Introduction

In the world of industrial cleaning and surface preparation, the **automatic blasting machine** stands out as a game changer. These **Automated Blasting Systems and Machines** are designed to streamline the blasting process, making it faster and more efficient than traditional methods. But what exactly is automated blasting? Simply put, it involves using machinery that automates the abrasive cleaning process, reducing manual labor while enhancing precision.

What is an Automatic Blasting Machine?

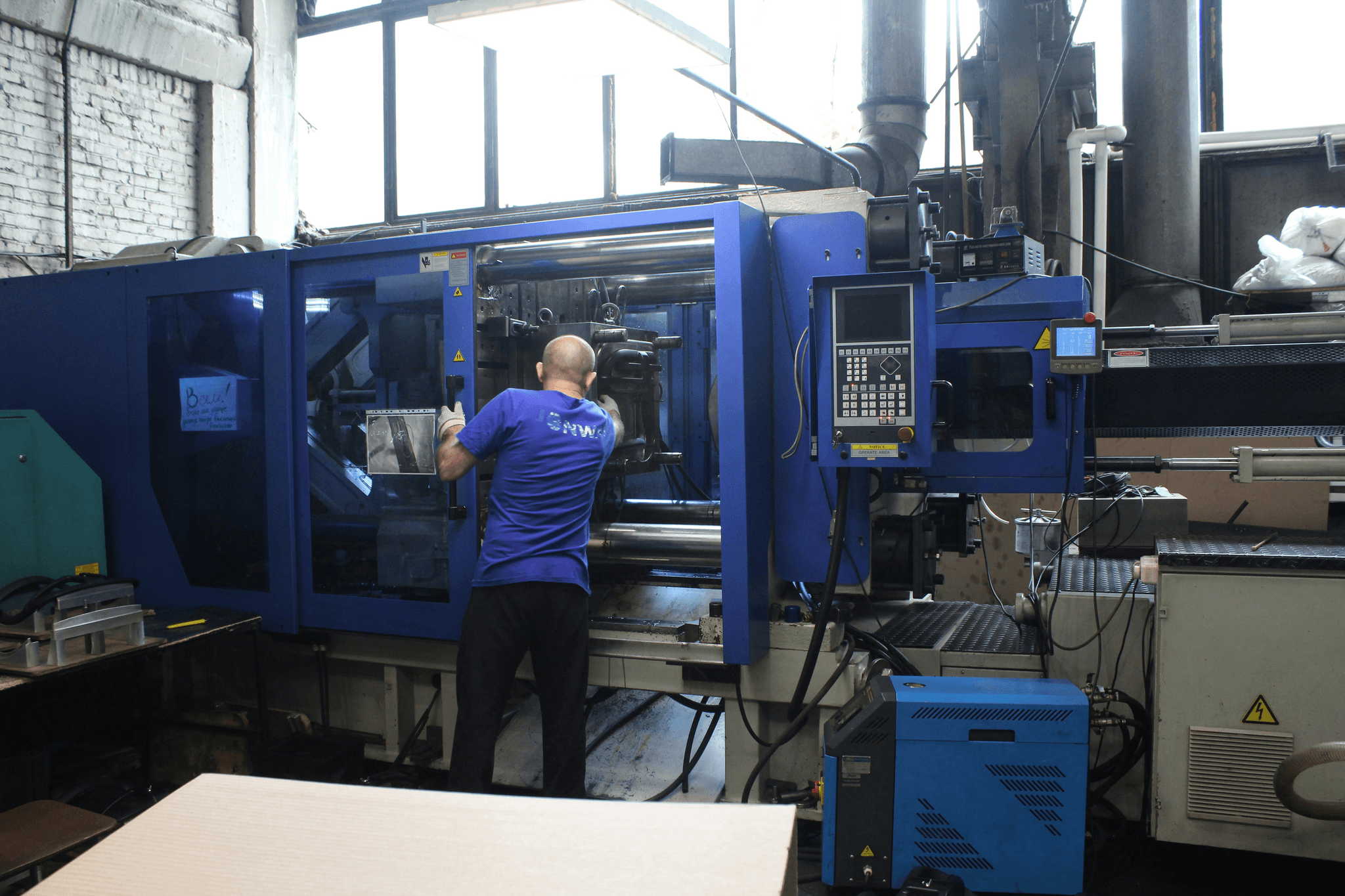

An **automatic blasting machine** utilizes advanced technology to propel abrasive materials onto surfaces, effectively removing contaminants and preparing them for further processing or finishing. This type of equipment can vary in design but typically includes features such as programmable settings and real-time monitoring capabilities to ensure optimal performance. Understanding what automated blasting entails is crucial for businesses looking to improve their operations.

Benefits of Using Automatic Blasting

The benefits of using an **automatic blasting machine** are manifold; they include increased efficiency, reduced labor costs, and improved safety standards in the workplace. By automating the blasting process, companies can achieve consistent results while minimizing human error—a critical factor in industries where precision matters. Additionally, these machines often come equipped with dust collection systems that enhance air quality during operation.

Key Industries Utilizing Blasting Machines

Several key industries benefit from the use of **Automated Blasting Systems and Machines**, including manufacturing, automotive, aerospace, and construction. In manufacturing settings, these machines help prepare surfaces for painting or coating by ensuring they are free from rust or other impurities. The aerospace industry also relies on automatic sandblasting machines for maintaining aircraft components' integrity while adhering to strict safety regulations.

