Introduction

In the world of electrical systems, arcing horns play a crucial role that often goes unnoticed. These unsung heroes help manage electrical discharges and protect equipment from potential damage. But what do arcing horns do, and why are they so important?

Understanding the Role of Arcing Horns

At their core, arcing horns are designed to provide a controlled path for electrical arcs to travel, minimizing damage to surrounding components. They act as a bridge during fault conditions, ensuring that any electrical discharge is safely directed away from sensitive areas. This vital function contributes significantly to the overall reliability of electrical systems.

Importance of Arcing Horns in Electrical Systems

The importance of arcing horns cannot be overstated; they enhance safety and operational efficiency in transformers and other high-voltage equipment. By preventing destructive arcs from forming in critical components, these devices ensure longevity and reduce maintenance costs. Moreover, understanding what is the arcing horn in a transformer can help engineers design more resilient systems.

Common Myths about Arcing Horns

Despite their significance, there are several common myths surrounding arcing horns that can lead to misunderstandings about their functionality. One prevalent myth is that they are interchangeable with corona rings; however, knowing what is the difference between corona ring and arcing horn reveals distinct purposes for each device. Additionally, many people wonder about the sounds associated with these devices—what is an arcing sound really? Clearing up these misconceptions helps improve awareness of their true value in maintaining electrical safety.

The Basics of Arcing Horns

Arcing horns are crucial components in electrical systems, particularly in high-voltage applications. They serve as protective devices that help manage electrical discharges, preventing damage to equipment and ensuring safety. Understanding what arcing horns do is essential for anyone involved in electrical engineering or maintenance.

What Do Arcing Horns Do?

So, what do arcing horns do? Primarily, arcing horns provide a controlled path for electrical discharge during fault conditions, such as short circuits or overloads. By directing the arc away from sensitive components, they minimize potential damage and enhance the longevity of transformers and other equipment.

In addition to protecting equipment, arcing horns also help reduce the risk of fire hazards associated with arcing events. They create a safer environment by dissipating energy and reducing the intensity of arcs that can lead to catastrophic failures. Ultimately, their role is vital in maintaining operational integrity within electrical systems.

