Introduction

In the world of mechanical fastening, the role of spring washers is often underestimated, yet they are vital for ensuring secure connections. Spring lock washers, a specific type of locking washer, provide an ingenious solution to combat loosening due to vibrations and dynamic loads.

Understanding Spring Washers

Spring washers are specialized fasteners designed to maintain tension and prevent loosening under various conditions. Unlike standard flat washers, spring lock washers have a unique shape that allows them to exert a continuous force against the nut or bolt they support. This innovative design ensures that even with movement or vibration, the connection remains tight and secure—making them essential in many applications.

Importance of Locking Mechanisms

Locking mechanisms are crucial in maintaining the integrity of assembled parts in any mechanical system. Without proper locking solutions like lock nuts or locking washers, components can loosen over time due to environmental factors such as vibration or thermal expansion. Employing effective spring locking devices not only enhances durability but also significantly reduces maintenance costs and downtime associated with loose fasteners.

Overview of Spring Lock Washers

Spring lock washers serve as a reliable option among various fastening solutions available today. These unique components come in different designs tailored for specific applications, providing flexibility and effectiveness across industries from automotive to aerospace. By utilizing a spring lock washer, you ensure that your assemblies remain intact under challenging conditions while benefiting from an easy installation process that saves both time and effort.

What is a Spring Lock Washer?

