Introduction

Grounding equipment is an essential aspect of electrical safety and system reliability, often overlooked until something goes wrong. Understanding the intricacies of grounding hardware can make a significant difference in both residential and commercial applications. This introduction sets the stage for exploring what grounding hardware is, its components, types, applications, installation processes, and how to select the best options available.

Understanding Grounding Equipment

Grounding equipment serves as a protective measure against electrical faults and surges, ensuring that excess electricity is safely directed away from sensitive components. At its core, grounding hardware provides a pathway for fault currents to flow safely into the earth. By comprehending the fundamental principles behind grounding systems, we can appreciate their critical role in maintaining electrical safety and operational integrity.

Importance of Grounding Hardware

The importance of grounding hardware cannot be overstated; it safeguards both people and equipment from potentially hazardous electrical incidents. Properly installed grounding systems can prevent damage from lightning strikes or power surges while also reducing electromagnetic interference in sensitive electronic devices. Investing time in understanding this crucial aspect can lead to safer installations and longer-lasting equipment.

Overview of Grounding Systems

Grounding systems come in various forms tailored to meet specific needs across different applications—be it residential setups or industrial environments. These systems typically consist of various components working together seamlessly to provide effective protection against electrical faults. As we delve deeper into what grounding hardware entails, we will uncover the key elements that make up these vital systems.

What is Grounding Hardware

Grounding hardware is a crucial aspect of electrical safety and system reliability. It encompasses various components designed to establish a low-resistance path for electrical currents to flow safely into the ground, preventing damage to equipment and reducing the risk of electric shock. Understanding grounding hardware is essential for both residential and commercial applications, ensuring that systems operate effectively and safely.

Definition and Purpose

At its core, grounding hardware refers to the tools and components used to create an effective grounding system. The primary purpose of this equipment is to protect people, property, and electrical systems from faults or surges in electricity. By providing a safe pathway for excess current, grounding equipment mitigates risks associated with lightning strikes, power surges, and short circuits.

Key Components of Grounding Systems

The components of grounding systems are diverse but work together seamlessly to ensure safety and functionality. Essential elements include ground rods, plates, conductors, connectors, spark fittings, and armor rods—all integral parts that contribute to a robust grounding setup. Each component plays a specific role in establishing an effective connection with the earth while enhancing overall system performance.

Common Materials Used

Copper is often favored for its excellent conductivity; however, galvanized steel is also popular due to its resistance against corrosion. Other materials like aluminum may be used in specific applications where weight savings or cost-effectiveness are prioritized in the selection of grounding equipment.

Components of Grounding Systems

Ground Rods and Plates

Ground rods are typically made of conductive materials such as copper or galvanized steel and are driven deep into the ground to establish a low-resistance path for electrical currents. These rods serve as the primary connection point for grounding systems, preventing voltage surges from damaging electrical equipment. Ground plates function similarly but are installed horizontally; they provide an alternative solution when soil conditions make driving rods impractical.

Both ground rods and plates are vital components of grounding systems that help mitigate the risks associated with electrical faults. Their effectiveness largely depends on proper installation techniques outlined in the installation process of grounding components. Selecting the right type—be it a rod or plate—can significantly impact your overall grounding strategy.

Conductors and Connectors

Conductors play an essential role in transmitting electrical energy between various components of your grounding system. Typically made from copper or aluminum, these wires must be robust enough to handle potential fault currents while maintaining low resistance levels for optimal performance. Connectors facilitate secure connections between conductors, ensuring that every part of your system works seamlessly together.

Choosing high-quality conductors and connectors is crucial when considering types of grounding hardware; subpar materials can lead to increased resistance or even failure during critical moments. Moreover, understanding how these elements fit within your overall system can help you make informed decisions during the selection process for grounding hardware. After all, a reliable connection is key to effective grounding solutions.

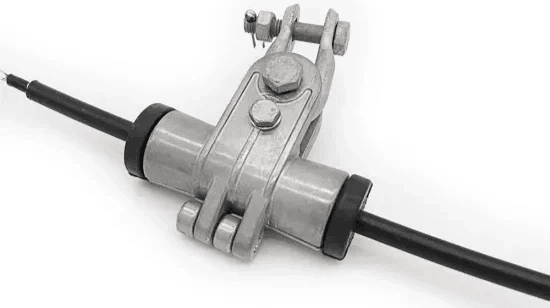

Spark Fittings and Armor Rods

Spark fittings are specialized devices designed to protect connections from arcing caused by electrical surges; they act as a safeguard against potential damage that could result from high-voltage situations. These fittings ensure that ground connections remain intact under stress while also allowing flexibility in installations where movement may occur over time. On the other hand, armor rods provide additional protection to conductors by reinforcing them against mechanical wear and environmental factors.

Both spark fittings and armor rods contribute significantly to enhancing the durability of your entire grounding system—a must-have if you're looking at applications of grounding hardware in challenging environments like industrial settings or telecommunications networks. When selecting these components, consider their compatibility with existing hardware; this will ensure long-term reliability without unexpected failures down the line.