Essential Safety Features

Emergency Stop Mechanisms

Every automatic blasting machine is equipped with emergency stop mechanisms that act as a lifeline in critical situations. These systems allow operators to halt the machine's operation instantly, preventing potential accidents or injuries caused by unforeseen malfunctions or hazardous conditions. The presence of easily accessible emergency stops not only enhances safety but also instills confidence in users who may wonder, What is automated blasting? Knowing that swift action can be taken in emergencies helps create a safer working environment.

Protective Housing Design

The protective housing design of Automated Blasting Systems and Machines plays a vital role in safeguarding both personnel and equipment. These robust enclosures are engineered to contain debris, reduce noise levels, and protect operators from flying particles during the blasting process. By investing in an automatic sandblasting machine for sale with superior housing designs, companies can ensure compliance with safety regulations while maximizing operational efficiency.

Dust and Fume Extraction Systems

One of the standout features of modern automatic blasting machines is their dust and fume extraction systems, which are essential for maintaining air quality within workspaces. These systems efficiently capture harmful particles generated during the blasting process, reducing respiratory hazards for operators and improving overall workplace conditions. Moreover, understanding how much mobile dustless blasting costs can help businesses realize the long-term savings associated with investing in advanced extraction technologies that promote health and safety.

Efficiency in Operation

In the world of industrial cleaning and surface preparation, efficiency is key. Automatic blasting machines are designed to streamline operations, reduce labor costs, and enhance productivity. By integrating advanced technologies, these machines ensure that tasks are completed with precision and speed.