Components of Arcing Horns

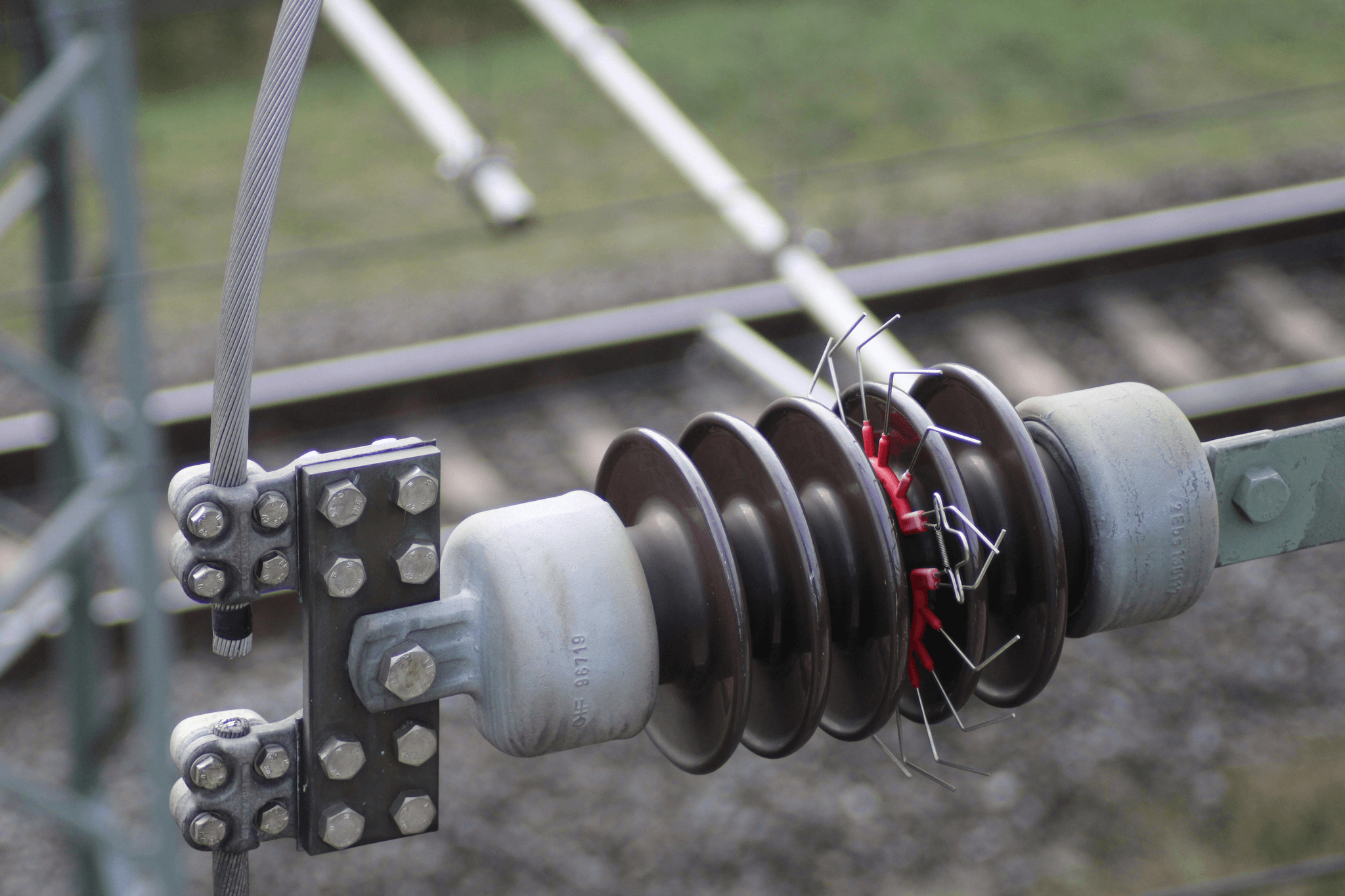

The construction of an arcing horn involves multiple components designed to work together effectively. Typically, an arcing horn consists of two conductive rods positioned at a specific distance apart to create an air gap for arc formation. These rods are often made from materials like copper or aluminum due to their excellent conductivity and durability.

Other essential elements include insulators that support the rods while preventing unwanted current flow to surrounding structures. Additionally, some designs may incorporate protective coatings or treatments to enhance resistance against environmental factors like moisture and corrosion. Understanding these components helps clarify how each part contributes to the overall function of the arcing horn.

How Arcing Horns Work

How do these devices operate? When a fault occurs within an electrical system, such as during a short circuit event, voltage levels can spike dramatically. This sudden increase can lead to an arc forming between the two conductive rods of the arcing horn—essentially creating a controlled lightning bolt that safely redirects excess energy away from critical equipment.

The design ensures that this arc occurs at a predetermined point rather than elsewhere in the system where it could cause more severe damage or failures. Once formed, the arc dissipates energy through heat and light while allowing current flow through alternative paths designed for this purpose. Thus, understanding how arcing horns work is key for optimizing safety measures in high-voltage environments.

Arcing Horns vs. Corona Rings

When it comes to electrical systems, the terms arcing horn and corona ring often come up in discussions about safety and performance. While both components play crucial roles in managing electrical discharge, they serve distinct purposes and are designed for different applications. Understanding what arcing horns do versus what corona rings do can help you make informed decisions when selecting components for your system.

What is the Difference Between Corona Ring and Arcing Horn?

