Introduction

In the vast landscape of industrial manufacturing, China has emerged as a powerhouse, particularly in the production of bolt clamps. Among the numerous factories that contribute to this thriving sector, one stands out for its commitment to quality and innovation: Spark Fittings. This introduction will delve into the significance of saddle clamps, specifically focusing on their applications and importance in various industries.

Discovering China’s Leading Bolt Clamps FactoryKnown for producing high-quality saddle clamps, including specialized Saddle Clamp Electrical options, this factory has become synonymous with reliability and durability. With a robust manufacturing process and a keen eye for detail, Spark Fittings is at the forefront of meeting industry demands.

The Role of Spark Fittings in the Industry

Spark Fittings plays a crucial role in supplying essential components like saddle clamps that are vital for electrical applications and cable management systems. Their innovative approach ensures that each saddle clamp is designed to provide optimal support while maintaining safety standards across various installations. As industries evolve, Spark Fittings remains committed to enhancing its product offerings to meet changing market needs.

Understanding Saddle Clamps and Their Applications

Saddle clamps are versatile components used primarily for securing cables and pipes in place, ensuring stability during operation. Specifically designed options like Saddle Clamp for Cable showcase their adaptability across different sectors such as construction, telecommunications, and electrical engineering. By understanding the various applications of these essential fittings, businesses can make informed decisions about their infrastructure needs.

Overview of China’s Manufacturing Landscape

With a rich history in industrial manufacturing, the country has emerged as a global leader in producing high-quality components like saddle clamps, Saddle Clamp Electricals, and other essential fittings. The competitive nature of this market has led to continuous innovation and improvement, making it an exciting time for businesses looking to source reliable products.

Key Players in the Bolt Clamps Market

In the realm of bolt clamps, several key players dominate the market landscape in China. Companies like Spark Fittings have established themselves as leaders by consistently delivering quality saddle clamp products that meet international standards. These manufacturers not only focus on producing saddle clamp for cable applications but also invest heavily in research and development to stay ahead of industry trends.

The presence of both large-scale manufacturers and specialized producers creates a diverse marketplace where quality can vary significantly. Consequently, businesses must carefully evaluate potential suppliers to ensure they choose partners who prioritize excellence in their bolt clamp offerings. As competition heats up, companies are increasingly emphasizing their unique selling propositions, such as innovative designs or superior materials used in their saddle clamps.

Importance of Quality Standards

Quality standards play a pivotal role in shaping China's manufacturing landscape, particularly within the bolt clamps sector. Adhering to rigorous quality protocols ensures that products like saddle clamps not only meet but exceed customer expectations regarding performance and durability. This focus on quality helps establish trust with clients who rely on these components for critical applications such as electrical installations.

Manufacturers are often required to comply with both domestic regulations and international certifications, which further underscores their commitment to producing reliable saddle clamp electrical components. By maintaining high-quality standards throughout the production process—from material selection to final testing—companies can minimize defects and enhance customer satisfaction. Ultimately, prioritizing quality helps manufacturers differentiate themselves in an increasingly crowded marketplace.

Innovations in Manufacturing Techniques

Innovation is at the heart of China's manufacturing success story, particularly concerning bolt clamps like saddle clamps for cable applications. Advanced manufacturing techniques such as automation and precision machining are being embraced by leading companies to streamline production processes while maintaining high levels of accuracy and consistency. These innovations not only improve efficiency but also contribute significantly to reducing costs without compromising product quality.

Furthermore, emerging technologies like 3D printing are beginning to revolutionize how manufacturers design and produce components such as saddle clamp electrical fittings. This shift allows for greater customization options while minimizing waste—a win-win scenario for both producers and consumers alike! As these innovations continue shaping the industry landscape, we can expect even more exciting developments that promise enhanced performance from products like saddle clamps.

Spark Fittings: A Leader in Bolt Clamps

Established with a vision to revolutionize the fastening solutions market, Spark Fittings has consistently pushed boundaries while maintaining an unwavering commitment to excellence. Their reputation is built on years of experience and a keen understanding of customer needs, making them a trusted partner for businesses requiring reliable saddle clamps.