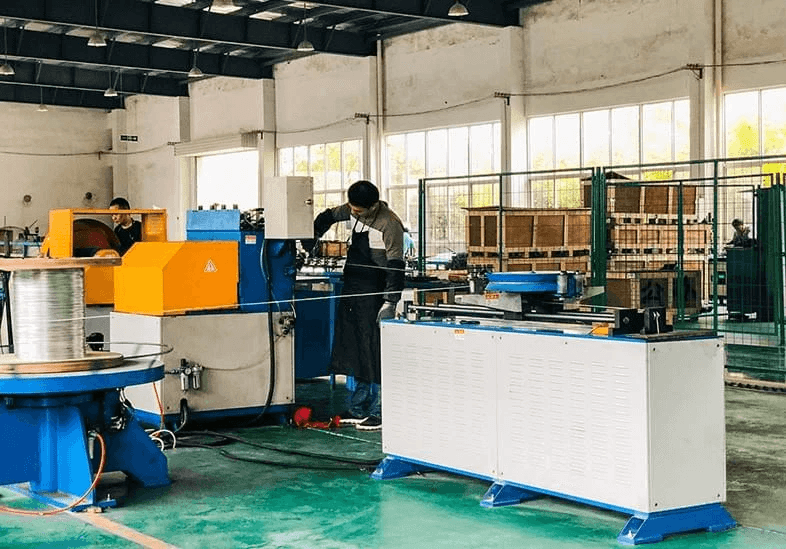

Automated Control Systems

Automated control systems in automatic blasting machines make the entire process seamless and user-friendly. These systems allow operators to set parameters for blasting intensity, duration, and material type with just a few clicks. By minimizing human error through automation, businesses can achieve consistent results while optimizing their operational workflows.

Moreover, Automated Blasting Systems and Machines often come equipped with intuitive interfaces that enable real-time adjustments based on immediate needs. This adaptability not only enhances productivity but also contributes to a safer working environment by reducing manual intervention during operation. Ultimately, an efficient automated control system is crucial for maximizing the effectiveness of any automatic blasting machine.

Programmable Settings for Precision

One of the standout features of an automatic sandblasting machine for sale is its programmable settings that ensure precision in every blast cycle. Operators can customize settings tailored to various projects—whether they’re working on delicate components or robust surfaces requiring heavy-duty cleaning. This level of customization guarantees that each job meets specific requirements without compromising quality.

Additionally, programmable settings allow for repeatability across multiple projects; once a setting is perfected for a particular task, it can be saved and reused as needed. This not only saves time but also significantly reduces the potential waste associated with trial-and-error methods commonly seen in manual blasting processes. In essence, these precise controls elevate the standard of work achievable with automated blasting technology.

Real-Time Monitoring Capabilities

Real-time monitoring capabilities are another vital aspect of modern automatic blasting machines that contribute to operational efficiency. These systems provide continuous feedback on performance metrics such as pressure levels, material usage, and equipment health—allowing operators to make informed decisions instantly. With this data at their fingertips, companies can quickly adapt processes to address any issues before they escalate into costly downtimes.

Furthermore, real-time monitoring helps maintain optimal conditions throughout the blasting process by alerting users to deviations from preset parameters or potential malfunctions in machinery like BASKET BLASTERS or other specialized units. This proactive approach not only enhances safety but also ensures consistent quality across all applications—making such features indispensable for industries relying heavily on automated blasting solutions like shot blasting or mobile dustless blasting services.

