Introduction

In the world of industrial machinery, understanding the intricacies of transmission chains is crucial for optimal performance and longevity. These chains, often composed of multiple interlinked components, serve as the backbone for various mechanical systems. Among these components, the chain link plays a pivotal role in ensuring smooth operation and reliability across numerous applications.

Understanding Industrial Transmission Chains

Industrial transmission chains are designed to transfer power efficiently from one component to another, making them essential in many manufacturing processes. The primary function of a chain link within this system is to connect various parts while allowing for flexibility and movement without compromising strength. By grasping how these links work together, industries can enhance their operational efficiency and minimize downtime.

Importance of Track Section Forgings

Track section forgings are integral to the stability and durability of industrial machinery that relies on chain links for motion. These forged components provide enhanced strength compared to their cast counterparts, ensuring that they can withstand heavy loads and harsh environments. By incorporating high-quality track section forgings into their designs, manufacturers can significantly improve the overall performance and lifespan of their products.

Overview of Chain Accessories

Chain accessories may seem like minor components at first glance, but they play an essential role in maximizing the effectiveness of chain links within a system. From connectors to tensioners, these accessories enhance functionality by ensuring proper alignment and reducing wear over time. Choosing the right accessories not only optimizes performance but also contributes to safer operations across various industries.

What is a Chain Link in Industry

A chain link is essentially a component that connects various parts of a chain, allowing for seamless movement and transfer of power. Understanding the functionality, types, and applications of chain links can significantly enhance operational performance across various industries.

Functionality of Chain Links

Chain links are designed to provide strength and flexibility in mechanical systems. They facilitate the transmission of force between different components while maintaining durability under various conditions. The interlocking nature of chain links allows them to bear heavy loads without compromising on performance or safety.

In many machines, chain links are crucial for converting rotary motion into linear motion, making them indispensable in conveyor systems and automotive applications. Their ability to withstand tension and compression ensures that they can handle demanding tasks effectively. Thus, understanding how these links function can lead to better maintenance strategies and improved machinery lifespan.

Types of Chain Links

Chain links come in various shapes and sizes, each tailored for specific industrial needs. The most common types include roller chain links, which are widely used in bicycles and motorcycles due to their efficiency; block chain links that offer enhanced load-bearing capabilities; and leaf chains often found in hoisting equipment for their strength-to-weight ratio.

Additionally, there are specialized variations like double pitch chains that allow for longer spans between sprockets without sacrificing strength or reliability. Each type serves unique purposes across different sectors—from manufacturing to agriculture—making it essential for industries to select the appropriate type based on their operational requirements.

Applications in Various Industries

The versatility of chain links makes them applicable across multiple industries including automotive, manufacturing, construction, and agriculture. In automotive applications, chain links are integral in timing mechanisms ensuring engines run smoothly at precise intervals. Meanwhile, manufacturing facilities rely on robust conveyor systems equipped with durable chain links to streamline production processes efficiently.

In construction settings, heavy machinery utilizes strong chain links for lifting operations where safety is paramount. Agriculture also benefits from these components as they drive equipment such as harvesters and tractors—ensuring that farmers can depend on reliable machinery during critical seasons.

The Role of Track Forgings

Track forgings play a crucial role in the industrial landscape, providing strength and durability to various applications. These components are essential for ensuring that machinery operates smoothly and efficiently, particularly in systems that rely heavily on chain links for movement and support. Understanding the manufacturing process, advantages, and common uses of track forgings can help industries make informed decisions about their equipment.

Manufacturing Process of Track Forgings

The manufacturing process of track forgings typically involves heating metal to a high temperature and then shaping it under pressure. This method allows for precise control over the material's structure, resulting in components that exhibit superior strength compared to those made through casting or machining alone. Each step is meticulously planned to ensure that the final product meets stringent industry standards while maintaining compatibility with existing chain link systems.

Once the metal is forged, it undergoes various finishing processes such as heat treatment or surface hardening to enhance its durability further. These processes not only improve performance but also ensure that the forged components can withstand harsh environmental conditions often encountered in industrial settings. Ultimately, this careful attention to detail during manufacturing results in track forgings that are reliable and long-lasting.

Advantages of Forged Components

Forged components offer several advantages over their counterparts made from other methods, primarily due to their enhanced mechanical properties. One significant benefit is their improved tensile strength, which makes them ideal for applications where heavy loads are involved—think of how chain links must endure rigorous stress without failing! Additionally, forging leads to finer grain structures within the material, enhancing fatigue resistance and reducing susceptibility to cracking.

Another advantage is the versatility of forged components; they can be tailored for specific applications by adjusting factors like shape and size during production. This adaptability means industries can create customized solutions that fit seamlessly into their existing systems while optimizing performance across various machinery—especially where chain links are involved! Moreover, forged parts typically require less maintenance than cast or machined alternatives due to their superior wear resistance.

