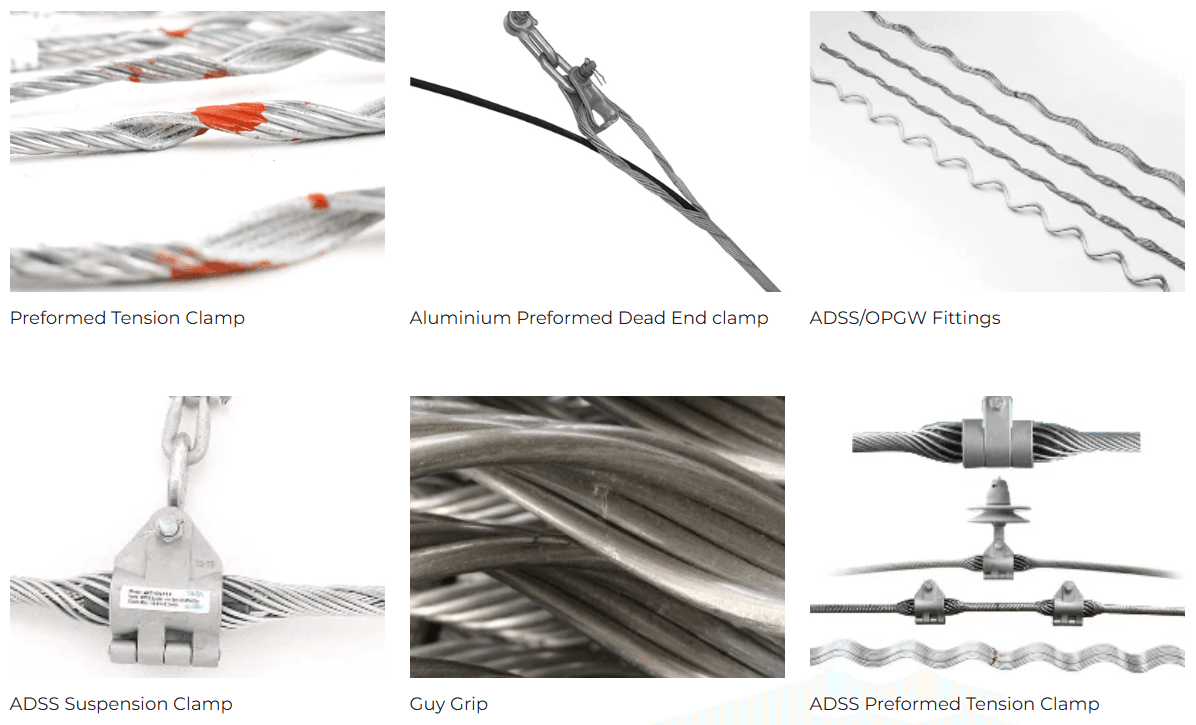

Introduction

Trunnion clamps are essential components in various industrial applications, providing stability and support for equipment. These specialized devices ensure that machinery operates smoothly and safely, making them indispensable in sectors like electrical transmission and railways. In this exploration, we will delve into the benefits of bolted aluminum designs and highlight the role of Spark Fittings in offering high-quality aluminum clamp assemblies.

Understanding Trunnion Clamps

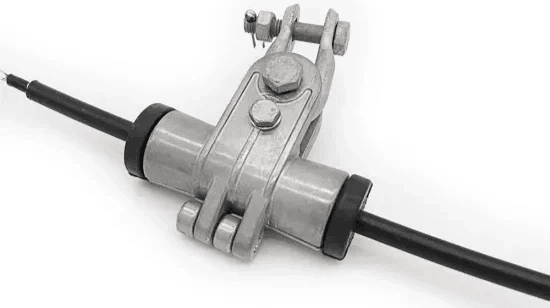

A trunnion clamp is a mechanical device used to secure and stabilize equipment, particularly in suspension systems. It typically consists of a cylindrical body that holds the load while allowing for rotational movement around its axis. Understanding how these clamps function is crucial for anyone involved in industrial operations or maintenance, as they play a pivotal role in ensuring safety and efficiency.