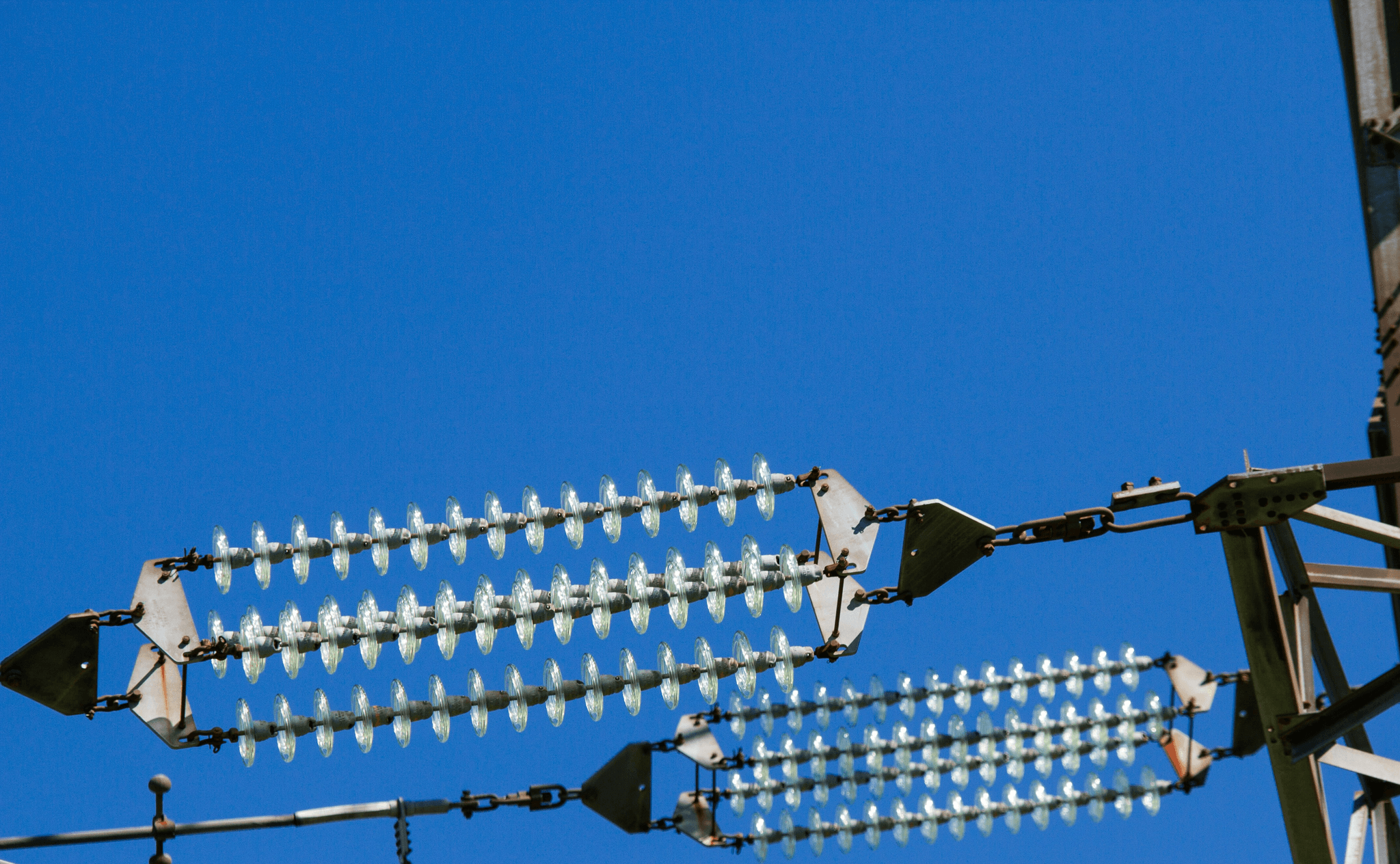

The primary distinction between a corona ring and an arcing horn lies in their function and design. An arcing horn is specifically designed to divert electrical arcs away from critical components, preventing damage during fault conditions. In contrast, a corona ring serves to reduce the electric field strength around high-voltage conductors, minimizing the risk of corona discharge—a phenomenon that can lead to energy loss and equipment deterioration.

In terms of physical appearance, arcing horns typically feature elongated shapes with pointed tips that promote the ionization of air during faults, while corona rings are usually circular or oval-shaped fixtures placed around insulators or conductors. This fundamental difference highlights their unique roles within an electrical system: arcing horns primarily mitigate arc flash risks, whereas corona rings focus on enhancing insulation performance by reducing electric field intensity.

