Introduction

In the realm of high voltage power transmission lines, understanding the role of stay insulators is crucial for ensuring safety and reliability. These specialized components support various structures, including electrical cables and guy wires, by providing essential insulation and stability. By effectively managing electrical flow and minimizing risks, stay insulators play a pivotal role in maintaining the integrity of our energy infrastructure.

Understanding Stay Insulators

Stay insulators are vital components designed to prevent electrical leakage while securing overhead structures like transmission lines. They act as a barrier between conductive materials and ground wire systems, ensuring that high voltage does not escape into unintended pathways. With various designs available, including pin type, strain type, and suspension type insulators, each serves a unique purpose in supporting cable clamps and guy wires.

Importance of Insulation in High Voltage Lines

Insulation is paramount in high voltage power transmission lines as it protects both equipment and personnel from dangerous electrical discharges. Without effective insulation provided by stay insulators, the risk of short circuits or catastrophic failures increases significantly. Properly installed stay insulators not only enhance safety but also contribute to the longevity and efficiency of electrical cable systems.

Overview of Stay Insulator Variants

There are several variants of stay insulators tailored to specific applications within the electrical industry. Pin type stay insulators are commonly used for their straightforward installation process, while strain type models excel in supporting guy wire systems under tension. Suspension type stay insulators provide stability for horizontal runs of electrical cables, ensuring they remain secure even under challenging environmental conditions.

Pin Type Stay Insulator

Pin type stay insulators play a crucial role in ensuring the stability and safety of high voltage power transmission lines. Designed to support guy wires while maintaining electrical isolation, these insulators are vital for preventing short circuits and ensuring efficient energy transfer. Their robust construction and versatility make them suitable for various applications in overhead electrical cable systems.

Features and Applications

Pin type stay insulators are characterized by their cylindrical shape, typically made from materials that can withstand extreme weather conditions and electrical stress. These insulators are often mounted on vertical pins or brackets, providing a secure attachment point for guy wires that stabilize transmission lines. Commonly used in high voltage power transmission lines, they find applications in both urban and rural settings where reliable electrical cable support is paramount.

The versatility of pin type stay insulators extends beyond just high voltage lines; they are also utilized in telecommunications infrastructure, providing stability to antenna systems. Their design allows for easy integration with various types of cable clamps, making them adaptable to different installation scenarios. Given their importance in maintaining the structural integrity of overhead systems, these insulators are essential components for any utility company focused on delivering safe electricity.

Benefits in Transmission Lines

One of the standout benefits of pin type stay insulators is their ability to enhance the reliability of high voltage power transmission lines by preventing sagging or swaying due to environmental factors like wind or ice accumulation. This stability ensures that electrical cables remain properly aligned, reducing the risk of contact with trees or other structures that could lead to outages or safety hazards. Moreover, their robust design minimizes maintenance needs over time, allowing utilities to focus resources elsewhere.

Additionally, pin type stay insulators provide excellent dielectric strength, which is essential when dealing with high voltage electricity. This characteristic helps prevent electrical breakdowns during adverse weather conditions or unexpected surges in the system. By utilizing these insulators effectively within their infrastructure, companies can enhance overall safety while optimizing performance across their entire network.

Installation Considerations

When installing pin type stay insulators, it’s crucial to consider several factors to ensure optimal performance and longevity. Proper alignment is key; misalignment during installation can lead to increased stress on both the insulator and the attached guy wire, potentially resulting in failure under load conditions over time. Additionally, selecting an appropriate cable clamp is vital for securing the electrical cable without causing damage during tensioning.

Another important consideration involves choosing materials that can withstand local environmental conditions—this includes assessing temperature ranges as well as exposure to moisture or corrosive elements like saltwater near coastal areas. Regular inspections after installation help identify any wear or degradation early on so adjustments can be made promptly before issues escalate into larger problems affecting service reliability.

Ensuring compliance with local regulations regarding installation practices will also contribute significantly towards achieving optimal outcomes when using pin type stay insulators within your power transmission infrastructure.