Common Uses in Industry

Track forgings find widespread application across numerous industries thanks to their remarkable strength and reliability. In construction equipment such as cranes or excavators, these components provide essential support structures capable of handling heavy loads with ease—just imagine a massive crane lifting tons while relying on robust chain links! Similarly, railways utilize track forgings for rail ties and fasteners because they must endure constant stress from moving trains without compromising safety or stability.

Other notable uses include agricultural machinery where track forgings contribute significantly to equipment longevity under challenging conditions like dirt or moisture exposure. They also play a vital role in mining operations where heavy-duty machinery relies on strong components for optimal performance—again highlighting how intertwined these parts are with efficient chain link mechanisms! As industries continue evolving toward more demanding applications, the importance of high-quality track forgings remains undeniable.

Chain Accessories and Their Importance

These accessories not only complement the functionality of the chains but also enhance their overall performance in various environments. Understanding the different types of chain accessories available can help businesses make informed choices that lead to improved operational outcomes.

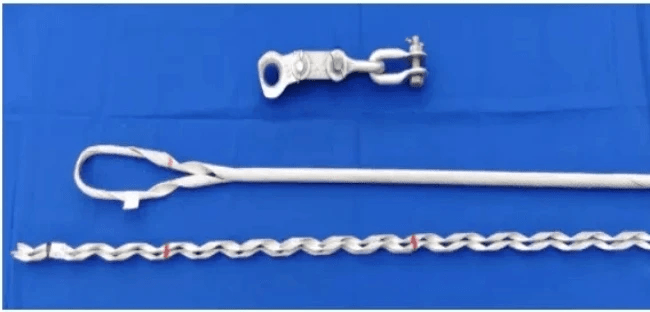

Different Types of Chain Accessories

Chain accessories come in a variety of forms, each designed to serve specific purposes within an industrial setting. Common types include connecting links, master links, and tensioners, all integral to creating strong and reliable chain link systems. Additionally, there are safety devices like chain guards and wear pads that protect both the chains and surrounding equipment from wear and tear.

The diversity among these accessories means that they can be tailored to meet specific needs across different industries. For instance, heavy-duty applications may require robust connecting links that can withstand high loads, while lighter operations might opt for more flexible options. Understanding these differences is crucial for ensuring optimal performance from your chain link systems.

How Accessories Enhance Performance

The right chain accessories significantly enhance the performance of chain links by improving their strength and reliability under load. For example, using high-quality master links ensures that the entire system can handle stress without failure, which is critical in high-stakes environments like construction or manufacturing. Furthermore, accessories such as tensioners allow for precise adjustments that maintain optimal tension throughout operation.

Incorporating specialized accessories can also lead to increased safety margins by reducing risks associated with equipment failure or accidents caused by improper installations. By ensuring proper alignment and secure connections between components, these accessories help prevent costly downtime due to maintenance issues or unexpected breakdowns. Ultimately, investing in quality chain link accessories pays dividends through enhanced productivity and safety.

Choosing the Right Accessories for Your Needs

n your operations involving chain links. Additionally, consulting with manufacturers or suppliers can provide valuable insights into which products best suit your specific needs.

Don’t forget about future scalability! Choosing adaptable or modular options allows you to upgrade your system as demands increase without needing a complete overhaul—saving both time and money down the line. Remember: investing wisely in appropriate chain link accessories today will set up your operation for success tomorrow.

Spark Fittings: Innovators in Armor Rods

These components are crucial for protecting conductors from mechanical damage and environmental factors. With a commitment to innovation, Spark Fittings continues to revolutionize the way we think about chain link accessories.

Overview of Spark Fittings

Spark Fittings has established itself as a pioneering force in the manufacturing of armor rods designed for electrical and mechanical applications. Their products are engineered to provide superior protection and reliability, ensuring that chain links operate smoothly even under challenging conditions. By focusing on quality and durability, Spark Fittings sets a high standard for the industry.

Customization Options for Armor Rods

One of the standout features of Spark Fittings is their extensive customization options for armor rods, allowing clients to tailor solutions that meet specific needs. Whether you require unique dimensions or specialized materials, their team works closely with customers to create customized armor rods that seamlessly integrate with existing chain link systems. This level of personalization not only enhances functionality but also ensures optimal performance across various industrial applications.

Importance of Material Matching

Choosing the right material for armor rods is paramount, especially when considering compatibility with different types of conductors used in chain links. The right material can significantly affect performance, longevity, and resistance to corrosion—a critical factor in outdoor environments where exposure can lead to rapid deterioration. By matching materials appropriately, users can ensure their chain link systems remain robust and efficient over time.