When to Use Each

Knowing when to use an arcing horn or a corona ring depends largely on the specific requirements of your electrical system. If you're dealing with high-voltage applications where arc flash events are a concern—such as transformers or overhead lines—installing arcing horns can significantly enhance safety by providing a controlled path for arcs to dissipate safely into the atmosphere.

On the other hand, if your setup involves long-distance transmission lines or high-voltage insulators where corona discharge might be an issue, employing corona rings will help minimize energy losses and prolong equipment life by maintaining optimal electric field conditions around conductive elements.

Ultimately, understanding these distinctions allows engineers and electricians alike to tailor their approach based on operational needs—whether focusing on preventing destructive arcs with arcing horns or mitigating energy loss through strategic placement of corona rings.

Impact on Electrical Systems

The impact of choosing between an arcing horn and a corona ring extends beyond mere functionality; it affects overall system reliability and safety as well. Properly installed arcing horns can drastically reduce potential hazards associated with arc flashes in transformers—an essential consideration given that such events can lead to catastrophic failures if not managed effectively.

Conversely, implementing corona rings enhances insulation performance by reducing voltage stress on conductors, which translates into fewer maintenance issues over time due to reduced wear-and-tear from excessive electric fields. This proactive approach ultimately results in lower operational costs while ensuring that systems remain efficient under varying load conditions.

In summary, both components play vital roles within electrical systems but cater to different challenges; understanding their respective functions ensures optimal performance while safeguarding against potential risks associated with high-voltage operations.

The Science Behind Arcing Sounds

When it comes to electrical systems, understanding the phenomenon of arcing sounds is crucial. An arcing sound can be a signal that something isn't quite right, often indicating an electrical discharge or fault. These sounds can range from a faint crackle to a loud pop, and they are generally associated with the operation of devices like transformers and the presence of arcing horns.

What is an Arcing Sound?

An arcing sound is essentially the audible manifestation of electrical energy jumping between two conductive points. This phenomenon occurs when there’s a breakdown in insulation or when voltage levels exceed safe limits, causing electricity to leap through the air. In relation to arcing horns, these components help manage such discharges by providing a controlled path for electricity, thereby minimizing unwanted noise and potential damage.

Causes of Arcing Sounds

Several factors can contribute to the occurrence of arcing sounds in electrical systems. For instance, environmental conditions such as humidity or dirt accumulation can lead to insulation failures, prompting arcs to form unexpectedly. Additionally, improper installation or wear and tear on components like arcing horns can exacerbate these issues—making it essential for operators to recognize what do arcing horns do? They play a vital role in preventing excessive noise and ensuring smooth operation within transformers.

Mitigating Arcing Sounds in Transformers

To effectively mitigate arcing sounds in transformers, regular maintenance is key. Ensuring that your equipment has properly functioning arcing horns will help direct any stray electrical discharges away from critical components and reduce noise levels significantly. Furthermore, using high-quality materials during installation—like those found in armor rods—can enhance durability and minimize the risk of faults that lead to those pesky sounds we all dread hearing.

The Role of Arcing Horns in Transformers

Arcing horns play a crucial role in the functioning of transformers, acting as protective devices that mitigate electrical arcing. When high voltage is present, these horns help to safely dissipate electrical energy, preventing damage to transformer components and ensuring reliable operation. Understanding what an arcing horn in a transformer does can provide insights into its importance in maintaining electrical safety and efficiency.

What is the Arcing Horn in a Transformer?

The arcing horn in a transformer is essentially a pair of conductive rods placed strategically to guide any stray electrical discharges away from sensitive areas. These horns create a controlled path for electricity during fault conditions, effectively channeling arcs away from the transformer's core and windings. By understanding what do arcing horns do, one can appreciate how they protect transformers from potential failures caused by excessive voltage or insulation breakdown.

Benefits of Using Arcing Horns

Using arcing horns offers several benefits that enhance the longevity and reliability of transformers. First, they significantly reduce the risk of catastrophic failure by directing harmful electrical discharges away from critical components, thereby preserving their functionality. Additionally, these devices help maintain system stability by minimizing disruptions caused by arcing sounds that could indicate underlying issues—something every facility manager wants to avoid.