Strain Type Stay Insulator

Strain type stay insulators are essential components in the realm of electrical engineering, particularly in maintaining the stability of high voltage power transmission lines. These insulators are designed to withstand considerable mechanical stress, making them ideal for supporting guy wires that secure overhead structures. Their unique design allows them to effectively isolate electrical cables from the ground while providing robust support.

Design and Function

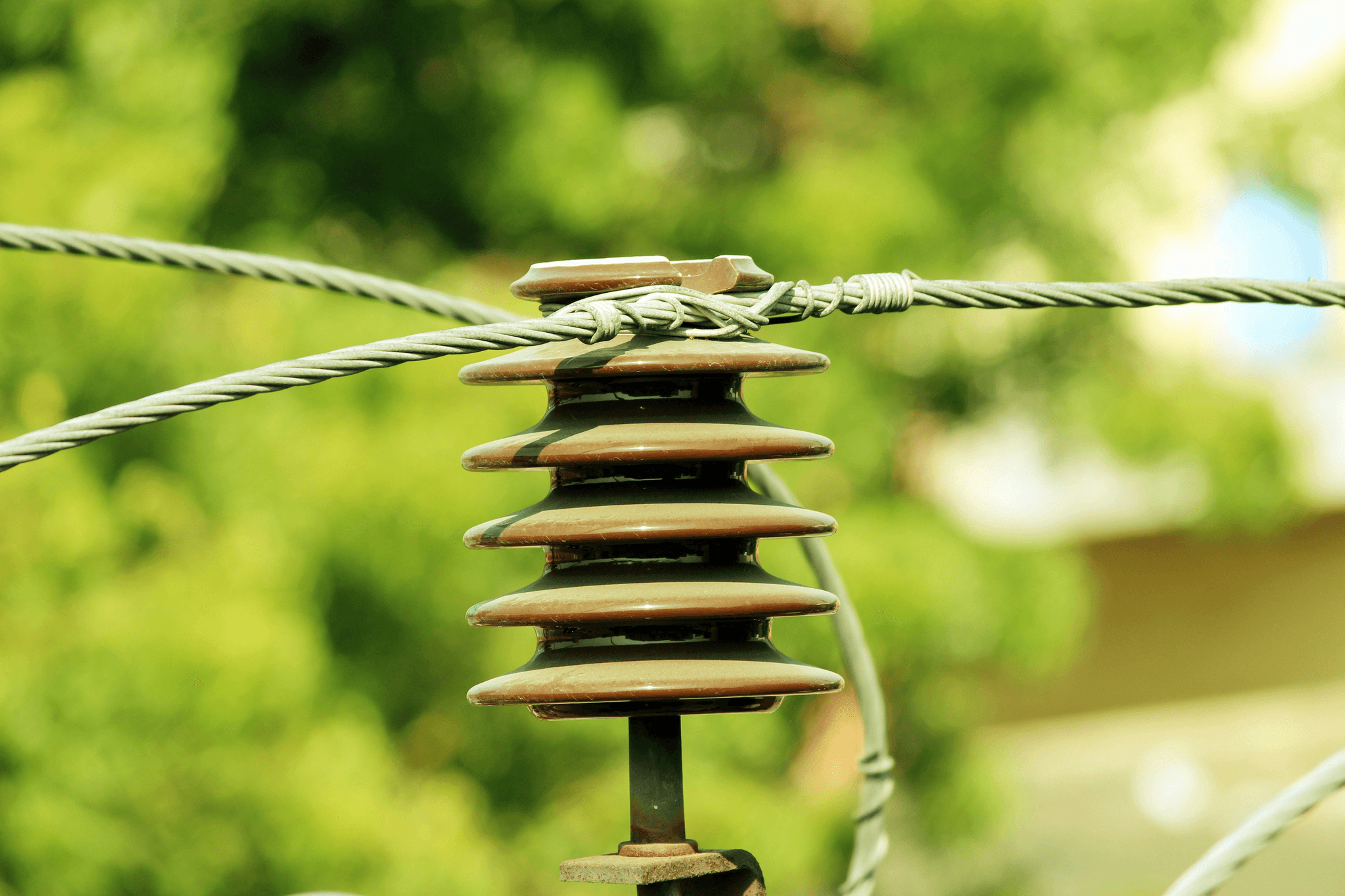

The design of strain type stay insulators is characterized by their elongated structure, which typically features a series of ceramic or polymer discs stacked together. This configuration not only enhances their insulating properties but also facilitates the distribution of mechanical loads across the entire assembly. By performing this dual role, these stay insulators ensure that electrical cables remain insulated from potential grounding issues while simultaneously supporting the tension exerted by guy wires.