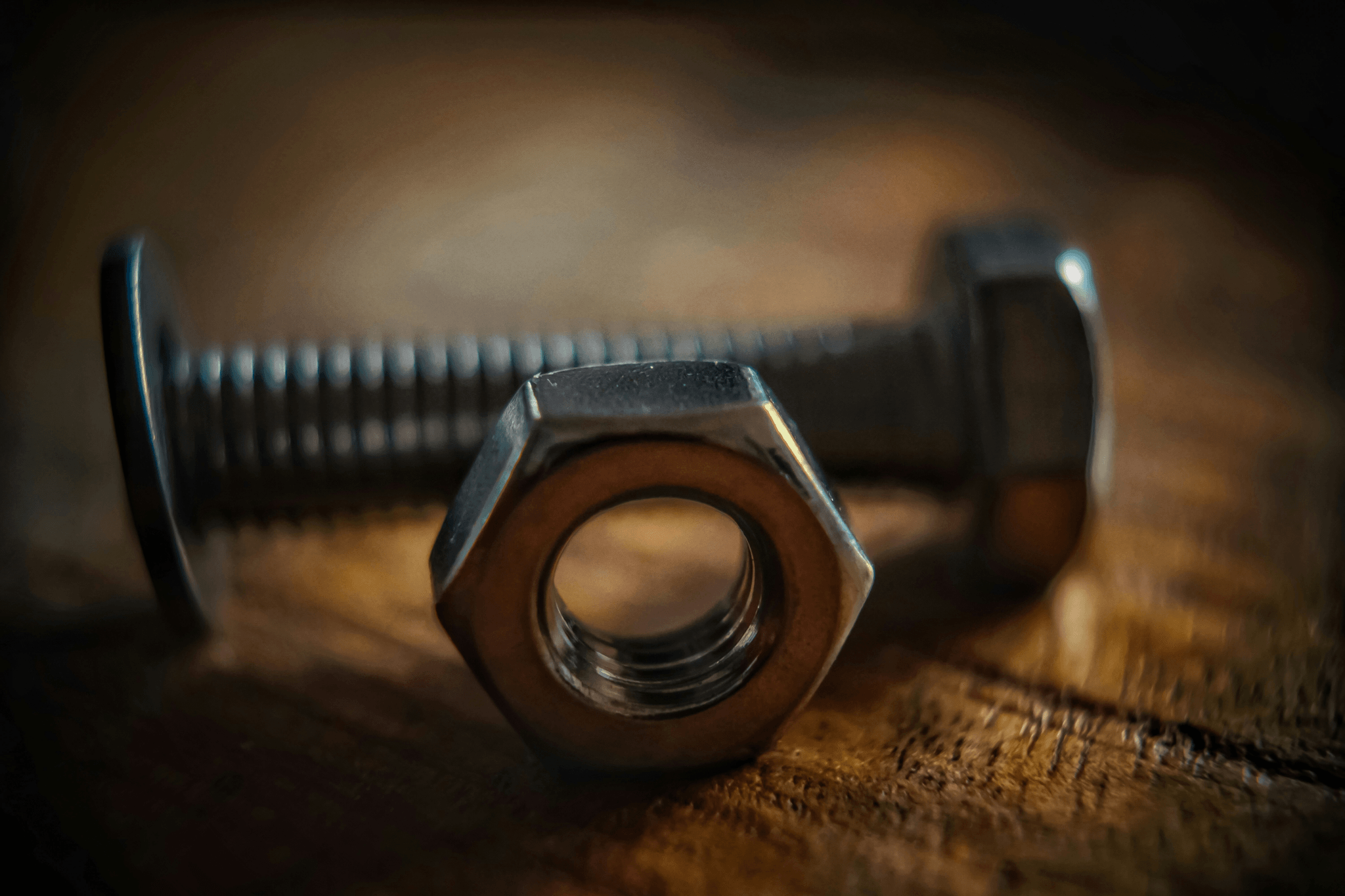

A spring lock washer is a specialized type of locking washer designed to prevent loosening of fasteners due to vibrations or dynamic loads. These ingenious little devices employ spring tension to create a secure grip on nuts and bolts, ensuring that your assembly remains tight over time. In essence, spring locking mechanisms are critical for maintaining the integrity and safety of various applications across multiple industries.

Definition and Functionality

The definition of a spring lock washer revolves around its primary function: to provide resistance against loosening in mechanical assemblies. Unlike traditional washers, which merely distribute load, the spring lock washer uses its unique shape and material properties to exert force against the nut or bolt head, effectively creating a locking effect. This functionality is essential in applications where vibration or movement could lead to fastener failure, making the spring lock washer an invaluable component in any assembly requiring reliability.

Types of Lock Washers

Lock washers come in various types, each tailored for specific applications and requirements. The most common types include split lock washers, which feature a helical design that provides increased friction; tooth lock washers that have serrated edges for enhanced grip; and wave washers that offer flexibility under load conditions. Understanding these different types of lock washers helps you choose the right one for your needs—after all, not every situation calls for just any old washer lock!