Types of Grounding Hardware

Mechanical and Electrical Grounding

Mechanical grounding involves connecting non-electrical conductive parts to the ground for structural integrity and safety. This type of grounding hardware is crucial in preventing accidental contact with live wires or equipment, thereby reducing the risk of electric shock. On the other hand, electrical grounding focuses on providing a low-resistance path for fault currents to flow safely into the earth, protecting both people and equipment from hazardous voltage levels.

In mechanical systems, components such as ground rods or plates are often used to achieve effective earthing. For electrical systems, conductors play a pivotal role in ensuring that any fault current has a clear path back to the ground. Understanding these distinctions helps in selecting the best grounding hardware for your specific needs.

Isolated and Bonded Systems

Isolated systems are designed to keep different circuits electrically separated while still providing adequate grounding capabilities. This approach is particularly useful in sensitive environments like hospitals or laboratories where interference from stray currents can lead to significant operational issues. In contrast, bonded systems connect various conductive parts together as one single unit grounded effectively; this helps prevent dangerous voltage differences that could occur between separate components.

The choice between isolated and bonded systems largely depends on application requirements—residential setups may benefit more from bonded approaches while industrial settings might lean towards isolation techniques for enhanced safety measures. Both types contribute significantly to overall system reliability when correctly implemented during the installation process of grounding components.

Custom Solutions from Spark Fittings

Spark Fittings offers tailored solutions that cater specifically to unique project needs within various industries—be it telecommunications or heavy industry applications requiring specialized types of grounding hardware. Their custom offerings ensure that clients receive products designed precisely for their operational challenges while maintaining compliance with industry standards.

These bespoke solutions often incorporate advanced materials and innovative designs aimed at maximizing performance under demanding conditions—ensuring durability against environmental factors such as moisture or corrosion over time. When selecting the best grounding hardware for your project, considering custom options allows you greater flexibility in meeting specific requirements without compromising on quality or effectiveness.

Applications of Grounding Hardware

Grounding hardware plays a crucial role in various sectors, ensuring safety and efficiency in electrical systems. From homes to industrial facilities, understanding the applications of grounding hardware helps in selecting the right components for specific needs. This section explores the diverse environments where grounding equipment is essential.

Residential and Commercial Use

In residential and commercial settings, grounding equipment is vital for protecting both people and property from electrical faults. Grounding systems help prevent shock hazards by directing excess electricity safely into the ground. Moreover, they ensure that sensitive electronics are shielded from power surges, making them indispensable in modern homes and businesses.

When considering what is grounding hardware for these applications, it’s important to focus on components of grounding systems that are specifically designed for smaller scales, such as ground rods and conductors. These elements work together to create a reliable network that enhances safety during everyday use of electrical appliances. Additionally, proper installation of these components can significantly reduce risks associated with lightning strikes or power surges.

Selecting the best grounding hardware for residential and commercial use involves evaluating local codes and standards to ensure compliance. Homeowners should consult with professionals who understand the nuances of grounding systems tailored to their specific needs. Ultimately, investing in quality grounding equipment not only safeguards property but also promotes peace of mind.

Industrial and Utility Applications

In industrial settings, where heavy machinery operates continuously, robust grounding hardware is essential for maintaining operational integrity and safety standards. Grounding systems help mitigate risks associated with equipment failure due to electrical faults or static discharge—issues that can lead to costly downtime or even catastrophic accidents if not properly managed. The types of grounding hardware used here include larger ground rods and specialized connectors designed to handle high currents.

Utility companies also rely heavily on effective grounding solutions to protect their infrastructure from lightning strikes and other natural phenomena that could disrupt service delivery. Implementing comprehensive components of grounding systems ensures uninterrupted operation while safeguarding both employees and equipment from potential hazards related to electricity transmission over long distances. The installation process of these heavy-duty components must adhere strictly to industry standards due to their critical roles in public safety.

When selecting the best grounding hardware for industrial applications, it’s crucial to consider factors like environmental conditions—such as moisture levels—and types of materials used in construction. Custom solutions may be necessary depending on specific site requirements or existing infrastructure challenges faced by utility providers. In this context, understanding what is grounding hardware can greatly influence operational success.

Specialized Solutions for Telecommunications

Telecommunications networks require specialized solutions when it comes to grounding equipment due to their complex nature and reliance on sensitive electronic devices. Effective grounding systems are paramount in preventing interference that could disrupt communication signals or damage critical infrastructure like data centers or cell towers. Herein lies a need for advanced types of grounding hardware tailored specifically for telecommunications applications.

Components of grounding systems used within this sector often include surge protection devices alongside traditional ground rods—ensuring both safety from surges caused by external factors like lightning strikes while maintaining signal integrity throughout network operations. The installation process of these specialized components demands precision; any oversight could lead not only to service interruptions but also significant financial repercussions due to lost connectivity.

Selecting the best grounding hardware means looking beyond standard offerings; telecommunications providers must evaluate products based on performance metrics relevant specifically within their field—such as response times during surge events or resistance levels under varying conditions. As technology evolves rapidly within this industry segment, ongoing innovation will continue shaping future developments surrounding effective use cases for quality-grounded infrastructures worldwide.