History and Background of Spark Fittings

Spark Fittings was founded with the mission to provide superior fastening solutions tailored for various industrial applications. Over the years, they have evolved from a small workshop into one of China’s leading manufacturers, specializing in products like saddle clamps that meet rigorous industry standards. Their journey reflects not just growth but also an ongoing dedication to quality and innovation that resonates throughout their operations.

The company has invested significantly in research and development, allowing them to stay ahead of market trends and customer demands. This proactive approach ensures that their saddle clamp offerings are not only functional but also equipped with features that enhance performance in real-world applications. As they continue to expand their product range, Spark Fittings remains focused on delivering value through quality craftsmanship and cutting-edge technology.

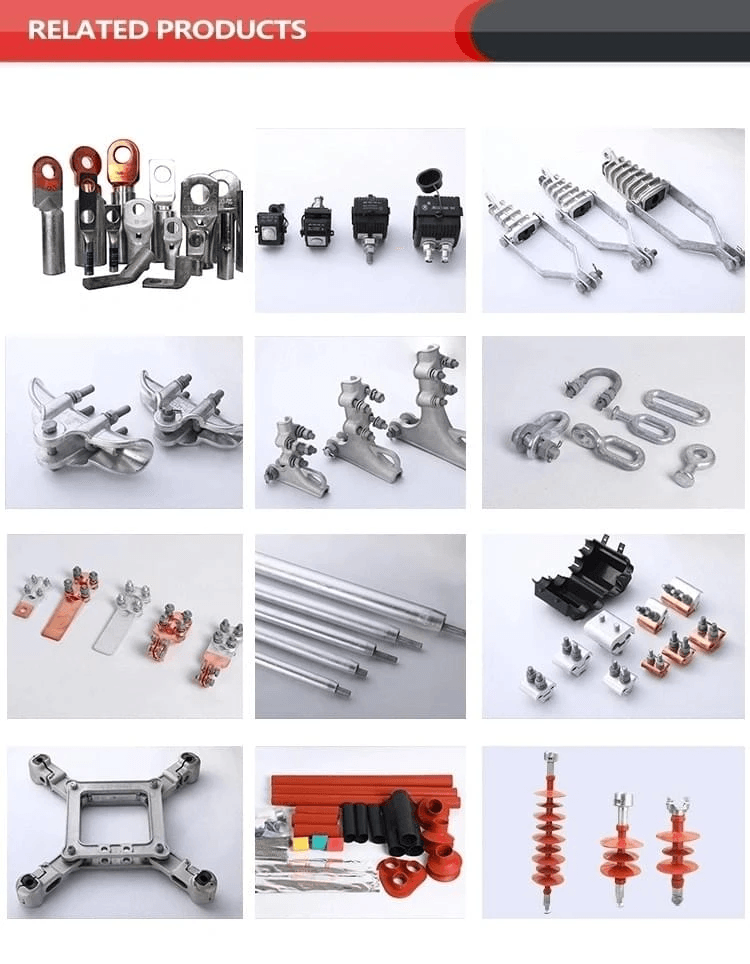

Product Range: Saddle Clamp Electrical and More

Spark Fittings boasts an impressive array of products designed for various applications within the bolt clamp category, with saddle clamps being a standout item in their product line-up. The range includes specialized options such as Saddle Clamp Electrical models designed specifically for electrical installations, ensuring optimal support and stability for cables under diverse conditions. Additionally, they offer versatile saddle clamps for cable management that cater to different sizes and materials.

Each product is engineered with precision, providing users with reliable solutions that stand up against environmental challenges such as moisture or corrosion. The diversity within their product range allows customers to find just the right saddle clamp for cable needs without compromising on quality or performance. Whether it's heavy-duty industrial use or more delicate applications, Spark Fittings has something tailored specifically for those requirements.

Commitment to Quality and Durability

They understand that durability is paramount in industries where equipment faces constant strain; hence every component undergoes rigorous testing before it reaches customers' hands. This quality assurance process ensures that each saddle clamp meets stringent safety standards while providing exceptional performance over time.

Moreover, Spark Fittings emphasizes using premium materials sourced from reputable suppliers which enhances the longevity of their products significantly—an essential factor when considering options like Saddle Clamp Electrical units or other specialized designs meant for challenging environments. By prioritizing durability alongside functionality, they have created a loyal customer base who trust them implicitly when selecting fastening solutions.