Versatility and Adaptability

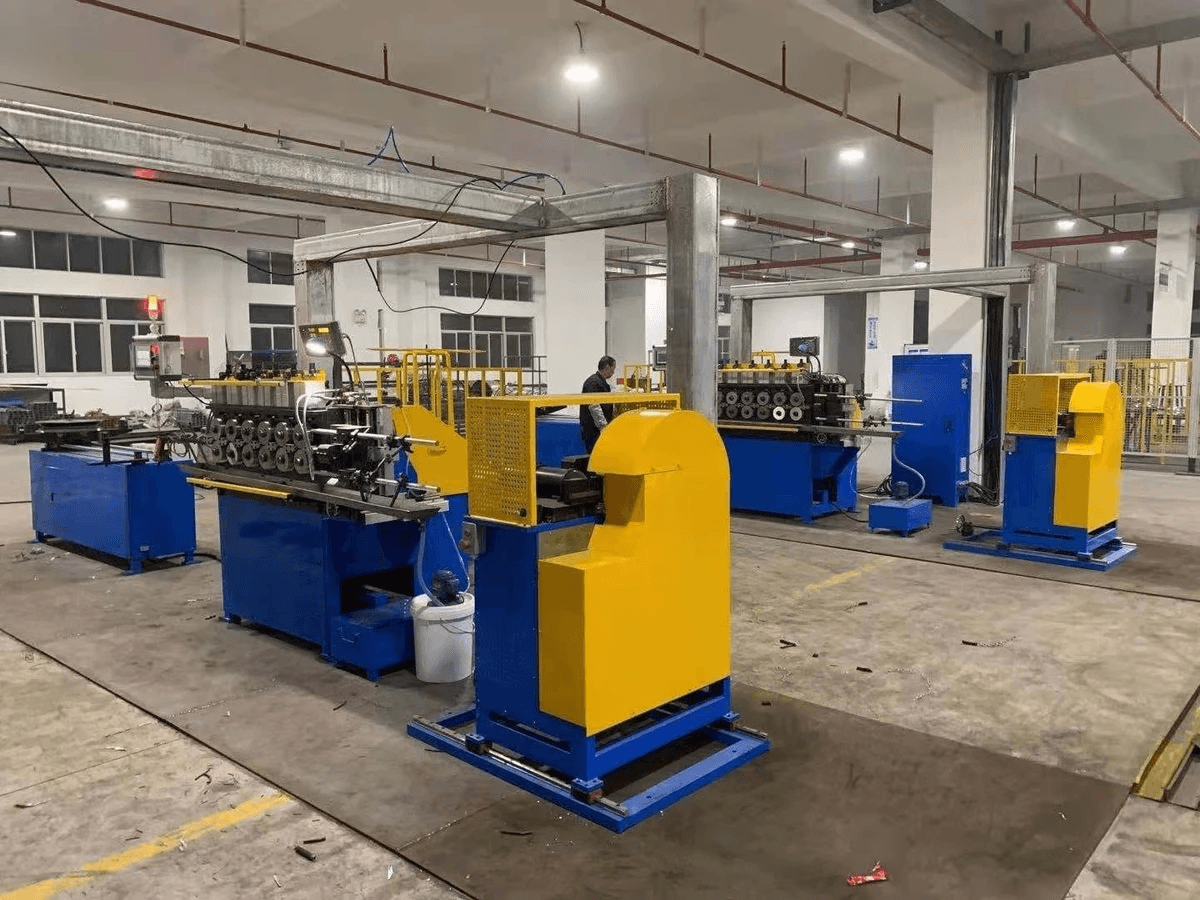

When it comes to the versatility of automatic blasting machines, their ability to handle a wide range of materials is nothing short of impressive. From metals to plastics, these Automated Blasting Systems and Machines can be tailored to meet the specific demands of various industries. This adaptability not only enhances efficiency but also allows businesses to tackle diverse projects without needing multiple machines.

Compatibility with Various Materials

One of the standout features of an automatic blasting machine is its compatibility with various materials, making it a favorite in many sectors. Whether you're working with steel, aluminum, wood, or even delicate substrates, these machines can be configured for optimal performance across different surfaces. This flexibility ensures that users can achieve consistent results regardless of the material being processed.

Customization Options for Specific Tasks

Customization options are another significant advantage offered by Automated Blasting Systems and Machines. Users can modify settings such as pressure levels and media types to suit specific tasks—whether it's achieving a coarse texture or a smooth finish. With an automatic sandblasting machine for sale that caters to unique project requirements, businesses can streamline operations while maintaining high-quality standards.

Multi-Functionality in Different Applications

The multi-functionality inherent in modern automatic blasting machines makes them indispensable in various applications—from automotive refinishing to industrial cleaning. For instance, BASKET BLASTERS are designed for efficient handling of smaller parts while providing uniform surface treatment—a perfect fit for industries that require precision work on intricate components. The ability to switch between different functions not only saves time but also reduces operational costs associated with using multiple specialized machines.

Quality Control Mechanisms

In the world of automatic blasting machines, maintaining quality is paramount. Automated Blasting Systems and Machines are designed with integrated mechanisms that ensure every blasted surface meets stringent standards. This focus on quality control not only enhances the end product but also boosts operational efficiency.

Integrated Inspection Systems

Integrated inspection systems are a game-changer for automatic blasting machines, providing real-time feedback during the blasting process. These systems utilize advanced sensors and imaging technology to assess surface quality immediately after treatment, allowing operators to make adjustments on-the-fly. By implementing these automated inspection features, manufacturers can significantly reduce waste and rework costs, ultimately answering the question: How much does shot blasting cost? The answer becomes clearer when you consider the savings from improved accuracy.