Benefits of Bolted Aluminum Designs

Bolted aluminum trunnion suspension clamps offer numerous advantages over traditional materials, primarily due to their lightweight yet robust construction. The use of aluminum not only reduces the overall weight of the assembly but also enhances corrosion resistance, making them ideal for outdoor applications where exposure to elements is a concern. Furthermore, these clamps facilitate easy installation and maintenance, allowing for quick adjustments without compromising structural integrity.

The Role of Spark Fittings

Spark Fittings stands out as an industry leader when it comes to manufacturing high-quality trunnion clamps and aluminum clamp assemblies. Their commitment to quality ensures that each product meets rigorous standards, providing customers with reliable solutions tailored to their specific needs. With a range of innovative designs and proven performance records, Spark Fittings exemplifies excellence in the field of bolted aluminum trunnion suspension clamps.

What is a Trunnion Clamp?

When discussing the world of mechanical assemblies, trunnion clamps are often at the forefront of conversation. A trunnion clamp is a specialized fastening device designed to support and secure equipment in various applications. These clamps play a critical role in ensuring stability and alignment, particularly in systems that require precision and strength.

Definition and Function

A trunnion clamp is essentially a bracket that holds an object securely in place while allowing for controlled movement or rotation. It serves as a pivotal point in machinery, ensuring that components remain aligned despite external forces or vibrations. In the realm of bolted aluminum designs, these clamps are particularly valued for their lightweight yet robust construction, making them ideal for both industrial and transportation applications.

Key Components of Aluminum Clamp Assembly

An aluminum clamp assembly typically consists of several key components: the clamp body, bolts, nuts, and sometimes additional hardware like washers or spacers. The clamp body is usually made from high-strength aluminum to provide durability without adding unnecessary weight. Bolts and nuts work together to create a secure connection that can withstand dynamic loads while allowing for easy disassembly when maintenance is required.

Types of Trunnion Clamps

Trunnion clamps come in various types tailored to specific applications and requirements. For instance, bolted aluminum trunnion suspension clamps are designed to support heavy loads while providing flexibility during operation—ideal for scenarios like electrical transmission or rail systems. Other variations may include adjustable clamps that allow users to modify tension settings or fixed types that offer maximum stability without adjustment features.

Advantages of Bolted Aluminum Trunnion Suspension Clamps

When it comes to the world of trunnion clamps, bolted aluminum trunnion suspension clamps stand out for several compelling reasons. Their design not only prioritizes functionality but also integrates features that cater to modern engineering demands. Let's dive into the specific advantages that make these aluminum clamp assemblies a preferred choice across various applications.

Lightweight Yet Sturdy Design

One of the most significant advantages of bolted aluminum trunnion suspension clamps is their lightweight construction combined with impressive strength. The use of aluminum in these clamp assemblies allows for a reduction in overall weight without compromising structural integrity. This lightweight nature makes installation easier and reduces stress on supporting structures, making them ideal for demanding environments.

Moreover, this sturdy design ensures that even under high loads or extreme conditions, the trunnion clamp maintains its performance and reliability. Engineers appreciate how bolted aluminum designs can support heavy machinery while being easy to handle during installation and maintenance. Ultimately, this blend of lightness and strength enhances operational efficiency across various industrial applications.

Corrosion Resistance and Durability

Another standout feature of bolted aluminum trunnion suspension clamps is their exceptional corrosion resistance and durability. Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent rusting and degradation over time. This characteristic makes these clamps particularly suitable for outdoor installations or environments where exposure to moisture or chemicals is a concern.

Furthermore, the durability of these aluminum clamp assemblies translates into lower long-term maintenance costs and less frequent replacements compared to traditional materials like steel. Users can rest assured knowing that their investment in trunnion clamps will withstand the test of time, even in harsh conditions. In industries where reliability is paramount, such resilience becomes a critical factor in equipment selection.