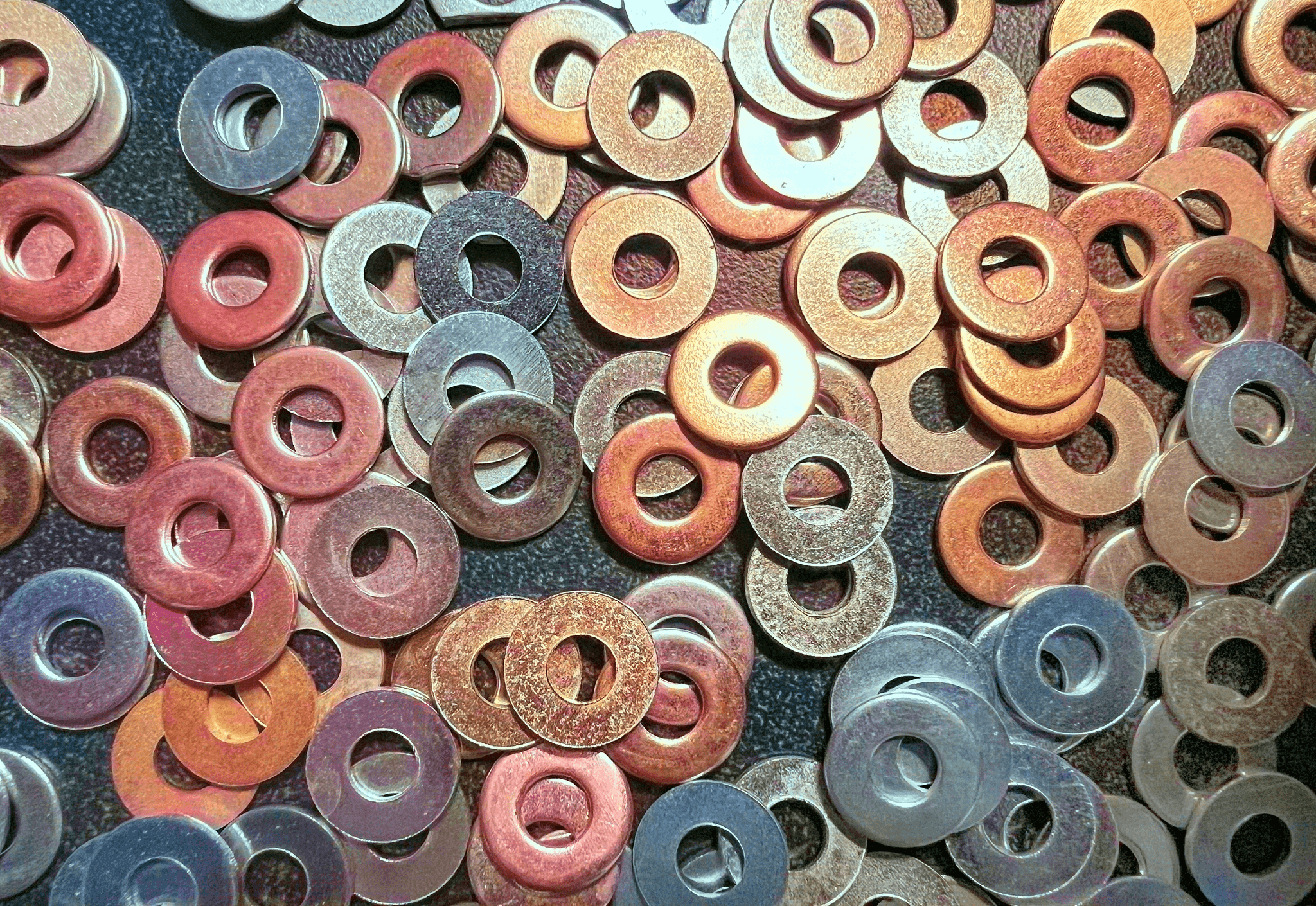

Material Composition

Material composition plays a significant role in the performance of spring locking devices like the spring lock washer. Typically made from carbon steel or stainless steel, these materials provide both strength and resilience against wear and corrosion. Additionally, some manufacturers may use specialized coatings or finishes to enhance durability further—ensuring that your chosen lock washer can withstand even the harshest environments while keeping your assemblies secure.

How Spring Lock Washers Work

Spring lock washers are ingenious little components that play a critical role in securing fasteners. Their design allows them to maintain tension and provide resistance against loosening, especially in dynamic environments where vibrations are common. By understanding the mechanism of action behind spring locking, we can appreciate why these lock washers are essential for so many applications.

Mechanism of Action

The mechanism of action for a spring lock washer is quite fascinating. When a bolt or screw is tightened, the washer compresses and exerts a radial force against the surface it’s mounted on, creating friction that helps prevent loosening. This unique ability to absorb vibrations and maintain pressure makes the spring lock washer an invaluable tool in various fastening scenarios.

As the assembly experiences movement or vibration, the spring locking feature allows the washer to adapt by redistributing force evenly across its surface. This adaptability not only enhances grip but also prolongs the life of both the fastener and the assembled components. Essentially, while other fasteners may fail under stress, spring lock washers rise to the challenge with their reliable performance.

Benefits of Spring Locking

Spring locking offers several benefits that make these washers stand out from traditional fastening solutions like flat washers or lock nuts. One major advantage is their ability to provide consistent clamping force over time; as parts settle or shift due to thermal expansion or mechanical stress, spring lock washers adjust accordingly without losing effectiveness. This means fewer maintenance checks and replacements—who doesn’t love that?

Another benefit lies in their versatility; they can be used across various materials and environments without compromising their integrity. Whether you're working with metal, plastic, or even wood, there's likely a suitable spring lock washer for your project needs. Plus, they excel in vibration-prone applications where standard locking mechanisms might falter—think automotive assemblies or heavy machinery.

Lastly, using a spring lock washer can enhance safety by reducing potential failures caused by loosening fasteners over time. With less chance of components coming undone unexpectedly, you’re not just securing parts; you’re also safeguarding lives and investments alike.

Applications in Different Industries

The applications for spring lock washers span numerous industries due to their reliability and effectiveness as locking washers. In automotive manufacturing, these components are crucial for securing engine parts where vibration is relentless; without them, loose bolts could lead to catastrophic failures on the road! Similarly, in aerospace engineering where precision is paramount, using high-quality spring locks ensures every component remains securely fastened during flight.

In construction and heavy machinery sectors, you'll often find these little heroes at work holding together critical structures exposed to harsh conditions and intense vibrations—the kind that would make most other fasteners cringe! They’re equally valuable in electrical equipment applications like spark fittings products because they help maintain tight connections essential for safety and performance.

From consumer electronics to industrial machinery—spring lock washers prove indispensable across multiple fields by enhancing durability while minimizing maintenance efforts required down the line. So whether you're tightening up your bike's handlebars or assembling complex machinery at work site—you can count on these trusty little devices!