Consistency in Surface Finishing

One of the standout benefits of using an automatic sandblasting machine for sale is its ability to deliver consistent surface finishes across multiple batches. Unlike manual processes that may vary due to human error, Automated Blasting Systems ensure uniformity by following programmed settings meticulously. This consistency not only enhances product aesthetics but also ensures that surfaces are prepared adequately for subsequent treatments or coatings.

Durability Testing Protocols

Durability testing protocols are essential components of any effective quality control mechanism in automatic blasting machines. These tests evaluate how well materials withstand various environmental conditions after being blasted, ensuring long-lasting performance in real-world applications. Understanding what are the two types of blasting—abrasive and non-abrasive—can further inform these protocols, enabling manufacturers to select appropriate methods based on their durability requirements.

Leading Brands in the Market

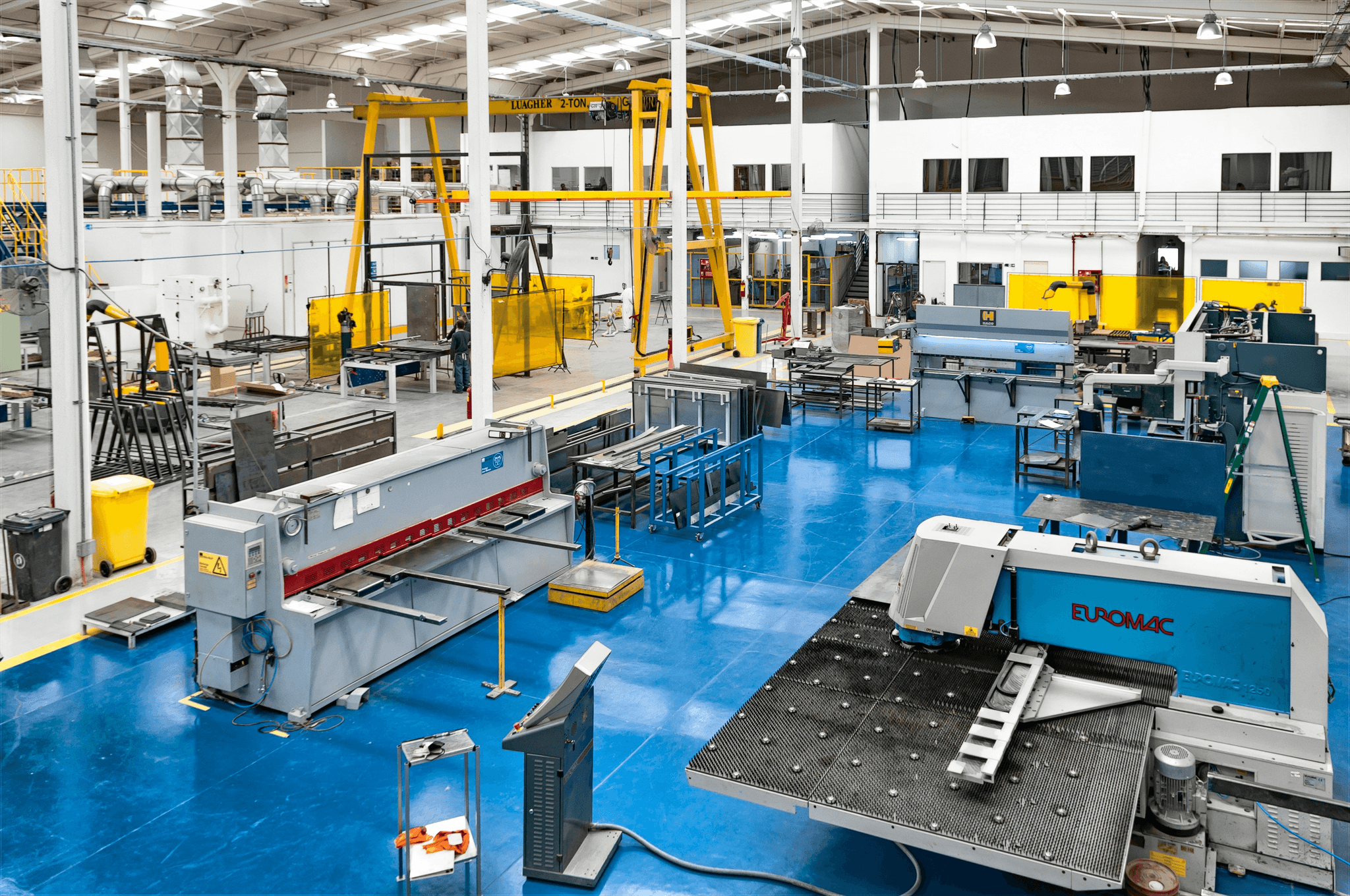

In the realm of automatic blasting machines, several brands have carved out a niche, but few stand out quite like Spark Fittings. This company has made a name for itself by offering a range of Automated Blasting Systems and Machines that cater to diverse industry needs. Their commitment to innovation and quality ensures that customers receive machines designed for efficiency, safety, and versatility.

Overview of Spark Fittings’ Offerings

Spark Fittings specializes in advanced automatic blasting machines that streamline surface preparation processes across various sectors. Their product line includes Basket Blasters and an automatic sandblasting machine for sale, both designed to enhance productivity while maintaining high safety standards. With features like programmable settings and real-time monitoring capabilities, Spark Fittings’ offerings are tailored to meet the specific requirements of modern manufacturing environments.

Notable Competitors and Innovations

While Spark Fittings holds its ground as a leader in automated blasting technology, it faces competition from other notable brands in the market. Companies such as Graco and Wheelabrator are also pushing the envelope with their innovative approaches to automated blasting systems. These competitors are continually developing cutting-edge solutions that not only improve efficiency but also reduce costs—important considerations when asking how much does shot blasting cost or how much does mobile dustless blasting cost?

Trends in Automatic Blasting Technology