Installation Process of Grounding Components

When it comes to the installation process of grounding components, a methodical approach is essential. Proper grounding equipment ensures safety and functionality in electrical systems, making it crucial to adhere to best practices during installation. Understanding the various components of grounding systems will help streamline this process.

Step-by-Step Guide

The first step in installing grounding hardware is to assess your site and understand what is needed based on the types of grounding hardware you plan to use. Begin by marking the location for ground rods or plates, ensuring they are positioned according to local codes and regulations. Next, dig a hole for the ground rod or plate; if using multiple rods, space them appropriately as outlined in your product guide.

Once the holes are ready, insert the ground rods vertically into the earth until only a few inches remain above ground. Connect conductors securely using appropriate connectors; ensure all connections are tight and corrosion-resistant for longevity. Finally, test your system with a multimeter to verify proper grounding before covering any excavated areas.

Safety Considerations

Safety should always be paramount when working with grounding equipment and electrical installations. Before starting any work, ensure that all power sources are turned off and that you’re equipped with personal protective equipment (PPE). Familiarize yourself with safety protocols related to electrical work; this includes understanding how different types of grounding hardware interact with existing electrical systems.

Be cautious when digging; underground utilities may pose hazards if not identified beforehand. Additionally, maintaining a clean workspace can prevent accidents—tripping over tools or materials can lead to injuries that could easily be avoided. Always keep emergency contact information handy in case an unexpected situation arises during installation.

Tools and Equipment Needed

To effectively carry out the installation process of grounding components, having the right tools at hand is vital. Essential tools include a shovel for digging holes for ground rods or plates, as well as a hammer or sledgehammer for driving rods into the earth securely. You’ll also need wire cutters/strippers for preparing conductors and connectors for secure attachments.

A multimeter will be necessary for testing your completed system—this ensures that everything is functioning correctly before finalizing your installation process. Having safety gear such as gloves, goggles, and sturdy footwear will protect you while working on these important components of grounding systems. By preparing adequately with these tools and understanding their purpose within various applications of grounding hardware, you'll set yourself up for success.

Selecting the Best Grounding Hardware

Choosing the right grounding hardware can feel like finding a needle in a haystack, especially with so many options available. To ensure optimal safety and performance, it's essential to evaluate your specific needs first. The right grounding equipment not only protects your electrical systems but also enhances their longevity and reliability.

Evaluating Your Needs

When it comes to selecting grounding hardware, understanding your unique requirements is crucial. Consider factors such as the type of installation—residential, commercial, or industrial—as each application may demand different components of grounding systems. Additionally, assess environmental conditions like soil resistivity and potential electrical load; these will guide you in choosing the most suitable types of grounding hardware for your situation.

Another critical aspect is compliance with local codes and regulations related to safety standards for grounding equipment. If you're unsure about what is required, consulting with a professional can save you time and money in the long run. By taking these steps to evaluate your needs thoroughly, you'll be better positioned to make informed decisions.

Comparing Different Products

Once you've assessed your needs, it's time to dive into comparing different products on the market. Look for comprehensive product guides that detail what is grounding hardware and highlight various components of grounding systems available today. Pay attention to product specifications such as material durability, conductivity ratings, and compatibility with existing systems; these factors will significantly impact performance.

Don’t forget to consider warranties and customer reviews when evaluating products; they often provide insights into real-world applications of grounding hardware that specifications alone cannot convey. Price is also an important factor—while you shouldn't compromise on quality for cost savings alone, finding a balance between affordability and reliability will yield better results in the long run.

Why Choose Spark Fittings

Moreover, Spark Fittings offers exceptional customer support throughout the installation process of grounding components; their knowledgeable team can guide you through selecting the best options based on your specific requirements. With a reputation built on trustworthiness and customer satisfaction over years in the business, choosing Spark Fittings means investing in reliable solutions that keep your electrical systems safe.

Conclusion

In the world of electrical safety, grounding equipment plays a pivotal role in protecting both people and property. Understanding the nuances of what is grounding hardware is essential for anyone involved in electrical installations or maintenance. By recognizing the various components of grounding systems, types of grounding hardware, and their specific applications, one can make informed decisions that enhance safety and efficiency.

Key Takeaways on Grounding Equipment

Grounding equipment serves as the backbone of electrical safety by providing a reliable path for fault currents to dissipate safely into the earth. It encompasses a wide range of products, from ground rods to connectors, all designed to ensure that systems operate without risk of shock or fire. Familiarity with the installation process of grounding components is crucial; improper installation can lead to catastrophic failures and serious safety hazards.

Importance of Proper Installation

An incorrectly installed system may fail during critical moments, leaving you vulnerable to electrical surges or outages. Selecting the best grounding hardware while adhering to established installation guidelines ensures optimal performance and longevity—making it a non-negotiable aspect for both residential and commercial applications.

Future Innovations in Grounding Hardware

As technology advances, so too does the potential for innovations in grounding equipment that promise enhanced performance and reliability. Emerging materials and designs aim not only at improving efficiency but also at reducing environmental impact through sustainable practices. Keeping an eye on these advancements will be essential for anyone looking to stay ahead in selecting the best grounding hardware for their needs.