When to Use Spring Washers

Understanding when to deploy a spring lock washer can significantly enhance the integrity of your fastening solutions. These handy little devices are particularly effective in situations where vibrations or movement are present, making them a go-to choice for various applications. By recognizing the ideal scenarios for using spring locking mechanisms, you can ensure that your assemblies remain secure and reliable.

Ideal Scenarios for Lock Washers

Spring lock washers shine in environments where traditional fasteners might falter due to vibration or dynamic loads. For instance, they are perfect for machinery, automotive applications, and any equipment subjected to constant motion. In these cases, the unique design of a spring lock washer provides an extra layer of security that prevents loosening over time—essentially acting as a safety net against failure.

Moreover, if you're dealing with softer materials that might deform under pressure, using a spring lock can distribute forces more evenly compared to standard flat washers or lock nuts. This makes them an excellent choice in construction projects involving metal-to-metal connections or sensitive electronic components. Choosing the right locking washer ensures that your assembly remains intact and functions as intended under challenging conditions.

Choosing the Right Washer Lock

Selecting the appropriate washer lock isn't just about picking one off the shelf; it requires careful consideration of several factors. First and foremost, assess the specific application and environmental conditions where your spring locking mechanism will be used—temperature fluctuations, exposure to chemicals, or moisture levels all play crucial roles in material selection. For example, stainless steel spring locks may be ideal for outdoor applications due to their corrosion resistance.

Next up is size—ensuring that your spring lock washer fits snugly with both bolt and nut is essential for optimal performance. A poorly fitted washer not only undermines its function but could also lead to catastrophic failures down the line. Finally, consider consulting manufacturer guidelines or industry standards when choosing between different types of locking washers; this will help you avoid common pitfalls associated with incorrect usage.

Common Mistakes in Usage

Even seasoned professionals can stumble into traps when using spring locks; understanding these common mistakes could save you time and money down the road. One frequent error is neglecting to clean surfaces before installation—dirt or debris can compromise how well a spring lock functions by preventing full contact between components. Always start with clean surfaces for maximum effectiveness!

Another misstep involves over-tightening—a common misconception is that cranking down on fasteners will provide greater security; however, this often leads to deformation of both the washer and connected parts instead of enhancing stability. Remember that spring locking mechanisms are designed to absorb some movement; excessive force can negate their benefits entirely! Lastly, some users overlook compatibility issues between different types of fasteners; ensure you're pairing your spring lock washers appropriately with bolts and nuts designed for use together.

Comparing Spring Washers to Other Fasteners

When it comes to securing components, the choice of fastener can make a significant difference in performance and reliability. Spring lock washers, with their unique design and functionality, stand out among various options available in the market. Understanding how spring locking compares to flat washers and lock nuts can help you make informed decisions for your projects.

Spring Lock Washers vs. Flat Washers

Spring lock washers and flat washers may seem similar at first glance, but their roles in fastening are quite distinct. While flat washers primarily distribute load and prevent surface damage, spring lock washers provide an added layer of security by preventing loosening due to vibration or torque. This makes the spring lock washer an essential choice in applications where stability is crucial, giving it a clear edge over standard flat washers.

Moreover, the design of spring locking allows them to exert a continuous force against the nut or bolt head, ensuring that even under stress or movement, your assembly remains tight. Flat washers lack this feature; thus, they do not offer the same level of protection against loosening forces. In scenarios where reliability is paramount—think automotive or aerospace applications—a spring lock washer is often the better option.

Advantages Over Lock Nuts

Lock nuts are another popular fastening solution known for their ability to resist loosening; however, they come with some drawbacks when compared to spring lock washers. One major advantage of using a spring lock is that it simplifies assembly processes without requiring additional tools or complex installations associated with some lock nuts. In many cases, just adding a washer lock washer can enhance security without complicating your workflow.

Additionally, while lock nuts can be effective at resisting vibrations, they may not perform as well under extreme conditions where thermal expansion occurs—this is where a spring locking mechanism shines through. The flexibility of a spring lock washer allows it to adapt more effectively to changing conditions without compromising its grip on the fastened components. Thus, for long-term stability and ease of use across various industries—from construction to electronics—spring locking mechanisms hold significant advantages over traditional lock nuts.