The Significance of Armor Rod Material

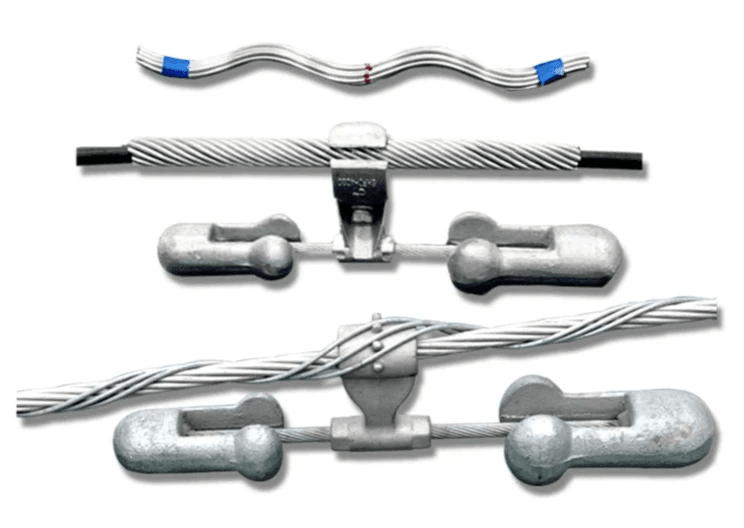

When it comes to armor rods, the choice of material is crucial for ensuring optimal performance and longevity. The right material not only affects the durability of the rod but also its compatibility with various conductors in industrial applications. Understanding how to select materials based on conductor type can significantly enhance the effectiveness of these essential components.

Choosing Material Based on Conductor

Selecting armor rod materials should begin with an evaluation of the conductor type it will protect. Different conductors, such as aluminum or copper, require specific materials to ensure a secure fit and optimal performance in their respective environments. For instance, aluminum conductors often pair well with alloyed steel armor rods due to their lightweight properties and excellent conductivity, while copper conductors may benefit from more robust options like stainless steel for added strength.

Additionally, manufacturers must consider the operational environment when choosing materials for armor rods. If a chain link is exposed to harsh weather conditions or corrosive substances, using high-grade stainless steel or specialized alloys can provide better protection against wear and tear. Ultimately, making informed decisions about material selection based on conductor types will lead to enhanced safety and efficiency in industrial applications.

Corrosion Considerations

Corrosion is one of the most significant threats facing armor rods in various environments, especially those exposed to moisture or chemicals. Choosing corrosion-resistant materials is essential for maintaining the integrity of both the armor rod and the underlying conductor it protects. For instance, utilizing galvanized steel or plastic-coated options can help mitigate corrosion risks while ensuring that your chain link remains functional over time.

Furthermore, it's vital to consider how environmental factors might accelerate corrosion processes; saltwater exposure is notorious for degrading metal components quickly. Regular inspections and maintenance can help identify early signs of corrosion before they lead to catastrophic failures in your equipment. By prioritizing corrosion resistance when selecting armor rod materials, industries can safeguard their investments and minimize downtime caused by repairs.

Color Coding for Easy Identification

Color coding is an effective strategy in managing multiple types of armor rods within a facility or job site—especially when dealing with various chain links that serve different functions or specifications. By implementing a standardized color-coding system, workers can quickly identify which rod corresponds with which conductor type at a glance—reducing errors and improving efficiency during installation or maintenance tasks.

Moreover, utilizing distinct colors allows teams to streamline inventory management by easily tracking which materials are available versus what needs replenishing. This simple yet effective approach fosters better communication among team members while minimizing confusion during critical operations where every second counts! In essence, color coding serves as an invaluable tool that complements proper material selection for maximizing productivity across various industries.

Conclusion

In wrapping up our exploration of industrial transmission chains, it’s clear that chain links play a pivotal role in various industries. These unsung heroes not only link components but also contribute significantly to the overall efficiency and reliability of machinery. Understanding the functionality and types of chain links can empower users to make informed decisions tailored to their specific applications.

Key Takeaways on Chain Links

Chain links are fundamental in ensuring smooth operations across multiple sectors, from manufacturing to transportation. The diversity in types—such as roller, block, and leaf chain links—allows for specialized applications that cater to different needs. Ultimately, selecting the right chain link is crucial for optimizing performance and longevity in any mechanical system.

Essential Points on Track Forgings

Track forgings are integral components that enhance the durability and strength of industrial equipment. The manufacturing process involves shaping metal under high pressure, which results in superior structural integrity compared to traditional methods. This means that investing in track forgings can lead to reduced maintenance costs and increased operational efficiency over time.

The Future of Chain Accessories and Manufacturing

Looking ahead, the future of chain accessories appears promising with advancements in materials science and engineering techniques. Innovations will likely focus on enhancing performance while reducing weight, making accessories even more efficient without compromising strength. As industries continue to evolve, staying updated on these developments will be essential for maximizing productivity through effective use of chain links and their accompanying accessories.