Maintenance Tips for Arcing Horns

To ensure that arcing horns continue to perform optimally, regular maintenance is essential. Inspecting them for signs of wear or corrosion can prevent unexpected failures; after all, prevention is better than cure! Furthermore, keeping them clean and free from debris will help maintain their effectiveness in guiding electrical discharges safely—after all, no one wants an unexpected arc ruining their day!

Selecting the Right Armor Rod

Choosing the right armor rod is crucial for ensuring the effectiveness of arcing horns in electrical systems. Armor rods serve as protective devices that enhance the durability of conductors by preventing mechanical damage and reducing electrical stress. Understanding the materials, compatibility, and customization options can make a significant difference in performance.

Armor Rod Materials Explained

Armor rods come in various materials, each offering distinct advantages for use with arcing horns. Common materials include fiberglass, aluminum, and composite options that provide excellent strength-to-weight ratios. The choice of material not only affects durability but also influences how effectively arcing horns function in mitigating electrical discharges.

When considering what do arcing horns do?, it's essential to recognize that armor rods help absorb and distribute stress during electrical events, which can prolong the lifespan of both the rod and the connected components. For instance, fiberglass rods are lightweight yet robust enough to withstand harsh environmental conditions while ensuring that arcing sounds are minimized during operation. Ultimately, selecting a suitable material enhances overall system reliability.

Importance of Material Compatibility

Material compatibility is paramount when selecting armor rods to pair with arcing horns effectively. Using incompatible materials can lead to accelerated wear or even failure of components due to galvanic corrosion or thermal expansion discrepancies. Therefore, it's vital to consider both mechanical properties and chemical resistance when making your selection.

For example, if you’re using an aluminum armor rod with an arcing horn made from a different metal type, you might encounter issues over time due to differing rates of thermal expansion or susceptibility to corrosion under certain conditions. This brings us back to understanding what is the difference between corona ring and arcing horn? While both serve protective roles in electrical systems, their material compositions must be compatible with adjacent components for optimal performance.

Spark Fittings and Customized Armor Rods

Spark fittings play a crucial role in integrating armor rods with arcing horns seamlessly within electrical systems. These fittings ensure secure connections while allowing flexibility for adjustments during installation or maintenance procedures. Customized armor rods can also be tailored specifically for unique applications where standard sizes may not suffice.

In situations where specific dimensions are required because of space constraints or particular operational needs—such as those found around transformers—custom solutions become invaluable. Understanding what is an arcing sound? helps highlight why proper fitting matters; any gaps or misalignments could lead to increased noise levels during operation due to ineffective discharge management by the arcing horn setup.

Ultimately, investing time into selecting appropriate spark fittings along with customized armor rods will enhance overall system safety and reliability while significantly reducing potential risks associated with improper installations.

Conclusion

In summary, arcing horns play a crucial role in enhancing the safety and reliability of electrical systems. They are designed to dissipate electrical energy and prevent damage caused by arcing, which is an essential function in transformers and other high-voltage applications. Understanding what do arcing horns do can help in appreciating their significance in maintaining system integrity.

Key Takeaways on Arcing Horns

Arcing horns are not just decorative elements; they serve a vital purpose in managing electrical discharge and protecting equipment from damage. They differ significantly from corona rings, which primarily focus on reducing corona discharge rather than handling arcing events directly. The importance of recognizing what is the arcing horn in a transformer cannot be overstated, as it directly impacts the longevity and performance of electrical systems.

Future Trends in Electrical Safety

The future of electrical safety is leaning increasingly towards advanced materials and technologies that enhance the efficiency of components like arcing horns. Innovations may lead to more effective designs that further minimize risks associated with arcing sounds and improve overall operational reliability. As we explore what is the difference between corona ring and arcing horn, we can expect to see developments that integrate both technologies for optimal performance.

How to Choose the Right Components for Your System

Choosing the right components for your electrical system involves understanding not only how each part functions but also its compatibility with existing infrastructure. When considering options, reflect on what do arcing horns do within your specific application context; their role could vary significantly between different setups. Additionally, consulting with professionals about spark fittings or customized armor rods can ensure you select components that meet your unique needs while addressing concerns about what is an arcing sound effectively.