Functionally, strain type stay insulators play a pivotal role in preventing electrical energy from leaking into surrounding structures or the ground wire system. Their ability to handle significant tensile forces makes them indispensable in maintaining the integrity and safety of transmission lines carrying high voltage electricity. In essence, they act as a buffer between mechanical support systems and electrical components, ensuring efficient operation without compromising safety.

Advantages for Guy Wire Systems

One of the standout advantages of strain type stay insulators is their exceptional performance in guy wire systems. They provide critical support to vertical structures such as utility poles and towers by anchoring guy wires securely without allowing any current leakage into those wires. This feature not only enhances structural stability but also minimizes risks associated with stray currents that could pose safety hazards.

Moreover, these stay insulators are designed to withstand harsh environmental conditions, making them suitable for outdoor applications where exposure to moisture and temperature fluctuations can be detrimental. The durability ensures long-lasting performance even in challenging weather scenarios, which is vital for maintaining uninterrupted service in high voltage power transmission lines. Ultimately, using strain type stay insulators leads to reduced maintenance costs and increased reliability over time.

Common Usage Scenarios

Strain type stay insulators find widespread application across various industries where high voltage power transmission lines are prevalent. They are commonly used in utility poles supporting overhead cables as well as telecommunications towers requiring stable guy wire configurations for optimal signal transmission. Additionally, these insulators may be found at substations where grounding systems need precise insulation to prevent interference with operational systems.

In rural areas where traditional wiring methods may face challenges due to terrain variations or extreme weather conditions, strain type stay insulators offer an excellent solution by ensuring consistent cable alignment and securing necessary supports effectively. Furthermore, they can be incorporated into renewable energy projects like wind farms where tower stability is crucial for efficient energy generation and distribution through electrical cables connected back to the grid.

Suspension Type Stay Insulator

When it comes to high voltage power transmission lines, suspension type stay insulators play a crucial role in maintaining the integrity of electrical cables. These insulators are designed to support and stabilize overhead cables, ensuring that they remain securely in place even under varying environmental conditions. By providing effective insulation and mechanical support, they help prevent electrical faults and enhance the overall reliability of the transmission system.

