Introduction

Importance of Choosing the Right Suspension Clamp

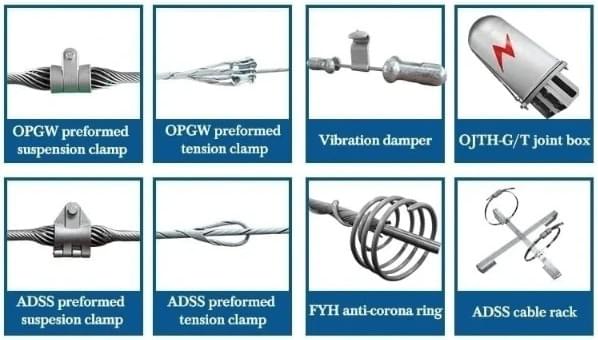

Selecting the best suspension clamp for overhead lines can significantly impact both safety and efficiency in electrical systems. The right clamp not only supports conductors but also plays a vital role in preventing wear and tear over time. With various options available, knowing what is a tension clamp used for and how it differs from suspension clamps can help you make an informed decision.

Understanding Suspension and Tension Clamps

Suspension clamps are specifically designed to hold conductors in place while allowing them to move freely under tension, making them essential for maintaining system integrity. On the other hand, tension clamps serve a different purpose; they secure cables tightly to prevent sagging or movement caused by environmental factors. By grasping these differences, you can better understand which type of clamp suits your project needs.

Key Features of Quality Suspension Clamps

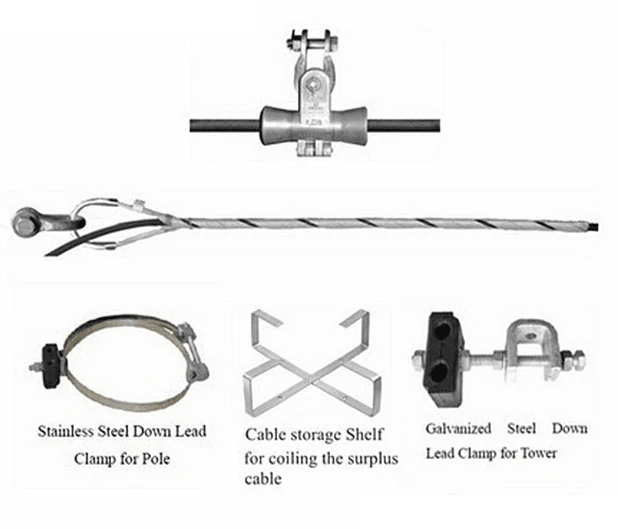

Quality suspension clamps come equipped with features that enhance their durability and effectiveness in overhead line applications. Look for materials that resist corrosion, such as aluminum or galvanized steel, as well as design elements that facilitate easy installation and maintenance. Additionally, understanding what is the full form of AGS clamp will provide insights into specialized options available on the market today.

What is a Suspension Clamp Used For?