The landscape of automatic blasting technology is evolving rapidly, driven by advancements in automation and environmental regulations. One prominent trend is the increasing integration of smart technology into Automated Blasting Systems and Machines, enabling more precise control over the blasting process. Additionally, there's a growing emphasis on eco-friendly practices—highlighting innovations that minimize dust emissions while maximizing effectiveness; this is crucial as industries seek answers to what are the two types of blasting?

Conclusion

As we wrap up our exploration of automatic blasting machines, it's clear that these devices are not just a trend; they represent the future of industrial cleaning and surface preparation. With advancements in technology, Automated Blasting Systems and Machines are becoming more sophisticated, enhancing efficiency while ensuring safety. The question What is automated blasting? can be answered with a simple explanation: it's the use of advanced machinery to streamline the blasting process, making it faster and more effective.

The Future of Automatic Blasting Machines

The future of automatic blasting machines looks bright, with innovations continuously emerging to improve their functionality. Expect to see enhanced features such as AI-driven control systems that allow for real-time adjustments based on material response during blasting. Additionally, as industries seek sustainable practices, mobile dustless blasting solutions are gaining traction for their eco-friendly benefits compared to traditional methods.

Maximizing Efficiency and Safety

Maximizing efficiency and safety in automated blasting operations is paramount for any business aiming to thrive in a competitive market. By incorporating essential safety features like emergency stop mechanisms and protective housing designs, companies can minimize risks associated with operating an automatic sandblasting machine for sale. Furthermore, integrating dust and fume extraction systems not only protects workers but also enhances productivity by maintaining a clean working environment.

Investing in Quality Machines for Success

Investing in quality machines is crucial for long-term success in any industry utilizing blasting technologies. Whether you're considering basket blasters or larger automated systems, understanding How much does shot blasting cost? will help you make informed decisions tailored to your budget and operational needs. Remember that choosing reliable brands ensures durability and performance; after all, no one wants to deal with frequent breakdowns when precision is key!