Purpose and Construction

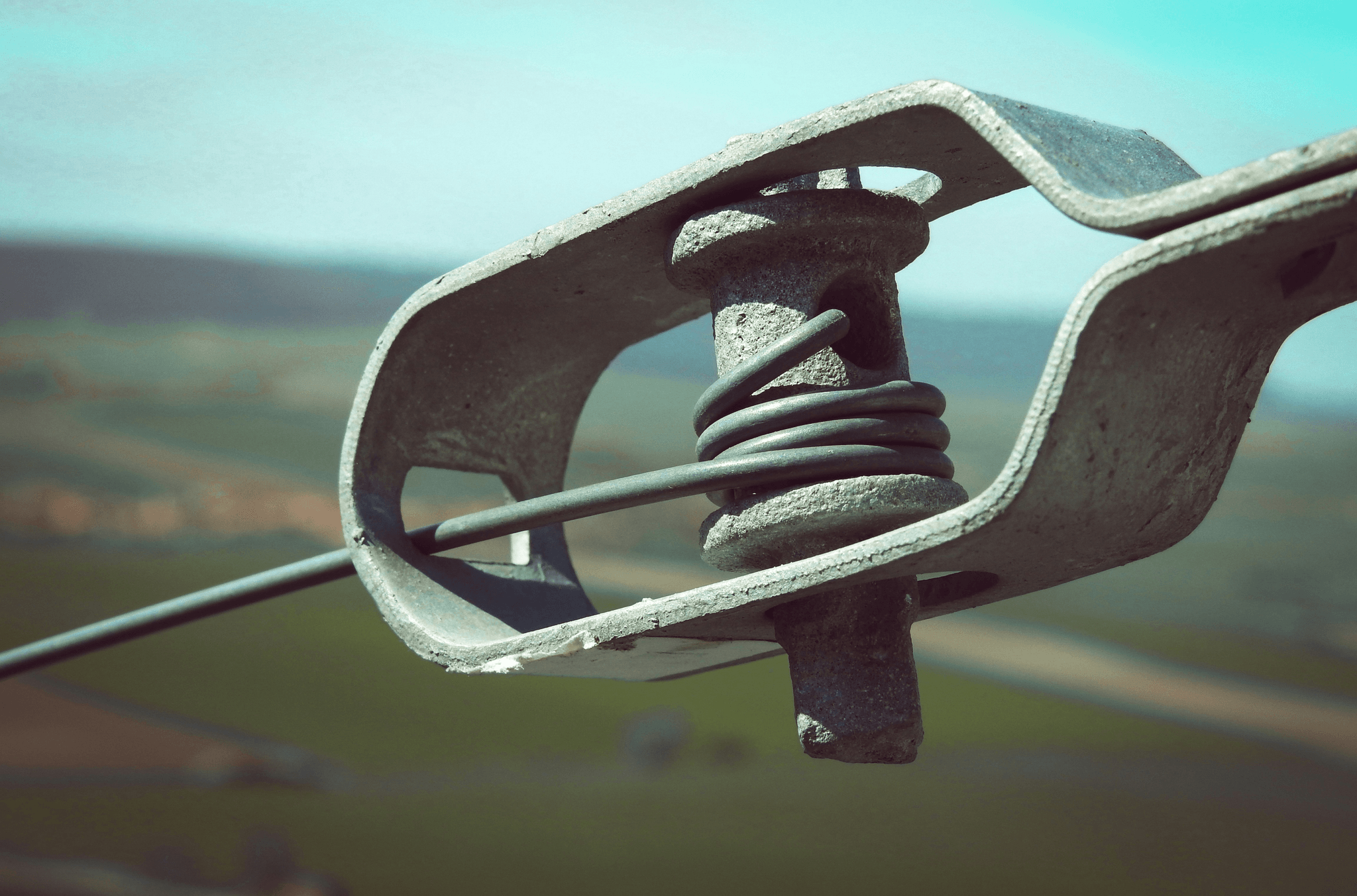

The primary purpose of suspension type stay insulators is to isolate electrical cables from their supporting structures while allowing for necessary movement due to wind or thermal expansion. Typically constructed from high-strength materials like porcelain or composite polymers, these insulators are engineered to withstand significant mechanical loads without compromising their insulating properties. A well-designed suspension stay insulator features a cable clamp that holds the electrical cable firmly in position, minimizing movement and potential wear over time.

Role in Electrical Cable Stability

Suspension type stay insulators are vital for maintaining stability within electrical cable systems, particularly in high voltage power transmission lines where tension can vary dramatically. By effectively distributing mechanical loads through the guy wire system, these insulators help prevent sagging or excessive strain on the cables themselves. This stability not only prolongs the lifespan of the electrical cables but also enhances safety by reducing the risk of accidental disconnections or failures.

Best Practices for Use

To ensure optimal performance from suspension type stay insulators, it's essential to follow best practices during installation and maintenance. First and foremost, proper alignment during installation is critical; misalignment can lead to uneven stress distribution that may compromise both insulation integrity and mechanical strength. Additionally, regular inspections should be conducted to check for signs of wear or damage—especially around cable clamps—to address any issues before they escalate into more serious problems affecting transmission line reliability.

Post Insulator

Post insulators play a vital role in the world of high voltage power transmission lines, ensuring that electrical cables remain safely suspended and insulated from their supporting structures. These insulators are designed to withstand the mechanical and electrical stresses encountered in various applications, particularly when it comes to grounding systems. With their robust construction and innovative design, post insulators are essential for maintaining the integrity and safety of transmission lines.