Functionality in Overhead Line Systems

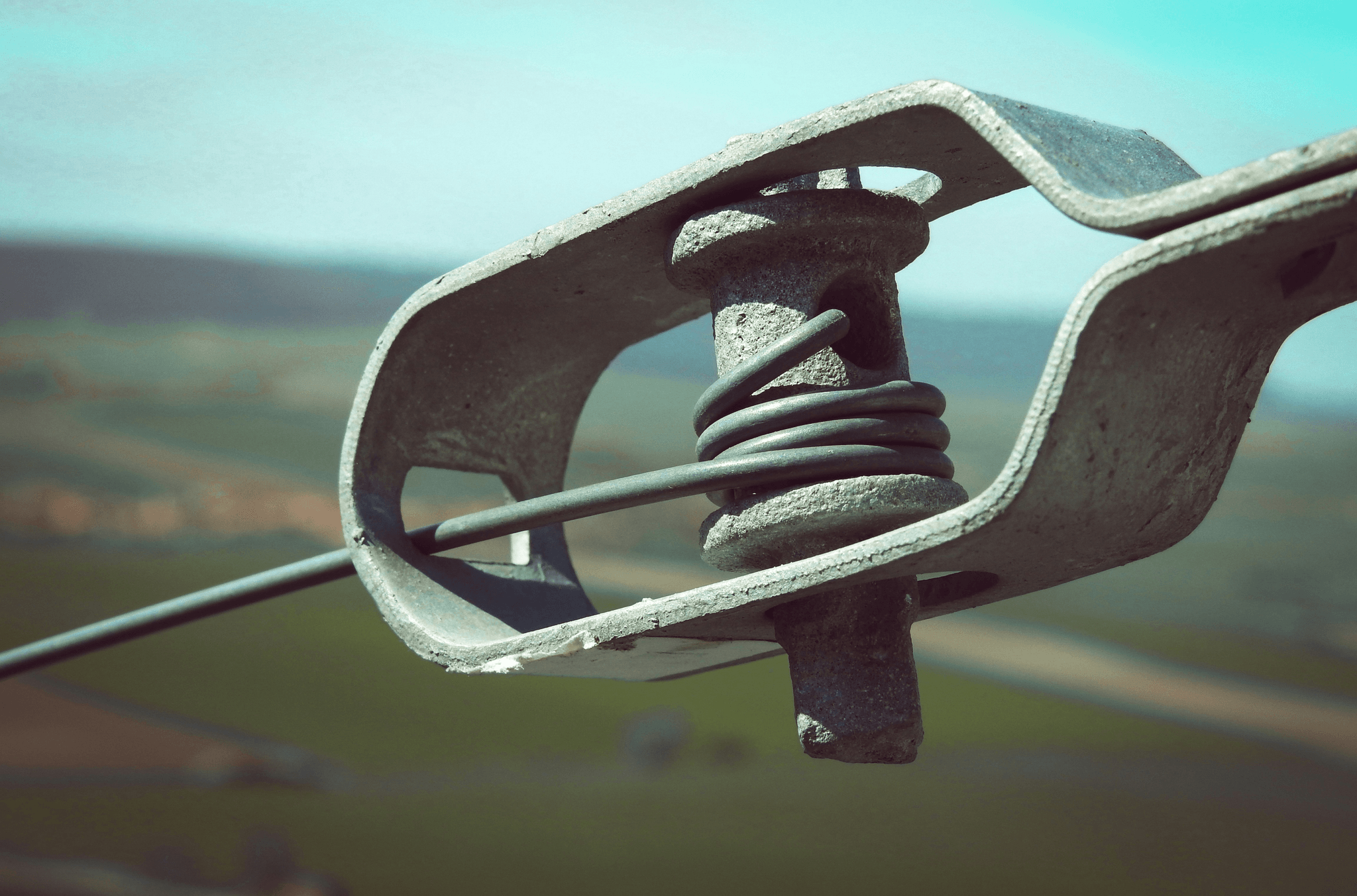

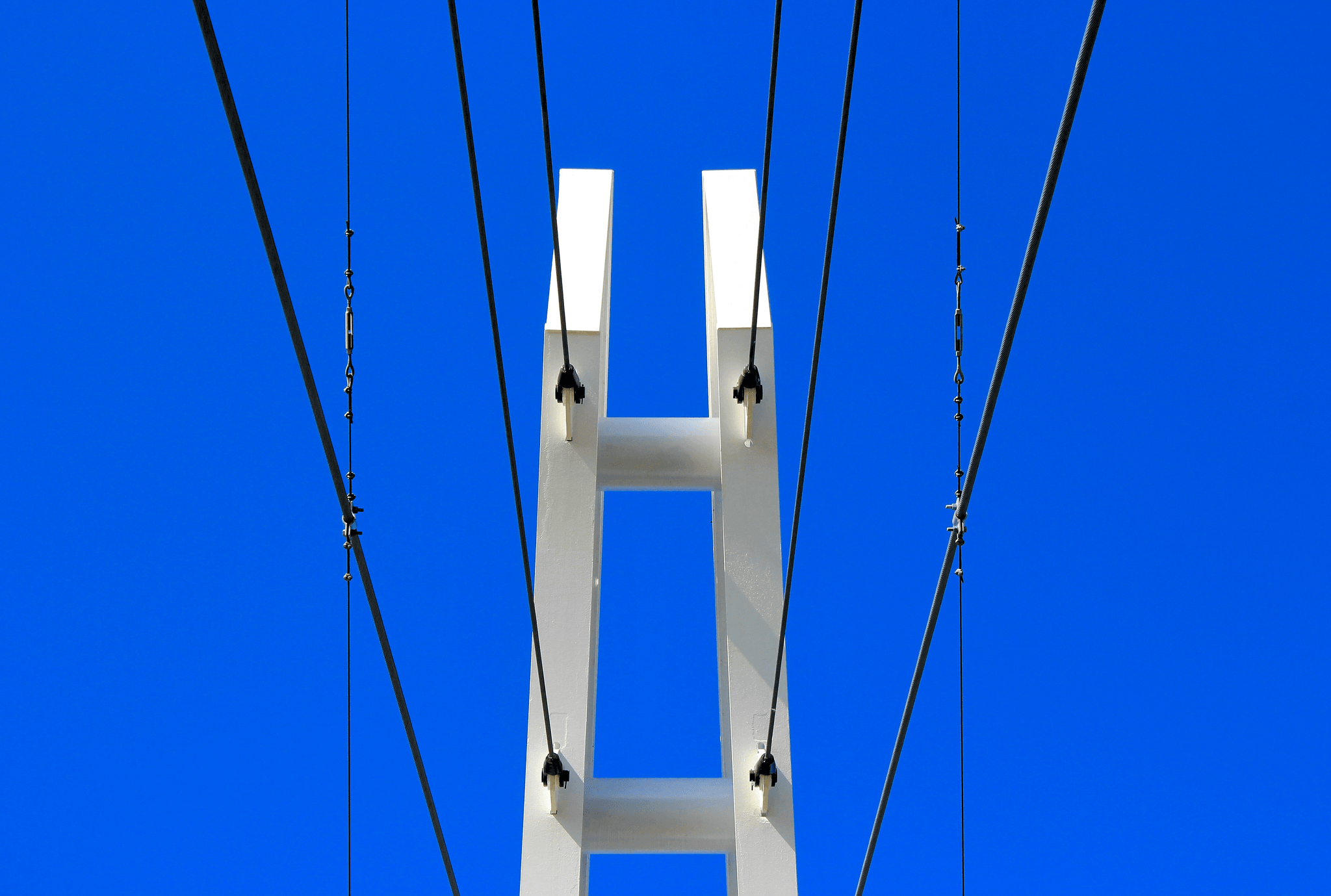

The primary function of a suspension clamp is to secure conductors within overhead line systems without restricting their natural movement. By providing a reliable attachment point, these clamps help maintain the integrity of the electrical system while accommodating thermal expansion and contraction of cables. Without proper suspension clamps, lines may sag excessively or even break under stress, leading to costly repairs and disruptions.

Supporting Conductors with Ease

A well-designed suspension clamp for overhead lines ensures that conductors are held securely yet allow for some degree of movement. This balance helps prevent undue stress on the cables and supports their longevity. Additionally, when dealing with ABC (Aerial Bundled Cable) installations, using the best suspension clamp for overhead lines becomes even more critical due to the unique characteristics of these cables.

Importance in Preventing Cable Damage

One cannot underestimate the importance of a quality suspension clamp in preventing cable damage. These clamps not only secure conductors but also protect them from external forces such as wind and ice accumulation that could lead to wear over time. By choosing an appropriate suspension clamp for ABC cable applications, users can significantly reduce maintenance costs and extend the lifespan of their electrical systems.

Exploring Tension Clamps

What is a Tension Clamp Used For?

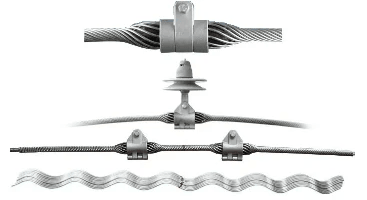

A tension clamp is primarily used to anchor conductors in overhead lines, preventing them from sagging or swaying excessively due to environmental factors like wind or ice. This clamp maintains the necessary tension on the cable, which is vital for both safety and performance. Without effective tension clamps, cables could experience undue stress that may lead to failure or damage, making them indispensable in any setup involving suspension clamp for overhead lines.

Key Differences Between Clamps

While both suspension clamps and tension clamps serve important roles in overhead line systems, they have distinct functions that set them apart. Suspension clamps are designed to support the weight of conductors without applying significant tensile force, while tension clamps actively maintain the conductor's position under load conditions. Knowing these differences helps you select the right type of clamp based on your specific needs—whether you're asking yourself what is a suspension clamp used for? or what is a tension clamp used for?

Applications in Cable Systems

Tension clamps find their applications in various cable systems beyond just overhead power lines; they're also essential for telecommunications and other critical infrastructure projects. By ensuring proper cable alignment and stability, these clamps help prevent issues such as electromagnetic interference or signal degradation that can occur when cables shift out of place. Whether you’re looking into the best suspension clamp for overhead lines or considering options for ABC cable installations, understanding how tension clamps work will help you make informed decisions.

Understanding Suspension Clamp Materials

Raw Materials for Effective Performance

When discussing what is a suspension clamp used for?, it's essential to consider the raw materials from which they are made. High-quality suspension clamps are typically crafted from durable metals that can endure high tension and resist corrosion. The most common materials include aluminum and galvanized steel, each offering unique benefits suited for different applications in overhead line systems.