Easy Installation and Maintenance

Bolted aluminum trunnion suspension clamps are designed with user-friendliness in mind, making installation straightforward even for those who may not be seasoned professionals. The assembly process typically requires minimal tools and can often be completed quickly, reducing downtime during setup or repairs significantly. This ease of installation allows companies to maintain productivity while ensuring that safety standards are upheld.

In addition to straightforward installation, maintenance is equally hassle-free due to the robust yet accessible design of these aluminum clamp assemblies. Regular inspections can be performed without specialized equipment or extensive disassembly processes—just a simple check-up goes a long way! This combination saves both time and resources while promoting longevity in equipment life cycles.

Applications of Trunnion Clamps

Trunnion clamps, particularly the bolted aluminum trunnion suspension clamp, are versatile components that find applications across various industries. Their lightweight yet sturdy design makes them ideal for settings where both strength and efficiency are crucial. Let’s explore some key areas where these aluminum clamp assemblies shine.

Use in Electrical Transmission

In the realm of electrical transmission, trunnion clamps play a pivotal role in securing overhead lines and ensuring reliable power delivery. These bolted aluminum trunnion suspension clamps provide robust support for conductors, minimizing sag and maintaining optimal tension under varying environmental conditions. Their corrosion-resistant properties also mean they can withstand harsh weather, making them a favorite among utility companies.

Trunnion clamps facilitate quick installation and adjustments, allowing for efficient maintenance of electrical systems without extensive downtime. The lightweight nature of aluminum clamp assemblies further enhances their usability in aerial applications, reducing the load on supporting structures like poles and towers. This combination of durability and ease-of-use makes trunnion clamps indispensable in modern electrical transmission networks.

Applications in Electrified Railways

Electrified railways benefit significantly from the use of trunnion clamps to secure overhead catenary systems that supply power to trains. Bolted aluminum trunnion suspension clamps ensure that these systems remain stable and properly aligned as trains pass by at high speeds. The reliability offered by these aluminum clamp assemblies translates to safer journeys for passengers while optimizing energy efficiency for railway operators.

Moreover, the corrosion resistance inherent in bolted aluminum designs means that these clamps can endure exposure to elements like rain or snow without compromising performance over time. This longevity is crucial for railway infrastructure, which often requires minimal maintenance to operate effectively. As electrified railways continue to expand worldwide, the demand for effective solutions like trunnion clamps will only increase.

Industrial Equipment and Machinery

In industrial settings, trunnion clamps are essential components used in various machinery applications—from assembly lines to heavy equipment manufacturing processes. The bolted aluminum trunnion suspension clamp provides a reliable solution for securing moving parts while allowing flexibility during operation or maintenance activities. This adaptability is vital when machines require frequent adjustments or repairs.

The use of aluminum clamp assemblies also contributes to weight reduction in machinery designs without sacrificing strength or stability—an important consideration as industries strive toward more efficient operations with lower energy consumption rates. Additionally, the easy installation process associated with these trunnion clamps means less labor time is required during setup or modifications, ultimately enhancing productivity on factory floors.

Choosing the Right Aluminum Clamp Assembly

Selecting the appropriate aluminum clamp assembly is crucial for ensuring optimal performance and longevity in various applications. With a plethora of options available, it’s essential to consider several factors that will guide your decision-making process. The right choice not only enhances efficiency but also contributes to safety and cost-effectiveness.

Factors to Consider

When choosing a trunnion clamp, several factors should be at the forefront of your mind. First, consider the load requirements; different applications may demand varying levels of strength and support from your bolted aluminum trunnion suspension clamp. Additionally, think about environmental conditions—will your aluminum clamp assembly face exposure to moisture, chemicals, or extreme temperatures?

Another important factor is compatibility with existing systems and components. Ensure that the dimensions and design of the trunnion clamp align with your current setup for seamless integration. Finally, don’t overlook manufacturer reputation; opting for trusted brands can provide peace of mind regarding quality and reliability.

