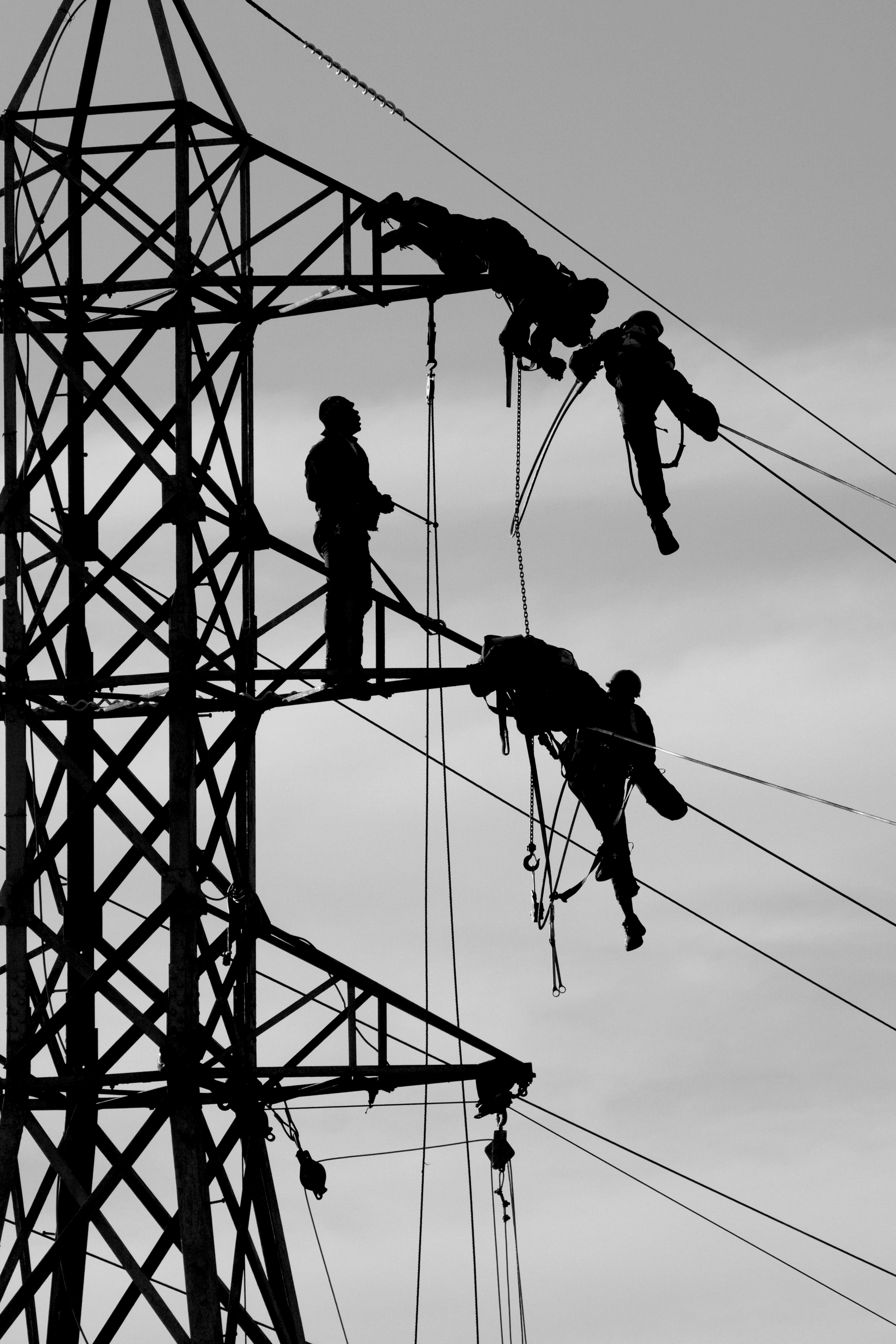

Step-by-Step Armor Rod Installation

The process begins with assessing the transmission line where you intend to apply the preformed armor rod. First, ensure that you have all necessary tools and materials at hand, including gloves for safety. Next, clean the area around the conductor thoroughly; this step is often overlooked but critical for a secure fit.

Once your workspace is ready, slide the preformed armor rod over the conductor, aligning it properly to avoid any misplacement. After positioning it correctly, use your hands to gently press down on both ends of the rod to secure it in place. Finally, inspect your work closely; a well-installed armour rod should fit snugly without any gaps.

Common Mistakes to Avoid

One of the most common pitfalls during armor rod installation is neglecting to clean the conductor beforehand; dirt and grime can prevent proper adhesion and lead to premature failure of your armour rods in transmission lines. Another mistake is failing to check compatibility between different types of rods; not all PLP Armor Rods or Afl armor rods are suitable for every application.