These raw materials not only enhance the mechanical strength of a suspension clamp but also contribute to its lightweight characteristics, making installation easier and more efficient. For instance, aluminum is favored for its excellent strength-to-weight ratio while galvanized steel provides superior corrosion resistance, especially in harsh environments. Ultimately, selecting a suspension clamp for ABC cable requires understanding how these materials perform under various conditions.

Aluminum vs. Galvanized Steel

When comparing aluminum with galvanized steel in terms of what is a tension clamp used for?, several factors come into play. Aluminum clamps are generally lighter and more resistant to oxidation but may not be as robust under extreme mechanical stress compared to their galvanized counterparts. On the other hand, galvanized steel offers excellent durability and is often preferred in areas exposed to severe weather conditions or heavy loads.

Moreover, both types have their specific applications; aluminum is often chosen for projects requiring minimal weight without sacrificing too much strength, while galvanized steel is ideal when maximum durability is paramount. Understanding these differences helps ensure you select the best suspension clamp for overhead lines based on your specific needs and environmental conditions. The choice between these two materials ultimately impacts both performance and longevity.

The Role of Armor Rods in Suspension Clamps

Armor rods are an essential component often associated with suspension clamps, particularly when considering what is the full form of AGS clamp? These rods serve multiple purposes: they help distribute stress more evenly across conductors while providing additional protection against abrasion and wear over time. This added layer of protection can significantly extend the life of both the cables and clamps used in overhead line systems.

Incorporating armor rods into your installation not only enhances overall performance but also mitigates potential damage caused by environmental stresses or mechanical impacts—something every installer should keep in mind when selecting components like a suspension clamp for ABC cable systems or any other application involving overhead lines. By understanding their role within this context, users can make informed decisions about which products best suit their needs.

The Full Form of AGS Clamp

The AGS clamp, which stands for All-Weather Grip Suspension Clamp, plays a pivotal role in ensuring that conductors are securely held in place while withstanding various environmental conditions. This clamp not only provides stability but also enhances the overall safety and efficiency of electrical systems.

Importance of AGS Clamp in Electrical Systems

The importance of the AGS clamp in electrical systems cannot be overstated. It provides reliable support for overhead lines, ensuring that they remain intact even under tension or adverse weather conditions. By using a suspension clamp for overhead lines like the AGS, utilities can prevent cable sagging and potential damage, which is vital for maintaining uninterrupted service.

Moreover, the AGS clamp helps in distributing mechanical loads evenly across conductors, reducing stress points that could lead to failure. As such, it contributes significantly to the longevity and durability of overhead line installations. Understanding what is a suspension clamp used for highlights its critical role in safeguarding electrical infrastructure.

Applications and Benefits

AGS clamps have a wide range of applications within electrical systems, particularly in supporting conductors associated with overhead transmission lines. These clamps are designed to accommodate different conductor sizes and types, making them versatile tools for utility companies looking to optimize their installations. Additionally, they are essential when considering what is a tension clamp used for; while tension clamps handle stress from pulling forces, suspension clamps like the AGS ensure stability along spans.

The benefits of using an AGS clamp include enhanced resistance to environmental factors such as wind and ice loading as well as ease of installation. They also minimize wear on conductors by providing smooth surfaces that reduce friction during movement caused by wind or thermal expansion. For those seeking the best suspension clamp for overhead lines or specific applications like suspension Clamp for ABC cable (Aerial Bundled Conductors), choosing an AGS model can offer both reliability and performance.

Selecting the Right AGS Clamp for Your Needs

Selecting the right AGS clamp requires careful consideration of several factors to ensure optimal performance in your specific application. First off, it's essential to determine the type and size of conductor you will be using since not all clamps are compatible with every wire type—this is where knowing what is the full form of AGS clamp becomes handy!

Next, you should evaluate environmental conditions such as temperature fluctuations or exposure to moisture that could affect your choice—after all, these clamps need to withstand whatever Mother Nature throws at them! Lastly, consulting product specifications will help you find out what is the HS code for suspension clamps if you're involved in import/export activities related to these components.

In conclusion, whether you're working on new installations or maintaining existing infrastructure, understanding how to select an appropriate suspension clamp can save time and money down the road while ensuring safety standards are met.

HS Code for Suspension Clamp

The HS code serves as a universal classification system that identifies products traded internationally, which helps streamline customs processes and trade regulations. Knowing the correct HS code for your suspension clamp for overhead lines can save you time and money while ensuring compliance with legal requirements.

What is the HS Code and Its Importance?