Performance in Vibration-Prone Environments

One area where spring lock washers truly excel is in vibration-prone environments such as machinery operation or vehicle assemblies. The unique design of these locking washers enables them to maintain tension even when subjected to continuous movement or shocks—something that standard fasteners might struggle with over time. By utilizing a spring locking mechanism instead of traditional fasteners like flat washers or simple screws alone, you enhance your assembly's resilience against vibrational forces.

Furthermore, studies have shown that assemblies using spring locks demonstrate significantly lower failure rates compared to those secured solely with flat washers or other fastening methods under similar conditions. This increased reliability translates directly into reduced maintenance costs and improved safety—a win-win situation for any project manager! When working on equipment exposed to constant motion—think heavy machinery or automotive parts—the choice between a conventional fastener and a robust spring lock washer becomes clear.

The Role of Spring Lock Washers in Electrical Equipment

Spring lock washers play a crucial role in the electrical equipment sector, providing essential locking mechanisms that enhance durability and performance. These specialized locking washers are designed to prevent loosening due to vibrations, which is particularly vital in high-stakes environments like electrical installations. When it comes to ensuring reliability in connections, the use of spring lock washers cannot be overstated.

Use in Spark Fittings Products

In the realm of spark fittings products, spring lock washers are indispensable for maintaining secure connections. These components help ensure that electrical contacts remain tight even when subjected to fluctuating temperatures and vibrations. By employing a spring locking mechanism, these washer lock devices effectively mitigate the risk of disconnection and electrical failures.

Moreover, spark fittings often face challenging conditions where traditional fasteners might fail; this is where the unique design of spring lock washers shines. Their ability to provide continuous tension allows them to outperform standard flat washers or even lock nuts in many applications. Thus, using spring locking solutions not only enhances safety but also extends the lifespan of critical electrical equipment.

Importance for ADSS and OPGW Applications

When it comes to All-Dielectric Self-Supporting (ADSS) and Optical Ground Wire (OPGW) applications, the importance of using reliable fastening solutions like spring lock washers becomes evident. These systems are often exposed to harsh environmental factors such as wind, ice load, and temperature fluctuations that can compromise connections over time. Spring locking devices provide a robust solution by ensuring that all components remain securely fastened despite these challenges.

In addition, both ADSS and OPGW systems require optimal performance for effective signal transmission; any loosening could lead to significant operational issues or outages. This is where choosing the right washer lock washer becomes critical—spring lock washers excel at maintaining tension under stress while preventing corrosion or wear over time. Their unique properties make them an ideal choice for infrastructure requiring long-term reliability.

Enhancing Safety and Reliability

The application of spring lock washers significantly enhances safety across various electrical installations by minimizing risks associated with loose connections. In environments prone to vibrations or movement, these locking washers act as a safeguard against unexpected failures that could lead to accidents or costly downtime. With their ability to absorb shock while maintaining a firm grip on fasteners, they ensure that every connection remains intact.

Furthermore, when used correctly alongside other components like lock nuts or flat washers, spring locking mechanisms contribute to an overall increase in system reliability. The strategic combination of these fastening solutions can create a more resilient assembly capable of withstanding extreme conditions without compromising functionality or safety standards. Ultimately, investing in quality spring lock solutions translates into peace of mind for engineers and technicians alike.

Conclusion

In conclusion, spring lock washers are essential components that enhance the reliability and safety of various fastening applications. Their unique design provides a reliable locking mechanism that prevents loosening due to vibrations and dynamic loads. Understanding the nuances of spring locking can significantly improve the performance of your assemblies.

Key Takeaways on Spring Lock Washers

Spring lock washers serve a critical role in maintaining tight connections in mechanical systems. They are designed to absorb shock and prevent bolt or nut loosening, making them ideal for vibration-prone environments. Remember that choosing the right washer lock is key; not all spring lock washers are created equal, and their effectiveness can vary based on material composition and application.

Best Practices for Using Lock Washers

When using lock washers, it's crucial to ensure proper installation for optimal performance. Always pair your spring lock washer with the appropriate fastener size to maximize its locking potential; mismatched sizes can lead to failure. Additionally, avoid common mistakes like reusing old lock washers or over-torquing bolts, as these practices can compromise the integrity of your assembly.

Future Trends in Fastening Solutions

As industries evolve, so do fastening solutions like spring locking mechanisms. Innovations in materials and designs are expected to enhance the effectiveness of lock washers further while also addressing environmental concerns through sustainable practices. The future may see advancements such as smart fasteners that provide real-time feedback on tension levels, ensuring even greater reliability than traditional methods.