Performance Specifications

Performance specifications are critical when evaluating an aluminum clamp assembly for your needs. Look for details such as load capacity, material strength, and resistance to environmental factors like corrosion or wear-and-tear over time. A high-quality bolted aluminum trunnion suspension clamp should meet or exceed industry standards to ensure it performs effectively under pressure.

Moreover, pay attention to installation requirements—some clamps may offer easier installation processes than others, which can save you time and labor costs in the long run. Make sure you also consider maintenance needs; a design that allows for easy inspection and upkeep will enhance longevity and functionality.

Cost-Effectiveness and Value

While price is always a consideration when selecting any component like a trunnion clamp, it's essential to evaluate cost-effectiveness rather than just looking at upfront expenses alone. Investing in a high-quality bolted aluminum trunnion suspension clamp might seem pricier initially but could save you money through reduced maintenance costs and longer service life down the line.

Additionally, assess the value offered by different suppliers; some may provide warranties or customer support that can be invaluable if issues arise post-purchase. Always weigh these factors against potential savings from cheaper alternatives that might not deliver on performance or durability.

Spark Fittings: Industry Leader in Trunnion Clamps

When it comes to trunnion clamps, Spark Fittings stands out as a premier provider, known for its innovative designs and robust engineering. Their product line features a variety of bolted aluminum trunnion suspension clamps that cater to diverse industrial needs. By combining cutting-edge technology with user-friendly designs, Spark Fittings ensures that their aluminum clamp assembly is both efficient and reliable.

Overview of Spark Fittings' Products

Spark Fittings offers an extensive range of products tailored specifically for various applications involving trunnion clamps. Their bolted aluminum trunnion suspension clamps are engineered for superior performance, ensuring they can withstand rigorous conditions while maintaining structural integrity. Additionally, the company provides customized solutions to meet specific customer requirements, making them a go-to choice in the industry.

Quality Standards and Certifications

Quality is at the forefront of Spark Fittings’ operations, with stringent quality control measures in place throughout the manufacturing process. The company adheres to international quality standards and holds multiple certifications that validate the durability and reliability of their aluminum clamp assembly products. This commitment to excellence not only enhances customer trust but also reinforces their reputation as leaders in the trunnion clamp market.

Customer Success Stories

Numerous industries have benefited from implementing Spark Fittings’ bolted aluminum trunnion suspension clamps, showcasing impressive results across various applications. One notable success story involves a major electrical transmission company that improved its infrastructure's efficiency by integrating these high-performance clamps into its systems. Customers consistently report enhanced durability and reduced maintenance costs, proving that choosing Spark Fittings is a smart investment for anyone seeking quality in their clamp assemblies.

Conclusion

In summary, trunnion clamps play a pivotal role in various industries, providing essential support and stability for numerous applications. The bolted aluminum trunnion suspension clamp stands out due to its lightweight design, durability, and ease of installation. Understanding the advantages of aluminum clamp assembly can help in making informed decisions when selecting the right components for specific needs.

Key Takeaways on Trunnion Clamps

Trunnion clamps are indispensable tools that ensure secure connections in electrical transmission systems and electrified railways. Their bolted aluminum designs not only enhance strength but also offer significant resistance to corrosion, making them ideal for harsh environments. When considering an aluminum clamp assembly, it's crucial to weigh factors such as weight, durability, and maintenance requirements.

The Importance of Quality in Clamp Assembly

Investing in high-quality bolted aluminum trunnion suspension clamps ensures reliability and safety across applications. Moreover, reputable manufacturers adhere to stringent quality standards that guarantee performance consistency over time.

Future Trends in Aluminum Clamp Technology

The future of aluminum clamp technology is bright, with ongoing innovations aimed at enhancing efficiency and performance. Emerging trends include the development of smarter materials that adapt to environmental conditions and advanced manufacturing techniques that reduce production costs while maintaining quality standards. As industries evolve, the demand for reliable trunnion clamps will continue to drive advancements in design and functionality.