Characteristics and Design

Post insulators typically feature a cylindrical shape made from high-strength materials such as porcelain or composite polymers, providing excellent insulation properties against high voltages. Their design often incorporates multiple sheds or skirts that help to prevent water accumulation and reduce the risk of flashovers caused by contaminants like dust or salt. Additionally, many post insulators come equipped with integrated cable clamps that secure ground wires effectively while allowing for easy installation on towers or poles.

Importance in Ground Wire Applications

In ground wire applications, post insulators serve as critical components for ensuring that guy wires remain properly insulated from electrical conductors. By providing a reliable support system, they help maintain the necessary separation between conductive elements, thus preventing accidental contact that could lead to dangerous situations in high voltage power transmission lines. Furthermore, their ability to withstand environmental challenges ensures longevity and reliability in various weather conditions.

How to Choose the Right Type

When selecting a post insulator for your specific needs, consider factors such as voltage rating, mechanical strength, and environmental conditions where it will be installed. It's crucial to match the post insulator's specifications with those of your electrical cable system to ensure optimal performance and safety in high voltage applications. Additionally, consulting with manufacturers about customization options can help tailor solutions that meet unique requirements involving guy wire configurations or special installation scenarios.

Armor Rods from Spark Fittings

Armor rods are essential components in the realm of stay insulators, providing protection and support for electrical cables, especially in high voltage power transmission lines. These rods are designed to enhance the durability of cable clamps and prevent damage from environmental factors or mechanical stress. Understanding their materials and construction can help ensure optimal performance in various applications.

Materials and Construction

Armor rods are typically constructed from high-strength materials such as fiberglass or composite polymers, ensuring they can withstand harsh conditions often encountered in transmission lines. The robust design protects the underlying electrical cable while maintaining flexibility to accommodate movement caused by wind or other external forces. This combination of strength and adaptability makes armor rods an indispensable part of guy wire systems, enhancing the longevity of stay insulators.

Customization Options Available

One of the appealing aspects of armor rods is their customization potential; they can be tailored to fit various specifications based on project requirements. Custom lengths, diameters, and material compositions allow for a perfect fit with different types of stay insulators and ground wire configurations. This level of personalization ensures that whether you're dealing with standard installations or unique challenges in high voltage setups, there's an armor rod solution that meets your needs.

Color Coding and Installation Ease

Color coding is another practical feature associated with armor rods; it simplifies identification during installation and maintenance processes. Different colors can indicate specific sizes or types, making it easier for technicians to quickly find the right components when working on electrical cables or stay insulator systems. Coupled with user-friendly designs that facilitate straightforward installation, these features contribute significantly to minimizing downtime during maintenance operations on transmission lines.

Conclusion

In the world of high voltage power transmission lines, selecting the right stay insulator is crucial for ensuring safety and efficiency. With various options available, such as pin type, strain type, and suspension type stay insulators, it’s essential to consider factors like application needs and environmental conditions. Each type has its unique features and benefits that can significantly impact the performance of electrical cables and guy wire systems.

Selecting the Right Stay Insulator

Choosing the appropriate stay insulator involves understanding your specific requirements in relation to transmission line design and load-bearing capabilities. Considerations such as environmental factors, installation ease, and compatibility with cable clamps or ground wires play a vital role in this decision-making process. By evaluating these aspects carefully, you can ensure that your chosen stay insulator will provide optimal support for your high voltage power transmission lines.

Enhancing Safety in High Voltage Installations

Safety is paramount when dealing with high voltage installations; therefore, selecting quality stay insulators is non-negotiable. These components not only support electrical cables but also prevent accidents caused by electrical faults or mechanical failures in guy wire systems. Regular inspections and maintenance of these insulators further enhance safety measures, ensuring reliable performance over time.

Future Trends in Stay Insulation Technology

As technology continues to advance, we can expect exciting developments in stay insulation design and materials that promise improved durability and efficiency. Innovations may include enhanced composite materials for better resistance against environmental stressors or smart monitoring systems integrated into stay insulators to provide real-time performance data. Staying informed about these trends will be essential for anyone involved in high voltage power transmission lines to maintain competitive advantage.