In conclusion, choosing Spark Fittings means opting for reliability backed by decades of expertise—a combination that's hard to beat in today’s competitive landscape where every detail matters.

Saddle Clamps: What You Need to Know

Saddle clamps are essential components in various industries, providing secure and reliable support for cables and other materials. Understanding the types of saddle clamps available, their applications, and the benefits they offer can help you make informed decisions when selecting the right products for your projects. Let’s dive into the world of saddle clamps and discover what makes them so vital.

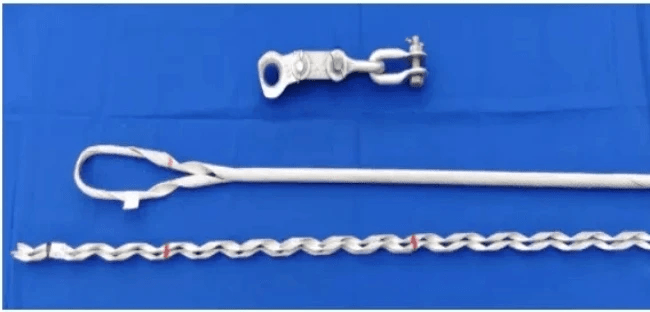

Types of Saddle Clamps Available

There are several types available, including standard saddle clamps, adjustable saddle clamps, and specialized saddle clamp electrical configurations designed for specific applications. Each type serves a unique purpose; for instance, adjustable options allow for flexibility in installation while maintaining a robust hold on cables.

Moreover, saddle clamp for cable comes in different sizes and materials to accommodate various cable diameters and environmental conditions. Whether you’re working with heavy-duty cables or lighter electrical wires, there’s a suitable saddle clamp out there that meets your requirements. The diversity in design ensures that no matter what your project entails, you'll find a fitting solution.

Applications for Saddle Clamp for Cable

Saddle clamps are widely used across numerous industries due to their versatility and reliability. Common applications include securing overhead power lines, supporting telecommunications cables, and even aiding in construction projects where stability is paramount. The ability to provide consistent support makes these clamps indispensable in both residential and industrial settings.

In addition to traditional uses, innovative applications have emerged as technology advances. For instance, with the rise of renewable energy sources like solar panels or wind turbines, saddle clamp electrical solutions have become crucial in ensuring safe installations that withstand environmental challenges. This adaptability highlights how integral these products are across various sectors.

Benefits of Using Saddle Clamps

The benefits of using saddle clamps extend beyond mere functionality; they also enhance safety and efficiency in installations. First off, using a high-quality saddle clamp ensures that cables remain securely fastened even under stress or movement—reducing the risk of damage or accidents significantly. This durability translates into lower maintenance costs over time as well.

Another advantage is ease of installation; many designs allow quick setup without requiring specialized tools or extensive training—perfect for both seasoned professionals and DIY enthusiasts alike! Additionally, employing a reliable saddle clamp can lead to improved performance by minimizing wear on cables due to friction or environmental factors over time.

In summary, whether you're looking at standard options or more specialized configurations like those found in spark fittings' product range, understanding what makes each type unique can guide you toward making better choices for your projects.

The Importance of Material in Armor Rods

Choosing the Right Armor Rod Material

There are several materials commonly used for armor rods, each offering unique advantages tailored to specific needs. For instance, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor installations that require a saddle clamp electrical application. On the other hand, steel offers superior strength and durability, ideal for high-load situations where a reliable saddle clamp is essential.

The selection process should also consider environmental factors such as exposure to moisture or chemicals that could compromise the rod's integrity over time. Additionally, compatibility with existing materials is crucial; using a saddle clamp for cable that matches the armor rod can prevent issues like galvanic corrosion. Ultimately, understanding these nuances will lead to better performance and increased lifespan of your installation.

Corrosion Prevention and Compatibility

Corrosion is one of the biggest threats to any metal component used outdoors or in harsh environments. Therefore, choosing materials with inherent corrosion resistance properties can save you from frequent replacements and maintenance costs down the line. When selecting an armor rod material, it's essential to consider coatings or treatments that enhance its resistance—such as galvanization or anodizing—which can be particularly beneficial when paired with a saddle clamp electrical setup.