Lastly, rushing through installation can lead to improper placement or inadequate tensioning, which can compromise performance over time. Taking your time and following each step meticulously will help you avoid these costly errors and ensure that your preformed line products perform as intended.

Tools and Equipment Needed

To successfully install an armour rod, you'll need several essential tools that streamline the process while ensuring safety and efficiency. First on your list should be a pair of high-quality gloves—safety first! You'll also want wire cutters or pliers for trimming excess material if necessary.

Additionally, having a torque wrench handy can help you achieve optimal tension when securing PLP Armor Rods or Afl armor rods onto conductors. Lastly, consider using a utility knife for any adjustments needed during installation; this tool will come in handy more often than you'd think! With these tools at your disposal, you're well-equipped for successful armor rod installation.

Choosing the Right Armor Rod

Selecting the right armor rod can feel like navigating a maze of options, but it doesn't have to be daunting. Understanding the factors that influence material selection, the significance of color codes, and how to compare various manufacturers can streamline your decision-making process. Let's dive into what makes choosing the perfect preformed armor rod a breeze.

Factors Influencing Material Selection

First and foremost is the environmental conditions; rods must withstand weather elements like UV radiation, moisture, and temperature fluctuations. Additionally, consider mechanical properties such as tensile strength and flexibility—these attributes ensure that your PLP Armor Rods or Afl armor rods can handle the demands of transmission line installations without compromising performance.

Another crucial factor is compatibility with existing line materials. You want to ensure that your chosen preformed armor rod harmonizes with other components in your system to prevent premature wear or failure. Finally, cost-effectiveness should not be overlooked; while investing in quality is essential, balancing performance with budget constraints will lead you to make an informed choice.

The Importance of Color Codes

Color codes are more than just a pretty face when it comes to armor rods—they serve a vital purpose in ensuring proper installation and identification. Different colors often indicate specific sizes or types of preformed armor rods, making it easier for technicians on-site to select the correct product quickly. This can significantly reduce errors during installation and improve overall efficiency.

Moreover, using color-coded systems helps maintain consistency across various projects and installations. When teams are familiar with these codes, they can work more effectively together without confusion over which PLP Armor Rods or Afl armor rods are needed for specific applications. Ultimately, embracing these visual cues contributes not only to safety but also enhances productivity in any transmission line project.

Comparing Different Manufacturers

With numerous manufacturers offering their take on preformed armor rods, comparing them requires a keen eye for detail and performance metrics. Start by examining product specifications from trusted brands such as PLP and Afl; look at their durability ratings and customer reviews for insights into real-world performance during armor rod installation processes.

Furthermore, consider warranty offerings—the best manufacturers stand behind their products with solid guarantees that reflect confidence in their craftsmanship. By aligning your needs with manufacturer strengths—whether it's superior materials from Spark Fittings or innovative designs from other competitors—you'll find an ideal match tailored specifically for your requirements.

In conclusion, choosing the right armor rod involves understanding material influences, appreciating color coding systems for quick identification during installation processes, and carefully comparing different manufacturers based on quality standards and warranties offered in preformed line products.

Conclusion

In wrapping up our exploration of armour rods, it’s clear that these components play a vital role in ensuring the longevity and reliability of transmission lines. From their robust design to their ability to mitigate wear and tear, preformed armor rods are indispensable in the utility industry. Whether you’re considering PLP Armor Rods or Afl armor rods, understanding these features will guide you in making informed decisions for your projects.

Summary of Key Features of Armour Rods

Armour rods are designed with durability and protection in mind, acting as a shield against environmental stresses that can damage transmission lines. The key features include their ability to distribute mechanical load, reduce abrasion, and provide excellent electrical insulation. When properly utilized during armor rod installation, these benefits ensure that your transmission systems operate efficiently and safely.

Future Trends in Armour Rod Technology

Looking ahead, the future of armour rod technology is promising with advancements focused on material innovation and enhanced performance capabilities. Manufacturers like Preformed Line Products are exploring new composites that offer greater strength-to-weight ratios while also being more environmentally friendly. Additionally, we can expect improvements in customization options for PLP Armor Rods and Afl armor rods to better meet specific project requirements.

How to Choose Your Armour Rod Supplier

Choosing the right supplier for your armour rods is crucial for ensuring quality and compatibility with your transmission line needs. Start by evaluating manufacturers based on their product offerings—considering factors such as whether they specialize in preformed armor rod solutions or custom designs like those from Spark Fittings. Finally, don't forget to check customer reviews and industry certifications to ensure you're partnering with a reliable provider who understands the intricacies of armor rod installation.