The HS code is a standardized numerical method of classifying traded products, developed by the World Customs Organization. It consists of six digits that categorize goods into specific groups based on their type, material, or use. For products like suspension clamps—essential components in overhead line systems—the correct HS code can significantly impact tariffs, taxes, and regulatory compliance when importing or exporting.

When considering what is a suspension clamp used for?, it’s essential to note that these clamps are integral in supporting conductors while preventing damage during installation and operation. Therefore, having an accurate HS code not only facilitates smoother transactions but also ensures that the right specifications are met according to international standards.

Navigating Import and Export Regulations

Navigating import and export regulations can be tricky without understanding how to use the HS code effectively. Each country may have its own set of rules regarding tariffs and duties applied based on product classification, making it vital to ensure you're using the correct HS code for your suspension clamp for ABC cable or any other type of cable system you work with. If you misclassify your product, you could face unexpected costs or delays at customs.

Moreover, knowing what is a tension clamp used for? can help differentiate between various types of clamps when discussing their respective codes during import/export procedures. Tension clamps are typically used to secure cables under tension; therefore, having clarity on these differences aids in proper classification.

Finding the Right HS Code for Your Products

Finding the right HS code for your products may seem daunting at first but is quite manageable with some guidance. You can start by consulting trade databases or working with customs brokers who specialize in electrical components like suspension clamps for overhead lines. They often have up-to-date information on classifications that will help you identify whether your product falls under specific categories related to suspension clamps or tension clamps.

Additionally, keep in mind that some manufacturers might provide detailed documentation regarding what is the full form of AGS clamp? This information could assist in determining its corresponding HS codes as well since AGS stands for Aerial Guy Suspension, which has its own classification within electrical fittings. Ultimately, investing time into finding the correct HS code will pay off by ensuring smoother operations across borders.

Choosing the Best Suspension Clamp for Overhead Lines

Selecting the right suspension clamp for overhead lines is crucial for ensuring the stability and safety of electrical systems. With a variety of options available, it’s important to consider quality, functionality, and compatibility with specific applications. This section will help you navigate through top brands, customization options, and essential factors to evaluate before making a purchase.

Top Brands to Consider: Spark Fittings

When it comes to the best suspension clamp for overhead lines, Spark Fittings stands out as a reputable brand known for its durable and reliable products. Their suspension clamps are designed with precision engineering to support conductors effectively while minimizing cable damage. Additionally, Spark Fittings offers a range of options tailored specifically for ABC cables, ensuring that you find the perfect fit for your needs.

Customization Options for Unique Needs

In many cases, standard suspension clamps may not meet all project requirements due to unique environmental conditions or specific installation challenges. Fortunately, many manufacturers offer customization options that allow you to tailor your suspension clamp for overhead lines according to your specifications. Whether it's adjusting dimensions or selecting materials that enhance performance in harsh conditions, customized solutions can significantly improve functionality and longevity.

Factors to Evaluate Before Purchase

Before finalizing your choice of a suspension clamp for overhead lines, consider several critical factors that can impact performance and safety. First and foremost is understanding what is a suspension clamp used for; this knowledge will guide you in selecting the right type based on your application needs. Additionally, assess material quality—aluminum versus galvanized steel—and ensure compliance with relevant HS codes for suspension clamps when importing or exporting products.

Conclusion

In summary, understanding the nuances of suspension clamps is vital for anyone involved in overhead line systems. These components play a critical role in ensuring the safe and effective operation of electrical installations. By grasping their functions, materials, and applications, you can make informed choices to enhance your projects.

Key Takeaways on Suspension Clamps

A suspension clamp for overhead lines is essential for supporting conductors and preventing cable damage. It is crucial to differentiate between suspension clamps and tension clamps; while both serve important functions, their applications vary significantly. Remember that the full form of AGS clamp refers to Aluminum Guy Support, which is particularly valuable in stabilizing overhead lines.

Best Practices for Installation and Maintenance

When installing a suspension clamp for ABC cable, ensure that you follow manufacturer guidelines to avoid any mishaps. Regular inspections can help identify wear or damage early, preventing larger issues down the line. Additionally, understanding what a tension clamp is used for will allow you to choose complementary components effectively.

Final Thoughts on Choosing the Right Clamp

Selecting the best suspension clamp for overhead lines involves considering various factors such as material type—aluminum versus galvanized steel—and specific project needs. Don’t forget about HS codes; knowing what is the HS code for suspension clamp can simplify import/export processes significantly. In conclusion, investing time in understanding these elements will lead to better outcomes in your electrical projects.