Moreover, ensuring compatibility between different metals used within your assembly is critical; mismatched materials can lead to accelerated wear due to electrolysis—a phenomenon you definitely want to avoid! By opting for compatible materials in both your armor rods and saddle clamps (like those designed specifically for cable use), you create a more robust system that stands up against time and elements alike.

Customization Options from Spark Fittings

Spark Fittings takes pride in offering customization options tailored specifically for your project’s needs when it comes to armor rods and associated fittings like saddle clamps. Whether you're looking for unique dimensions or specific material compositions, Spark Fittings provides solutions designed around your requirements—ensuring optimal performance every time you utilize their products.

In addition to standard offerings like standard-sized saddle clamps for cable applications, they also cater to specialized requests which may involve custom lengths or finishes that match existing infrastructure perfectly. This level of customization not only enhances functionality but also ensures aesthetic coherence across installations—making it easier than ever to achieve both form and function with your chosen components.

With Spark Fittings’ commitment to quality craftsmanship combined with their extensive range of customizable options, you’ll find exactly what you need without compromising on durability or effectiveness—because every detail counts when securing cables safely!

Innovations in Preformed Armor Rods Manufacturing

The manufacturing of preformed armor rods has undergone significant innovations, enhancing both efficiency and quality. These advancements not only streamline production processes but also ensure that the final products meet stringent industry standards. As a result, manufacturers can deliver more reliable and durable solutions that cater to the diverse needs of their clients.

Overview of Production Techniques

Modern production techniques for preformed armor rods involve a combination of traditional craftsmanship and cutting-edge technology. Automated machinery plays a crucial role in shaping and assembling these components, allowing for precision and consistency across batches. Additionally, techniques such as cold forming and heat treatment are employed to enhance the strength and flexibility of the rods, ensuring they can withstand various environmental conditions while supporting heavy-duty applications like saddle clamps.

The Role of Technology in Enhancing Quality

Technology has revolutionized the way preformed armor rods are produced, with innovations like computer numerical control (CNC) machining leading the charge. This level of automation allows for meticulous design specifications to be followed closely, minimizing human error during production. Furthermore, advanced quality control systems enable manufacturers to monitor every aspect of production in real-time, ensuring that each saddle clamp electrical component meets or exceeds quality benchmarks before it reaches customers.

Future Trends in Armor Rod Manufacturing

Looking ahead, several trends are likely to shape the future landscape of armor rod manufacturing. Sustainability will become increasingly important as companies seek eco-friendly materials and methods that reduce waste without compromising on performance. Additionally, there is a growing emphasis on customization; as clients demand more tailored solutions—such as specific saddle clamp for cable configurations—manufacturers will need to adapt quickly to these evolving requirements while maintaining high standards of quality.

Conclusion

In wrapping up our exploration of Spark Fittings and the world of saddle clamps, it’s clear why this leading manufacturer stands out in the industry. With their commitment to quality and innovation, choosing Spark Fittings for your needs ensures that you’re not just getting a product; you’re investing in reliability and performance. Whether you require a saddle clamp electrical or a saddle clamp for cable, Spark Fittings delivers exceptional solutions tailored to various applications.

Why Choose Spark Fittings for Your Needs

Their extensive experience in the market allows them to offer products that meet rigorous quality standards while also embracing innovative manufacturing techniques. By opting for Spark Fittings, you’re aligning yourself with a brand known for its durability and high-quality craftsmanship, ensuring your projects are equipped with the best tools available.

The Benefits of Quality Saddle Clamps

Investing in quality saddle clamps can significantly impact the efficiency and safety of your installations. These components provide essential support for electrical cables, ensuring they remain securely fastened even under challenging conditions. With options like saddle clamp electrical designed specifically for high-performance applications, you can trust that these products will enhance both functionality and longevity.

Final Thoughts on China’s Manufacturing Excellence

China's manufacturing landscape continues to evolve, showcasing remarkable advancements in technology and quality control practices. Companies like Spark Fittings exemplify this progress by delivering top-notch products such as saddle clamps that cater to both local and international markets. As we look ahead, it's evident that choosing reliable manufacturers who prioritize quality will remain crucial in driving success across industries.